You must be logged in to rate content!

2 minute(s) of a 891 minute read

3-23-2018

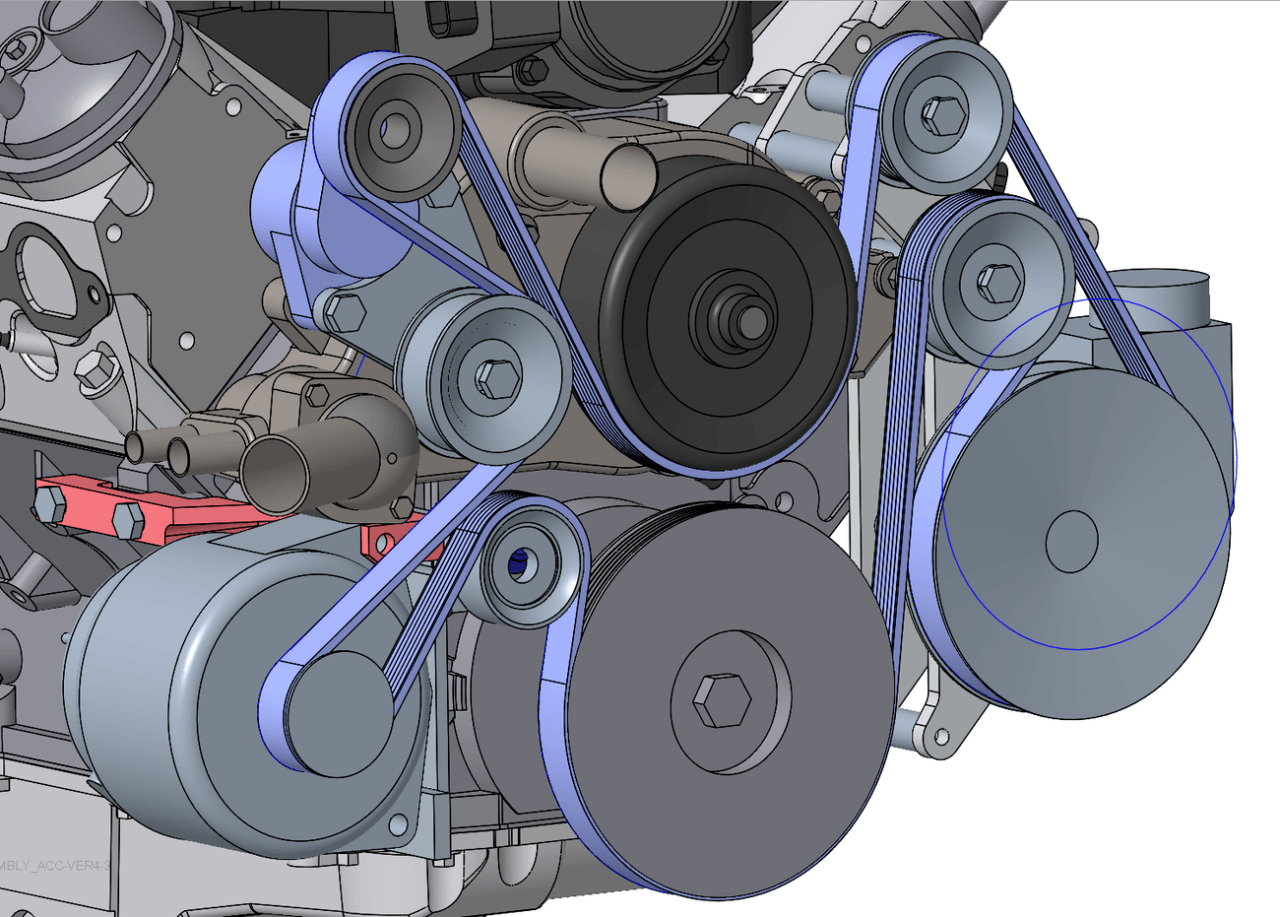

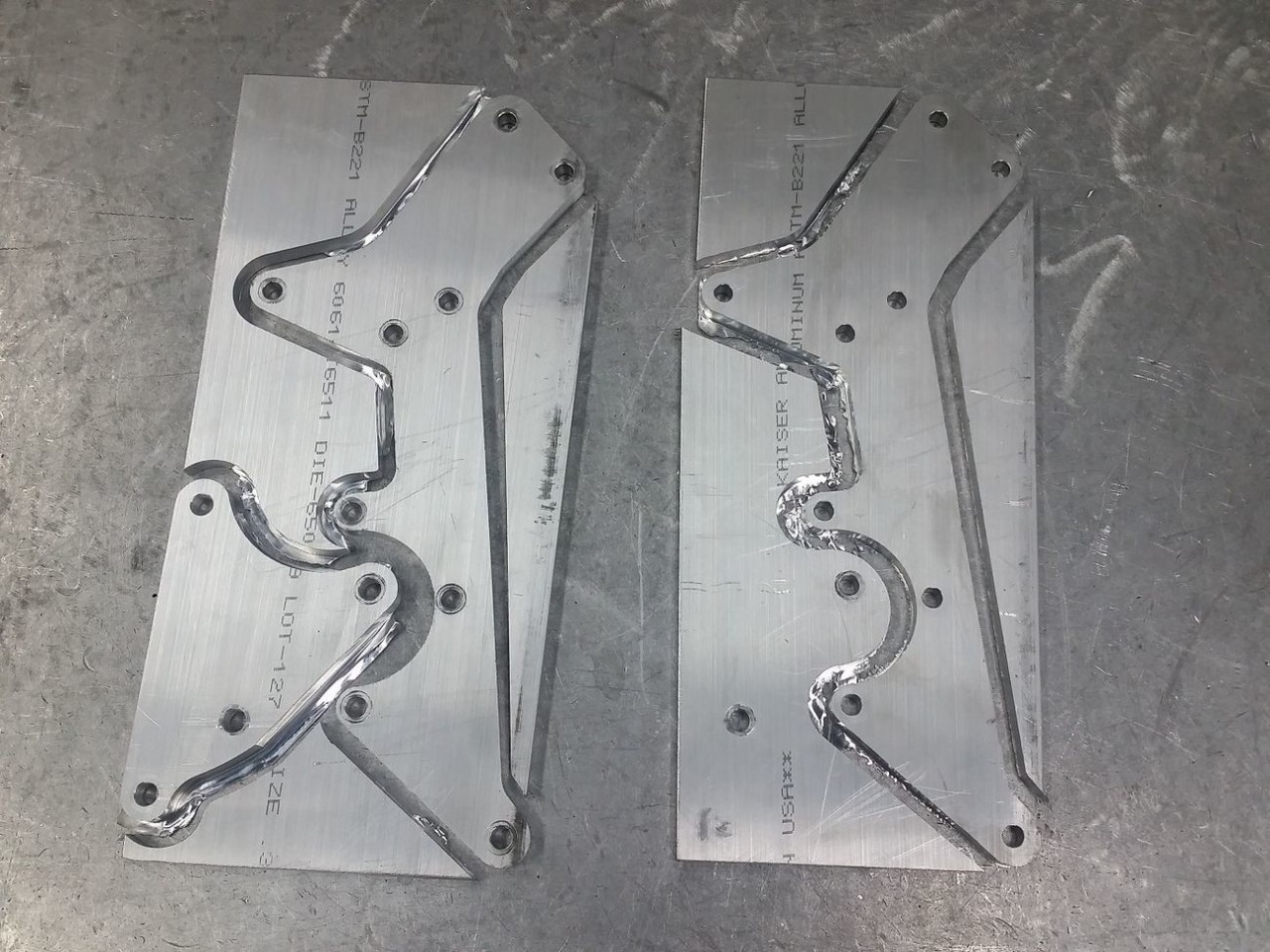

Sometimes you have to pick your battles, and with such a long list of stuff to still do, I farmed out the P/S pump bracket making to the CNC machine in the shop at work.

