You must be logged in to rate content!

8 minute(s) of a 150 minute read

6-2-2012

Updates!

Me car was running great! But the timing belt went closer to the block (wtf?) and push and destroy herself on the crank sensor plate that is mount on the sproket of the crank...

Result: this "gear" or washer on what the crank sensor make his reading, went of the sproket and spin free. My motor is no longer starting! ![]()

By chance I was at 400ft from my friend house (that's were I was going so...) Now my car is in his garage already on jack stand![]() the fun thing about this is when I call him to say I'm stock near him, he said me his tractor mower broke.. at the same time. Epic.

the fun thing about this is when I call him to say I'm stock near him, he said me his tractor mower broke.. at the same time. Epic.

Well we've try the tow hook and it work fine! But I'll have to reinforce it a little bit because it have bent a little to the left as we entered his parking (he towed me with a chain) So it have to be reinforce for lateral towing strengh if you understand what I mean!

Let you know soon what's next as we order a few thing to get it move again:

-New timing belt already loll

-New sproket/crank gear for timing belt

-New tensionner pulley as we thing it's the fault for the timing belt that have come closer to the block.

-New Oil return gasket for front turbo as, I have a leak!

-New solenoid for the IACV as mine is broken and it's the reason why my sequential turbo aren't working ( but still work in TTC mode,.. awesome!)

After what, I will run an 500km arround and if everything goes right, I'll go on tuning it with the AEM FIC and see if I need injectors!

see ya soon!!![]()

For Menty, and those who want to know how to mount a tow hook like I've done. Here is the "how to":

1. Things you need for making this

-drill

-grinder mount with a cutting wheel.

-a solid vice mount on your workbench.

-permanent pen/chalk

-rule or measuring tape

Things you need to buy:

-Tow hooks! (doh!) here it's an Benen Industries screw type tow hook for an S2000

-1/2 size, 3 and a half inches long bolts with lock nuts (here in the first pic was 5inches long one, my error!)

- a 6x10 inches, 1/4 inch tick plate (or more, but you will have to bent it so....) It could be 5x10 but It doesn't seem to exist.

-2 extra strengh nuts that fits the tow hook for mounting aplication

- and finally a 3/8 size, 3inches long minimum bolt with nuts, you'll see below why.

