You must be logged in to rate content!

14 minute(s) of a 173 minute read

5-28-2006

A couple updates:

Since I've decided to go with an O2M I also put together a thread outlining what I've done...

http://forums.vwvortex.com/showthread.php?2633108

Also,

Finally, after all of this time I put my water lines on the turbo...

For anybody looking for the size/type thread...the female thread on the turbo itself is gas line thread (whatever the official term for that is I don't know) in 3/8" variety.

Since I couldn't find any gas line fittings that had a barbed end, I then had to get a 3/8" pipe thread fitting to go into that with a 3/8" barb on the other side.

Now, the 3/8" may be a bit too big (I haven't tried getting the coolant line on it yet)...if it is, I'll just throw on a 3/8" to 1/4" barb.

EDIT: I did test fit the coolant lines and they fit perfectly on the 3/8" barbed fittings.

Pic:

This is a pic of the "Danco" brand elbow item I bought:

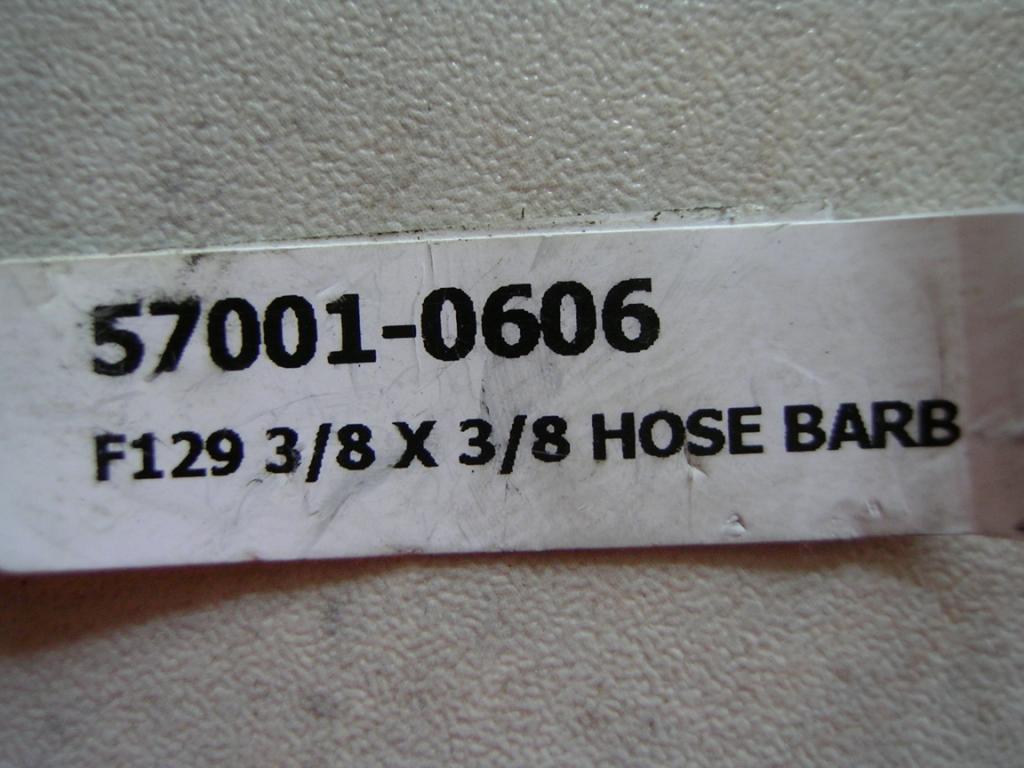

And the 3/8" thread to hose barb:

Installed:

Oh, and if I haven't mentioned it yet...you might notice a .69 turbine housing.

I'll update the thread on that after I drive it.

June 11, 2006

Update:

Car is complete (o2m swap)...

Here is the progress...

But now my clutch is slipping. Dammit.

July 06, 2006

Clutch is only slipping in 5th & 6th gears when it gets hot.

Besides that, it hooks up nicely!!!!

I'll be getting an upgraded clutch soon..and dammit I'll be pulling that ***** again.

July 13, 2006

I had schimmel install the diff when he rebuilt the tranny so I'm still not sure what happened.

On the bigger turbine housing...yea, I've already gone to a .69 from a .58 - but my boost is still moderate (at only 8.5psi).

When I turn up the boost I'll be going up to something like a .89 (if one exists) or .91...whatever the closest "existing" housing is.

B/c I definitely don't want to break the new trans .

September 17, 2006

Update:

Moral of the story (to save the read) is get the turbine/DP wraps and protect the car from heat!

Yea, bad pics...I actually repaired much of the harness in the center...re-wrapped it with high heat electrical tape then used some foil tape...Ghetto but very useful. Has saved my coolant hoses as well.

But those two pics show the actual harness. This doesn't go into the windage tray until it is at the pass side. Then it goes into the ECU.

