You must be logged in to rate content!

6 minute(s) of a 219 minute read

12-17-2013

Operation removable radiator support is underway!

I drew up several different ideas of how to make it happen but in a stroke of brilliance I came up with the most complicated way to do it yet! Who likes the easy way anyways.

I started by making cardboard versions of the adaptors. I made a sleeve that fit inside of the remaining radiator support pieces that are still attached to the inner fenders. It sticks out about 1" with 3 attachment points on each side. Using m6 bolts (two on top and one on the bottom) I am able to securely bolt the support in place. I then trimmed the radiator support so that it slides over the sleeves. I still have to work out the lower mounting points on the frame but that is the easy part.

Pics:

Existing radiator support pieces still attached to inner fender. AKA before!

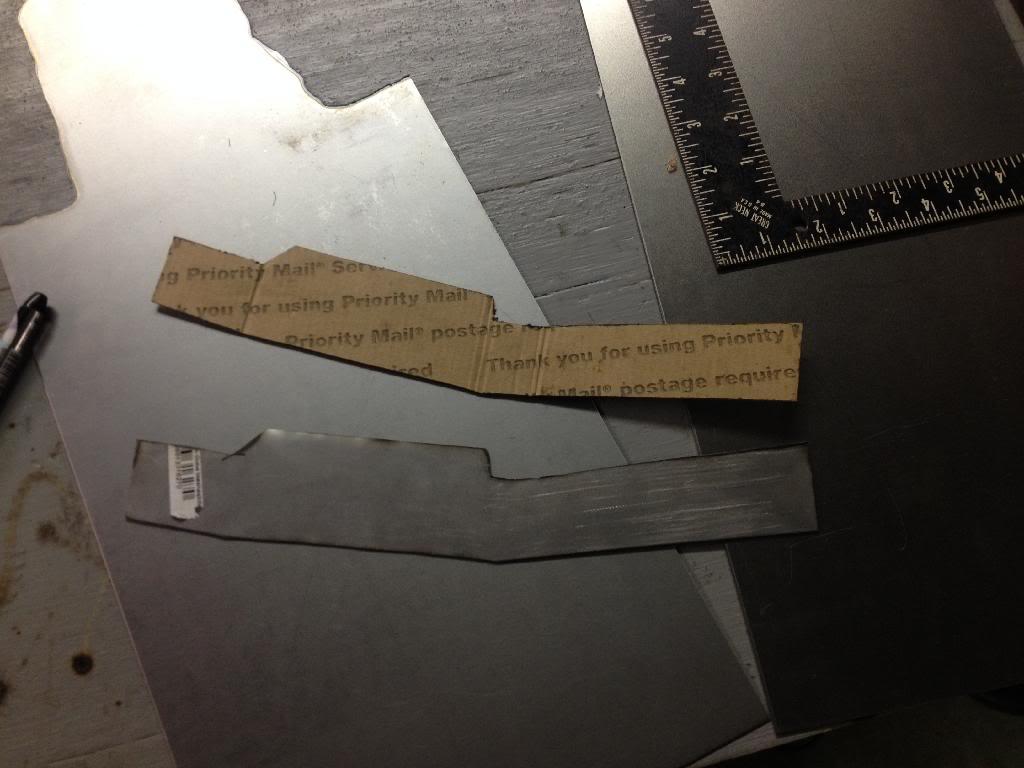

Template and metal cut out (I love love love my plasma cutter!)

Formed and nuts welded in place. Sorry I skipped a couple of steps.

In place

Welded then cleaned and primed

Trimmed radiator support

And in place bolted up. I did measurements before and after and they are the same. I also measured two other convertibles to verify my measurements.

12-18-2013

Finished up the upper mounts for the radiator support. And spent some time cleaning them up to make it look like I meant to do it.

Then I got a wild hair up my bum and figured I would join the tucked engine bay crowd.

First I eliminated all the unused wires such as ABS, AC, and the windshield washer bottle wires. Then I rewrapped the harness in ACE hardware friction tape which is extremely similar to the BWM wire wrap.

Then I proceeded to poke a hole in the inner fender after cutting out an access on the out side. I used an extra rubber grommet from the engine wiring harness to protect the wires.

I pulled the wires through the inner fender and then carefully routed them through the "tunnel" in the inner fender.

12-22-2013

So I had a slight distraction in the last couple of days. I stumbled across an e21 convertible and then an e21 dune buggy!

Then after 2 loads in the truck I had an empty bay again and some much needed patch panels for my Euro E21 323i.