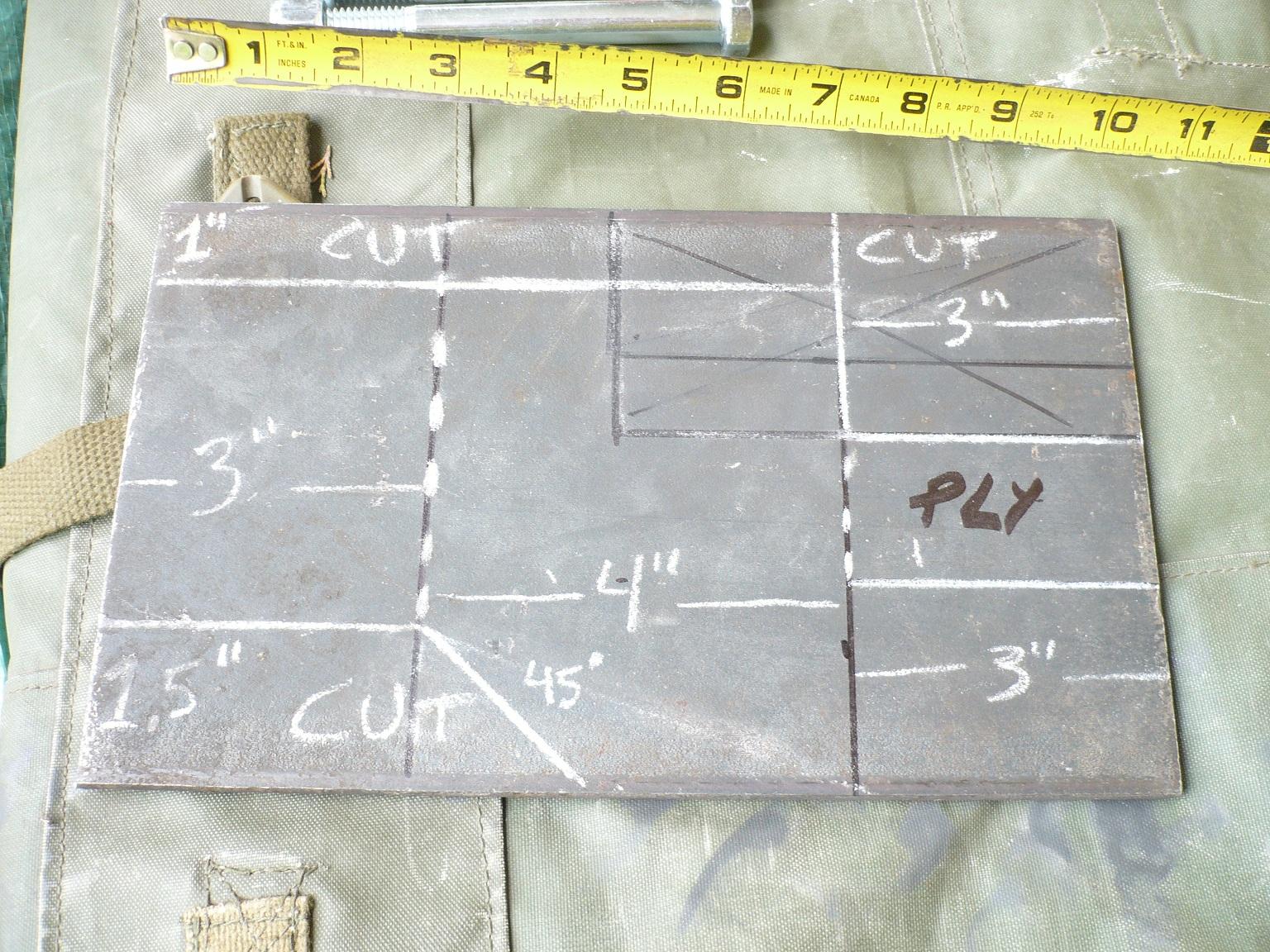

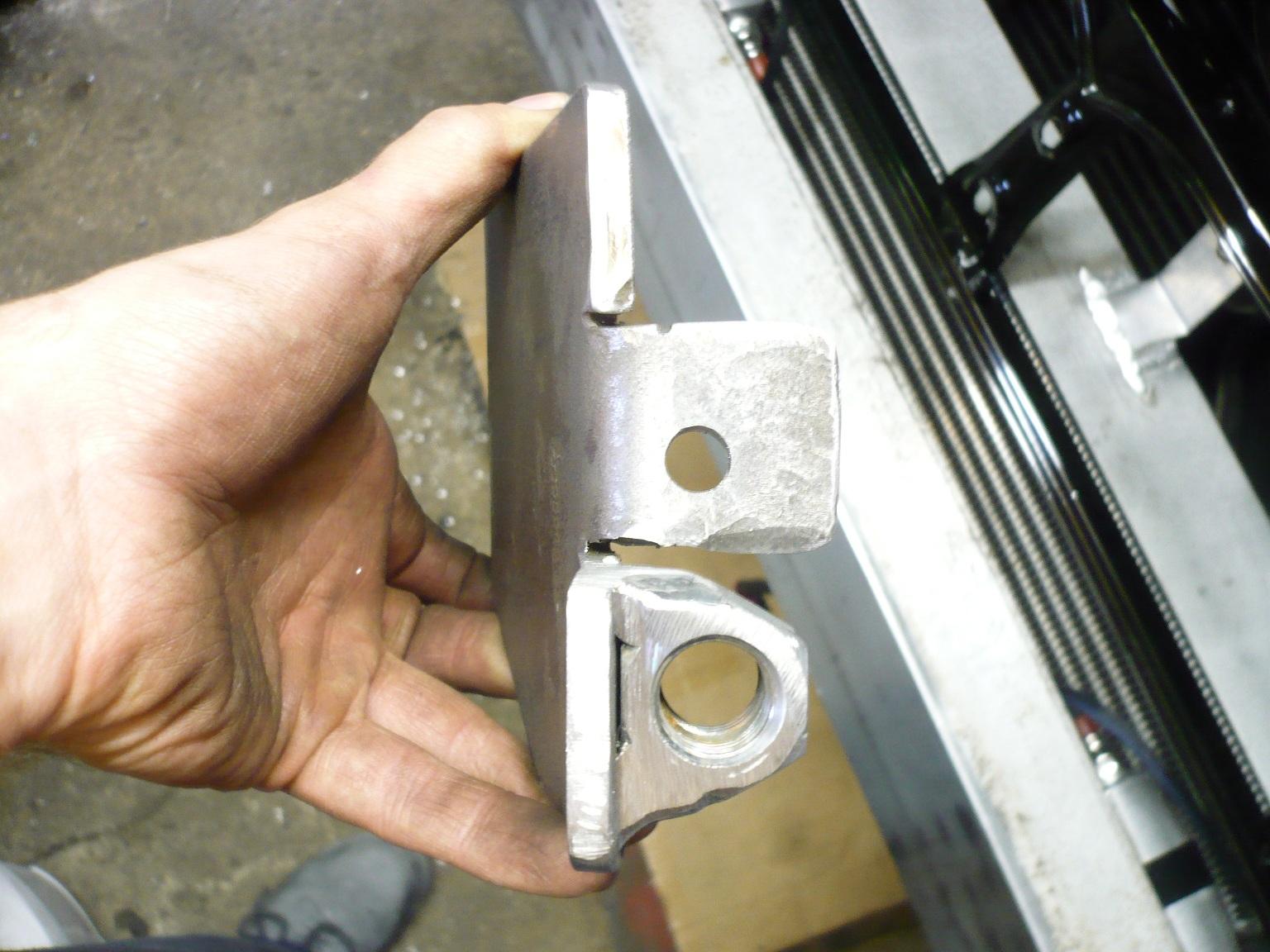

Here is the tamplates with all the measure. the little peace were I wrote "ply" would be bent at approx 80 degrees

