You must be logged in to rate content!

5 minute(s) of a 891 minute read

2-11-2018

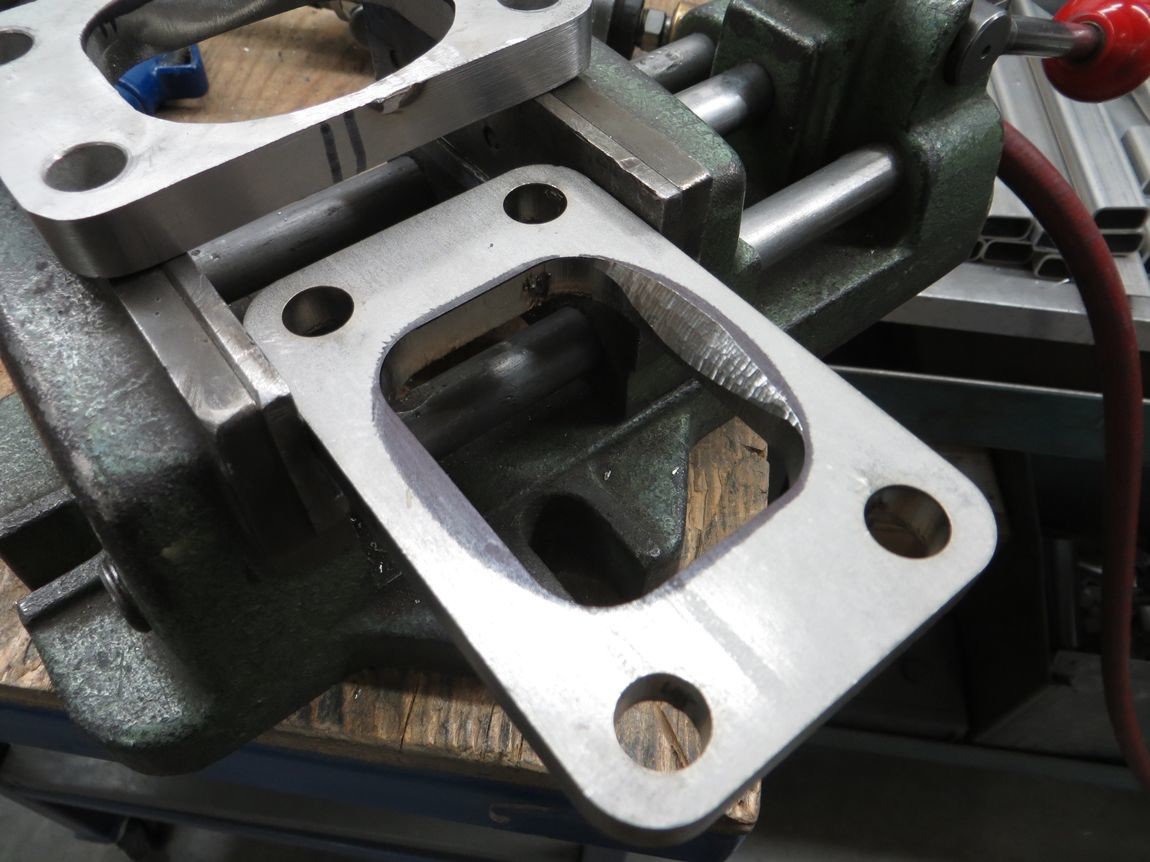

Starting working over the Precision T3 flanges, luckily they are identical in outer profile to the generic ones I had used for mockup.

Here is the difference in rectangular profile between the old (generic) one on top of the Precision one. It was a big enough difference to make me want to swap out, plus the Precision flanges have nice 10mm holes like the turbine housing, the generic flanges had 7/16" holes creating a lot of mounting slop.

A carbide bit on a pneumatic die grinder makes very quick work of the SS304.