What happened is this:

Turbo heat finally broke down the wiring harness (my bone-head didn't even think that would be a problem). It literally passes right over the turbo.

I had the onset of a small electrical fire after seeing some weird electrical problems (mostly related to my abs).

When I pulled over I saw melting wires and smoke coming from the pass side wire harness there just before it goes into the compartment where the ECU is.

Apparently, some wires melted into each other under the extreme heat over time, then the coating melted off....causing some wires to make contact with each other...which caused this to occur.

It's a real mess, my abs still isn't working b/c as I'm tracing back how far in the harness the burnt wires went, I can't get that far. Looks like I may have to pull the dash and most of the harness. I can't even see the bad wire b/c the coating melted completely off so I don't even know what wire it is (using color-coding from the wiring schematics).

So, as I said at the beginning. Don't go cheap when turbo'ing your car. Make sure you get those heat wrap thingamajiggies.

December 03, 2006

Update...

New wiring harness is installed and car is running perfectly.

Now I'm just going to finish up some little things that I've been needing to do over the past few months anyway.

Car is up on 4 jackstands in my garage for the winter....

Going to install my 13lb wastegate spring, in-line Walbro, and fix some other misc cosmetic things and get her ready for spring .

See you guys out there in the next few months!

December 04, 2006

Oh, I forgot to add that I have installed my turbo wrap, downpipe wrap (inferno wrap good to 2000degrees constant and 3000 deg spikes) and am still awaiting my other DEI turbo insulation kit that I will use to wrap my Exh Manny.

I'll snap pictures to add to this thead later. I'm thinking of relocating my ambient air temp guage (in MFA) to read under-hood temps...

I think that would be cool since I never care how hot/cold it is outside.

February 20, 2007

Here's my update:

Walbro was installed Jan '07...Ran a little light into the dash that tells me that the pump is running. Not loud at all.

Installed all of my heat shielding material (turbo wrap, downpipe wrap, exhaust manifold wrap) and man does this turbo spool!!!!

I upgraded from .58 to .69 and now I feel like I'm back at .58 with the top-end of the .69....

It's always in boost now. I start building boost at just over 2k (ie. 6th gear at 2k rpms if I mash it I start building boost). It's mad.

Trust me, if anybody is on the fence about this you're making a mistake.

I'm not sure exactly what the temp difference is under the hood but it's very noticeable.

New engine wiring harness was installed and everything checked out. Been driving the car for a good month so far with no problems.

Here's me talking about how well the thing drives with Jeff's updated chip.

February 23, 2007

Did I forget to add in this thread that I removed my AC? If I did, I'm sorry...

So, the connection at the firewall is now gone. I had to hammer it to the side when I installed the turbo but when I went to charge it I had a very small leak there and couldn't hold pressure.

At that point I just yanked everything out - and I guess I may have forgotten to update this thread on that 'small' detail .

Yes, long thread with lots of frustrations...but I'd do it again! I love this car.

December 31, 2007

Just a little update:

So I guess I blew out a seal (or seals) in the turbo. Since I got my Passat I've been beating on the VR a lot lately. I'm not sure why, but I think it's b/c the Passat gives me my "dub-fix" - so before I had it I would baby it a bit for fear of breaking it. Just a guess.

Either way,

I've been having fun with it and this afternoon I started it up and warmed it a bit to take her out and sure enough I'm burning oil. I can actually see the oil trying to come out of the housing somewhere. No, not a leak anywhere around the turbo...it's blowing out the exhaust as well as smoking at the turbine housing.

So, I guess a new T04e w/o water cooling will only last so long.

Time for an upgrade.

PM me Paul.

Let's talk.

EDIT:

I'm also thinking that I might have just made a mess in my turbo since I was idling the car for about 45 mins (don't ask....if you have kids you know how time can get the best of you ).

So, now I'm thinking it might just be a case of soaked seals (happened once before, smoked like a chimney).

I knew I should have put a restrictor in for times like this.

So, only time will tell. The car is going under the knife again soon anyway (new clutch, LSD for 02m, etc).

EDIT:

Not blown seals. Everything is fine. I just need a restrictor on the turbo oil feed.

When idling it likes to back up.

December 30, 2009

Sorry....

Update is that there is no update. Haven't driven the car in over a year.

Lost the time to get some "maintenance" done. I pulled the front end off last year to re-do the intercooler piping then ran into a brick wall (figuratively of course).

July 05, 2010

Bump (for a couple reasons):

1) Got the pics working again

2) Getting the car back together after 2 years of sitting in the garage!

C2 Drivers side (TB) short runner, re-vamped (obviously) Turbo piping, Euro Rad Support.

So, on the Euro Rad Support with C2motorsports DRIVERS SIDE short-runner....seems it's VERY close to the euro rad support.

