You must be logged in to rate content!

185 minute(s) of a 390 minute read

11-1-2021

LS1 Powered S14

Compliments of SicBastard at www.zilvia.net

6/17/07

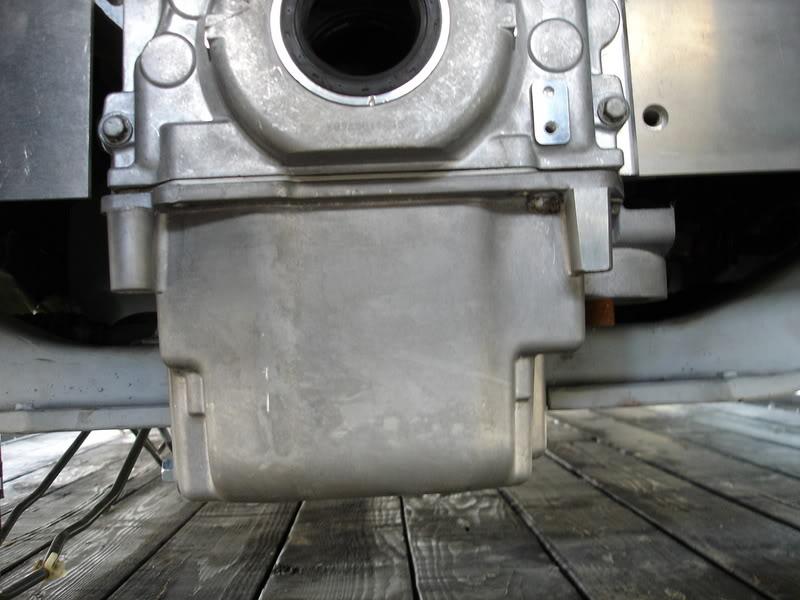

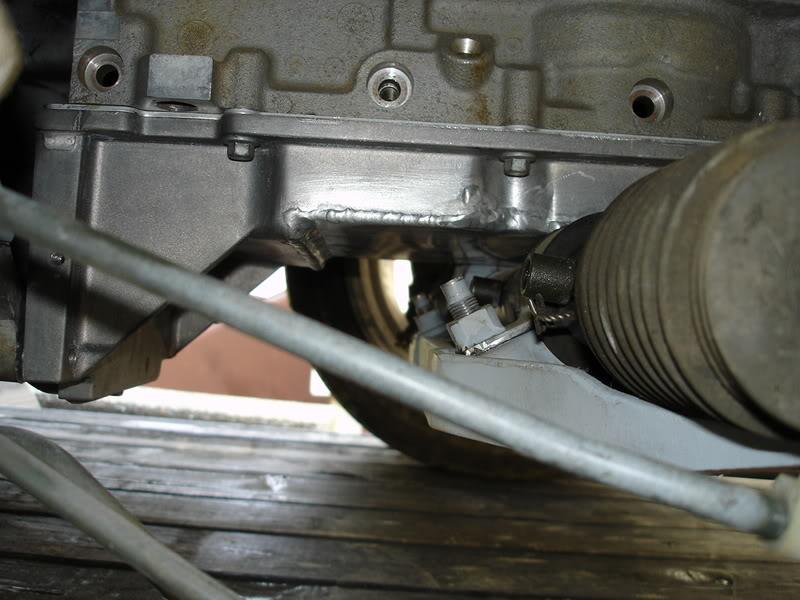

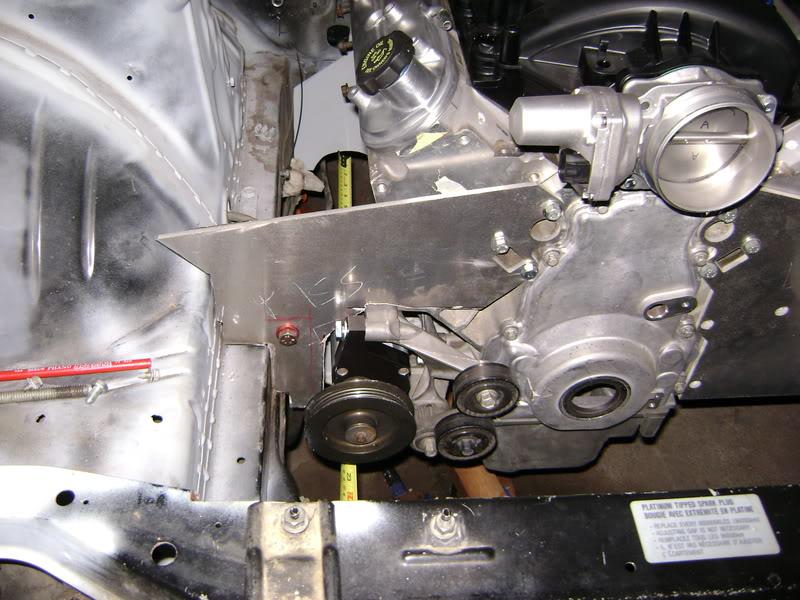

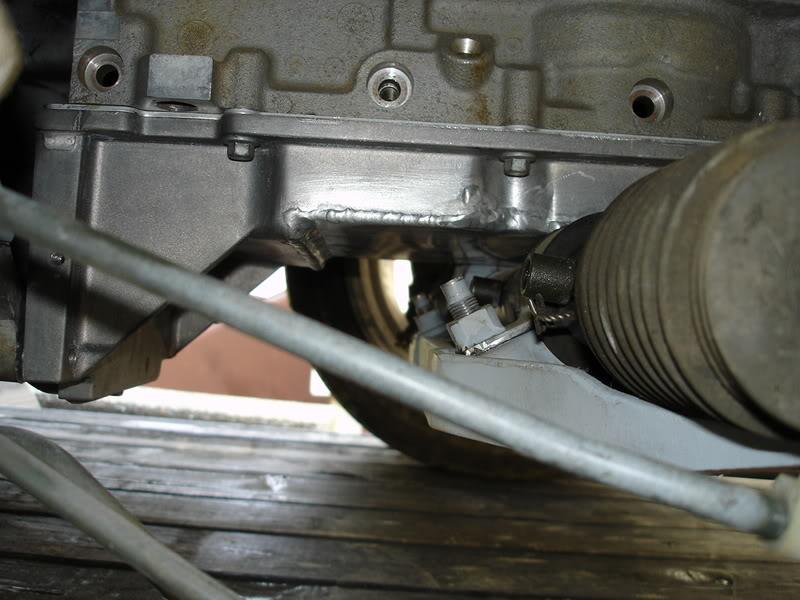

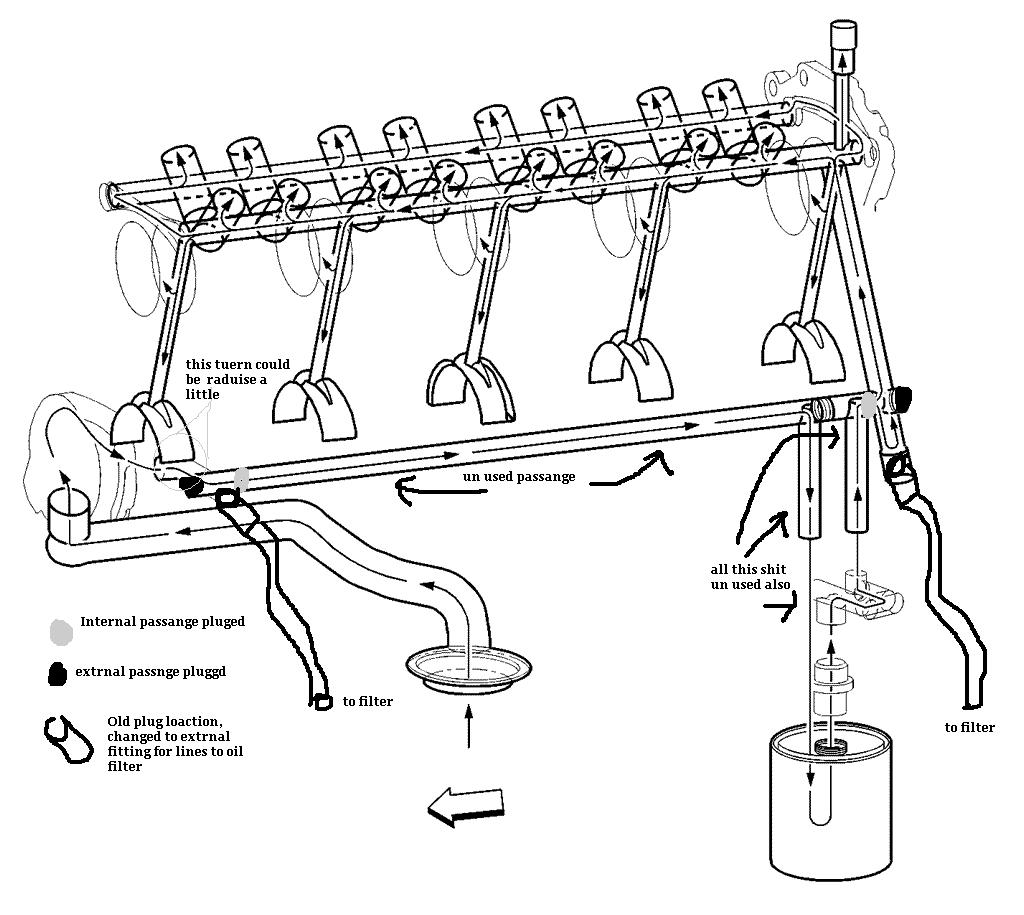

I've been obsessed with getting the engine and t56 as low and far back as possible. To that end I raised the floor of the GTO oil pan as high as I could and still clear at least a 4.125" stroke. Then I cut the ENTIRE front cross support in the middle of the cross member out, something that I havn't seen done before. This required first, reinforcing the bottom of the entire crossmember with 3/16th" plate and then two pieces of 1x1 steel tube between the steering rack mounts. Then I cut out the step at the back of the GTO pan sump so that the back of the sump could go right up against the steering rack.

Modded Crossmember

Milled pan sitting in engine bay

