You must be logged in to rate content!

11 minute(s) of a 536 minute read

8-9-2015

time for a progress report I guess ,

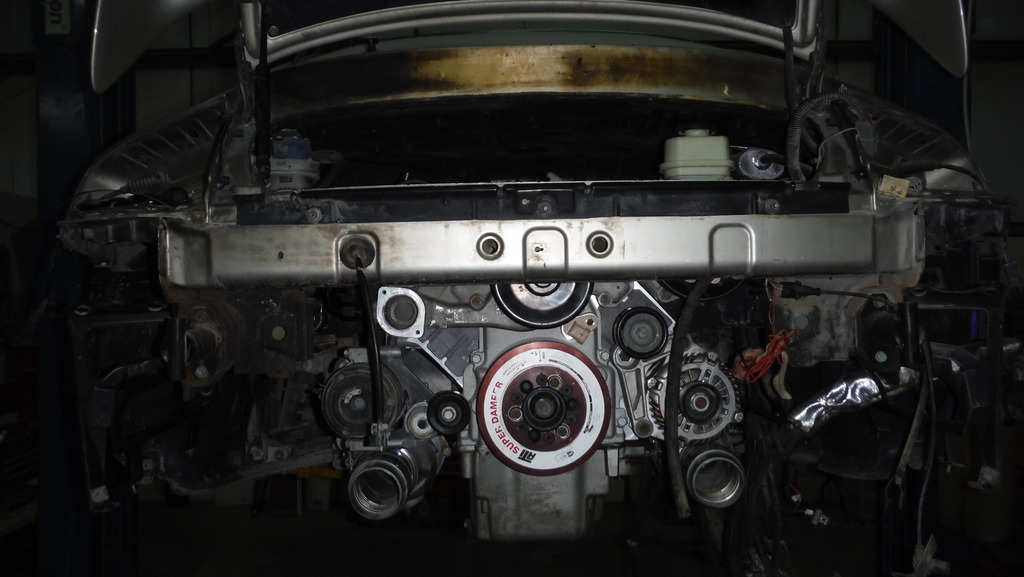

like I mentioned above, the old engine is out , and the new engine is finally sitting in the engine compartment :

after installing the engine it was time to look in to he exhaust again ,,, the plan was to reuse the old exhaust , which was possible if I cut the ball flange and weld the v band on it ,,,, the problem with that is mufflers sit close to the suspension cross member and I would not be able to route the discharge pipe from the turbo to the intercooler.

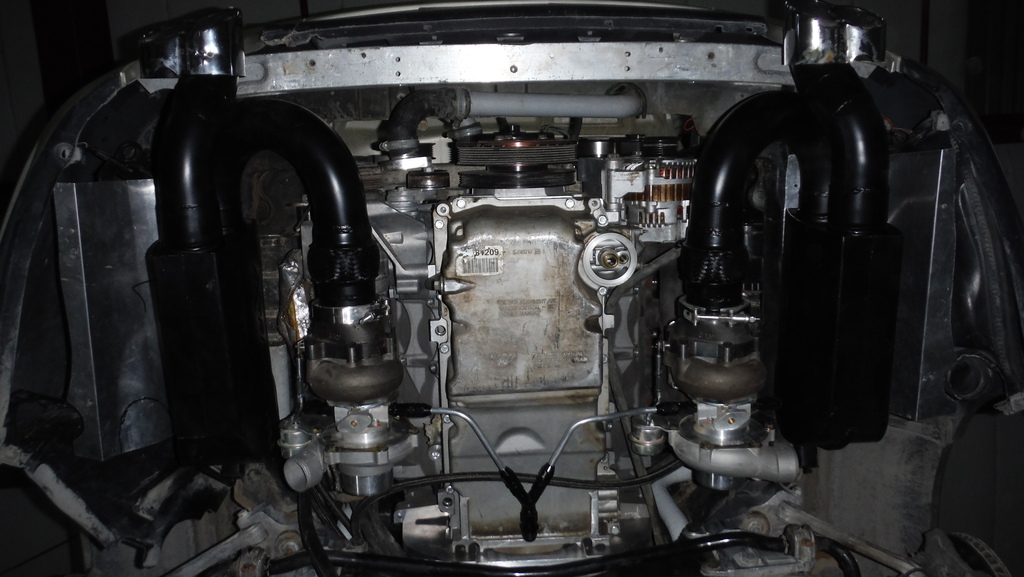

so after a bit of head scratching I decided to just build me a new exhaust system using a single muffler on each side instead of the two muffler preside system I had on it before.

