You must be logged in to rate content!

4 minute(s) of a 731 minute read

3-30-2020

The crappy weather and a somewhat finnicky baby still resulted in a good weekend in the garage.

Saturday

I managed about 90 minutes in the garage in the middle of the afternoon and things went smoothly. Before installing the water pipes the timing covers must be installed. It's counter-intuitive and an easy step to skip. My RTV Blue was delivered and ready to use; and I liberally applied it to the coolant pipes. These were installed finger-tight to allow the RTV to set up for 60 minutes.

Pics for clicks. It may look like a lot, but there is a groove below the RTV

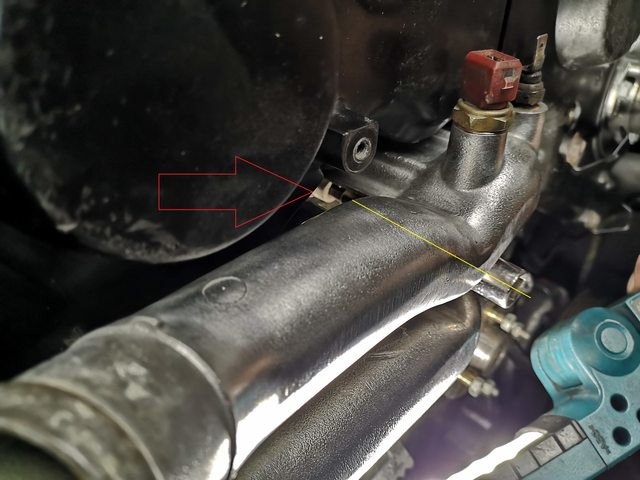

It was at this point it suddenly clicked as to why the perception is that these are hard to work on. Sure its a cramped engine bay and engine removal is almost mandatory for turbo replacement. For maintenance and general repairs; its not bad. The difficult part is just knowing the how or the where. The how is less important (unlike most European brands which seem to invent their own fasteners for each iteration). Case in point, see the image below. An extension is needed to reach this socket head cap screw; its location isn't exactly intuitive so a first time wrencher (wrenchist?) might struggle a bit, but the castings are designed with a relief so that they can easily be reached.

Red arrow shows fastener location. Yellow line depicts tool entry

After cleaning and installing the coolant pipes; I got the three accessory belts on and tensioned, installed the radiator, crank pulley, and fan clutch. I used the remainder of my 60 minute RTV setting window to tighten every bolt and hose clamp I could find. I was pleased to discover that most did not need adjustment. If anyone has a good source on double-layer spring clamps; I'd be happy to swap out all my worm gears for spring clamps. Nissan OEM clamps are double layer spring clamps which provide quite a bit more clamping force than the generic spring clamps which are all I can seem to get my hands on.

Sunday

Sunday was an easy day. I gave the battery terminals a good cleaning, filled up the radiator and started her up. Stumble/die. Attempt #2 ran for about 5 seconds and sounded pretty gross. I had forgotten I removed a MAF and cone filter to allow me to install the AC drier. I had it covered up with my fender guard and totally forgot about it.

Something important is missing

I replaced the MAF and it fired right up and sounded great. Yey. I brought it up to temperature, being sure to keep the radiator mostly full. Unfortunately I had overlooked the fact that most experts recommend not charging the AC system when its below 55F out; so that part of the project will remain incomplete. I set the car back on the ground and cleaned the garage. I think all told I was just over 5 hours for a timing belt job and AC condenser installation (and spring maintenance). Not too bad; and here its only March and shes ready basically for summer (with the exception of a goooood wash).

It's no show car; but it cleans up okay.

Easy items on my to-do list that can be done whenever:

-Wash/Wax

-Investigate slow leak on DS rear tire. Was 45 when I parked it, was about 18 yesterday. Ugh.

-Determine evaporator drip tube routing

-Burn off 93oct in the tank so I can capitalize on that sweet sweet ~$1/gal E85

-Charge AC system at the first sign of a 60F and sunny day