You must be logged in to rate content!

14 minute(s) of a 297 minute read

7-28-2014

I think it's time to go bigger. My stock location GTX3071 hybrid is now up for sale.

http://forums.nasioc.com/forums/show....php?t=2651944

7-29-2014

Turbo is sold, out of the car, and boxed up (original box with foam).

7-30-2014

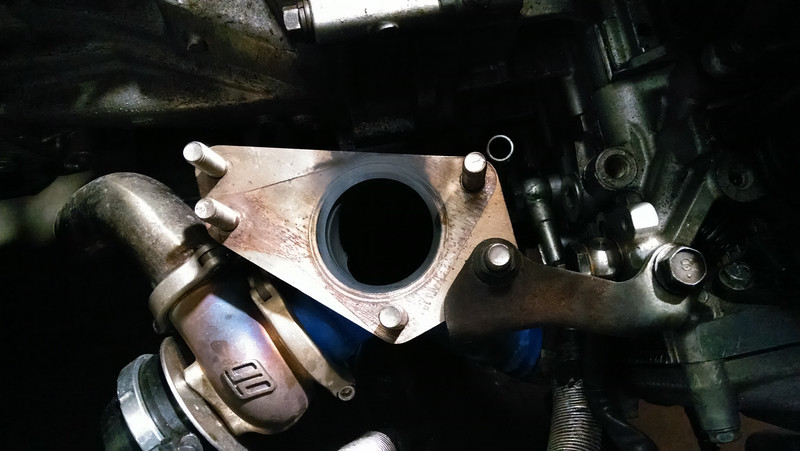

It appears I had a bit of an uppipe to turbo leak. That could explain the late-ish spool.

8-4-2014

Camera phone pics:

8-5-2014

Update:

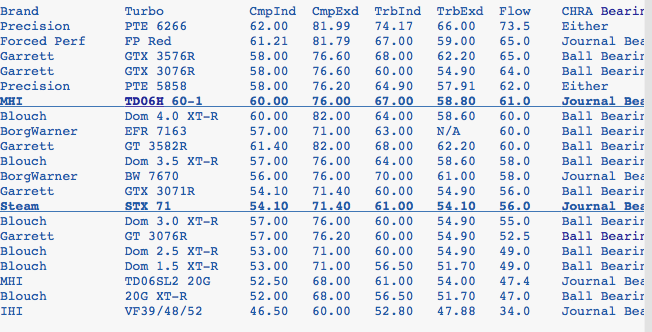

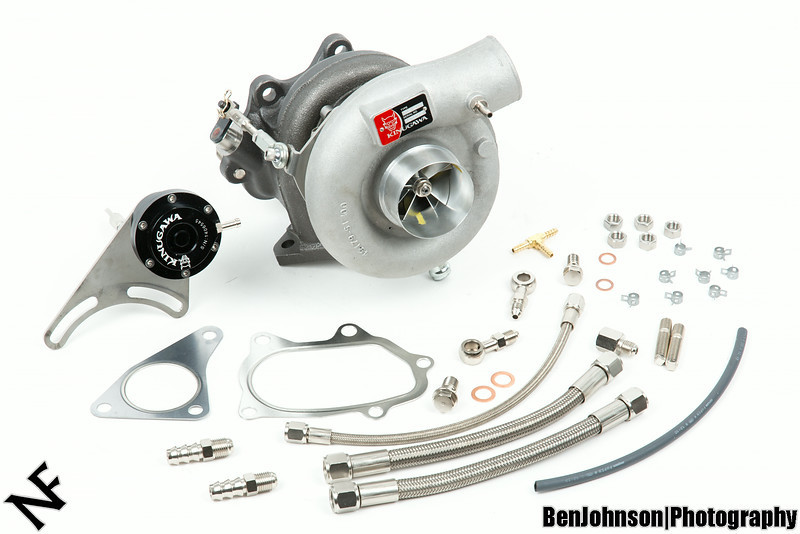

- The new turbo I put on the car is the Kinugawa TD06H 60-1 with Billet wheel. Thanks to Nuke at NF Performance for the hook up on the turbo! This turbo is a 60mm compressor, which is the largest size that can fit in the stock sized inlet (for easier install).