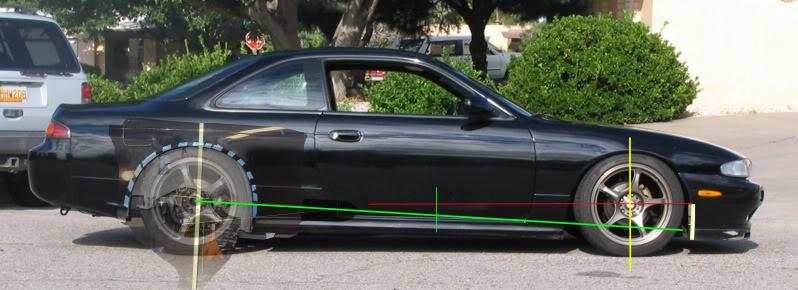

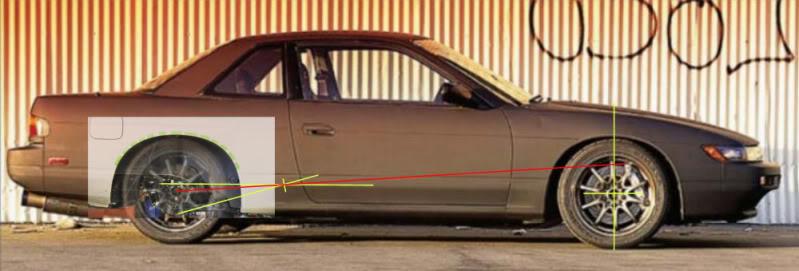

To give you an idea of how effective all this work is in setting back the engine and trans, here are two pictures of other LS1/S14s:

and mine:

My new problem is that the engine sits so low that my GTO oil sump now sits 0.75" below my crossmember. And that's not accounting for the 3/16" that I added to the bottom of the original crossmember!

I did not lower the crossmember relative to the car, and do not plan on doing so. Now I don't know what direction to go with the oil system. I only have a junk LS6 block and havn't started the engine build so I can still go any direction that I want. I'd like to stay away from the weight, complexity, and $$$ of a true dry sump system. I have a used accusump system and originally planned on just staying wet sump, and using the accumulator for a little insurance. But the sump is sittling so low that now I'm worried about ground clearance.

I'm torn between leaving it as it is, modifying the pan to use the LS7 twin pump system, or taking 3/4" out of the bottom of the sump, maybe adding wings and baffles and staying wet sump.

I noticed that the guys with project silvia at SCC had their anti-sway bar hanging below their crossmember after installing the front whiteline bar. Maybe I should just install a whiteline bar and call it a tubular oil-pan guard?

What Dave at SCC had to say,

"The front bar hangs down slightly farther than the stock bar, but there have been no problems with bottoming out. We like to think of it as a 27-mm tubular oil-pan guard.

...we hit one of those asphalt waves that get slowly kicked up when thousands of overweight trucks stop in the same place. The ridge of asphalt was high enough to hit the front anti-roll bar, lifting the car off the ground, bending the bar's pivot bushings and slamming the bar into the oil pan. The stock steel pan escaped only slightly dented, but we fear an aluminum pan would crack under a similar impact. If you're going to be sloppy, haphazard drivers like us, steel may be the way to go."