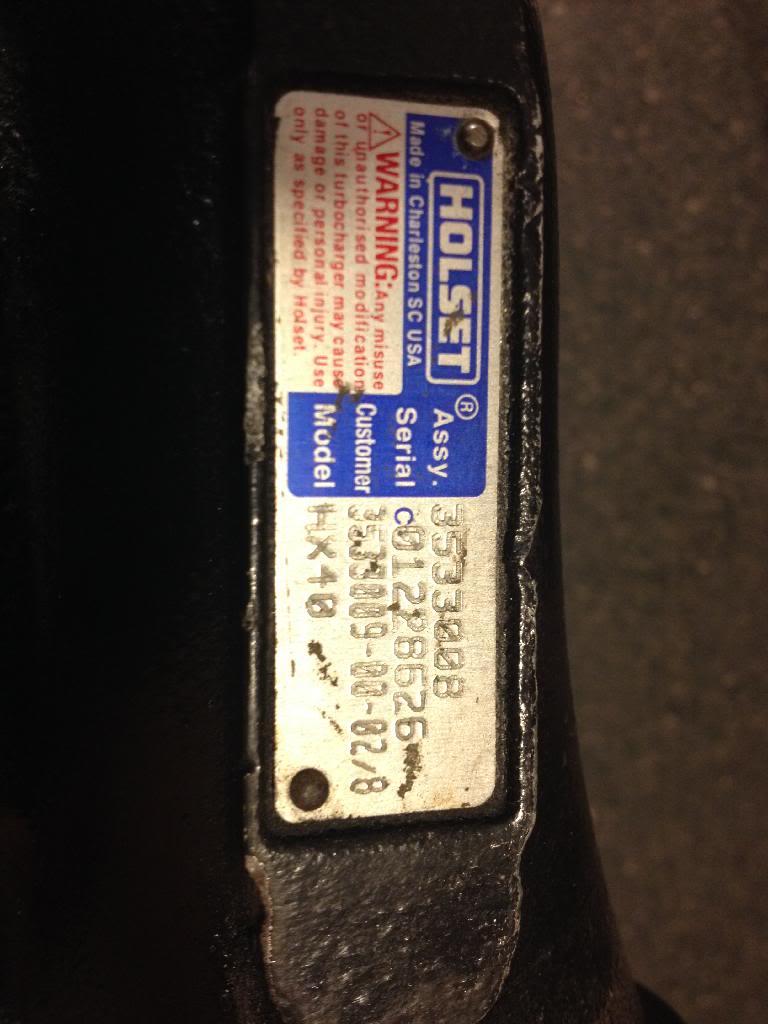

NEXT, I got a new toy today! A recently (within 200 miles) rebuilt Holset HX40 turbo!

I am going to clean it up and polish the cold side while I finish up the build and break in of the M30.

12-23-2013

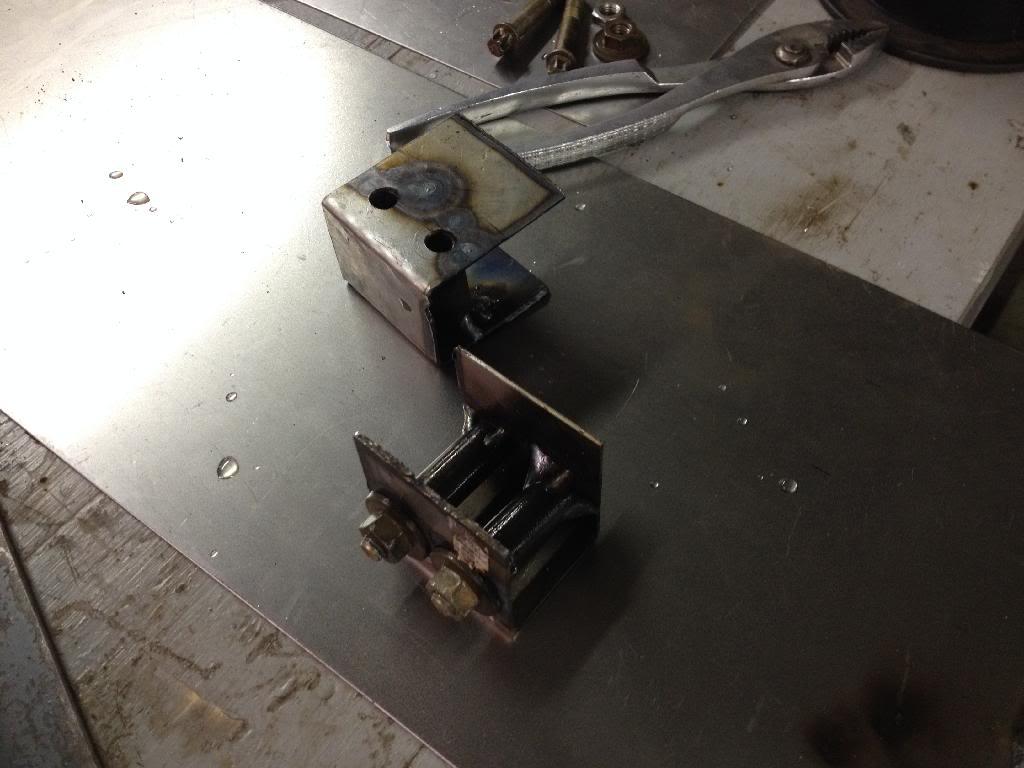

I made the hardware today for the lower mounts on the radiator support.

I cut and then bent some 16ga steel. I drilled holes and then welded in pipes to the center to provide support.

These are designed to slide tightly over the existing radiator support and be welded onto it. The bolts will secure the radiator support to a piece of angle iron that will be welded to the frame of the car. I mocked up the entire set up in the next couple of pictures. I will be welding everything into place after Christmas. Once again there are many ways to skin this cat, this is just the method I choose.

Nice!

Posted by Diggymart on 5/27/20 @ 3:41:07 PM