I started with positioning the muffler where I wanted it to be , then I welded a "u" pipe to it to connect it to the flex coupler on the turbo down pipe. here is how the two muffler look before I welded the outlet pipe:

and here is how the mufflers look when done :

and how they look after some high temp paint :

after finishing those I installed the intercoolers and started to make the heat shield between the mufflers and the intercoolers:

here is how it looks on the car :

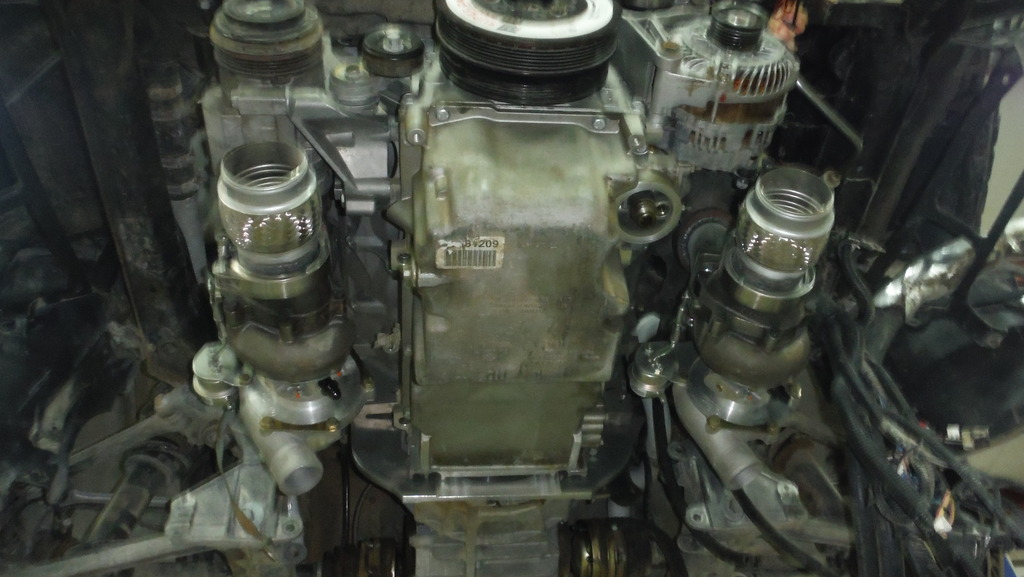

after finishing the exhaust I started on the plumbing for the coolant lines to the turbos.

the plan was to have the turbos get their cooling from the coolant line / heater hose going to the front of the car; where I would splice into that and have the coolant go from the engineto the turbos , then from the turbos to the heater up front then back to the engine again.

I started doing that but halfway through that I noticed that I was having too many hoses running all over the place and it looked messy. so I redid some of with some aluminum tubing to make it look good and less cluttered .

