You must be logged in to rate content!

5 minute(s) of a 210 minute read

5-11-2012

5-11-2012

Thanks yah'll! I'm "gettin' mad work in tonight, yo".

So I'll update later!

I'm finally ripping the Shep Stage 2 out of my other car, which I've been putting off for quite some time.

Oh, and....got some parts!

Fuel Lab Mini AFPR, in purple, of course. I have black snap fit lines coming in from MAP to finish that off. I opted to do this instead of a fuel rail so I can re-wire my Walbro 400lph without overrunning the stock FPR.

And...INJECTORS!! Picked up some 1250cc FIC BlueMax jobbers, as I'm realistic about my fuel needs and will feed this EGT skyrocketing monster with 93 until PHILLY decides to get a few more E85 pumps in my ureah.

Welp, I got some work done tonight, and got bored, and did some more work.

First off, I torqued the head down per the previous specs. The Service Manual sequence, with a torque sequence something like 10-30-55-95.

I then realized that I never received the Water Pump Adapter from MAP, and didn't want to finish the timing side of the motor without doing that. Thus, I proceeded to put a bunch of other crap on that I would've had to do at some point.

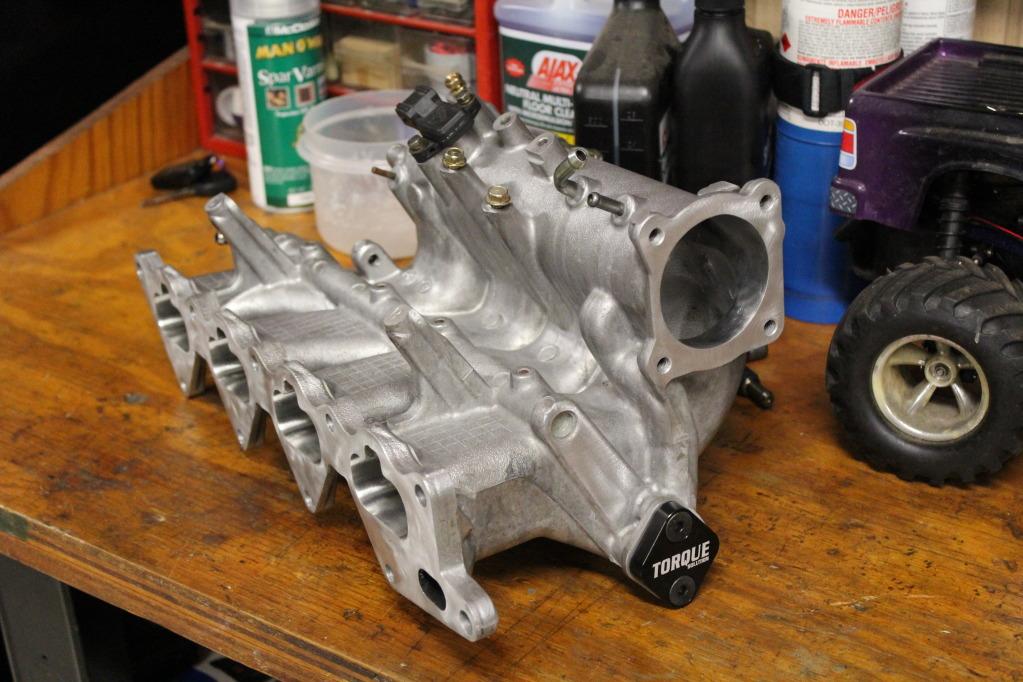

Threw on the Torque Solutions EGR Delete Plate and the Omni 4 Bar:

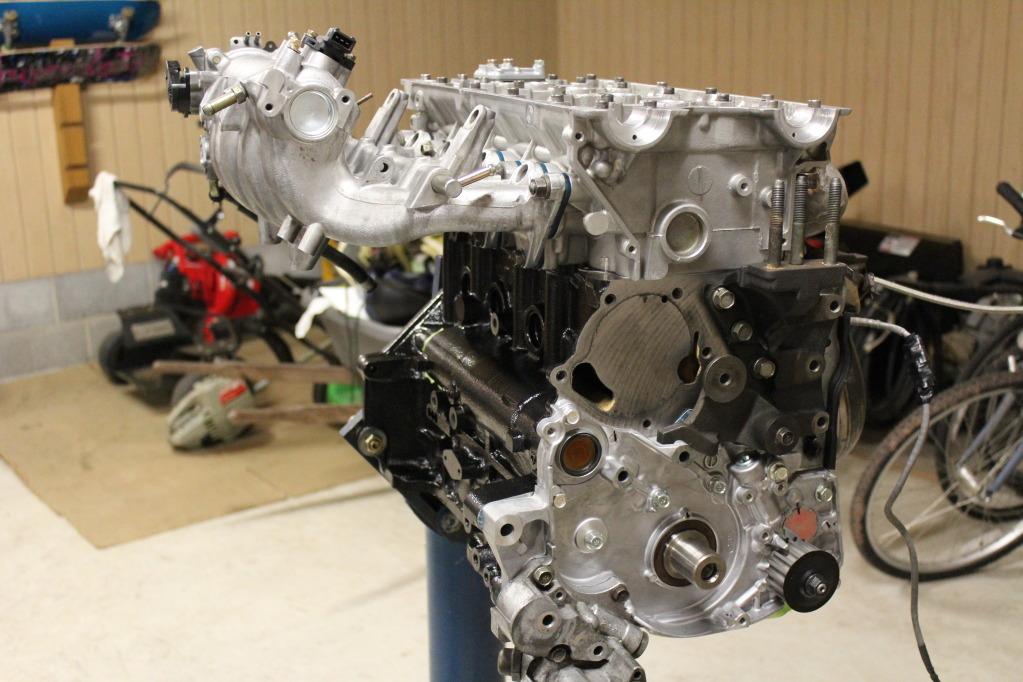

Threw on the Oil Filter Housing (Torqued everything to ~25ft/lbs), and an ugly bracket that I cleaned frivolously beforehand. Oh, and I started bolting the IM down at this point, too.

Torqued down the IM, and the turbo kit next (EM, Dump, Oil Feed Kit)!

This is where I got pissed off. I came to the conclusion that nothing will really fit in regards to venting the balance shaft inspection hole.

A) There's no way I can use a 10x1.25 to -6AN Fitting (STM) and fit a 90* out of there. Even with a cast 90* I don't think it will fit. Thus........I don't know how I'm going to vent my crankcase.

B) My previous banjo bolt idea won't work, as I can't get a 10mm to -6AN banjo fitting, although I was told I could before. Oh well.

I'm now at a loss of how to vent the crankcase.

This how tight it is in there:

Next is the point in the night where I got sick of bolting stuff on, and decided to polish my stock Fuel Rail since I'm not wasting any cayesh on a shiny aftermarket one.

With a quick 400 sand:

With a 400 and a 600:

I didn't like leaving the ends unpolished:

Everything with 400, 600, and Mothers:

Unfortunately, I got bored of that and took apart and rebuilt the throttle body, throwing it on the IM afterwords.

And last but not least, some random shots before I went inside:

My slowly shrinking parts pile:

The new pile (of crap) I must overcome:

From here on out, the only think stopping me is the water pump adapter. Once I get that I'll throw all of my new shiny OEM Mitsu timing components on, time the car, throw the longblock in the car, etc.

Oh, and I drilled the baffles out of my valve cover, tapped the holes, and drilled out the head for -10AN ports. I'll take some pictures of that and throw them up eventually.

Word!