You must be logged in to rate content!

8 minute(s) of a 278 minute read

12-7-2009

Motor and Trans are one.

Started on the wiring too. I acquired a brand new AWP harness with my orig trade/swap and this harness is about 80% of what I need for megasquirt, so I don't have to build from scratch. I felt kind of dirt though cutting off the factory ECu plugs-

The factory convoluted tubing and connectors are not my favorite, but since I am using a lot of the harness in tact, I am fine with it.

Here is a sample of one of the plugs that needed to be changed. Since the pin sizes were different for the 2 coolant plugs, I could not just repin to the new housing.

Shiny stuff

December 14, 2009

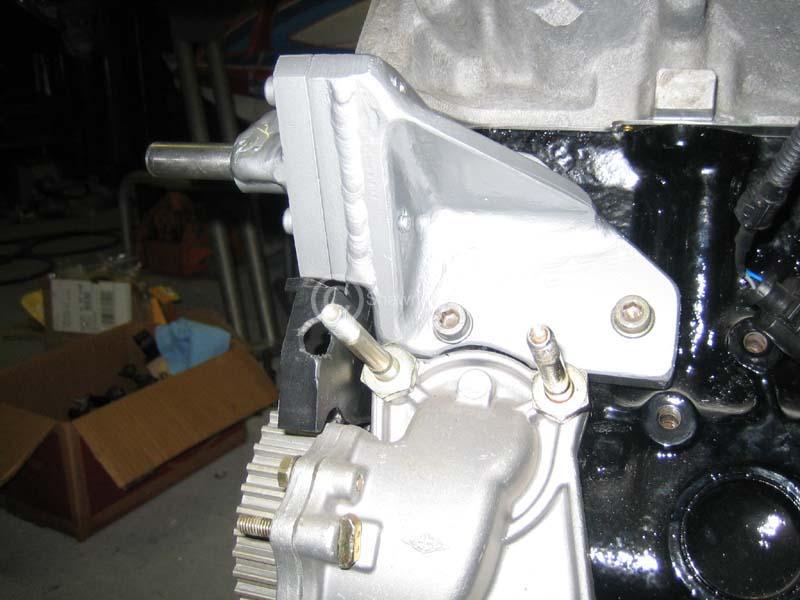

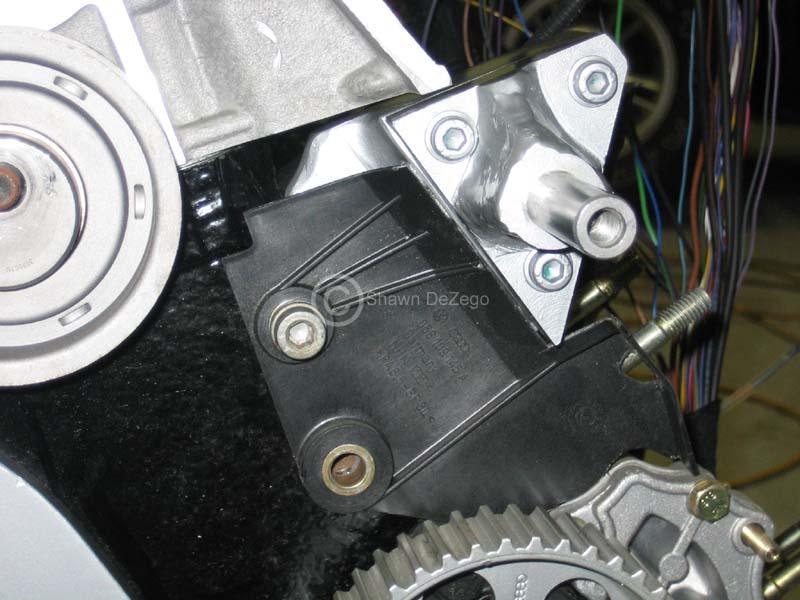

Some pics showing a lot of the custom brackerty I made. Most of which will be completely hidden so I am not sure why I spent so much time prepping and painting (outside of the rear alt mount setup).

Custom front support for custom Mk4 PS brkt to run all on serpentine belt

Custom Rear mount Mk4 Alt support

Custom brkt for using G60 Serp tensioner arm in my single belt setup

Front view of above

Side view of PS mount

Also, The crank bolt was never installed yet as I was trying to decide whether to use the 6pt or 12 pt 16v crank bolt. After researching and acquiring both, the 6pt is actually 10.9 grade and the 12 pt is 8.8.

Anyone who knows the 058 block/crank knows the bolt is always a problem and especially so on the G60, which is the reason for my over obsession. There is a bit more at stake here than on the non-interference 8v.

Anyway, after searching, I just found what I think may be an ARP solution from a completely different application. Even though my cog is pinned (earlier in this thread), extra insurance is never a bad thing. ...granted a $35 extra insurance

I will post up the details when the ARP hardware arrives in the next 7-10 days.