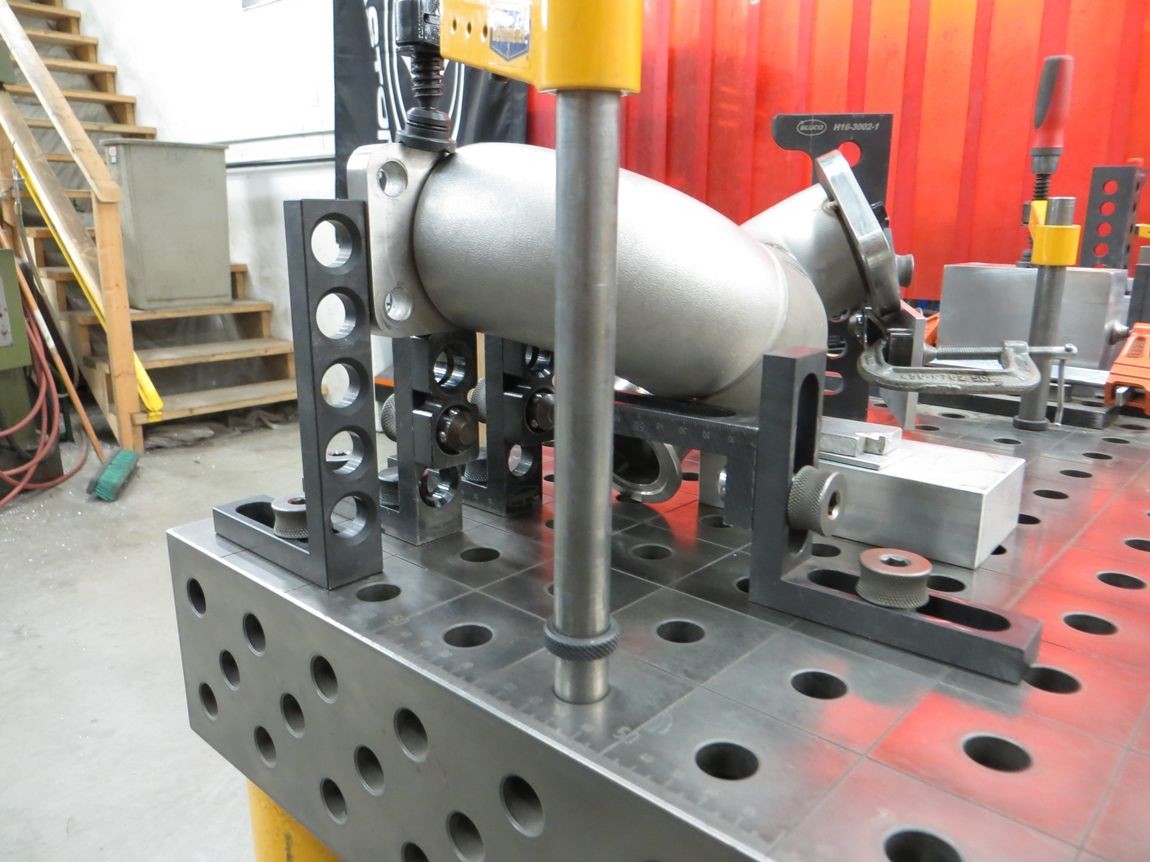

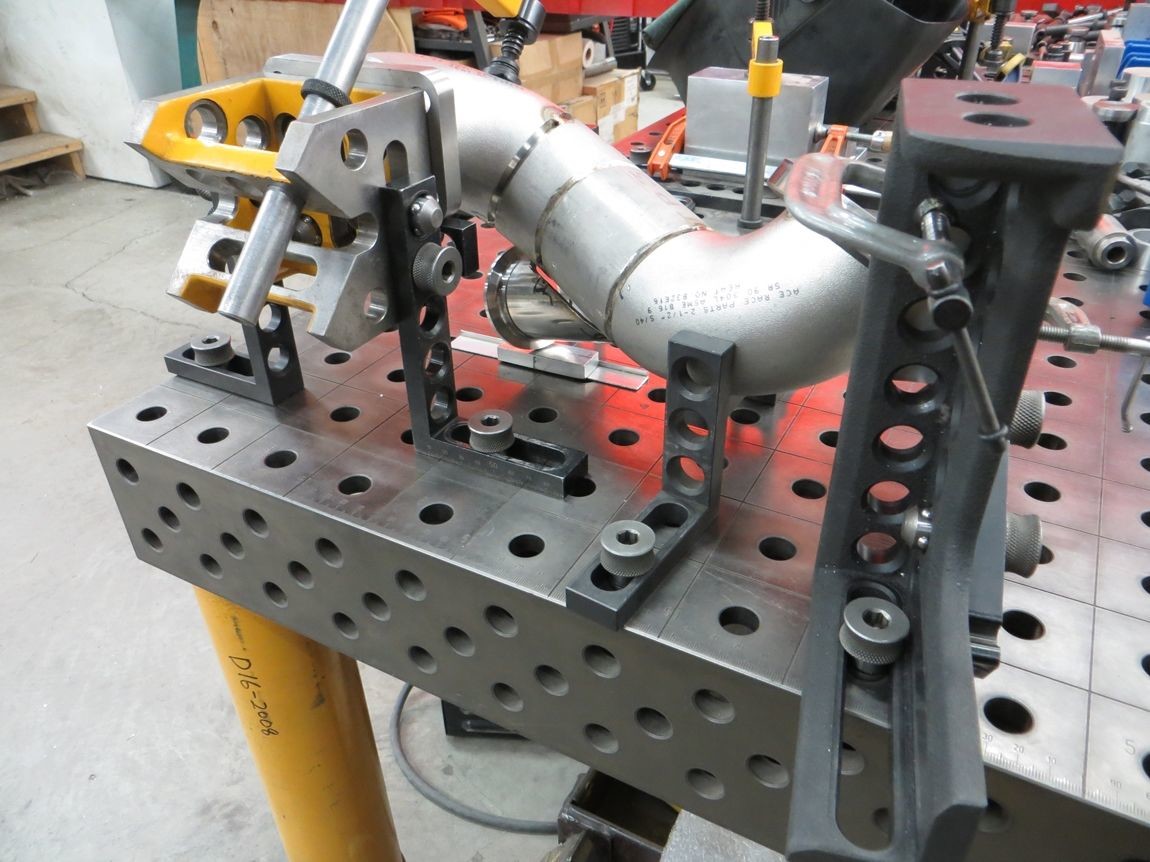

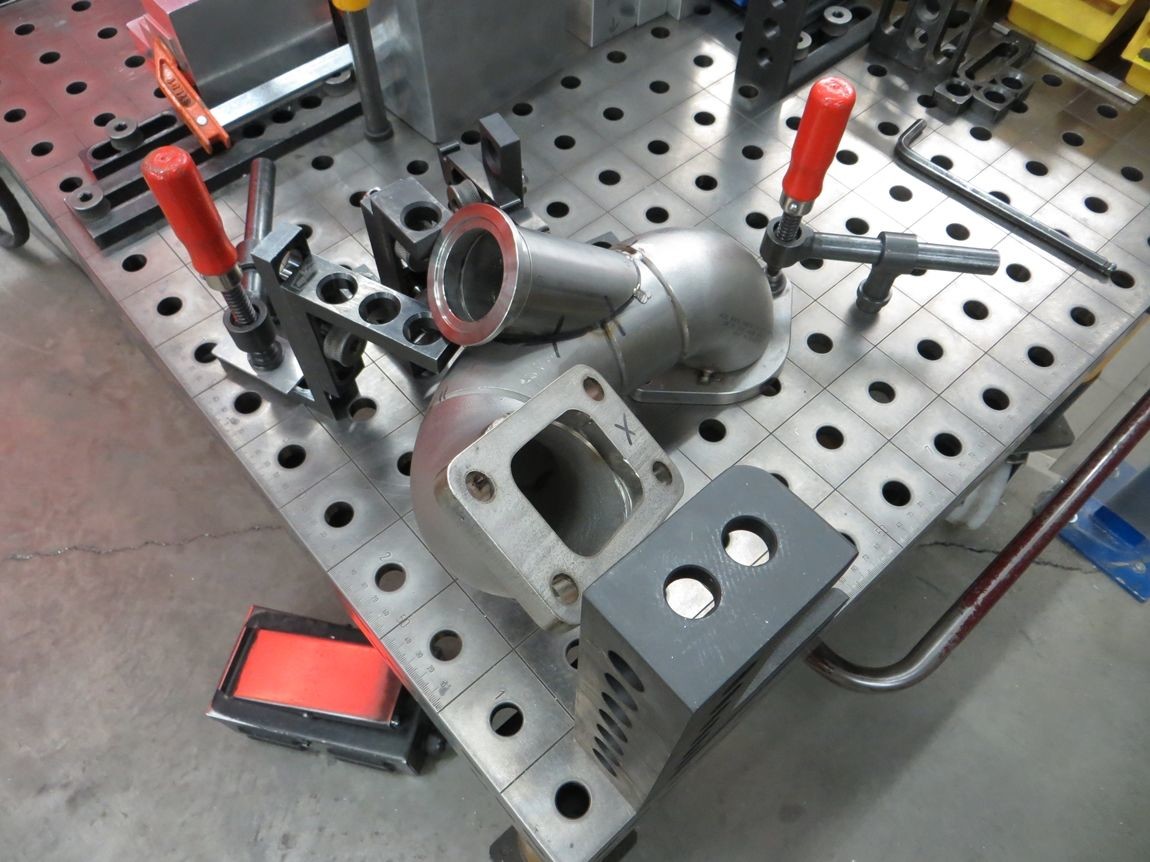

Because the new and old flanges are same in outer profile, I used the piping as-is to create a locating setup on the Bluco modular jig at work. We use this jig table for absolutely everything because it's just so easy and awesome. This setup will locate the Precision flanges in the same place as the mockup flanges, to remove any placement error when cut off the old ones.

New Precision flange in place on the driver side hotpipe, right were it's supposed to be.

