You must be logged in to rate content!

5 minute(s) of a 891 minute read

3-26-2018

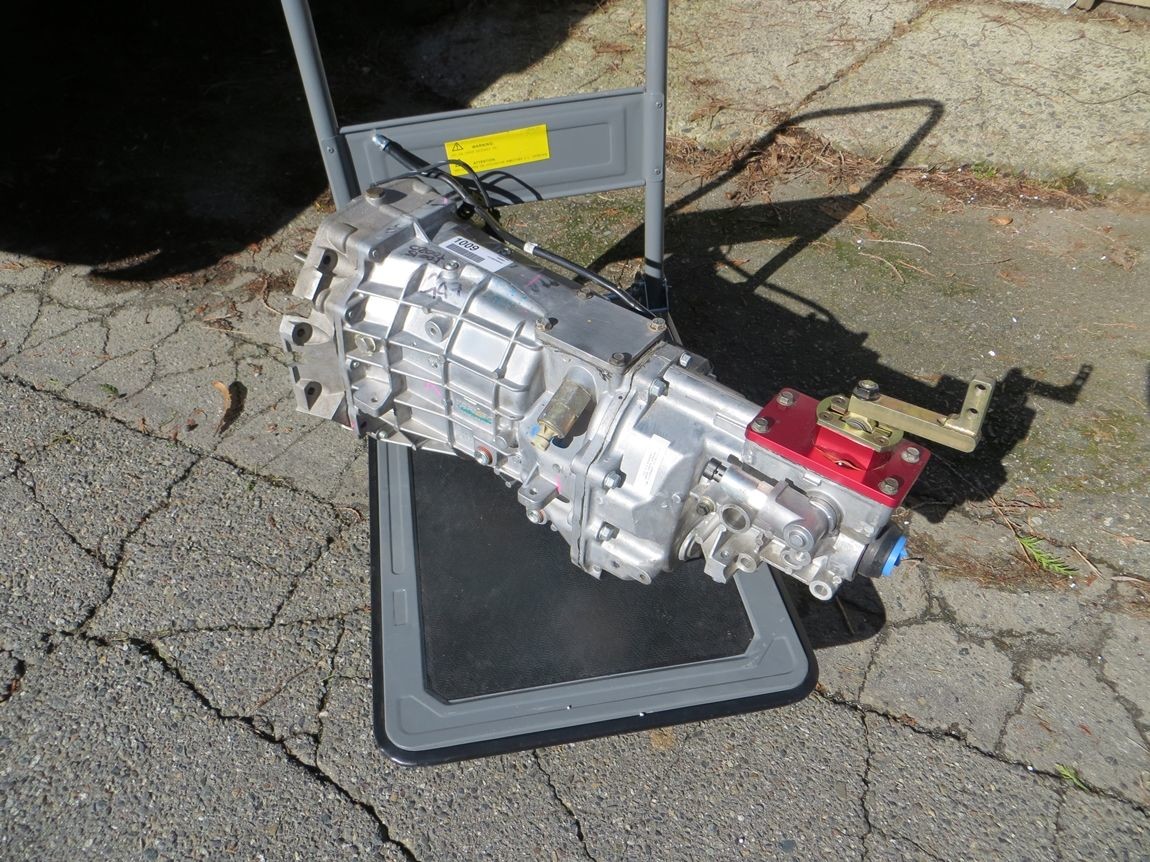

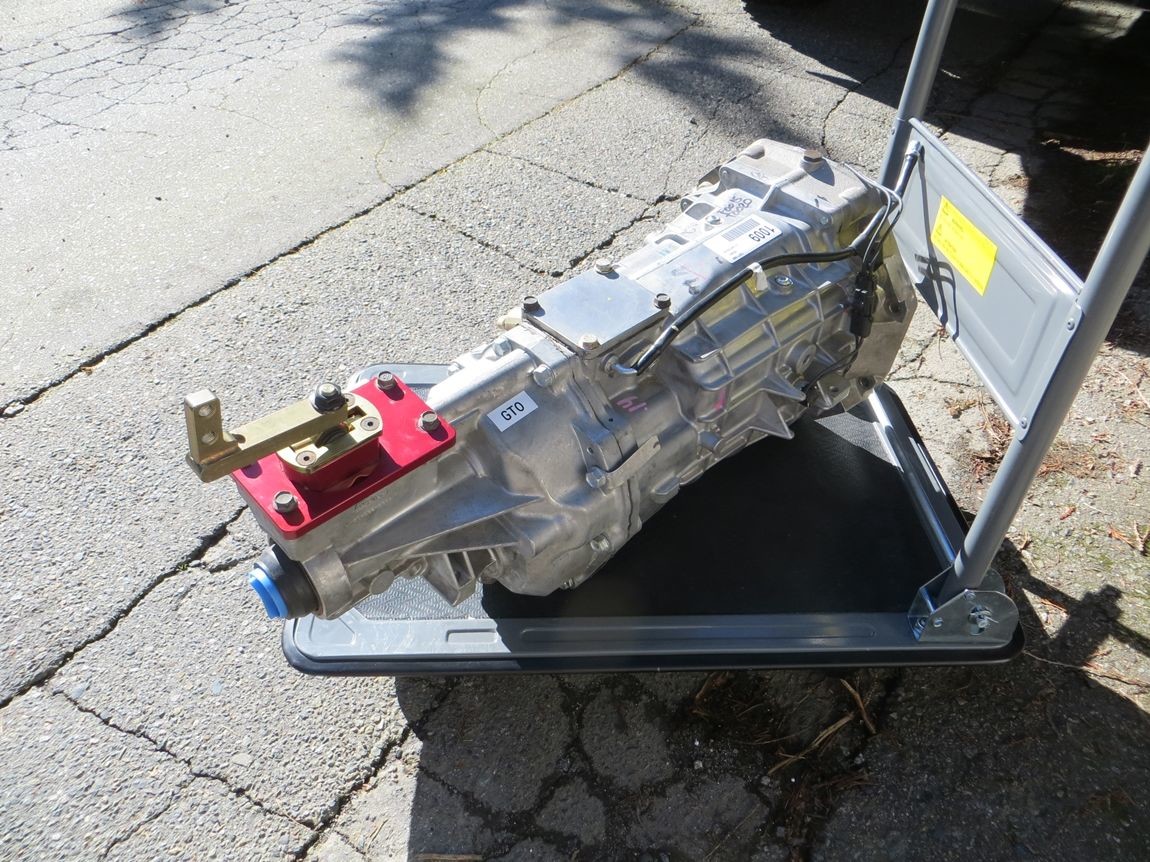

Got some good progress done on the car. I'm at the point of needing to remove or at the very least lift up the engine to swap oil pan.. so I thought I would remove the trans to get to make that job easier. The trans needs to come out anyways because I've had a McLeod Twin Street RXT clutch collecting dust for years just waiting to be install (from I think 2014!). As well, I got an F-body converted T56 Magnum that I'll be adding an oil sprayer pump setup too.

Got the rusty gross 2.5" years-old 'temporary' dual exhaust out from under the car and removed the driveshaft and the trans x-member. I have no idea why I was expecting the driveshaft to be a bit beat up.. I've put a lot of hurt on it.. but no scratches or chips or rust or anything.. it's 3.0" 0.80" wall (if memory serves correct) chromoly made locally. I should *hopefully* just need to swap out the slip yoke on the shaft from old 1350 26 spline unit to a new chromoly 31 spline 1350 unit.

While the trans was out, I needed to add an exhaust clearance notch on the driver side since when I made this trans x-member years ago I didn't think I'd end up twin turbo'ing it... oops!

Before I started any trans x-member work, I wanted to finish the stainless welding while the machine was all setup for small tungsten and pulsing..

