You must be logged in to rate content!

8 minute(s) of a 462 minute read

6-30-2016

my GUESS is that I blocked off the pcv valve and that might had something to do with it? or the rings were going out in the first place. it's weird because right after I got my head done I had a suspicious oil leak only in the intake manifold?

there was no oil in the pistons or on the spark plugs? ?

The head guy told me it was normal for if your rings to go if they are weak AFTER a head job.

3-5-2017

so with the help of gerb I was able to get my hands on the pistons I needed.

.20 over cp's.

I also opted to get some eagle rods, after buying/flirting with the idea of using rods from cx racing(took them back because the rod bolt was way smaller.

so it's been a while between last year and now when the motor blew up, and I acquired another s13 which has since ben totaled by some dumb ***** and I reinstalled my rb25 which has also blown up due to a rod knock.

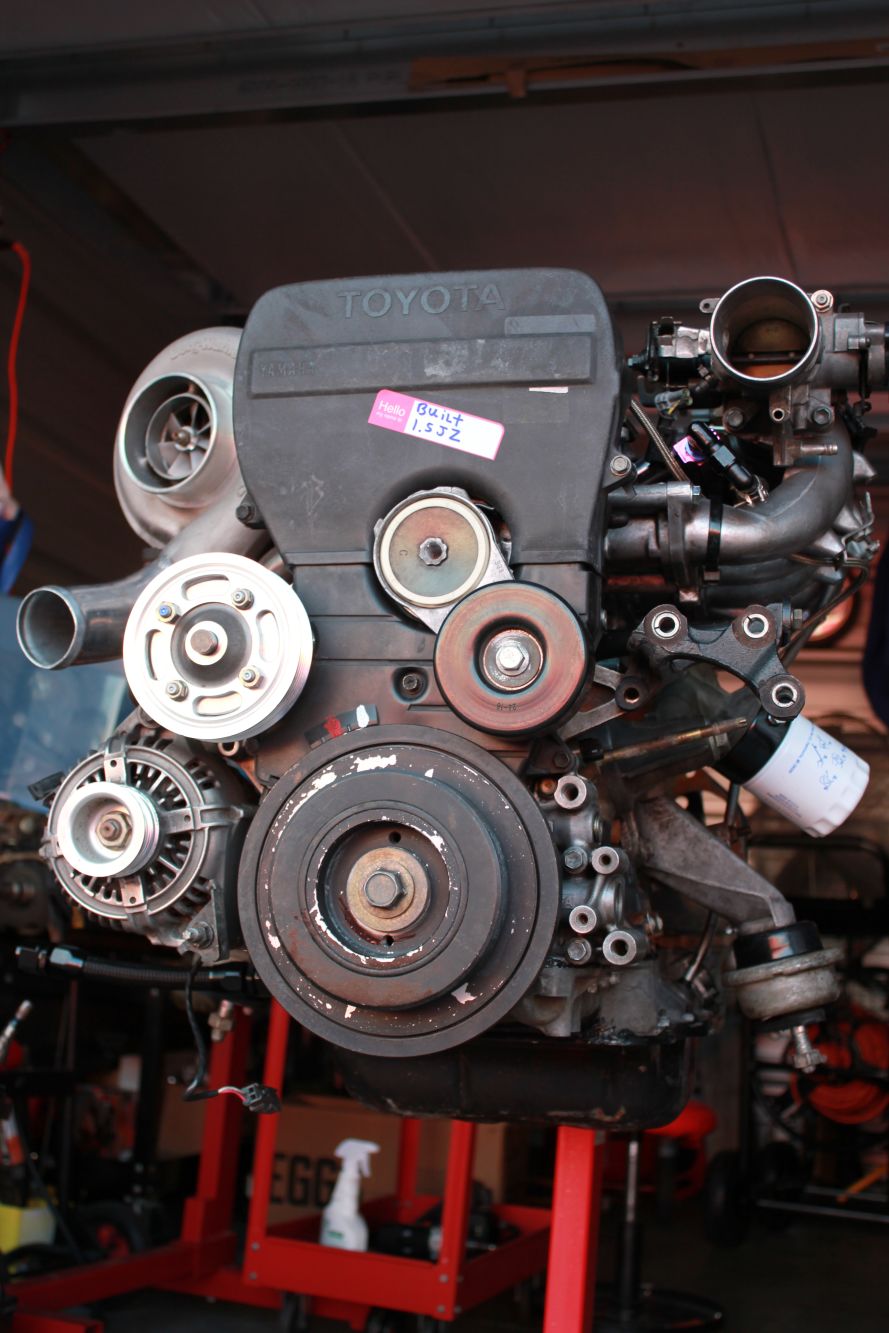

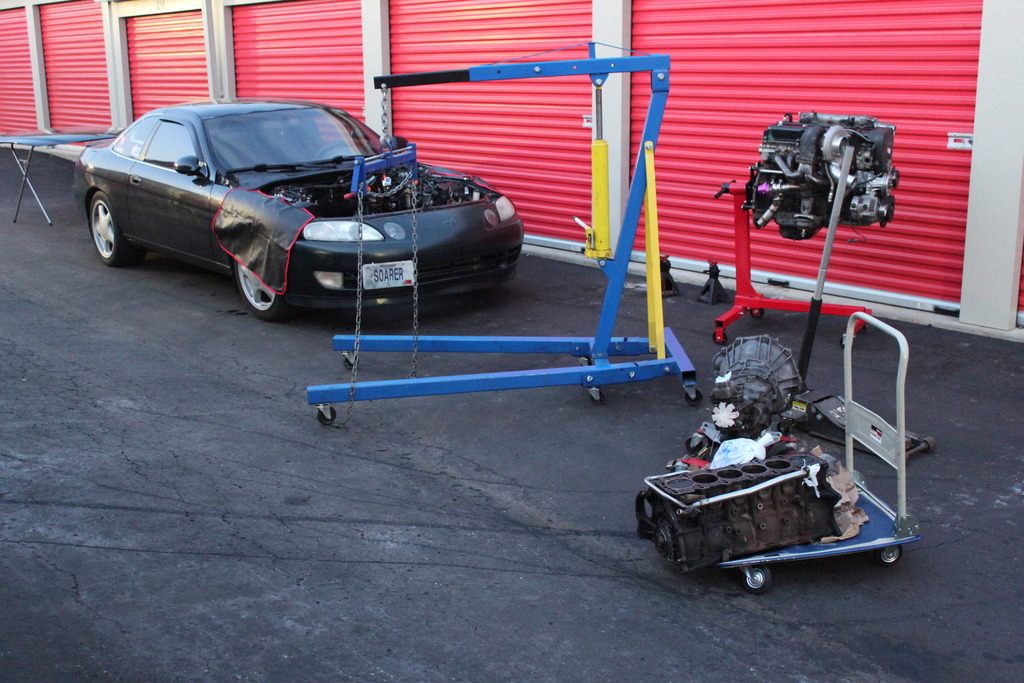

now I had time, so within 3 weeks I took my soarer out of service, swapped head and all the parts on the 2j block, swapped to the r-154 tranny I've had sitting for years and violia!!!