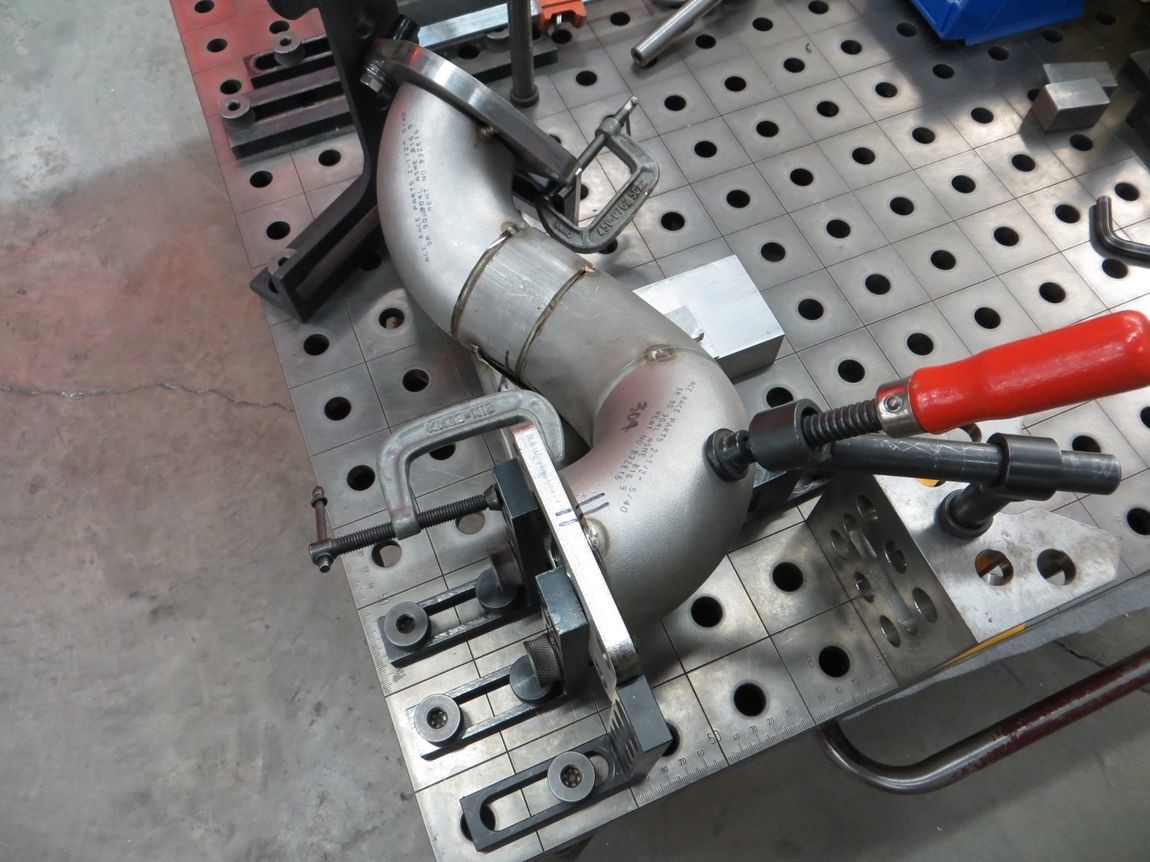

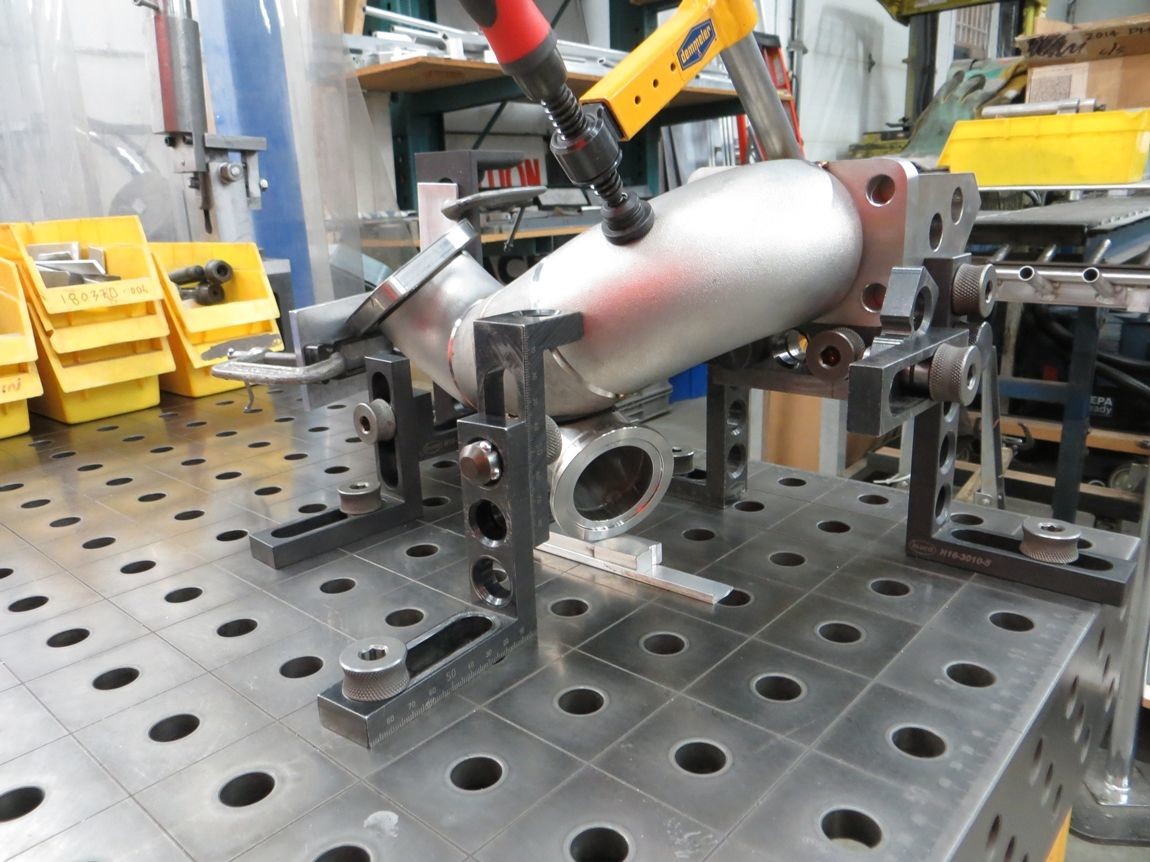

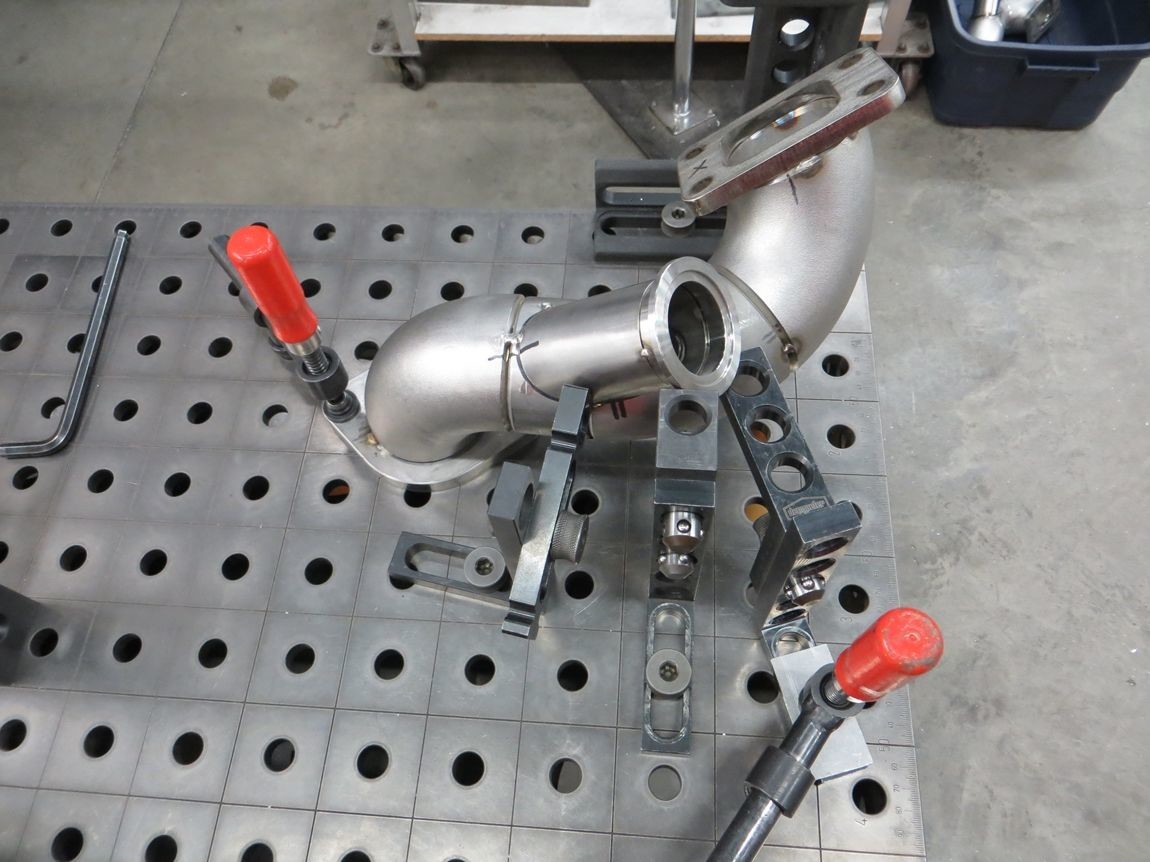

Setup for the passenger side hotpiping. Using plenty of clamps, height blocks, and locating angle brackets allows the hotpiping to just "click" into place in only one orientation...