My engine sits further back than an SR so I think I'll be alright in that regard, I dunno?

note the blue bar hangin' low

What do you guys think?

The clearances all around the trans are super tight in the tunnel, I couldn't raise 'em even if I wanted to.

6/21/07

some more pics

Right now I'm leaning towards staying wet sump and adding some side wings with baffles and these one way valves from billet fabrications out in Simi Valley California.

These guys make beautiful custom oil pans, plus they are near my old home town. Any one ever used their stuff?

I had to move so I'm still setting up my garage. Bought a new air compressor, and a new welder is in the works. The miller dealer is having a big show and tell day where you can try all the different welders next month, so I'll probably wait till then.

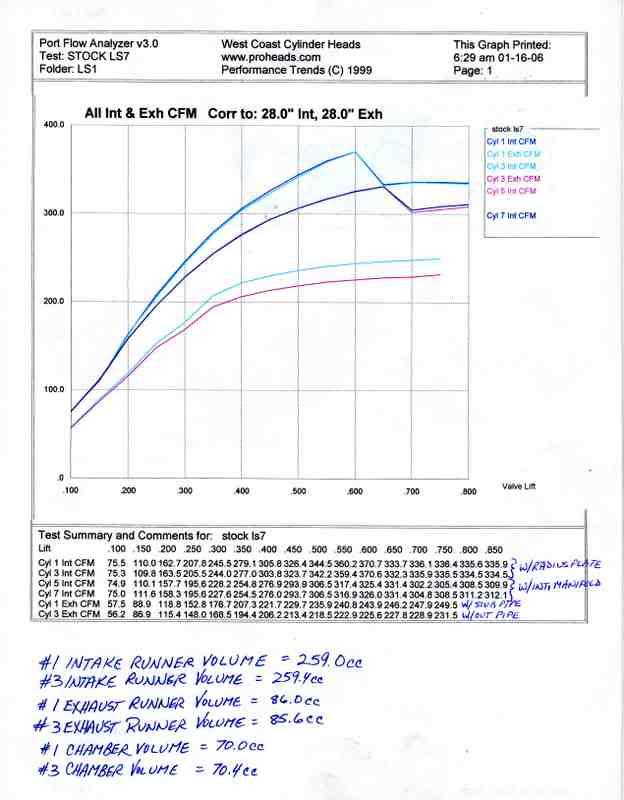

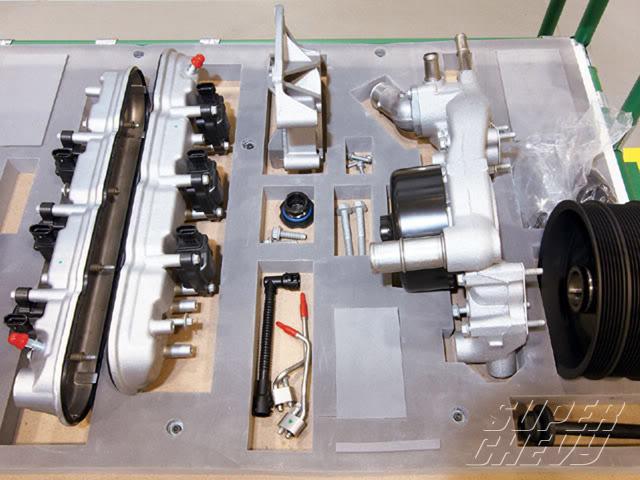

The LS7 heads are still with Richard over at WCCRH, and I just scored an LS7 intake on ebay for $200. I told Richard that I needed to go semi budget on the heads. He has a cnc program for the exhaust ports that add about 25cc/min of flow for $300, and he also has ti valves for about a grand. I will be getting neither of those. The heads come CNC'd from GM and I'm hoping to get away with spinning those rediculously large 2.2" intake valves to 7500 rpm with good ol brute force via WCCRH monster 1.450" (a big block chevy style) dual valve springs. The springs will require a little maching of the seats. The valves will most likely be manley stainless. They are heavy just due to the size.

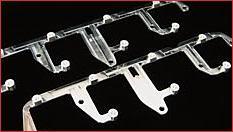

My Old Speed inc billet LS1 fuel rails come no where near lining up. Now I just have to deside if I should Fab new mounts for the rails or if I should just get new LS7 specific ones?

It's also about time I got my ohlins rebuilt, so they should be going down to South Carolina here pretty quick. I made a really strong plywood shipping box, because the are my new "Precious."