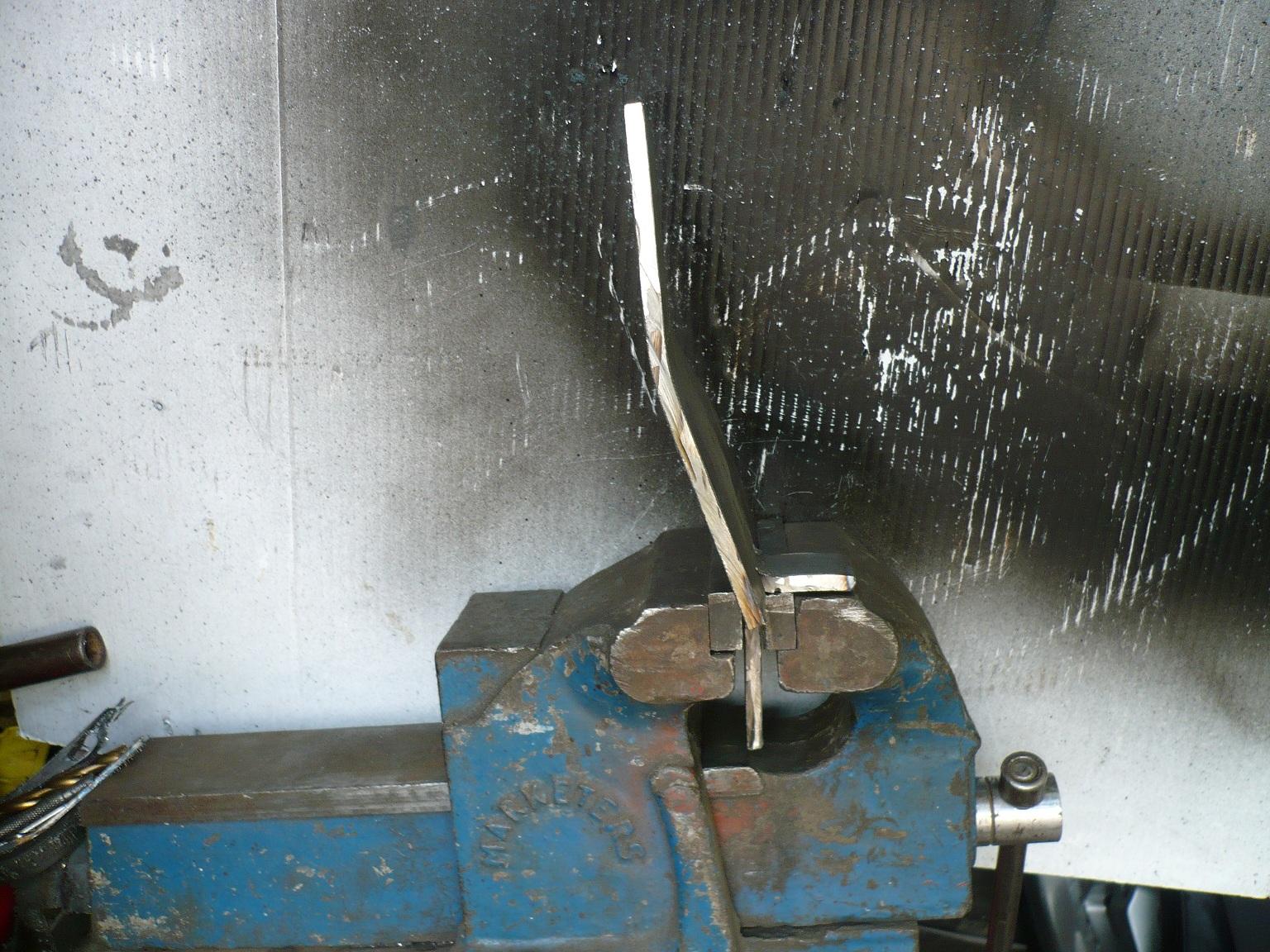

With the cutting done

On the measure plate picture you'll see two dotted line, sorry the one a the right as to go on all the width of the plate. you have to bent the plate in a shape like this