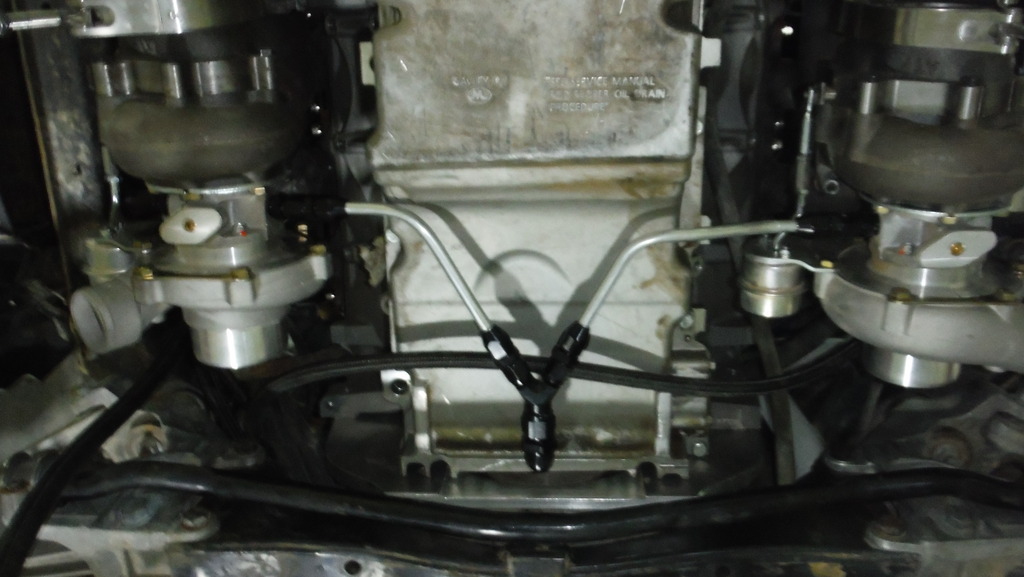

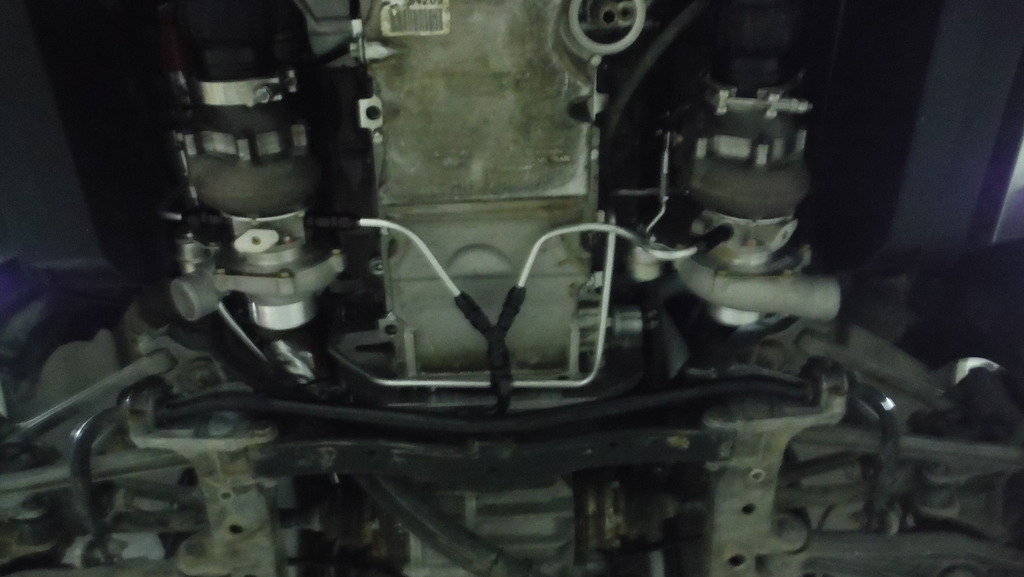

I started with a Y under the oil pan connecting both turbos to the heater hose, then I found out that I don't have enough compression fittings to finish the hoses from the heater hose to turbos. so I just finished bending the lines until the fittings show up

another convenient thing I found out is the Porsche oil pressure sensor actually fits in the holes on the side of the oil pan where the oil cooler fitting goes in , I just removed one of the pipe plugs and the sensor just thread right in :

so here is how it looks so far from under the car :

welded AN bung on heater hoses :

so now that the exhaust side is mostly done ( need to pug the O2 holes in the exhaustmanifolds and install the wide band sensor in the exhaust pipe) I can move on to the next item on the list , engine fuel lines and routing , and fuel system up front. the plan is to run a return line from the engine to the original return line and a new hard line under the car to the front of the car on the passenger side and up the wheel well and into the trunk/ enginecompartment up front.

I thought long and hard about the fuel system up front , and I finally came to the decision that I will use a single Bosch 044 external pump. I was planning on using dual aeromotive in tanks but looking at the sending unit and how f'd up the thing is inside the tank , I decided not to and just do it in a simple and tried and trusted matter.

I will post pics of the sending unit and how it is almost impossible to run a bigger hose through it , which led me to decide that running the external pump was the best way to do it.

the plan is to have the fuel feed hard line come up the front right wheel well along the AC line and end behind the small skid plate they have there , where a flexible hose will connect to it and run along the wheel well / frame rail to a small hole at the front of the well where it goes into the trunk area ( where the AMP is) and runs up to the CD changer area where the pump will sit. from that it will loop into a bulkhead fitting into the top of the tank where a hard line with a Y that runs to the bottom of both saddles of the tank will be plumbed.

so next up on the list is :

- finish turbo coolant lines

- install intake and other stuff on top of the engine

- run hard lies to the front and to the return line.

- plumb fuel pump and tank stuff

- test fuel system for leaks

- fill coolant system and check for leaks

- fill PS system

- swap front damaged CV boots

- replace front and rear shocks

- bleed clutch

- fire da bitch up !