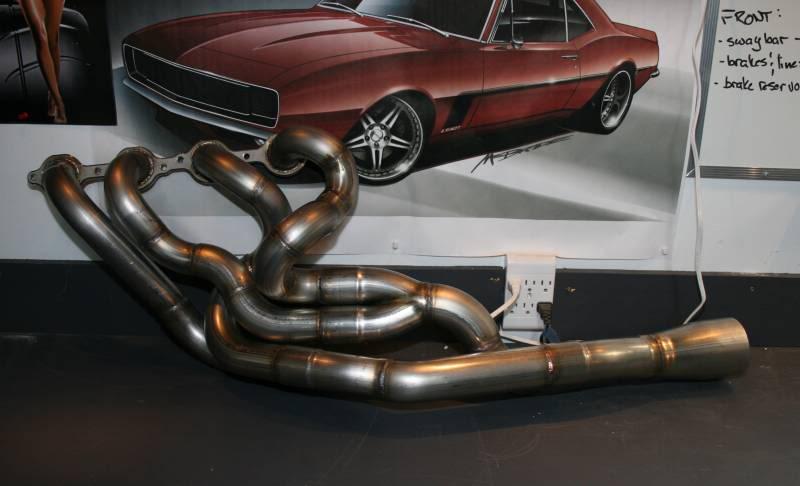

And the last little thing, is that I just picked up a new steering shaft universal joint from the nissan dealership out here on rt 46E. The little POS was $90, but the old one was a little notchy, and there's no point in cheapin out now. I also have a set of 2006 LS2 GTO headers that I've bolted up. I'll see if the drivers side will clear some the steering rack u joint that I just got. The passanger side sticks way out and hits the frame rail, but there are no other clearance issues, so I think that a vette LS2 manifold would be fine on the passanger side. I'll keep yall updated.

-=Peace and Tire Smoke=-

11/30/07

Cam Plans

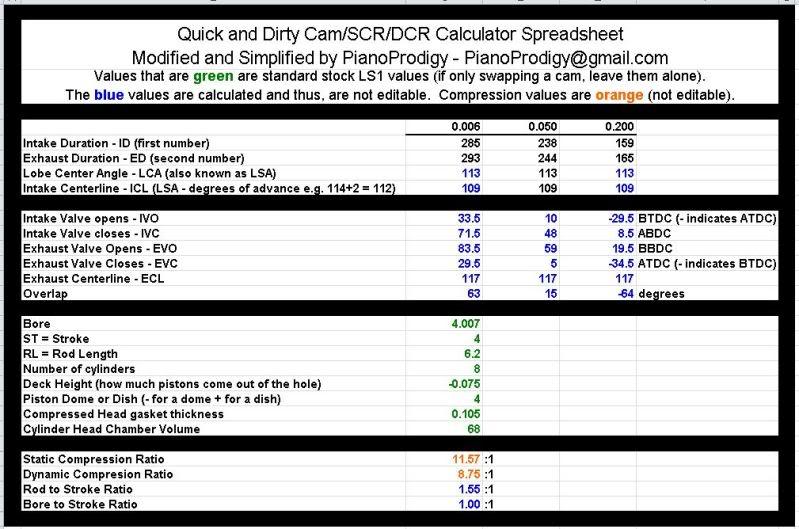

Well here is the cam that I cam up with and the engine specs all nice and neat thanks to the "Quick and Dirty Cam/SCR/DCR Calculator Spreadsheet Modified and Simplified by PianoProdigy" that I found somewhere over on LS1tech.com

Lift in inches__________________0.006 0.050 0.200

Intake Duration - ID (first number) 293 244 165

Exhaust Duration - ED (second number) 300 252 169

Lobe Center Angle - LCA (also known as LSA) 109 109 109

Intake Centerline - ICL (LSA - degrees of advance e.g. 114+2 = 112) 110 110 110

Intake Valve opens - IVO 36.5 12 -27.5 BTDC (- indicates ATDC)

Intake Valve closes - IVC 76.5 52 12.5 ABDC

Exhaust Valve Opens - EVO 78 54 12.5 BBDC

Exhaust Valve Closes - EVC 42 18 -23.5 ATDC (- indicates BTDC)

Exhaust Centerline - ECL 108 108 108

Overlap 78.5 30 -51 degrees

Bore 4.125

ST = Stroke 3.622

RL = Rod Length 6.2

Number of cylinders 8

Deck Height (how much pistons come out of the hole) -0.018

Piston Dome or Dish (- for a dome + for a dish) 2

Compressed Head gasket thickness 0.051 cometeic (stock is 0.054)