- This compressor is 6mm larger than the STX 71 turbo (that I previously had). The TD06H hotside is also quite a bit bigger (than the TD06SL2 that the last turbo had). This turbo is somewhat comparable in size to a GT 35R, FP Red, PTE 5858, DOM4 XTR, etc.

Here is it compared to some other turbo's commonly used on Subaru's:

Here are some photos of the turbo prior to install (it is a little dirty because I had been handling it and doing test fittings to make sure I got all the fittings and lines set up properly).

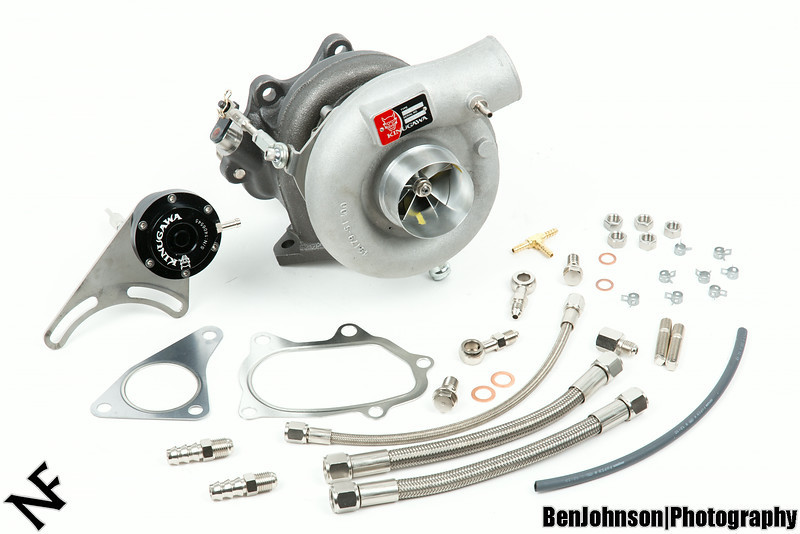

Here's the stock photo. The turbo really does come with everything you see.

Here's the photo of mine. At this point I had:

- Removed the Kinugawa billet wastegate actuator.

- Installed the GrimmSpeed wastegate block off arm.

- Installed the oil drain fitting and gasket.

- Installed both coolant banjo fittings.

- All other included parts can be seen in the photo.

The included oil line is very nice. It looks just like the FP kit I have on the car.

Also included are braided SS coolant lines (terminated with a barb fitting).

The turbo comes with a nice billet wastegate actuator. I'm not using it due to my EWG setup.

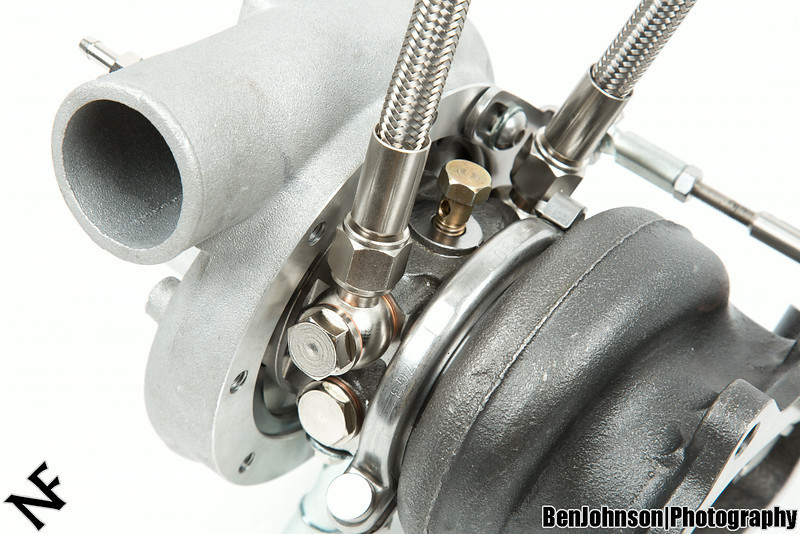

Front. Note the very thin inlet due to the 60mm compressor wheel just barely fitting in a 2.4" inlet.

Rear. 8cm hotside.