8-18-2015

more progress to report

i managed to finish a few things here and there , first off I installed the intake manifold and the associated stuff along with it . I decided to put the regulator on the exit side of the fuelrails on the passenger side , then run the return line to the front of the car while switching to the driver side when it goes behind ( or in front of) the engine - depending on how you look at it- and then have it connect to the original return line.

i also redid the coolant lines going to and from the turbo , at first the idea was to have them done in flexible hose ,,, but that looked like a mess, so i went with some hard line and compression fittings ,,, which was fine until i found out they don't make a 90 deg. compression fitting so i had to redo the lines because i had to clock the turbo center sections to gain some clearance for the fittings and line.

so i had to redo the lines because i had to clock the turbo center sections to gain some clearance for the fittings and line.

i then turned to the fuel system ; starting from the rear and working my way to the front ( well it was more like a bit here , a bit there ) .

the plan was to run a the filter in the stock location on the coolant tank , then have the feel line snake under the car along the AC hoses to the passenger side where it would connect to a hard line that paralleled the refrigerant hoses all the way tot eh passenger wheel well area , where it goes back to a braided hose and enters the compartment from there .

here is where the hard line enters the wheel well and connects to the braided hose:

and this is how it looks with the rock shield in place :

the braided line follows the frame contours tot he front of the wheel well , where it goes in to where the amplifier is :

on the inside of the trunk are the hose snakes back to the firewall area and goes up to the shelf where the cd changer was.

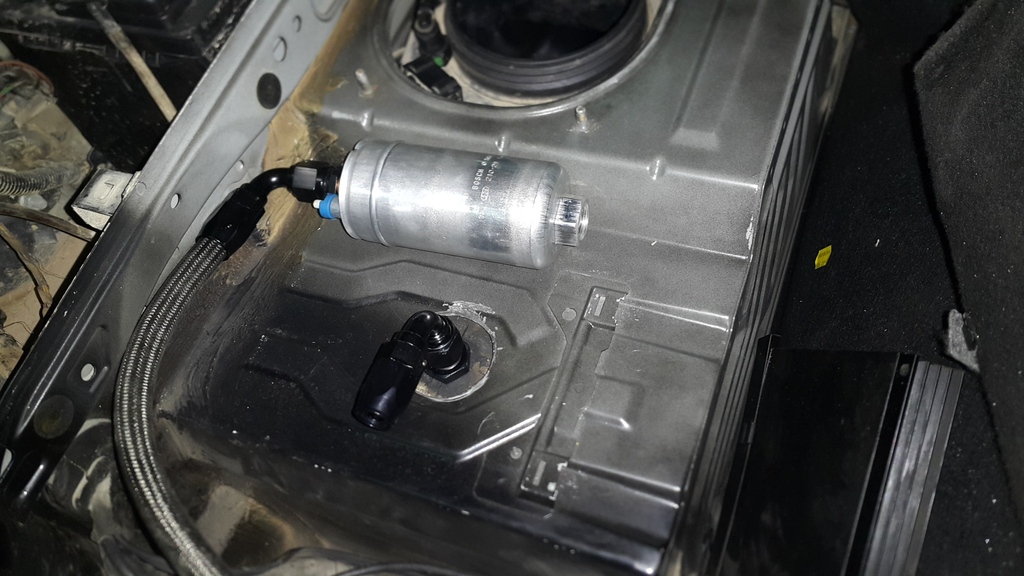

i decided to install an external bosch 044 pump there to keep things simple and easier to maintain. i also decided not to use the sending unit for running the feed line through ( no where to drill and install any fittings) , so drilled a hole through the floor and another in the top of the tank and installed a bulkhead fitting onto the top of the tank. from the bulkhead fitting i used a 1/2" aluminum tube that ran from the top of the tank to the bottom where it teed into two smaller 3/8 tubes that each went into one of the saddles of the tank.

this is some of the original crap inside the tank:

pump and fitting :

y inside tanks : ( forgot to snap pic of it when it was finished)

so that pretty much takes care of the feed side of the fuel system , all i have to do now is run the return line to the original return lines on the car , drop the fuel level sender in , splice into the pump signal and install the leash electronics relay in place and scratch the fuel system off the list

another thing i got around to do was fixing the front cv boots that were toast. i finished one side and all i have left is to finish the inner front pass side and slide it right in .

.

and i don't know if i mentioned this earlier but i am swapping all four struts on this car to newer used ones

so next up on the list is :

- run the return line.

- wire fuel pump

- test fuel system for leaks

- fill coolant system and check for leaks

- fill PS system and check for leaks

- bleed clutch

- pull pcm out and reflash

- start fabbing the turbo cold piping from turbo to intercooler

Nice details ????

Posted by Diggymart on 5/1/19 @ 2:11:40 PM