And new Precision flange properly located on the passenger flange..

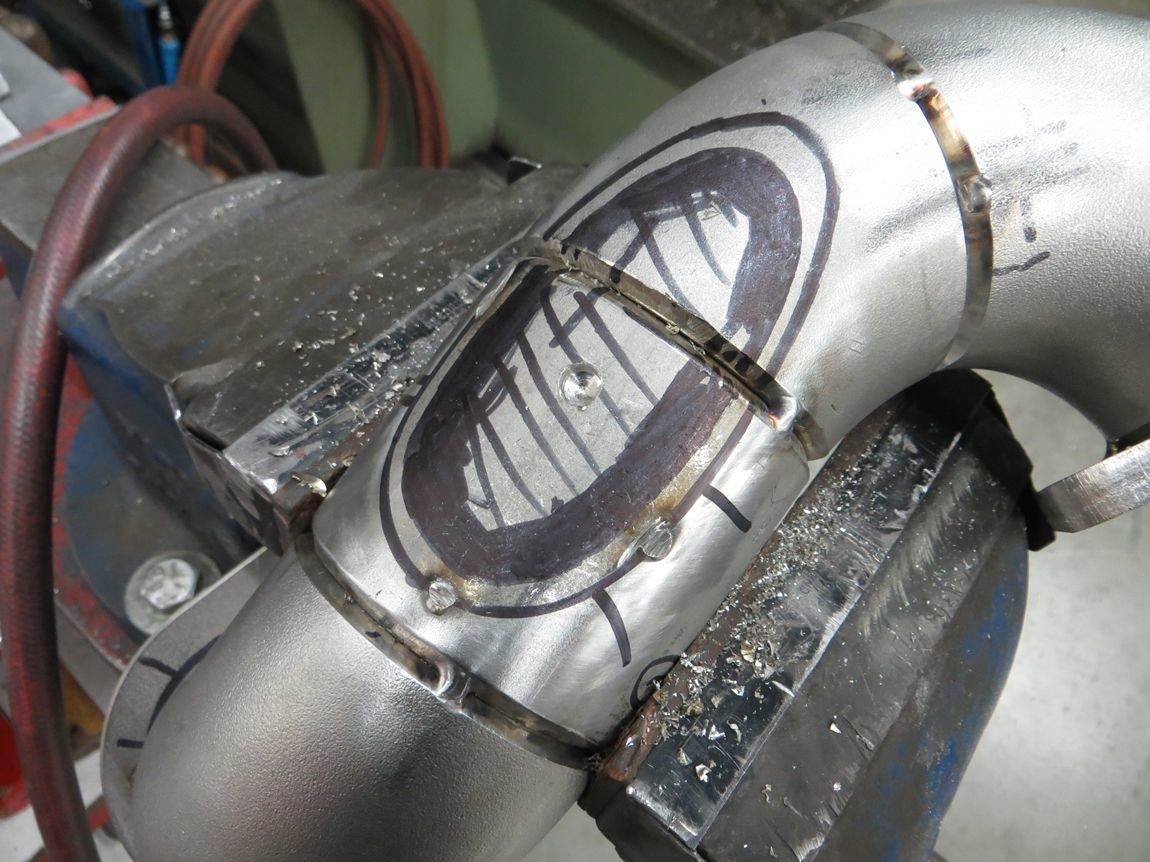

Then I got started on hogging out the hotpiping where the wastegate branches are located.

First step was to use the Scotchbrite buffing wheel to remove all my previous marker lines and start fresh.. mark a nice tight profile line and then a couple locating lines for alignment, then buzz off the tack welds...

Then I marked off the inner area that needed to be removed, constantly checking for accuracy by test placing the wastegate branch in place.

Holesaw for bulk material removal! As a first attempt I realize the holesaw could have been a bit lower down to lessen the amount of rounding/grinding needed to achieve the finished profile, oh well...

Then using a belt sander, cutoff zip wheel, carbide grinding bit, and a file, we have a large smooth opening.