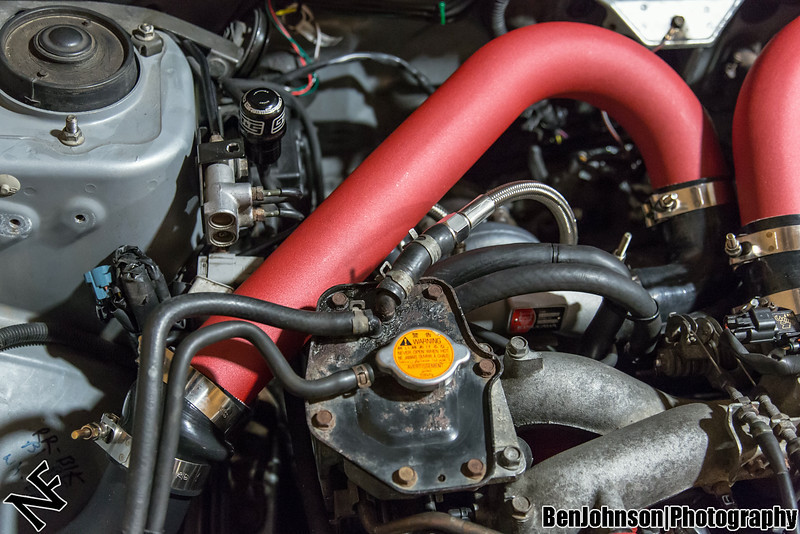

Coolant lines on the top ports. There is not enough room to use the bottom port (like the OEM fitting).

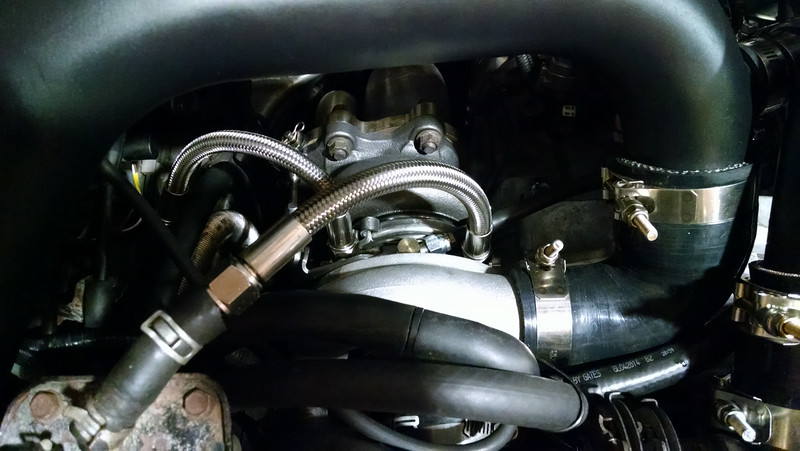

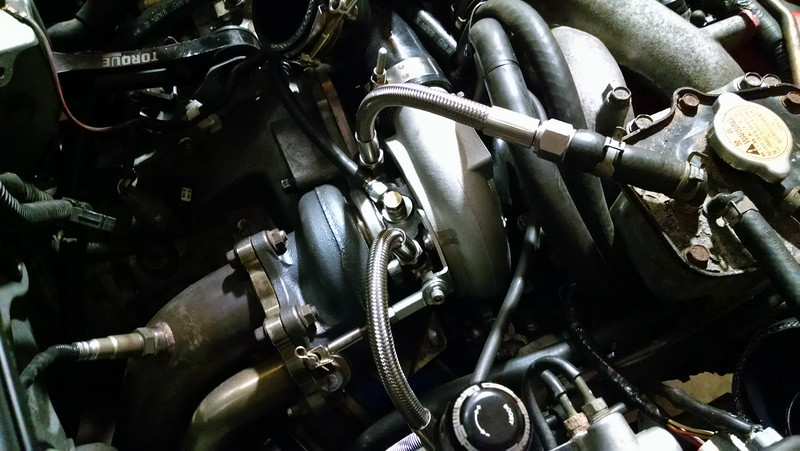

Install:

- Overall it went pretty smoothly. The turbo fits pretty well for jamming something similar to a 35R into a stock location setup. The braided coolant lines work out nicely the way I set them up. Everything bolts up without much of an issue.

- I did have to run the oil feed under the inlet and around to the other side of the turbo so the line could squeeze between the turbine housing and the coolant banjo fitting. There wasn't enough room on the passenger side.