January 07, 2010

Crank Bolt Dilemma solved:

We all know the 058 block/crank bolt fails, so In my over-obsession I was searching on the best bolt to use for this motor, since there is a lot at stake.

You may know that VW used two different bolts over the years on 16v's (possibly 3 if you look in the Bentley, but I will ignore since I have no info on the 3rd other than torque specs). There was a 6pt bolt which was 46mm in length and used a 7mm thick washer, and the later 12 pt bolt which was 39mm and used no washer.

I bought them both from VW and here are some facts:

- Thread and pitch are 14mm x 1.5

- The 6pt is 10.9 grade @ 46mm

- The 12 pt is 8.8 grade @ 39mm

- 8vs are 10.9 FYI and shorter of course @ 33mm

- Diesels and 06a blocks use a larger diameter bolt (16mm and ARP now makes a solution).

Note: (46mm 6pt bolt - 7mm washer = 39mm 12pt)

Here are the tq specs:

So, I started searching high and low for a hardened Stud and aircraft style nut, but was hard at finding what I wanted. I started looking through ARP's catalog to cross reference something and much to my surprise, I found two ARP possibilities.

1.) Mitsu - 2L (4G63) - 14mx1.5 x 1.525" (38.7mm) - ARP#207-2501

2.) Ford Duratec (1.8 & 2L) - - 14mx1.5 x 1.735" (44.1mm) - ARP#251-2501

They both come with a hardened 1/4" (6.35mm) washer which we would not use in either case because it is too large in diam.

So, I ordered #2 becuase it is longer (much like the PL bolt and I figured I could use some std hardened washer to take up some of the length and still end up with more thread bite in the crank. Note: The 6pt 46mm factory bolt is just about 1-2mm too long w/o using the 7mm washer and just starts to bottom out in the ABA crank as it makes contact, but could vary from crank to crank.

So, you can see that #2 above looks like it is a pretty darn good match when using the washer (and poss #1 if w/o the washer if the shoulder is large enough).

--------------------------->

I received the bolt and here are the deets.

Perfect length, perfect thread, but the head was unfortunately too big. Now, this could still be used as is, but you would have no way of getting the harmonic balancer on/off (not too good). So, I went up to the shop and threw it up on the lathe to trim the bolt head down a tad so that it fits through the Balancer hole.

Looks like it is now a winner. You can either use the thick stock 6 sided 16v washer with it, or get a thinner 14mm one from the hardware store which is what I did. This will actually give more threads to the crank which was no prob for my ABA crank.

Pics:

in comparison to the stock PL 6 sided bolts that uses the thick washer

Head a tad too big

Shaved a tad down on the lathe

Did someone say OCD?

Also, for reference:

ARP bolts are 200,000 PSI bolts which puts them at a 12.9 hardness and is impossible to find our size bolt in that spec. I wasn't even able to source a 10.9 bolt outside of the factory VW in a few hours of searching.

Also, if you are the engineering type and care to compare bolt strengths, here you go:

http://www.boltdepot.com/fastener-in...ade-Chart.aspx

Couple of fairly recent pics of some stuff I am working on.

- Making a timing belt cover to account for the tall ABA block (not finished in the pics) out of a few AEB ones.

- Starting to organize the harness

- Started making the custom coolant hard pipes

- Bolting some more stuff on for good

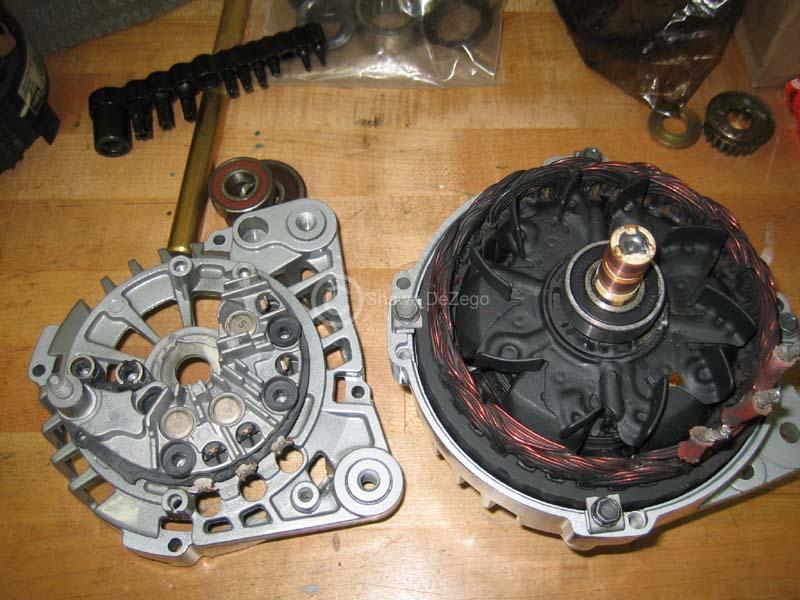

Also, rebuilt my 1.8t 120 Amp Alt. No finished pic, but it is done.