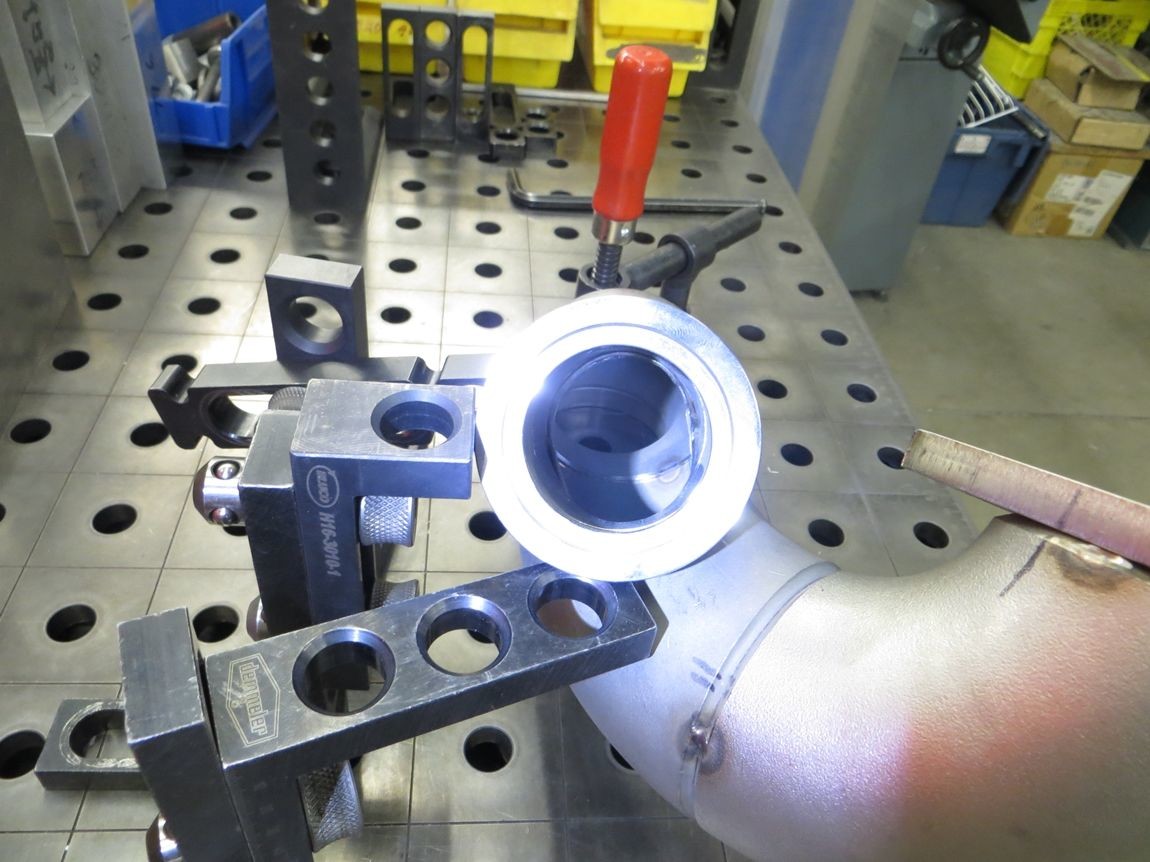

Close enough for my liking... so much flow!