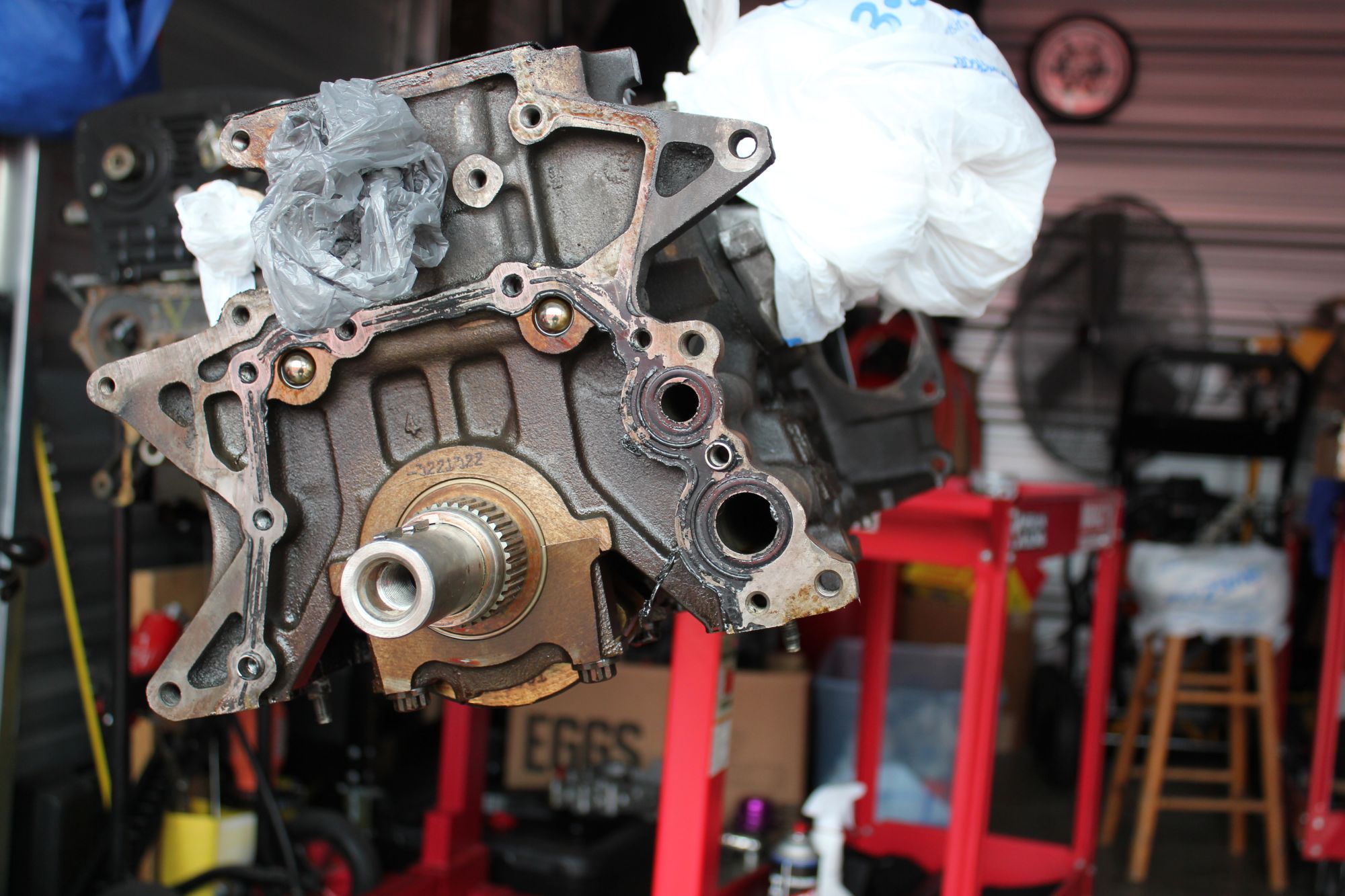

so first order of business was stripping the 1jz, all the stuff came off and I have it for sale for $200.00

then I snagged me a nifty cart to haul off the stuff that needed to be power washed!

so finally got the block and stuff back from the shop, oh it was a happy day, everything was so fresh and clean.

-BLOCK WAS DECKED/BORED TO .20 OVER

-HOT TANKED

-CRANK WAS POLISHED/BALANCED

-PISTON RINGS WERE FILED/INSTALLED

-RODS WERE BALANCED/WRIST PINS INSTALLED

TOTAL BILL $870-930 (HAVE TO LOOK AT RECEIPT)

not what I wanted to spend.

also picked up some break in oil

Next up was assembly time. Yes I was nervous as this will be my frist assembly of a bottom end and I can't **** up on this one. so after some youtube videos and some verbal advice from some people I took a crack at it. thankfully some warmer weather came by to help.

