You must be logged in to rate content!

5 minute(s) of a 891 minute read

3-19-2018

Haha I appreciate the support... I REALLY should make full 3.5" oval exhaust... only have the downpipes fab'd up until the firewall.

Then in no particular order I need to (off the top of my head):

- finish and weld bottom tanks on IC

- finish and weld top tank on IC

- tack weld support structure to core support, then remove core support to fully bench weld & paint

- swap the heads (buy new LS9 head gaskets)

- install new valvesprings

- swap oil pan

- make oil cooler lines to an oil cooler I've yet to buy or make brackets for

- measure and order turbo oil feed/drain lines

- make a nice-flowing Y block for turbo oil feed lines off of oil cooler return hose

- reroute FPR to be after fuel rail, not before

- install FIC 1000cc injectors

- make brackets to adapt fuel rails to new 42mm short injectors

- make boost distribution block for 2 x boost sensors (1 Holley, 1 Speedhut) and BOV feed

- relocate the breather can from driver fender to firewall, remake lines

- make charge pipes from turbos to IC

- weld stainless bung to downpipe for Holley WBO2

- weld stainless bungs on hot piping for EGT, EGP

- weld alu bungs on charge piping for pre-IC pressure, and IAT

- wire EGT/EGP, pre-IC pressure into Holley Dominator

- get 2 x 4" air filters and make connector tubes to the 4" 90* elbows on the turbo inlets

- CNC P/S pump bracketry (actually doing that this week) and finished accessory drive install

- make P/S pressure/return lines

- plumb push-lock Nylon lines to BOV from boost distribution block

- make boost lines from Holley solenoid to wastegates.. not sure if I'm doing stainless tube or just run push-lock air lines

- make new radiator shroud with cutouts for new fans

- pin the new fan wires to connect to existing fan relay on car side

On the to-do list but not required before first drive:

- MODIFY AND INSTALL INNER FENDERS

- remove heater box and make cover panel for firewall

- redo fuel system with swirlpot in trunk

- rear firewall behind rear seat back

- wire Holley Dominator for correct output to Speedhut speedo, to finally make speedo work

- figure out weird back-voltage issue in oil temp Speedhut gauge that makes Holley go into limp mode when gauge is connected

- fab tray-like sealing structure that mounts to hood, and closes out gap between core support and underside of hood

- make some type of scoop for the bottom 2" of rad to ram air it fresh air

- install a '69 Camaro chin spoiler I got for cheap of Craigslist

3-20-2018

Thanks Clint.. I'll push hard but not sure if I'll make it! I aim to have ALL turbo hotpiping welded up until the firewall by this coming weekend, as well as the cut P/S pump brackets to install this weekend as well.

Tonight I'm going to pick up the injectors, and going to "borrow back" the engine hoist from a friend who's had it for years. The plan this weekend is to strip down the engine to a short block, lift it up a bit to remove trans, lift it up a bit more to swap the oil pan, then reinstall for good and start hanging things back on!

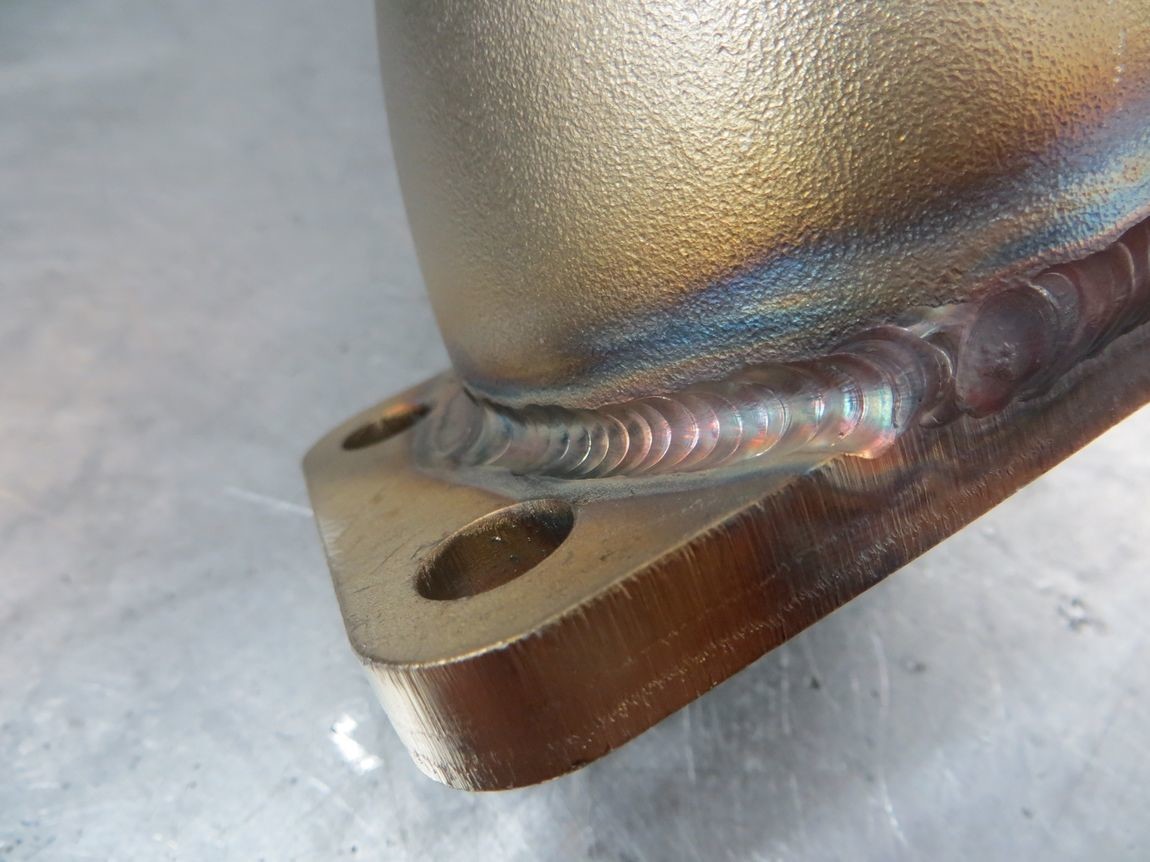

Spent 1hr on Sunday starting the schedule 40 welding, and another 4hrs last night. I was expecting it to take a while, but took a lot longer than I had anticipated, with all the backpurge setup and breaks. Aim to fusion weld the thinner 16ga downpipe/wastegate pipe stuff later this week.

The welds aren't quite as good as I was hoping, but I fed probably 12+ sticks of 36" filler rod into these, so there's plenty of weld material. They appear a bit more undercut in the pictures than they are in real life, maybe because of poor camera lighting. I was so hot.. 150-180 amps for probably 2.5hrs of seat time.. oi!

Wow thanks for sharing!

Posted by Diggymart on 3/3/19 @ 12:40:25 AM