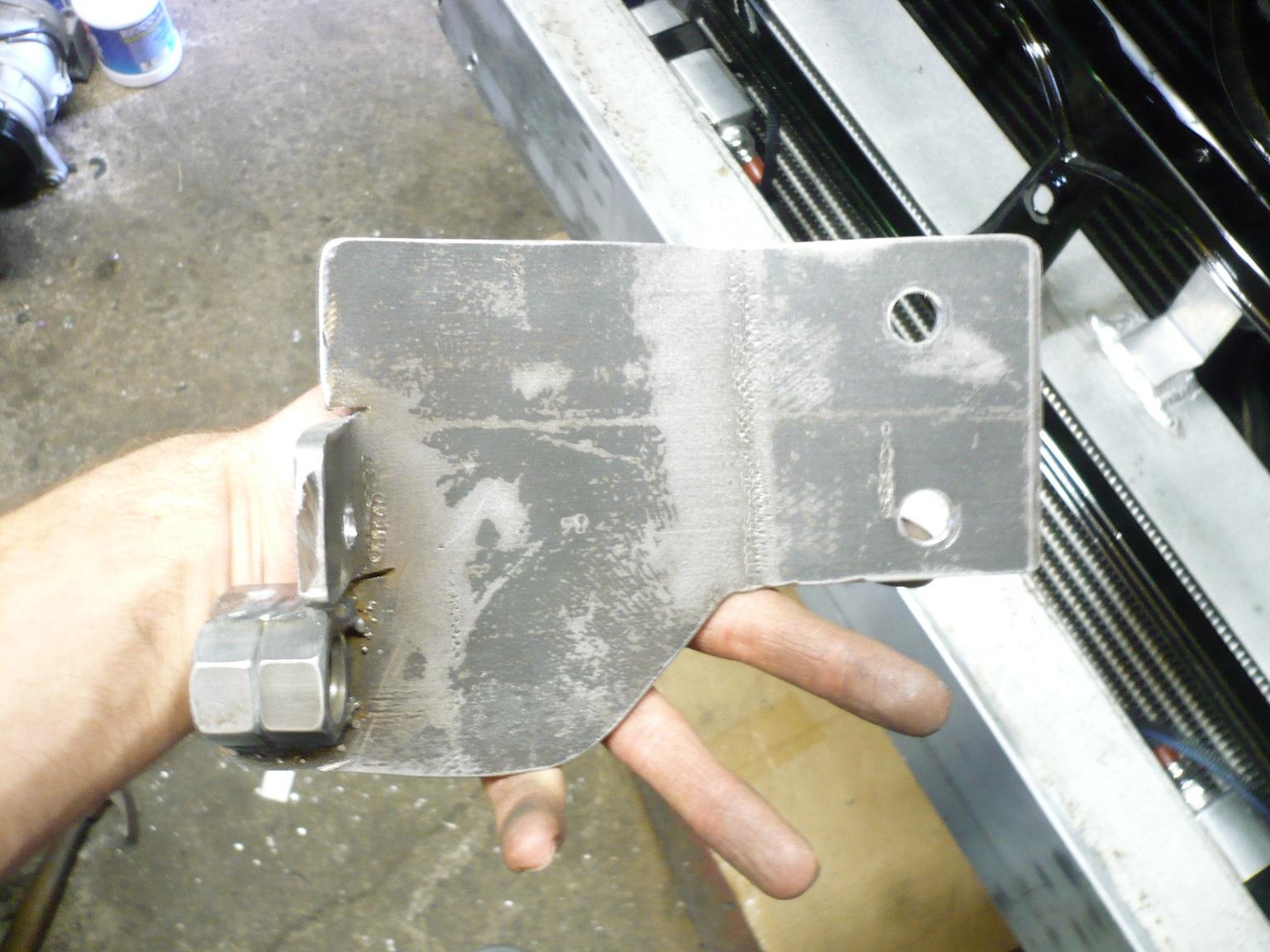

So it would follow the frame rail. You can see here the "ply" bent at 80 degrees that suit the aluminum beam for extra strengh for towing. ( I do not have bent all the plate because I would have broke my already ruin vice.

