You must be logged in to rate content!

4 minute(s) of a 891 minute read

10-15-2017

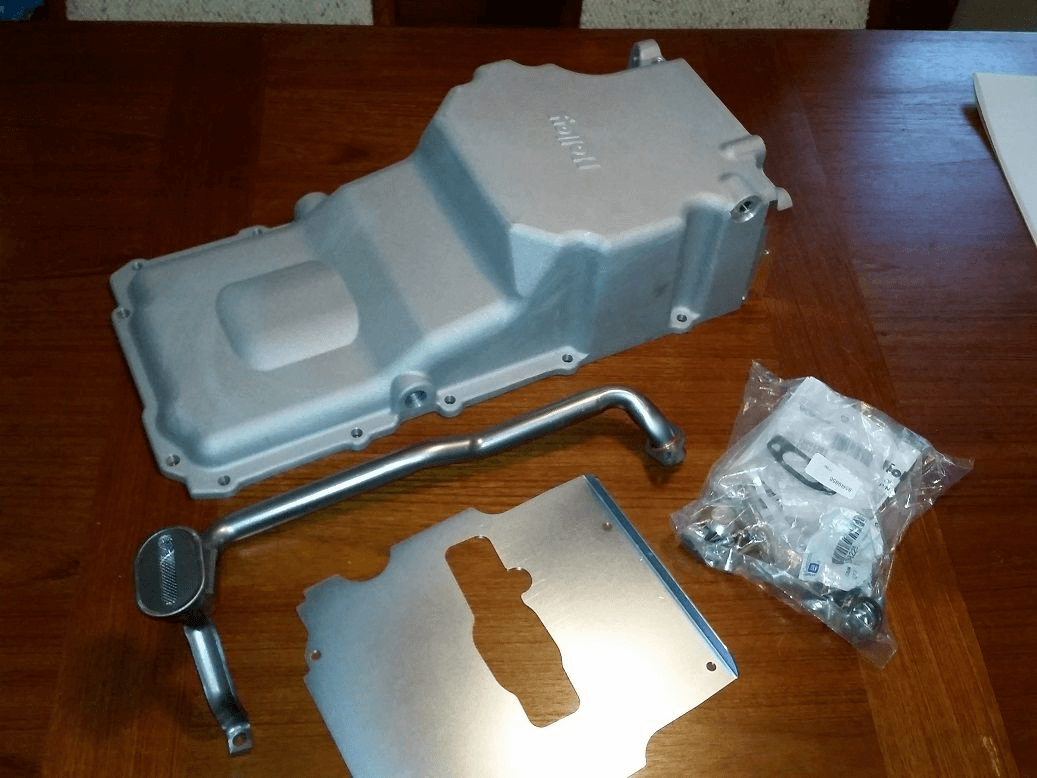

The parts collecting has started! Sprung for the new-design Holley oil pan for a couple reasons:

- has clearance for a 4.0" stroke

- has two turbo drain ports in a better location than the single port I currently have on my heavily modified truck pan (current port comes very close to my modified drag link at full lock)

- oil filter machining is higher up (closer to the block) than my truck pan, allowing me to run a bigger filter than the current shorty filter I have on my chopped truck pan

- my current pan has always seeped a bit of oil out of the front pan modifications (the original cut/weld mods I had done by a guy to get the pan to clear the subframe, terrible work.. porous welds, always wanted to remedy)

Also got some CTS-V manifolds to start fresh. For tire and thus inner fender clearance, the turbos are going to have to be fairly far forward.. so I like that the CTS-V manifolds have the flange all the way at the end, to minimize the length of the hotside piping needed between the manifold and turbo, and thus cantilevering forces etc. I also like how tight the collector is to the head, as in how the collector doesn't angle out much.. will help in keeping the hotside piping tighter inboard.