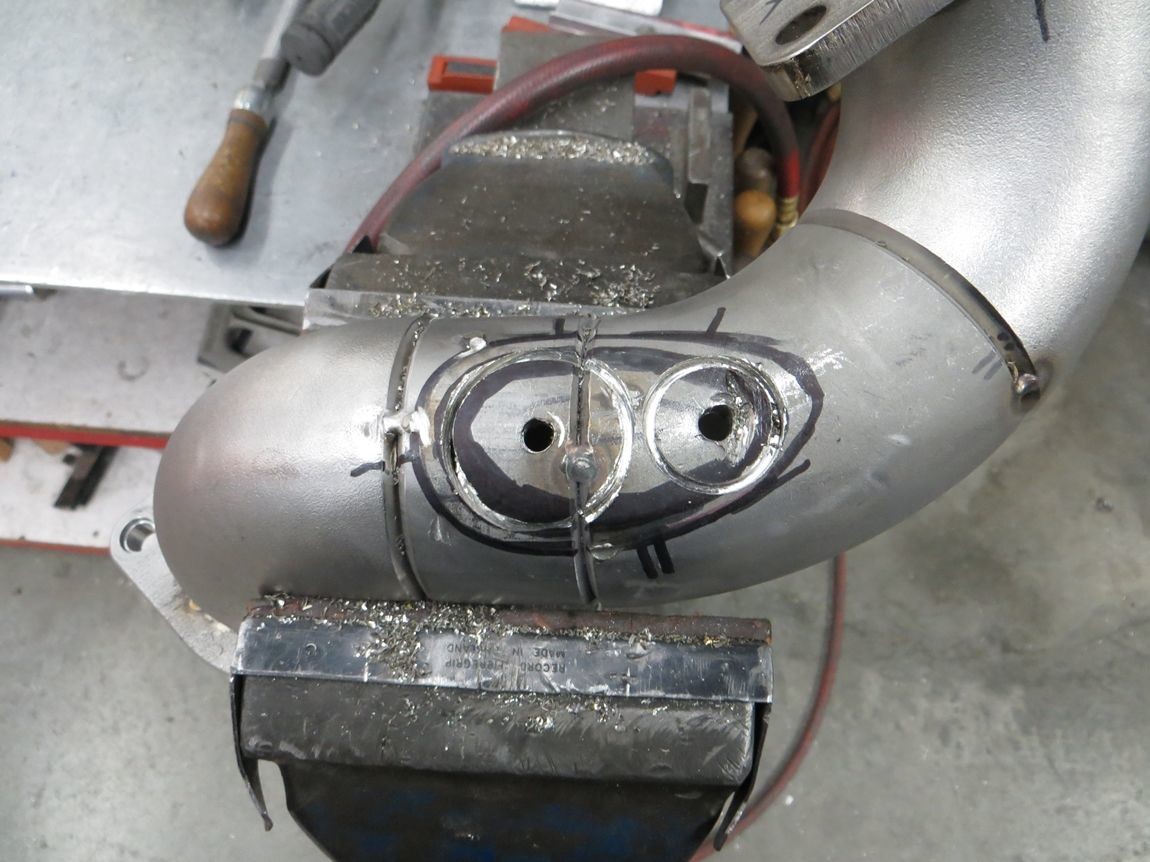

Learned for round 2.. holesaw'd much closer to the finished profile...

More cutting/grinding/smoothing....

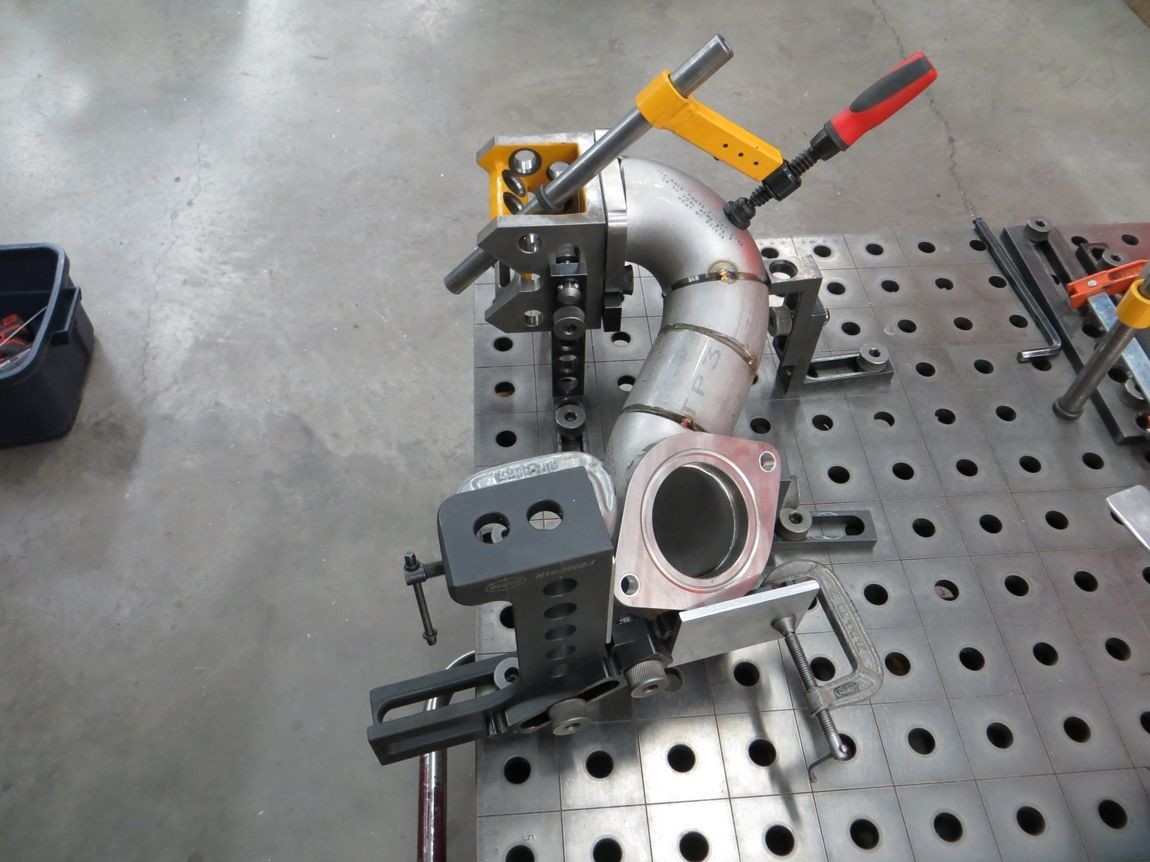

Again this jigging table is immensely helpful for quickly holding a weirdly shaped piece on top of another weird shape, so it doesn't annoyingly move around while tack welding in place.

Wow thanks for sharing!

Posted by Diggymart on 3/3/19 @ 12:40:25 AM