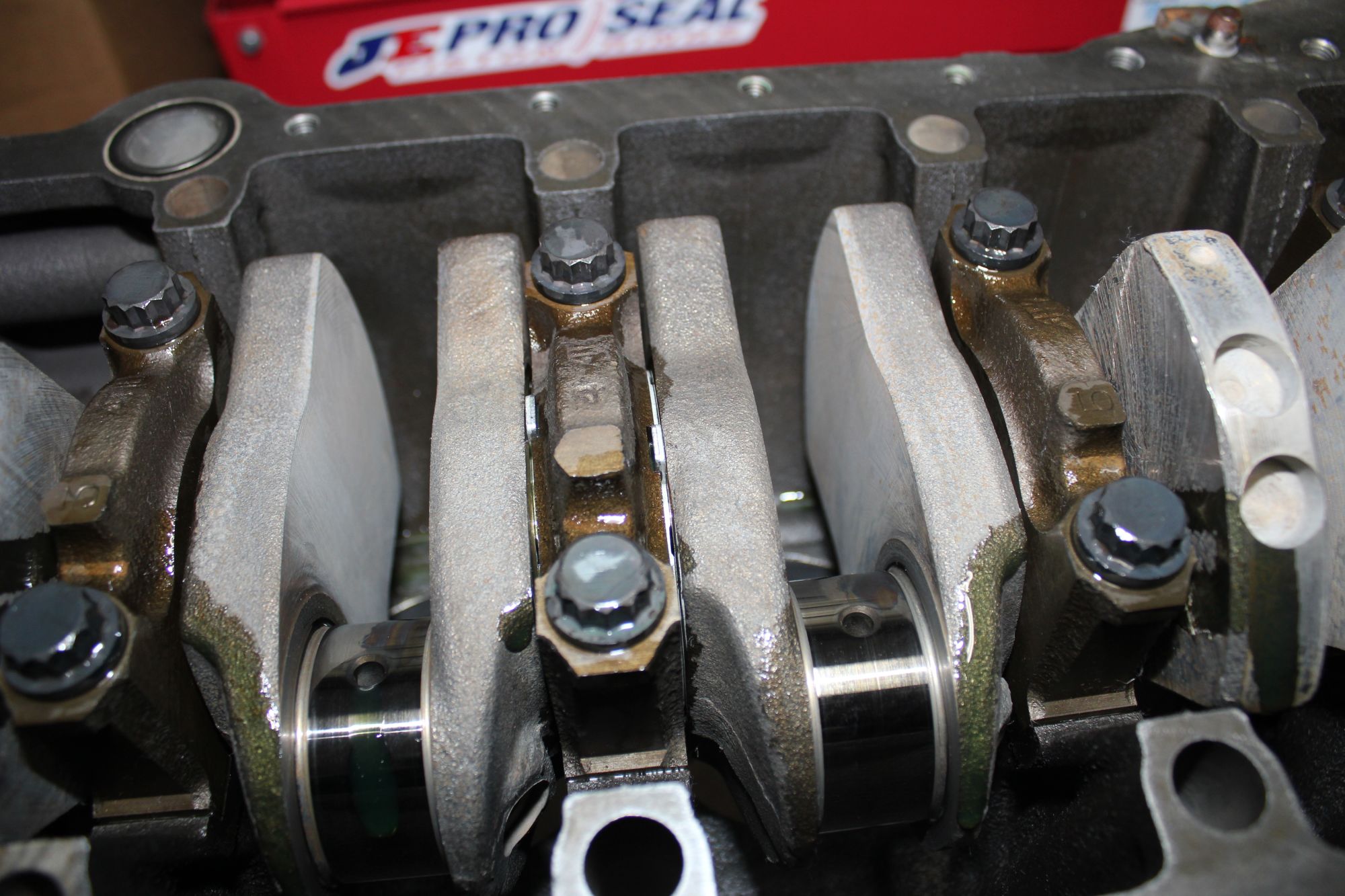

so aside from following the fsm, apparently the "big" thing is crank thrust, so I carefully did that and tried to make sure it was within spec

then it was on to the pis-on-ton loading

went in without a problem, no piston rings were injured!

next up was head gasket and oil pan/pump install, I have done this before on the thread so I skipped this illustration this time.

YES, the lower 1jz cam cover is too small, and I'm actually selling the set (top and bottom)