- I got it all done last night, primed the turbo, and fired it up. I ran it for a long time (30-40min) with a funnel in the coolent reservoir trying to burp the air out of the cooling system, but the bubbles just kept coming.

- Eventually I shut the car off and then could hear a leak from the CHRA area. It was losing coolant. Not a lot, but enough so it wasn't usable. I couldn't pinpoint the exact location. The coolant line banjo fittings seemed tight.

- Today after work I took off the FMIC pipe, the oil feed line, and the coolant feed line/banjo. This allowed me to access the plug in the lower cooling ports in the CHRA. The one on the driver side was completely loose!

- I tightened that down and put everything else back together. Fired it up and burped the air out within maybe 15 min. The fans only had to kick on a couple times and then the bubbles stopped.

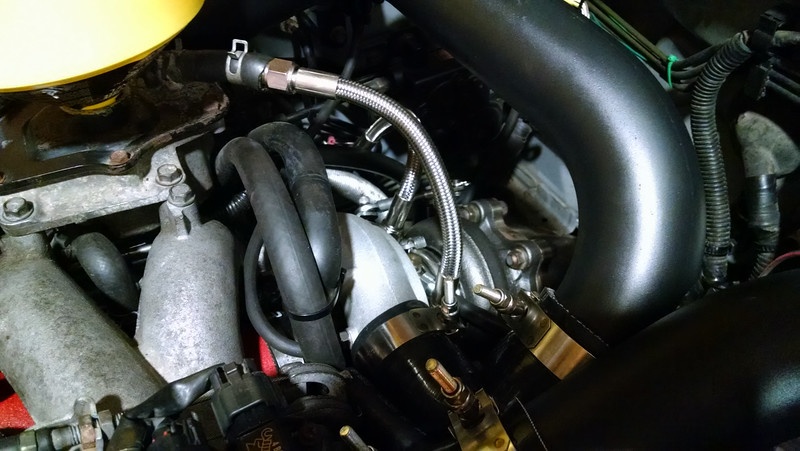

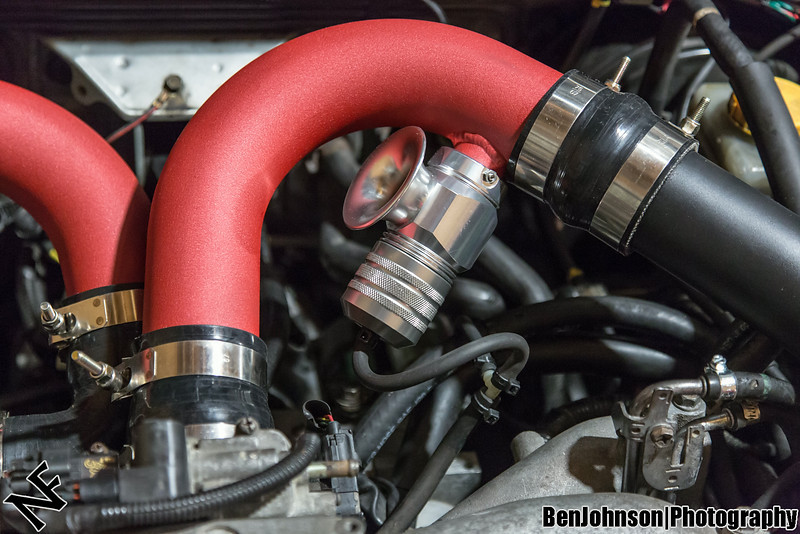

Here's a photo showing how the coolant lines are run.