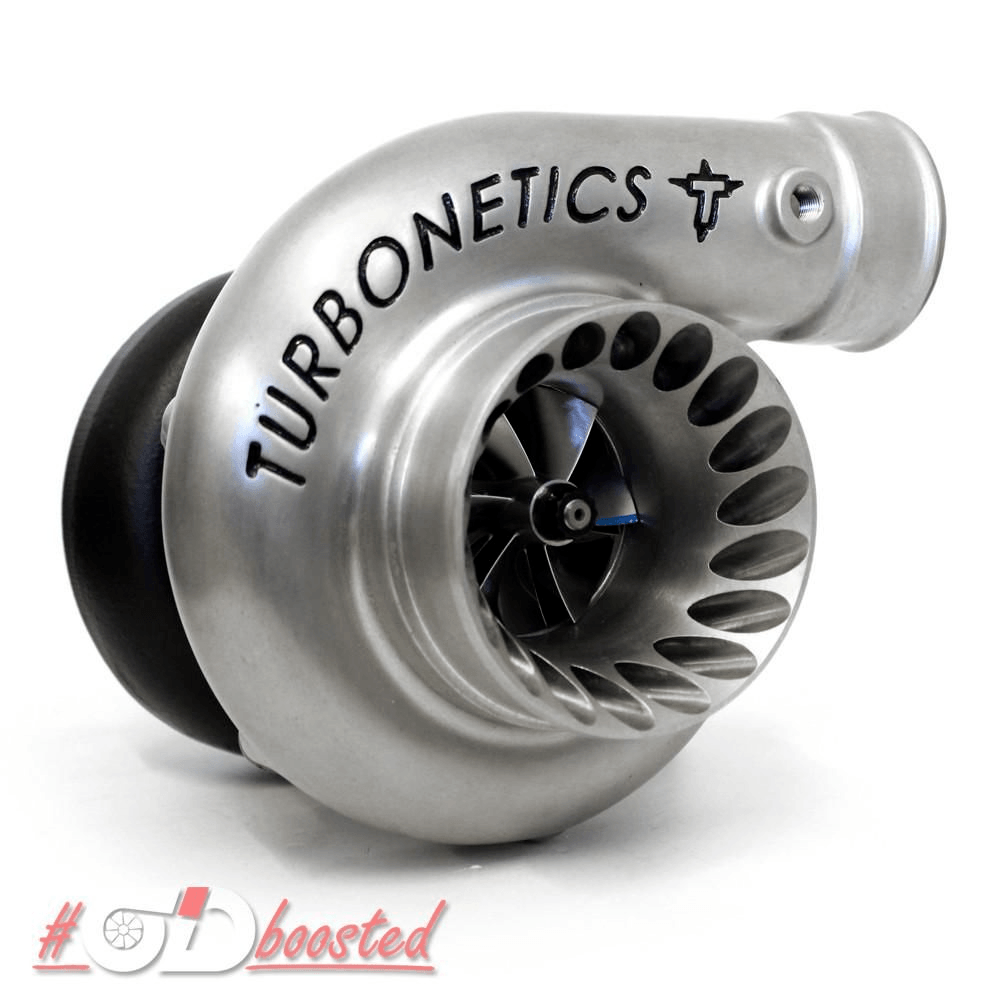

In the near future it'll be time for the turbo decision. I'm between the following turbo's from Turbonetics and Precision. Both are BB, with the Precision being about $150 more than the Turbonetics, but with the Turbonetics coming with the turbine housing already ceramic coated black. That being said, I'm heavily leaning towards the Precision just due to my previous experience as well as reputation:

1) Turbonetics GTK-700

- compressor: 64mm billet HPC wheel, 4" inlet, 2.5" outlet

- turbine: 65mm, 0.85 A/R, T3 flange inlet, 3" v-band outlet

- ball bearing CHRA, brushed compressor cover, black ceramic coated turbine housing