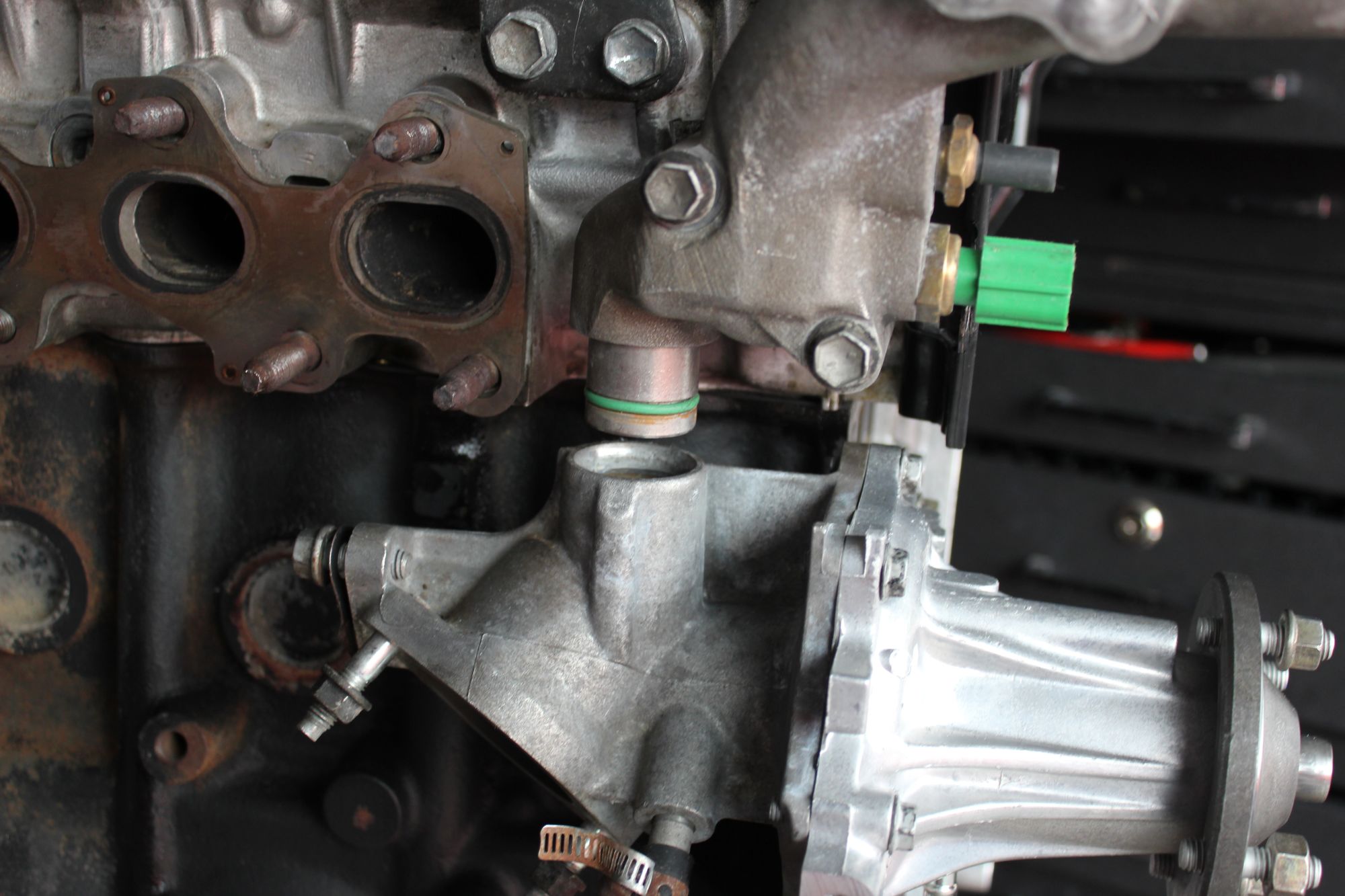

ran into an issue with the water neck.

so I made a FAILED attempt at being a machinist to fix it, I just sourced a n/a one at the junkyard and got that one.

so 20 bucks later it was welded and the crisis was averted.

now the motor was getting ready to "go in"

up next was the r-154 prepping. I opted for this clutch kit, why? because it's cheap and I'm poor.

and I also modded my w58 vss to work.

spent a few nights with no sleep.

I MUST SAY, the hardest thing about this whole tranny thing, was getting this damn bearing together, that snap ring is a mother!

luckily I had a pair of ring(not leg) spreaders and some clamps to make it work.

also had to cut some bolts because the pp ones for the w58 are too short.

now it's time to mate the 2 and form voltron!!! it was a foggy morning that day.

so finally got around to draining the fluid in the trans to replace it with some synchromesh. But I seen some small metal sheen particles in it.

at this point all I could do was grab my butt cheeks and hope for the best, it was too late now.

I installed the motor and tranny, and surprisingly the trans mount came up to the exact same spot as the w58 did GO ME. used the same shifter I had before the the shifter location hasn't changed.

only thing is I had to make the tranny mount holes bigger.

and yes the ds is a few inches short, still works/fits but u should get it extended.

and now it's done and done.

Great project!

Posted by Diggymart on 11/1/19 @ 10:59:41 AM