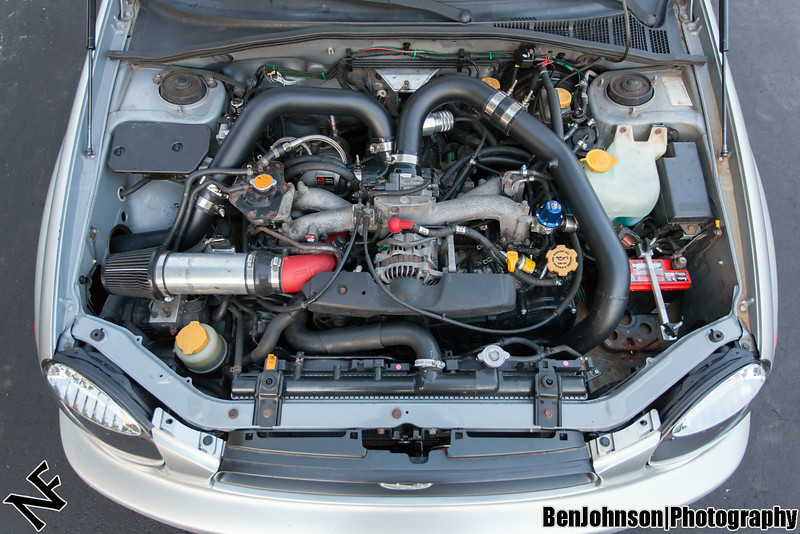

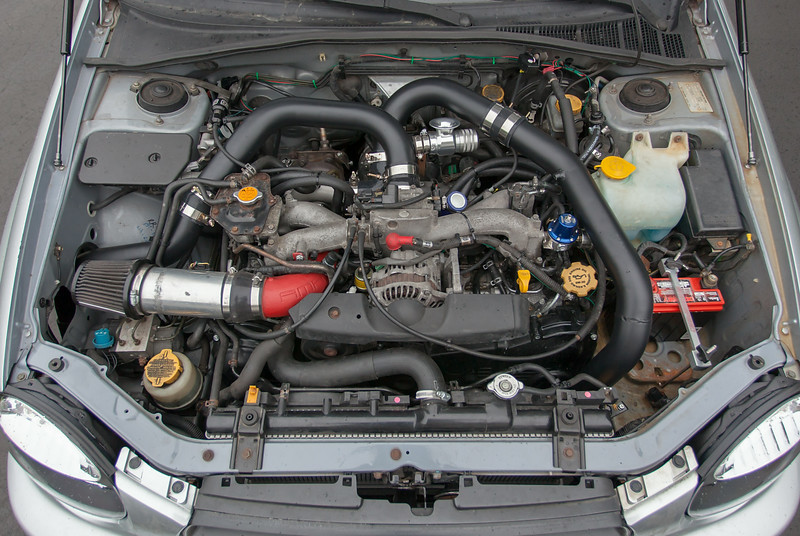

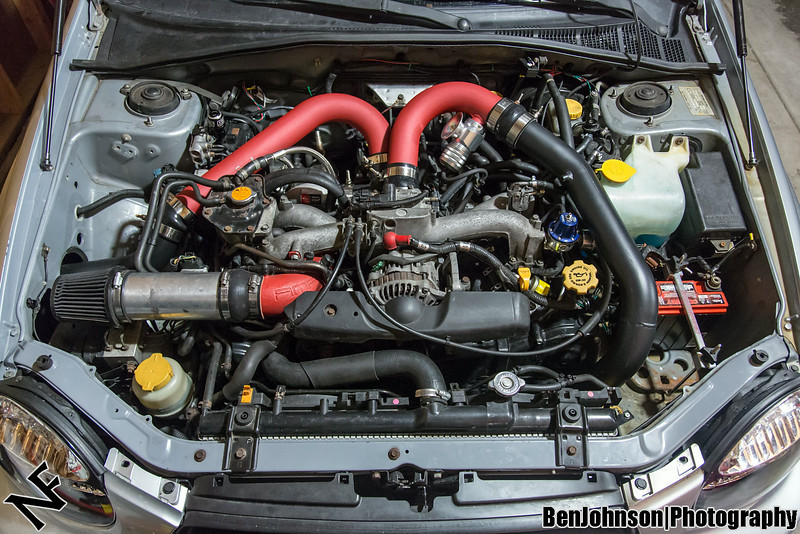

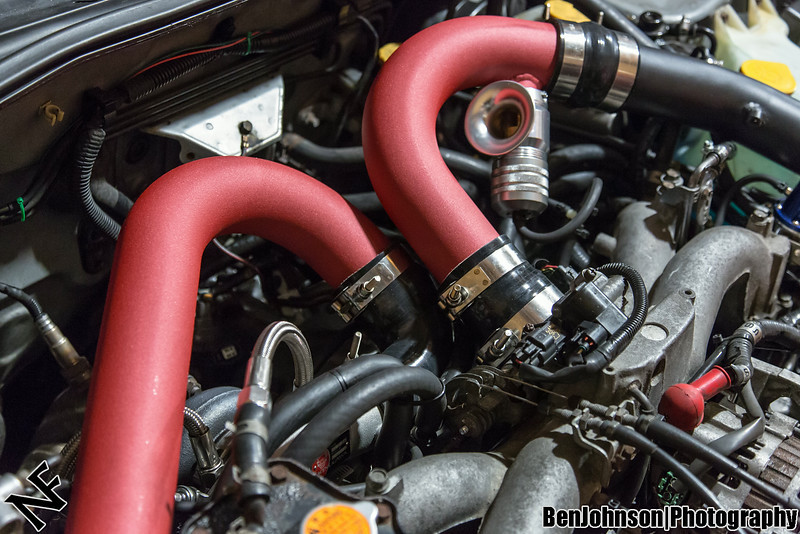

And here's a engine bay shot of the current setup.

Notes:

- I also reversed the airflow in the FMIC setup. All I had to do was wiggle the pipes a bit and the last two could be hooked into the opposite things (turbo vs. throttle body).

- This should keep the air going into the motor a lot cooler because it's not going right over the turbo before going into the throttle body. I really don't know why they were ever set up like this in the first place.

- The turbo is not tuned yet. Hopefully Nuke will be able to fit me in sometime soon. I am looking forward to seeing how this turbo will pan out. I'm hoping it will make a bit more power than the last one. We'll see...