Cylinder Head Chamber Volume 62.5 (hopefully with the .045 mill)

Static Compression Ratio 12.06 :1

Dynamic Compresion Ratio 8.60 :1

Rod to Stroke Ratio 1.71 :1

Bore to Stroke Ratio 1.14 :1

The plan was to build a cam and motor that would make a ton of horsepower, but have less of a tire shredding tendency to help with traction out of the corners. Redline will most likely be 7500 rpm. I fear giong any higher because of the massive (read heavy) 2.200 stainless intake valves, that I have to use due to budget constraints, in the LS7 heads. I'm also using a milder lobe then most: the older comp "Xtreme RPM for LS1 Hi lift" Which will produce 0.630" lift on both intake and exhaust with the stock LS7 1.8 rockers.

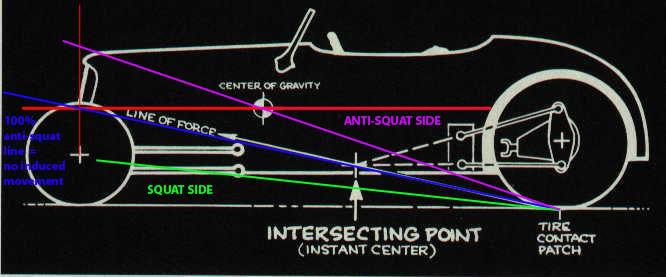

I'm guessing that this engine will peak just under 6800 rpm without much fall off to redline. I'm using a stock but port-matched LS7 intake, and custom headers. The oversquare engine comes out to 392 ci. I think that the 30 degrees of overlap should be just streetable enough. It's the late IVC that I'm hoping will curb the dynamic compression ratio enough for the hi compression pump gas combo, and simultaneously help push the peak power rpm up above the 6300 wall that so many other LS1 engines seem to sit at.

This cam is all still theoretical; the heads and intake are not. So if anyone has any knowledgeable input/ideas to provide, I'm all ears.

12/2/07

I've heard two different, very reputable LSX engine builders mention these lobes in passing, and finally looked them up:

Comp Cams : XTREME MARINEâ„¢ HYDRAULIC ROLLERS - HIGH LIFT

These have the same ramp designs as the lower lift Xtreme Marineâ„¢ designs but have higher lift to enhance power

output with cylinder head and engine modifications.

LOBE RATED DURATION IN LOBE TAPPET LIFT @ THEORETICAL VALVE LIFT

NUMBER DURATION DEGREES LIFT TDC @ “0â€Â LASH ROCKER ARM RATIO

CAMSHAFT TYPE

.050 .200 106° 110° 1.5 1.6 1.7

3473 290 234 152 .360 .081 .068 .540 .576 .612

3474 292 236 154 .360 .085 .071 .540 .576 .612

3410 294 238 154 .350 .088 .075 .525 .560 .595

3475 294 238 156 .360 .088 .075 .540 .576 .612

3376 296 240 157 .360 .092 .078 .540 .576 .612

3411 300 244 159 .350 .099 .085 .525 .560 .595

3370 304 248 167 .380 .107 .092 .570 .608 .646

3377 306 250 166 .360 .111 .096 .540 .576 .612

3371 308 254 171 .380 .119 .103 .570 .608 .646

3372 314 258 175 .380 .126 .111 .570 .608 .646

3373 318 262 179 .380 .134 .118 .570 .608 .646

3374 322 266 182 .380 .142 .126 .570 .608 .646

3375 326 270 186 .380 .149 .134 .570 .608 .646

3447 330 274 190 .380 .157 .141 .570 .608 .646

also from the 2007 comp cams catalogue it says:

"These profiles use the same design techniques of the baseline Xtreme Energy

â„¢ Hydraulic Rollers but have been optimized

to increase power and durability when run at steady rpm for extended periods of time. Specifically designed

for big blocks with heavier valve train components."

I'm only interested in the intake at 244 @ .05", but its advertised duration (or duration at .006" lift) is 300, vs the 293 of the origianl lobes I was going to use. These lobes sound great, they are designed for big ass heavy big block valves, which is exactly what I'm running with my 2.200" stainless intake valves. I don't need these lasier lobes on the exhaust because they are a more standard (and lighter) 1.600". The larger advertised duration (at the same .500" lift) will also allow me to run a little more advance and still have a lower DCR. At 8.6 I was pushing it a bit before.