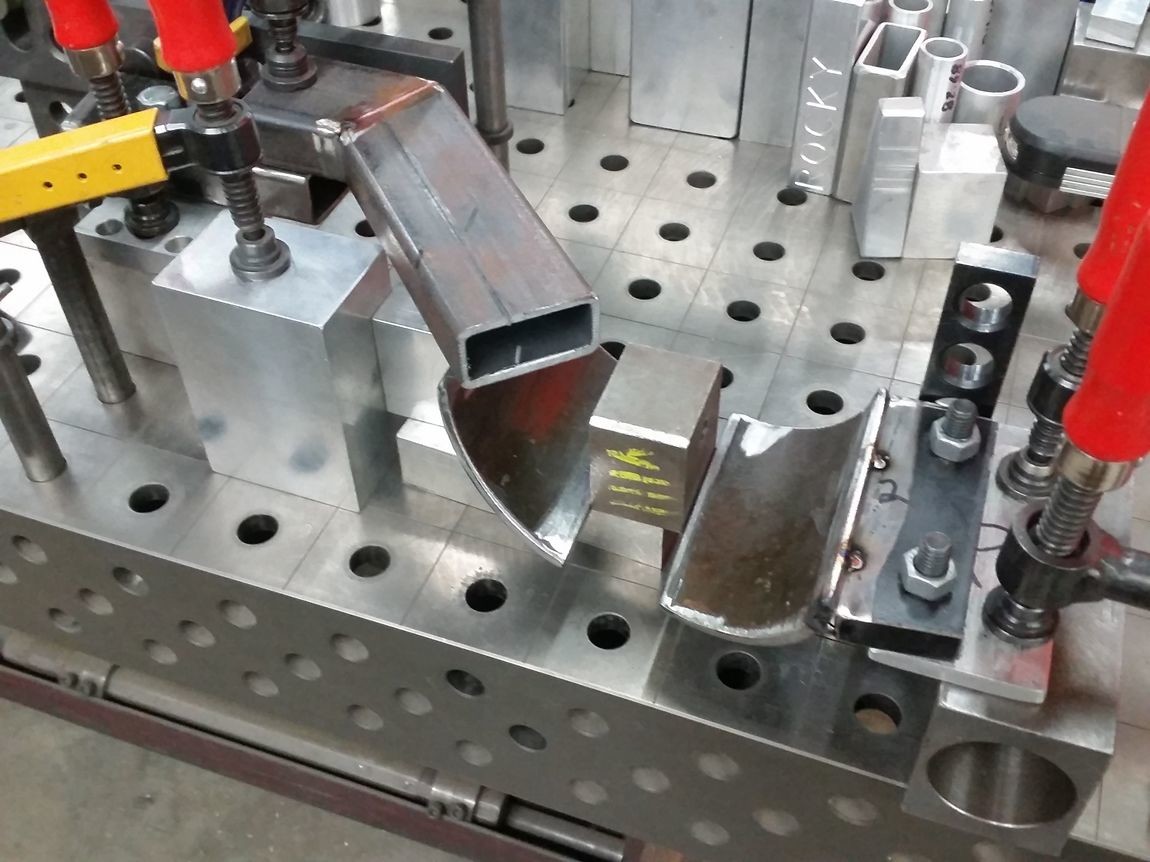

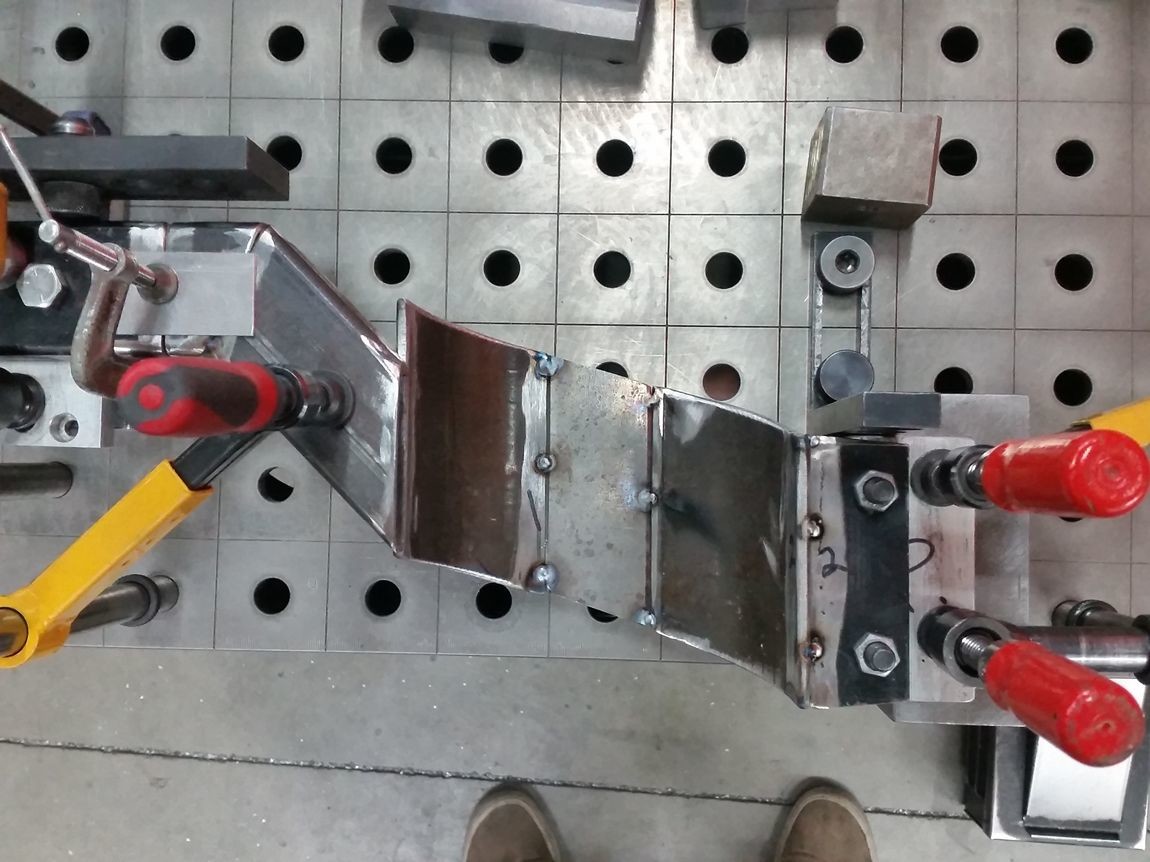

Next was to modify the existing trans x-member, which is obviously for single passenger side exhaust. The notch is made of 1/4" thick 4" pipe, and the dimensions would allow up to a 8" wide single oval pipe, or dual 4" wide oval pipes. The high clearance nature of this setup meant I could run 2.5" tall exhaust completely tucked above the underside of the subframe rails.. so I wanted to just duplicate these dimensions onto the driver side.