8-7-2014

Nuke spent a few hours tweaking the tune and did many revisions last night. The car is driving great. It is smoother and more well behaved off boost than it ever has been since I got it. The response is good, although it does come on in the higher RPMrange, as expected with a 60mm turbo. He also did some more WOT tuning of course

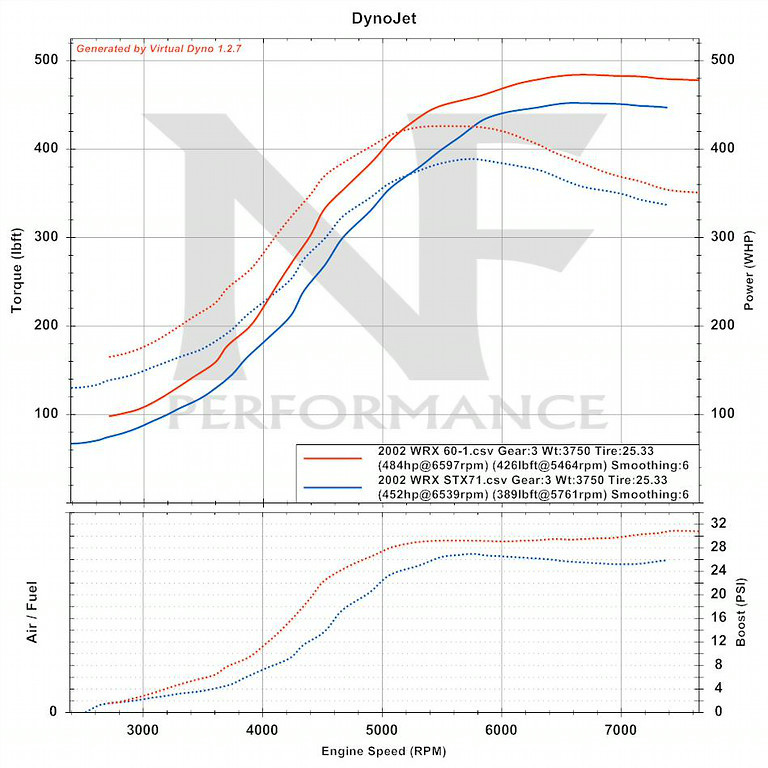

The power delivery is very smooth. It doesn't slam the midrange like a smaller turbo. It just builds and keeps climbing. Even revving it out to close to 8k the power is still there. Butt dyno just feels like it's going up and up the further you rev. Boost comes on sooner than the STX 71 (54mm compressor), but I did find I had an uppipe to turbo leak once I pulled that turbo off (PHOTO).