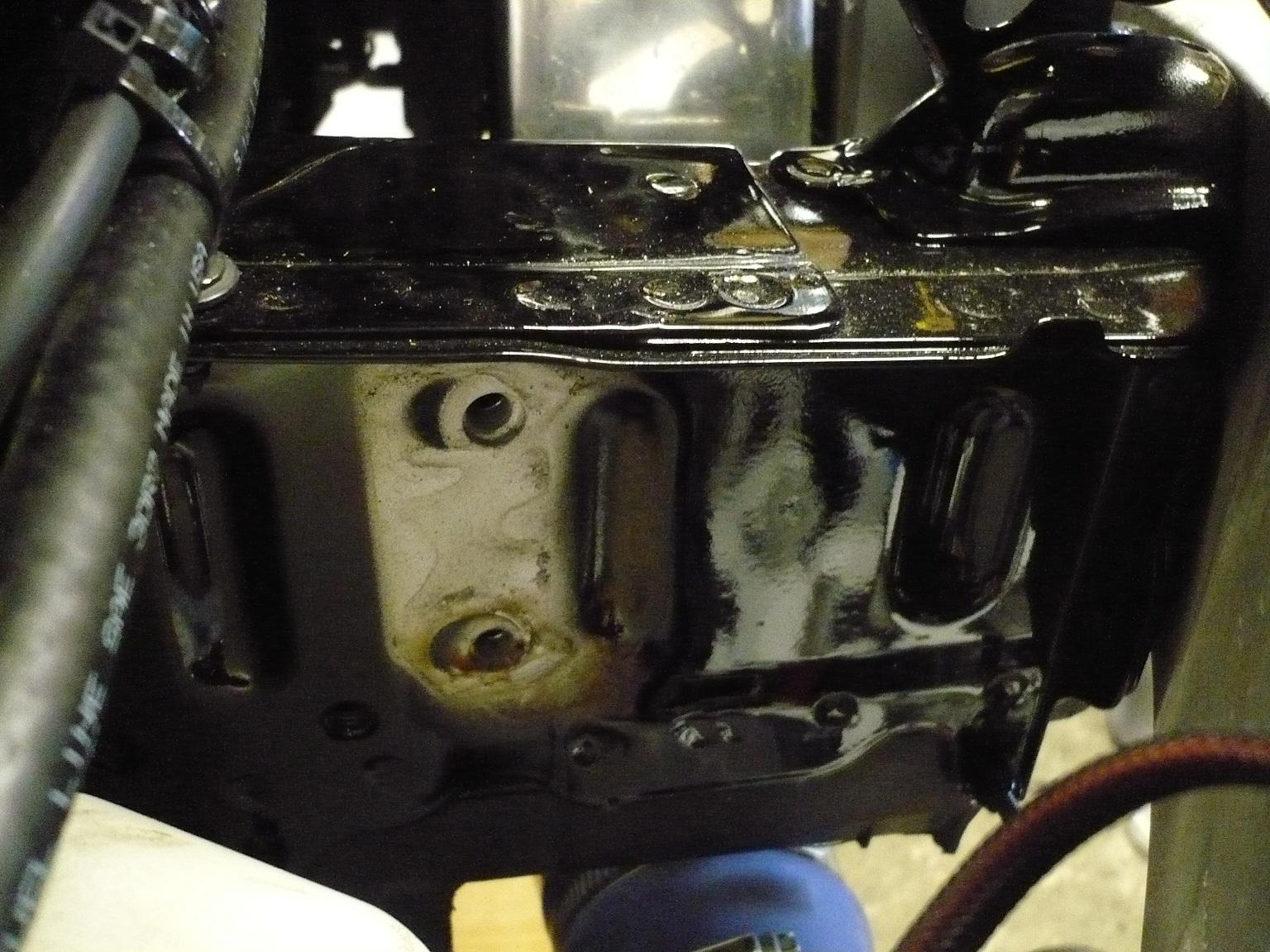

For the "where to mount this braket" remember we are on the right side of the car. Between the beam and the frame rail I have a braket. juste remove it for now, and drill a 1/2 size hole through the insert and through the frame rail.

After what you've got drill through the braket where you hole in the frame are. I suggest you do those hose after you've made your hole into the frame as doing them really perfect at 90 angle is pretty hard! So just use the drill or you pen to mark the braket through the hole in the frame for perfect (or almost) fitment! It have to be tight!! Use the 1/2 size 3and a half inches long bolt here!