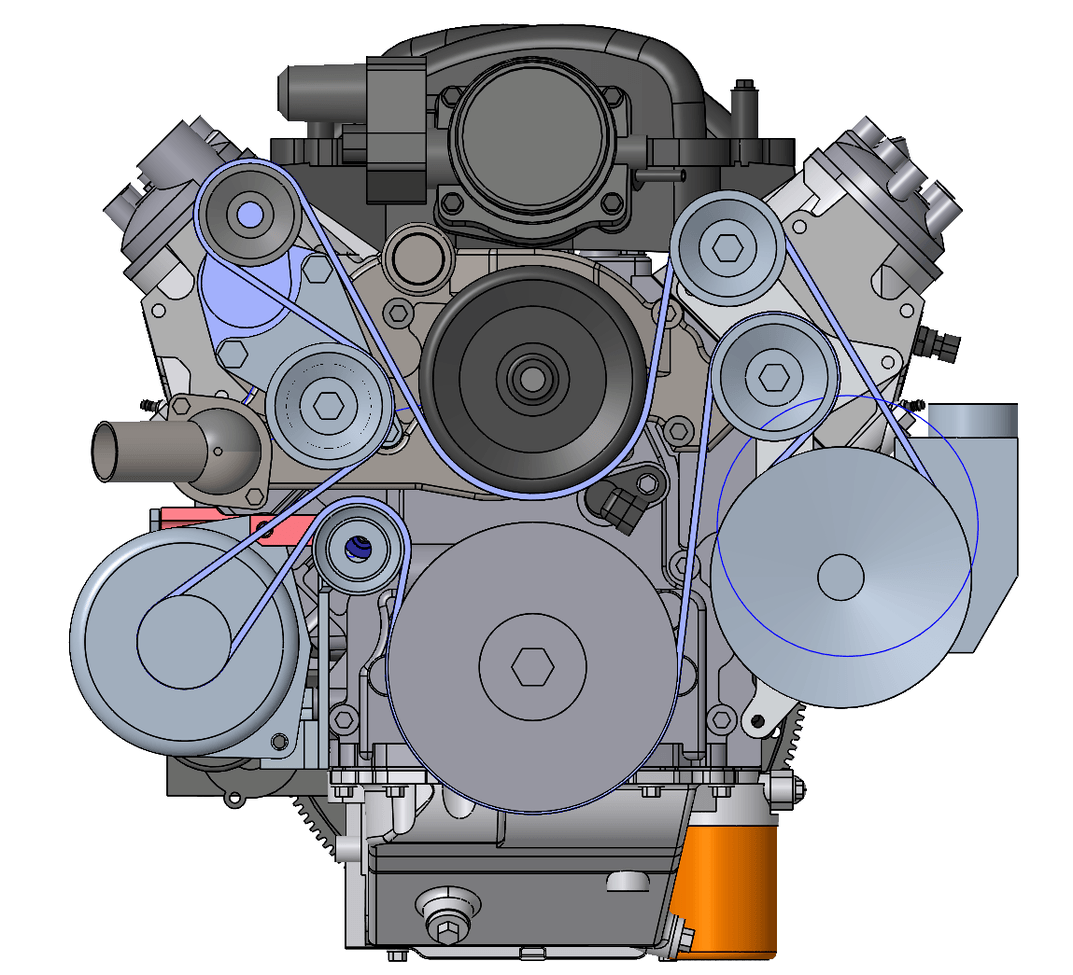

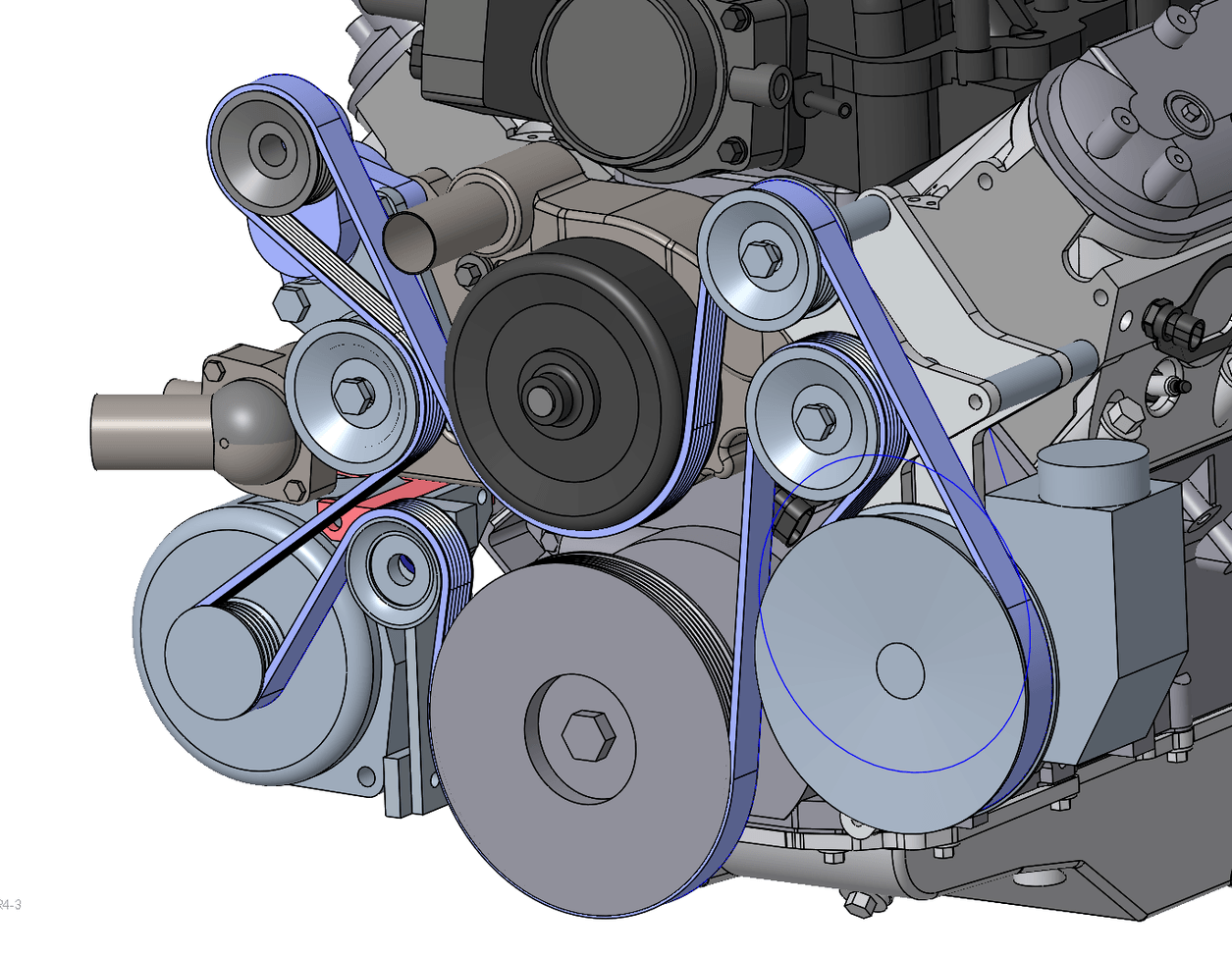

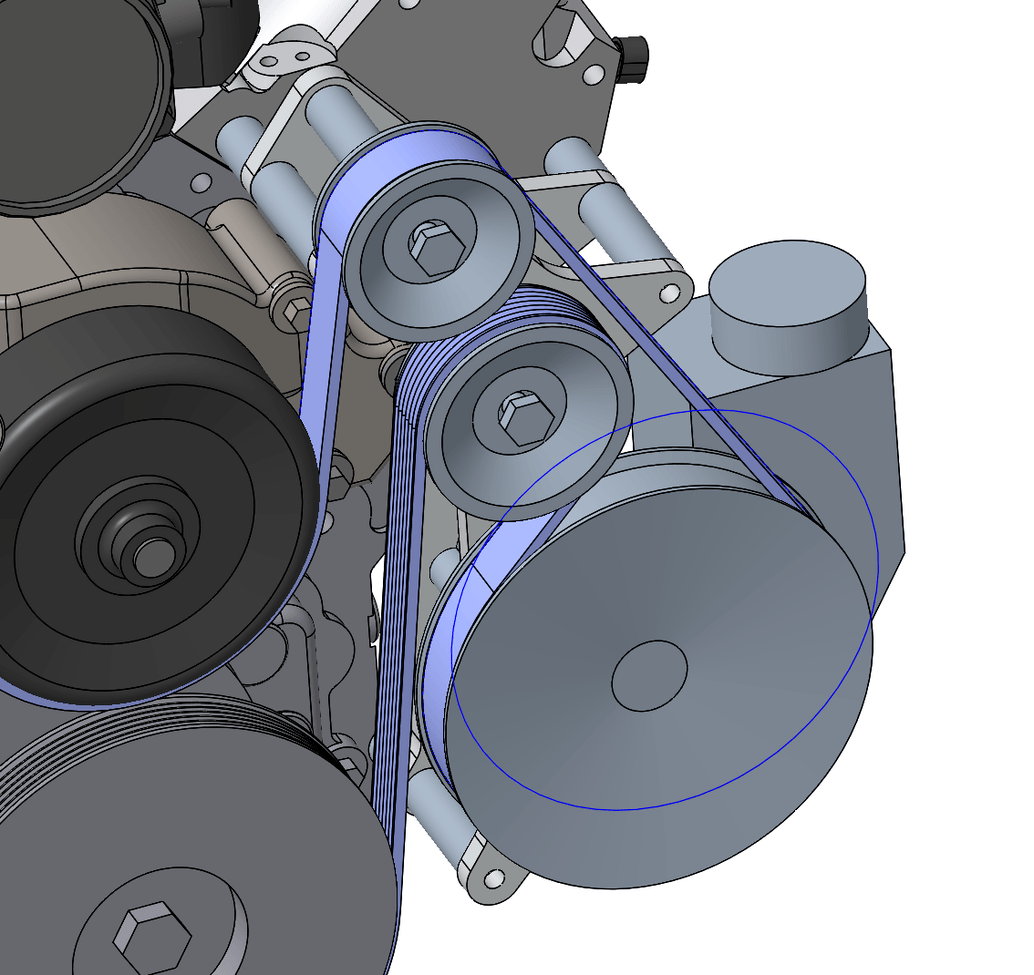

Here is "version 4.3" of accessory drive.. about as much wrap as the pulleys can possibly have. The idler pulleys are all OEM GM ones so quality shouldn't be a concern. The goal of this design revision from the last one several months ago was to move the P/S pump down 1-3" to get the pump reservoir away from turbo heat, and the current/past P/S pump pulley location is the blue sketched line. Also necessary was leaving room below/beside the pump for oil cooler lines to snake around, and maximizing belt wrap with the LS3 intake and '05-'08 Corvette LS3 waterpump.

The smooth idler pulley below the tensioner assembly is the biggest one I have (70mm OD).. I wanted to see if the design could theoretically hold a pulley that big, to reduce bearing speed. If in real life assembly the pulley is too close to the belt (to the right) after the tensioner settles, then I have a 60mm and 54mm OD pulleys that I can swap, to improve belt and thermostat clearance at the sacrifice of some pulley bearing life.

Wow thanks for sharing!

Posted by Diggymart on 3/3/19 @ 12:40:25 AM