2) Precision PT6466 CEA

- compressor: Gen2 64mm billet, 4" inlet, 2.5" outlet

- turbine: 66mm, 0.82 A/R, T3 flange inlet, 3" v-band outlet

- ball bearing CHRA, natural/raw compressor cover

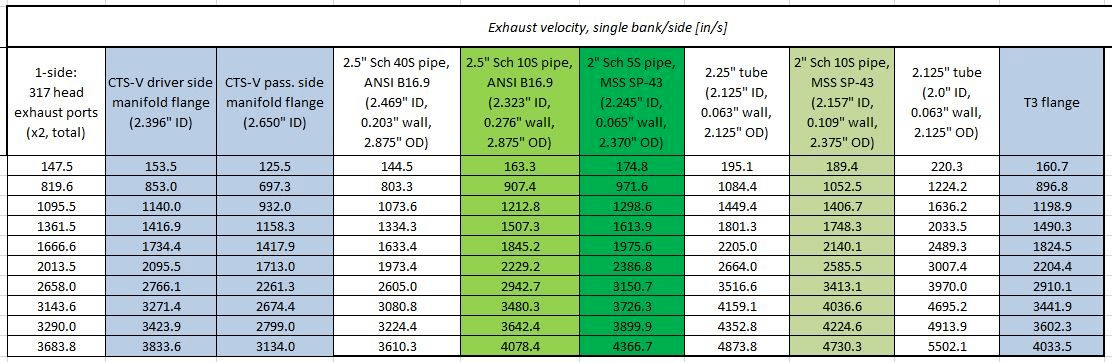

Also looking at various tube/pipe inner areas for exhaust flow. I originally was comparing just diameters but a small change in diameter can change the area a fair amount, so I started calculating exhaust velocity.. to try and keep it as uniform from exhaust port to manifold collector to hotside piping to turbo flange.

From a bunch of research in the Forced Induction section, it seems 2.25" inner diameter isn't a hindrance until decently past 1000hp, and 2.5" ID is just overkill until about 1500hp. So I'm aiming to keep it as close to 2.25" ID as possible.

I'm thinking schedule 5 pipe from Ace Race Parts.. short and long weld elbows are reasonably priced. I was originally wanting thick wall, but on Ace Race Parts the correct ID stuff is only available in SS304 2.5", and even in SS304 it's crazy expensive because of how thick the wall is. I'm thinking of trying 0.065" wall schedule 5 2.0" SS321.. I'm hoping that with 321's favorable high-temp characteristics as well as keeping the hotside piping under 12" long, that the turbo weight being supported by only 0.065" wall should be okay.

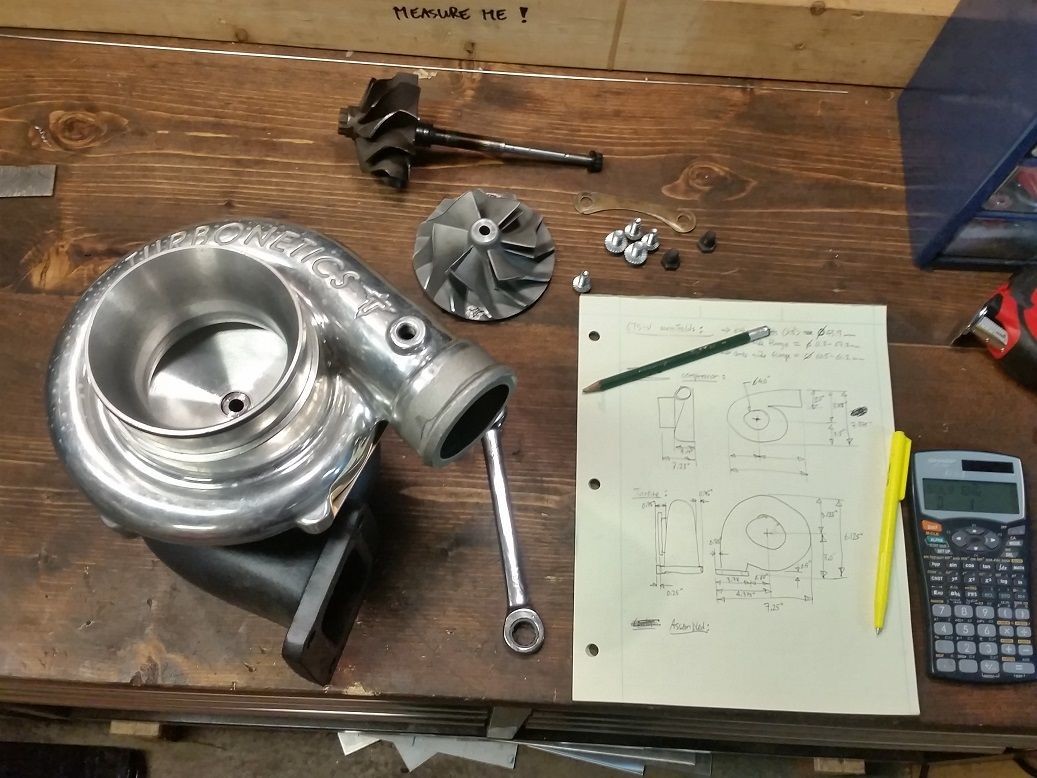

It's also super handy to still have the old too-small blown up TC-76 turbo for mock up purposes...

Wow thanks for sharing!

Posted by Diggymart on 3/3/19 @ 12:40:25 AM