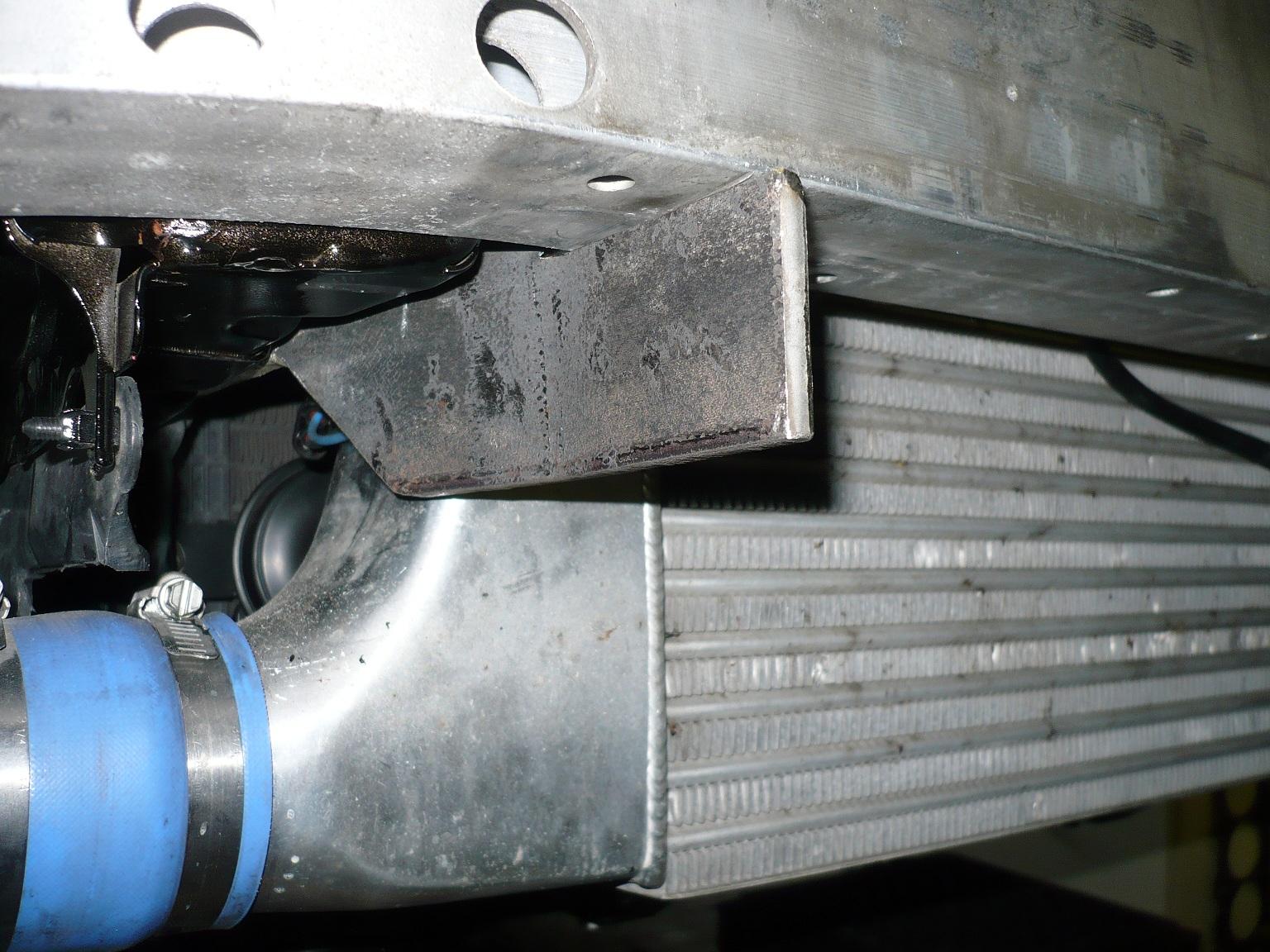

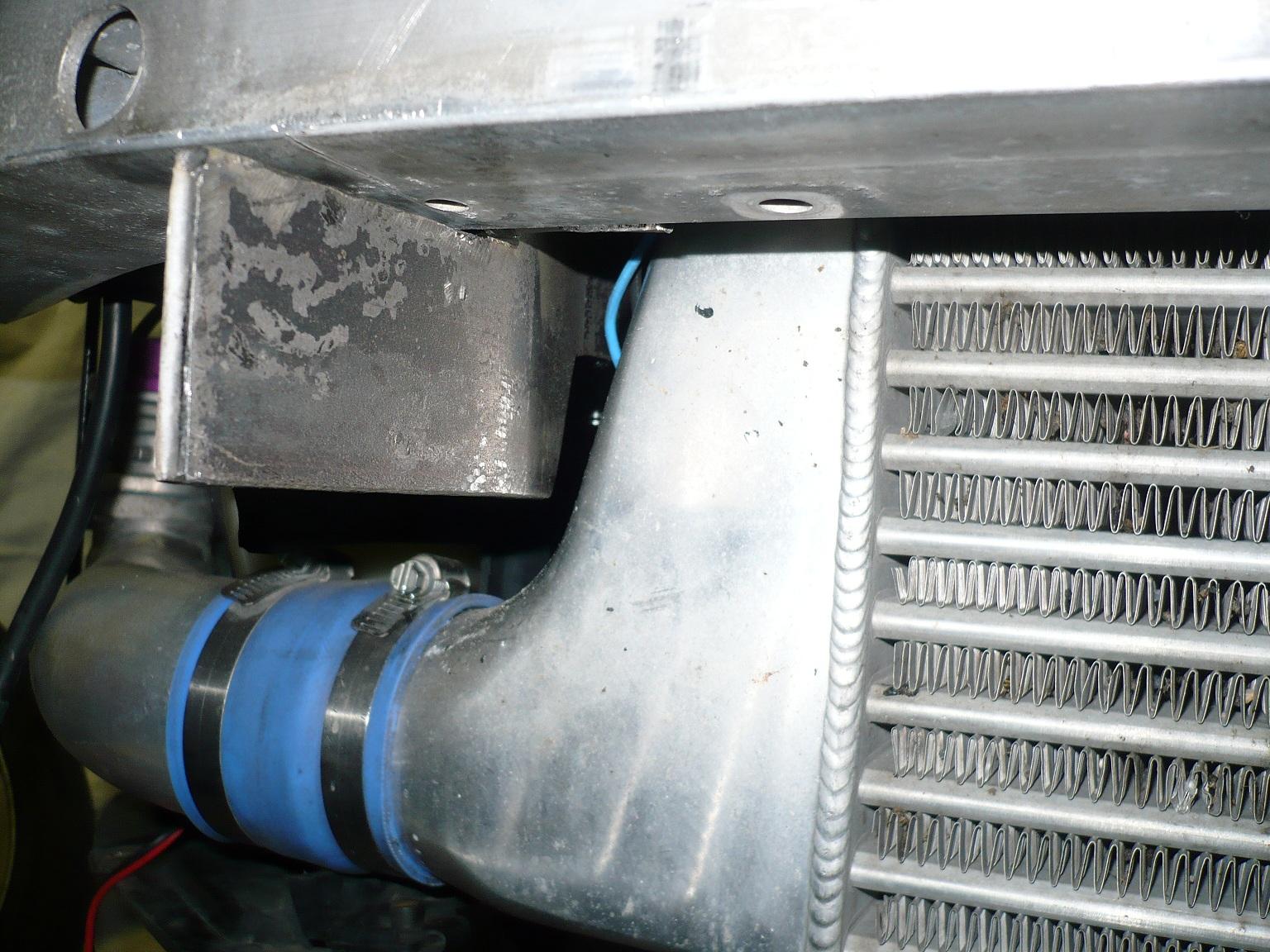

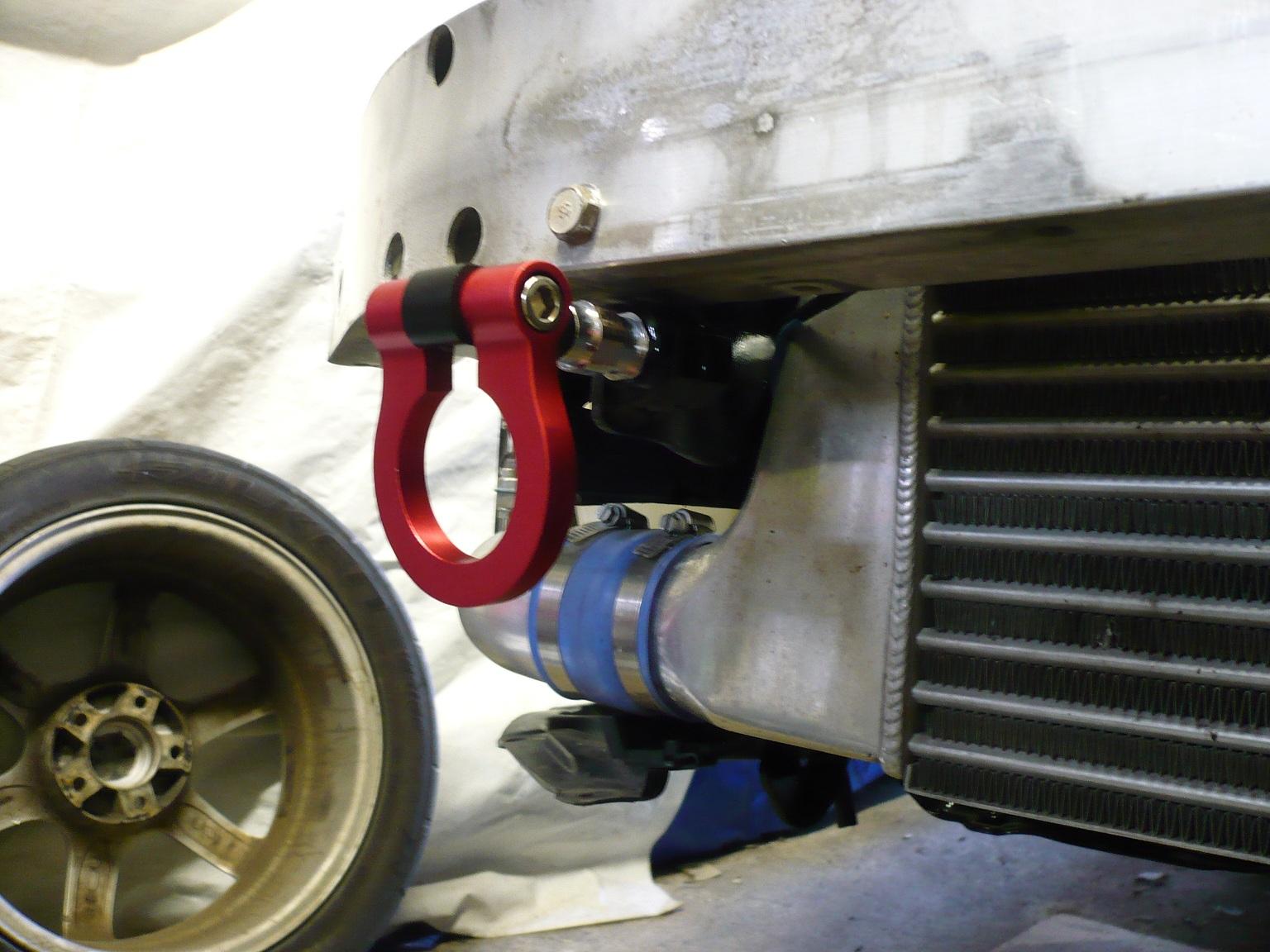

Here's the how it have to hang after. See it clean the Greddy intercooler pretty good

Now test fit the bumper, and be carefull, the braket fit tight into the grill!!! Watch for you paint!

At this moment, put the 2 nuts on the Tow hook and find where you want it, inside, near, outside, easy to remove or not etc... you have 3inch to adjust like you want.

As I want mine as close to the bumper possible, and that I don't want to remove it everytime, here where I mark my braket

Now weld it to the braket... I remove only the tow hook when I weld it but left the polish metal part that screw in in place.. I was nervous about the nuts to twist. MAKE SURE TO HAVE IT WELD ENOUGH!!