I'll call comps help line before making any final decisions, but here's some food for thought.

Who would have thought, Marine Lobes in a road racer?!

12/12/07

I'm not saying that anyone would be disappointed if they went with a set up from vengence. 575 hp at the crank is pretty impressive! But I'm confident that my set up will do better. Also the trick flow heads are not as good as a ported LS7 head on a large bore block; if you care, look up the dyno graps of cars equipped with both on ls1tech.coms dyno comparison forum, then look up both of their dry flows from the published flow bench results, you'll see I'm right. And regarding the "vindicator" cam: It's traditional split is too narrow for the heavily biased intake (or you cold say relatively poor flowing exhaust) on the LS7 heads. It's overlap is also much more narrow than the cam I'm proposing, which will cost power for the sake of driveability. And finally, it's smaller, which is fine for the 364 ci that it was designed for, but on my 392 will cost power again. I appreciate peeps throwing out suggestions, but before you reccomend that I scrap all of my parts and ideas for something else, I'm just asking that you do a minimum of research, or actually come from a place of knowlege before you post....in the mean time some cool pics of the halibrands and 275mm falken 615s.

1/1/08

I wasn't being defensive. I just get a little frustrated on this forum sometimes. I post up technical questions about camshaft design, and instead of replys, I get peoples' opinions on what sounds cool, and "vindicator ftw".You're right though, long tubes do sound nastier. The only reason I havn't mentioned them much before is that I was waiting to see what my final exhaust valve size was going to be, what the cam specs were going to end up at, the final bore and strokea, etc. Once that info and more is locked in there will be some serious posts on calculating header diameter, triY design, step location, blah blah. There' some serious power to be had with the right pipes!I just got my LS7 heads back from West Coast racing heads, and I've got to go pull my LS1 heads to see if the exhaust ports and header bolt location are the same. I hope they are because I'd rather use my scabby LS1 heads for the custom header mock up.And yeah those are halibrand cobra IIIs that were originally designed for ac cobra replicas. At first I was all excited to have original halibrands, but later found out that right before these models were made halibrand stopped being a US designed and made. All four wheels were slightly out of round (have sinces been fixed at Pico tire and wheel just North of LA) and the backs (17x10.5) were only made for a very short period of time and are a slightly different color than the fronts (17x9 without the deep dish for extra caliper clearance).

1/12/08

Halibrands definitely tickle my pickle!

And the progress is slow but steady.

...but it's about to come to a screaming halt for the next three months.

I have to move to Trenton NJ for a surgical clerkship, and I'm going to have to take call, overnight every fourth night. Then I'll have to move again.

Went over to my old stomping grounds TTP in Passaic NJ and media blasted my valve covers. Worked out great. Then I used a dremel with a 80 grit roll to remove the casting marks. I think I'm going to try and polish 'em.

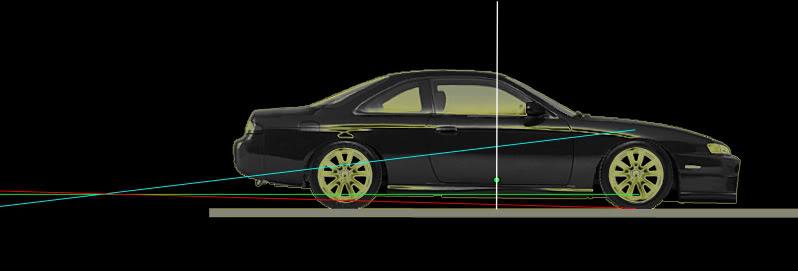

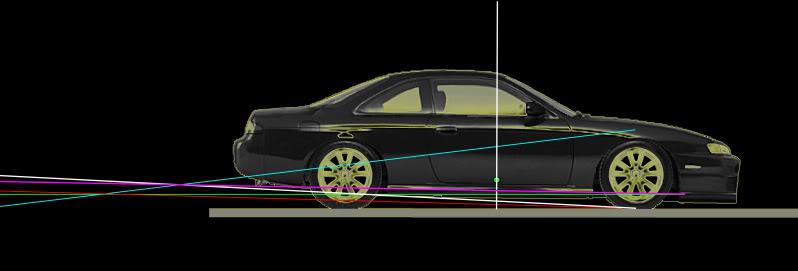

Took these pics for another thread to show how this bad boy is mid engine:

If you look close you can see the make-shift pendulum line that goes to the center of my front wheel. The car is level. And I think it's safe to say that this is a mid-engine car!