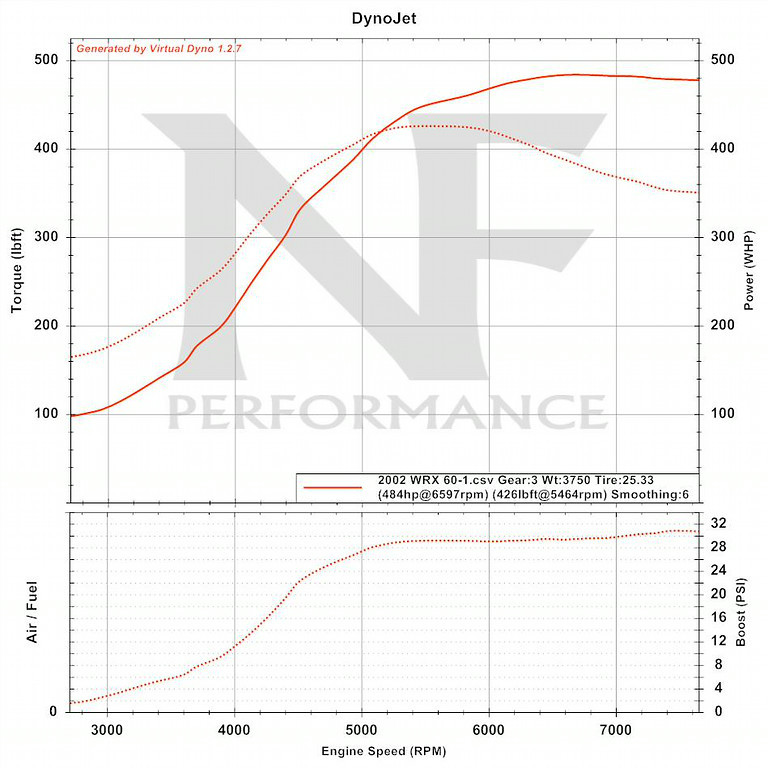

The 60-1 is currently tuned to around 30psi and it holds it flat all the way to redline. The Virtual Dyno shows it making 484 WHP / 426 WTQ. Not a huge jump in peak, but it's just a Virtual Dyno plot, so the 1/4 traps will tell the real story. It hits 20psi (and 300WHP) at around 4,400rpm's. It makes 400WHP at about 5,000rpm's and then climbs/flattens out to redline. It's a decent powerband for the street and plenty for drag. I am hoping this setup can get me close to 10's.

Compared to the STX71 (which had the uppipe to turbo leak hurting the spool, but still made decent power and trapped 122mph) the 60-1 setup has a decent bump in power throughout the rev range, and has power coming on 300-400rpm's sooner. Both hold boost well. The STX 71 was peaking around 27psi vs about 30psi for the 60-1. I think if I can pick up a few mph through the traps with the new setup I will be close to 10's with a good pass.

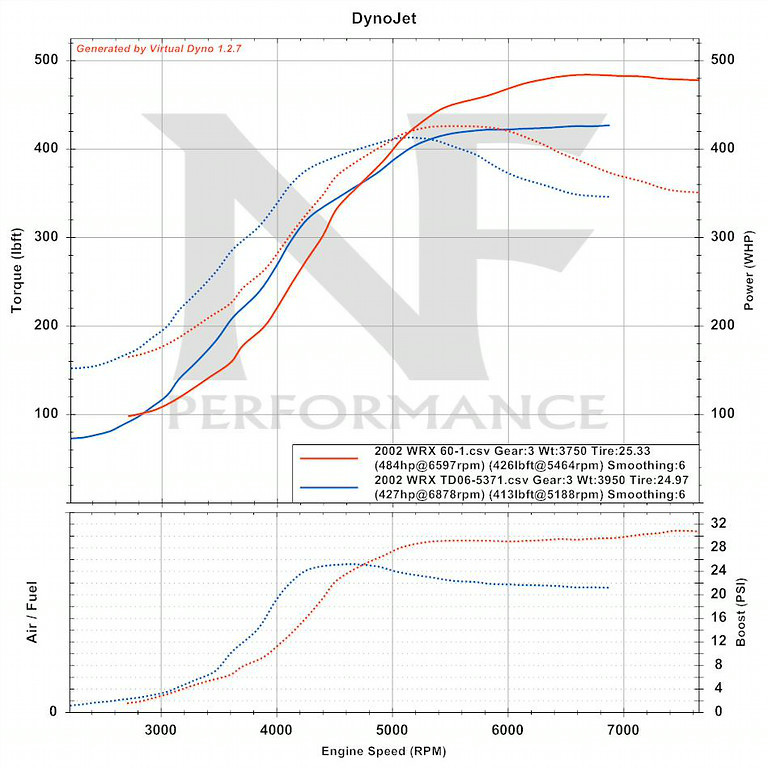

Versus the prototype STX 71 (which was a 53mm compressor inducer instead of 54mm of the production turbo) the 60-1 spools later by a few hundred RPM's but holds boost a lot better on the top end. I think this is a more typical example of what would happen when you go to a larger turbo (the STX71 was a bit of an anomaly since it had the uppipe leak and spooled slow for its size).