And also VERY IMPORTANT make sur you've tighten your tow hook properly with the bolt, if not, I may occur that when you will screw your two hook, it can be at an angle and not perfectly horizontal.

After what, cut the extra metal that is after you weld nuts, trim around a little with the grinder to be sure it fit inside the grill without problems, round the edge, etc. I, also, finally use the 80 degree bent end on the plate to screw it through the beam with the 3/8 size 3inches long bolt. Just mount the plate with your two 1/2 size bolt that goes through the frame rail and drill through the beam and through your plate, that's the easiest way. That will had strengh for lateral towing habilities.

So you're plate should now look like this.

Here a picture that showed the 3/8 size 3inches long bolt through the beam and the braket for extra strengh

Prep it, Paint it, mount it finally, and then screw in you're tow hook

If you welded your nuts to have the tow hook that clear the bumper for easy removal, you can do this after installing you bumper.

Finally mount!!

So the thing is, it as enough strengh to be tow, I tested it. But it's not enough strengh if you have to make a tight 90 degree turn into a parking spot or something when towed. So I'll had a 1/2 tick steel bar (longest possible) on the braket on the other side of the bolts where the tow hook mount, and solder it for it to be impossible to ben again (it move half a inch to the left but I don't want this to happened again!)

I'll update a picture of it when done!!

Enjoy!

For a great price for you tow hook, refer to ebay.