Anybody use this (drivers side short runner) with the euro rad support?

October 31, 2011

Well,

I've installed the rad support, re-routed my coolant lines, did some very small cleaning up under the hood, etc...

Car runs bug having some issues with a couple wires broken somewhere. Still not driving daily yet. Getting there. No recent dyno runs. 6speed still excellent.

December 28, 2011

So...

Tidying some things up under the hood (more than posted about earlier). I had an exhaust leak so I removed my turbo to put a new mounting gasket in. Turns out the turbo has the *slightest* amount of shaft play. This put my "project" (if you can call it that) into a different direction.

My re-route has never been ideal..when the re-route was welded it warped the metal a bit. It was doable but never an easy task to put new gaskets in (wastegate and wastegate flange to reroute) so I've decided to go with ATP's "new" (been out a couple years) downpipe v.2 which has the re-route already built in. You need the 44mm wastegate (ka-ching $) but it's got the v-band setup. So, saying bye bye to the lame old-school bolts and BS and finally upgrading. So, why get the turbo rebuilt when I'll have to get a v-band/tangential exhaust setup (needed for new downpipe)?

What's on order:

and:

And from Killa (again!):

And then (finally) time to turn up boost to about 15.

Since this thread has gone on for years I felt the need to update you guys on everything. I'll probably rebuild the turbo and sell it (unless somebody wants it for cheap to rebuild yourself).

December 30, 2011

Well, as you know those aren't my actual pics but the ATP stuff showed up yesterday and just ordered the turbo from Killa today.

January 10, 2012

It's here.

Doing work tomorrow.

44mm tial WG and new vband turbo downpipe going on soon. Old stuff coming out.

June 07, 2012

The new v-band setup is all installed. New vband t04e turbo, 44mm Tial Wastegate, new atp 3" vband downpipe. This is an ATP downpipe with Tial WG with built in re-route. Hell Yea!

Turned boost up to 15psi.

November 17, 2012

On to a fab shop locally for custom intercooler piping on Tuesday.

It's getting close to getting back on the road.

November 20, 2012

On her way!

February 11, 2013

Custom intercooler piping almost done. Ill let the pics speak for themselves. Sorry, iPhone pics only at this time...

Moved power steering reservoir:

Blow off valve re-route:

February 13, 2013

Ok,

So hoping to get this thread/discussion going again like it was back when I started it years ago...

Couple questions for you guys...

My next purchase is going to be a boost controller and wideband.

After all of these years I only have a boost gauge. No controller or wideband. But I'm looking to turn things up this time, my wastegate springs are set to 16psi right now. The car isn't running again yet but will be soon.

Obviously I'm looking to get a controller that has no spikes at all and is easy to use.

In a wideband I'm looking for something rather simple yet accurate. With a pod-style display. No boxes or anything big like that. I'm not tuning or racing with it...

Anybody have any ideas? I've got my eyes on the aem wideband and profecB boost controllers (thanks Jeff Atwood) .

And a pic as it sits now:

March 07, 2013

Guys,

Help requested with some heat protection. Seems my turbo oil outlet (that goes to oil pan) braided line now interferes slightly with my new ATP downpipe. It touches the flex section but only slightly.

I see a lot of heat protection sleeves at summit racing but unsure what is the right stuff to get. With exhaust temps getting extremely hot I'm unsure what will be a good form of protection. Most of them protect against radiant heat but I'm more worried about conductive heat.

Since this is a braided line I'm worried it'll get extremely hot under certain conditions.

Any ideas guys?

You need to reroute that line pronto. A heat sleeve is not meant to contain contact heat, only radiated. Build a new line, and if it's sufficiently far enough (i'd say about 6-8" sideways) no sleeve necessary, if it is braided, most is good for 300-500f radiant heat.

March 20, 2013

Well, what I have is the atp straight 18" oil return "kit". 10 AN straight fittings and 18" braided line.

What I just ordered was:

Custom ATP drain line (-10 braided line 20" long with 2 90 degree bends at each end)

1/2" NPT (45 degree) to -10 AN (2 in case I need them)

I'm not sure exactly what ill need until I get them. I will keep you guys posted.

45 degree fittings.

September 09, 2013

No big updates here...Been busy trying to get my B6 running (which I did, Thank God). Anyway, the biggest problem (besides motivation) has been this damned oil drain line. With the new setup it was contacting the downpipe, and as we discussed that's a big problem.

So, as stated in my last post I ordered a new custom line from ATP (they never fail for me, always have what I need and ship it quick). When I tried running the line it just didn't work correctly. This line is still quite rigid and just didn't fit correctly with the existing fitting in the oil pan.

You'll see in this picture that I need to move the fitting from where it's at to where my index finger is.

Re-install oil pan, put car back together and I should have a running car (I hope). Oh man, it's been years. Crazy.