8-8-2014

Here's a quick speedo video of my car running through the gears with the Kinugawa 60-1. The 50-100mph time is around 4.8 seconds. It was in the 5.5 second range when I was at the dragstrip with the STX71 (11.4s @ 122mph passes). With the 60-1 it seems like the car is still really moving in the 100mph+ range.

Kinugawa TD06H 60-1 @ 30psi on E85 Video

50-100mph is 4.8 seconds

484WHP on Virtual Dyno (Dynojet)

I did some comparisons vs. my old setups.

- I did 50-110mph because the extra top end really starts to show the differences in the faster setups. I didn't do higher than 110mph because I didn't have speedo vids that high for all the setups.

- I only used videos from when my cars had the 6 speed transmissions. The 5 speed gearing can skew things a bit depending on what speed range you choose and how many shifts are needed.

50-110MPH | 2nd/3rd/4th Gear | 6MT Long Gears

5.78s | 2011 WRX | Precision 6266 | 30psi | 2nd/3rd/4th Gear

6.10s | 2002 WRX | Kinugawa 60-1 | 30psi | 2nd/3rd/4th Gear

6.53s | 2011 WRX | Blouch 20G XTR | 28psi | 4th Gear ONLY

7.37s | 2002 WRX | SteamSpeed STX71| 27psi | 2nd/3rd/4th Gear

8-9-2014

Another quick video. Brake boost 2nd gear and pulled all the way through the top of 4th.

8-11-2014

I did some more work getting the reverse flow FMIC piping to work today. I had tried it previously just by switching the top two pipes that come with the 02-07 TurboXS FMIC kit. The pipes all fit together, but the passenger side sat too high and touched the hood. This caused the pipe to pop out under boost so I had to switch back.

Luckily I found someone locally that was willing to donate the two spare pipes that come with the FMS/TurboXS FMIC kit for the 08-14. He has a WRX, so I got the STI version pipes (for the STI flange turbo, and STI intake manifold). These pipes are both longer than the 02-07 pipes so I cut them down to fit.

The driver side works perfectly. I did have to sand off the powdercoating to get the TurboXS BOV to fit, but I am glad that I at least got it on. On the 02-07 kit I sanded a LOT and it still wouldn't fit so I had to use a hose and clamps. The passenger side pipes don't really line up, even after cutting, so I ordered a 45 deg coupler. It should arrive later this week or next week.

Additionally I had been having intermittent issue with the pipes popping out, even with the pipes in the standard configuration. This happened at least half a dozen times at the track and multiple other times on the street. To try to resolve this issue I bought a set of hump couplers.

The driver side mounted up fine. The hump coupler allows for a bit more movement and it also a hair longer. I managed to use a hump coupler and get the passenger side on as well. It's a bit kinked, but it does hold full boost. I will still be putting the 45 deg coupler on when I get it. I will also be putting hump couplers on at least the intercooler core endtanks. Maybe on the other two joints as well.

Here are some photos.

In progress:

Before:

After:

More details:

8-14-2014

I did some weighing of my WRX and RS hoods last night:

- RS (flat, steel, no insulation): 37.0lbs

- WRX (scoop, no splitter, insulation): 19.5lbs

- WRX (scoop, no splitter, no insulation): 18.5lbs

- WRX (no scoop, no splitter, no insulation): 17.0lbs

WRX hood is back on to save ~20lbs.

Quick shot with some new wheels!

I hosed off the wheels.

8-15-2014

Here are a few more photos. This was before I washed the wheels so they're pretty filthy. I'll have to take some new shots sometime.

2002 Silver Bugeye WRX Sedan

2004 Silver STI BBS Wheels

235/45R17 Federal 595 RS-R Tires