The green tape shows the center line of the trans drain plug (bottom line) and the "outside profile" of where a pickup fitting would be when installed into the drain port, so this is an area that I'll need to notch and gain room for an oil feed adapter fitting and hose end from the trans drain port to the oil pump..

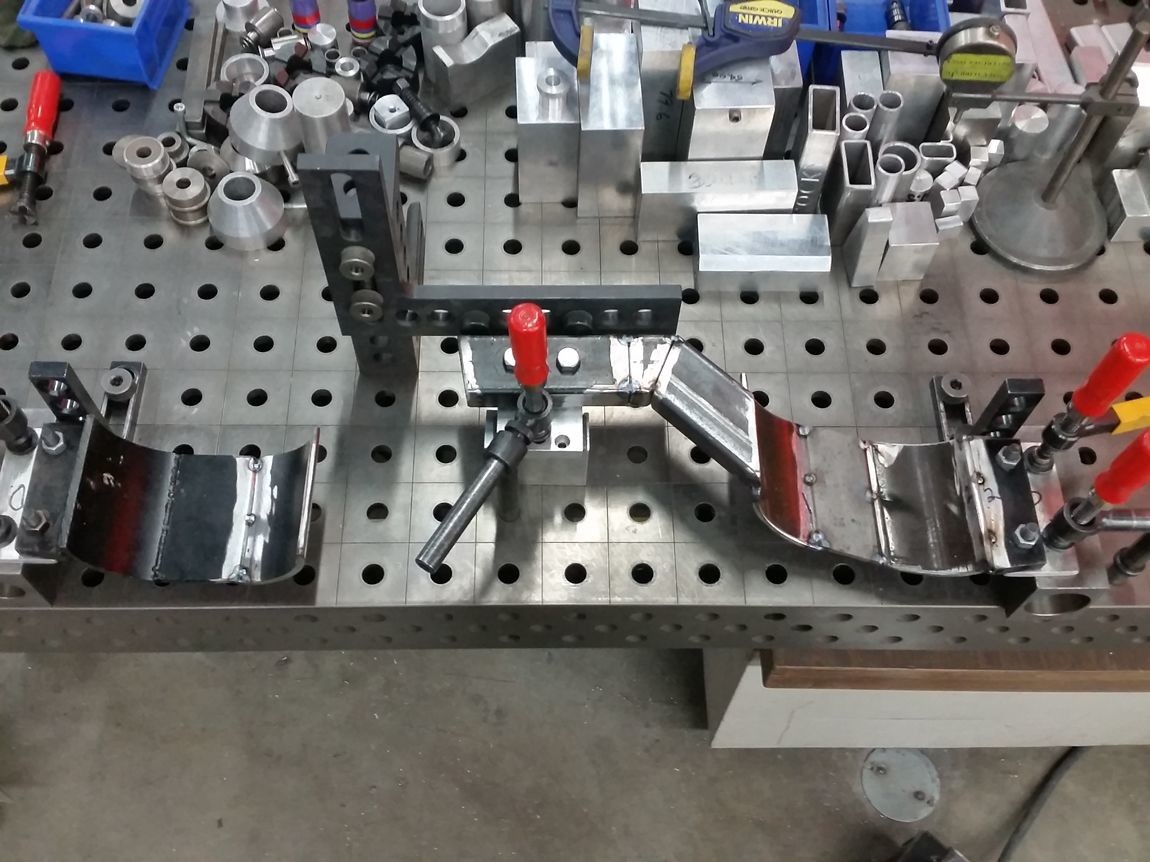

Utilizing the jigging table at work YET AGAIN.. this thing is so amazing. My current x-member fits the subframe/floor like a glove, so wanted to maintain the mounting points.. so drilled a couple brackets to locate all the holes, use some blocks to set the heights, and before/after modification should end up damn near identical!

Then cut it the hell up...

Gotta get creative when you want to bisect a 1/4" wall 4" pipe.. luckily we have a big honking bandsaw at work. If the fixturing setup works, it can't be ghetto, right?

These pics are just various states of building the trans x-member back up. The passenger side (right side of pic) I ended up narrowing the notch cutout down to 6" inner width (still super wide, a 4" pipe in oval size is 2.5"x4.875"). Narrowing the passenger side gains room for the passenger side trans drain port fitting (roughly mocked up by the machined aluminum block held by the yellow clamp). I just then copied this new notch width onto the driver side (left of pic).

Wow thanks for sharing!

Posted by Diggymart on 3/3/19 @ 12:40:25 AM