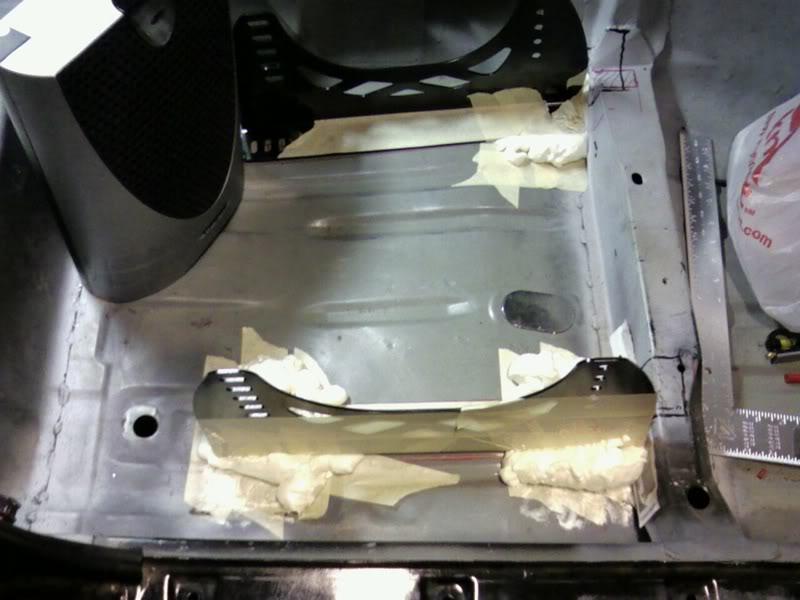

I've also been working hard on the seat mounts, because A: I want them low, and B: I want the seats in their final position before I weld in the harness bar.

First I removed the mini pilar that holds up the outer/rear stock seat mounting point, and then masked off everything. In order to make a template for the odd shaped floor, I bolted down my OMP seat mounts and injected some insulating foam. Cardboard templates may have been easier, but it was a fun experiment, and it worked out perfectly.

Notice the heater sitting in the car so that the foam would cure in my F'n freezing garage!

1/30/08

The LS7 heads have forced me to go big bore. I knew this when I bought them, but I naively believed the GMPP catalog that said that they will work with a 4.065 bore which ment I had the option of using a $1400 brand new L92 block. According to my head builder, who I believe over the catalog, 4.100" is closer to the truth. Incase you didn't already know the stock bores are:

LS2 4.000"

LS3/L92 4.065"

LS7 4.125"

Road race engines have been succesfully built utilizing LS7 heads on .035" over L92 blocks (yields a 4.100". But of course you're not left with much cylinder wall left, and if anything goes wrong, you can't overbore, you have to sleeve. Also, this is all presuming that you're starting with a block with almost no core-shift, good luck finding that as the L92s are notorious for having odd sleeve placement/core-shift.

So I've been looking into the other big bore options out there. Since a C5R or Warhawk block is out of my price range, that leaves me with the

1)stock LS7 $2400 new (maybe $1800 used)

2)Katech sleeved "budget LS2" something like $4000 (doesn't seem very budget to me).

3)darton MID sleeve (actually strongest on a LS1 block) but you're looking at $1000 for the machine work, another $1500 for the sleeves themselves, and then of course you need a block. So lets say you get a good deal on a used LS1 for $500, once you're done with shipping, we're talking at lest $3100

4)Iron LSX: can be had for $1800, but it will still require stress relieving and boring (it comes stock at something like 3.900" bore). Oh and did I mention that it's like 120lbs heavier than anything mentioned so far.

5) LS2 block with Darton Dry liners. What I'm leaning towards right now.

Require less machine work than the MID sleeves, and cost a bunch less for the liners themselves. Unlike the MID sleeves they do not require evans coolant and pump (a hidden $600 of the MIDs). You can get the machine work and the liners together for $1500. I can probably get a used LS2 block for south of $750, and you're looking at a total of $2250. Compared to the stock LS7: the darton dry are made of a much more ductile/stronger steel, can be bored out to 4.190 vs 4.155, and can safely support the pistons with longer stroke cranks, because the sleeve is deeper than even the LS7 (which has the deepest sleeves of the stock blocks).

3/3/08

I got a little pm today re the ohlins:...What I'm wondering just how much do they charge as I was looking into buying a used set and how long is the turnaround time? Please let me know...The short answer is 4 months and $300 if its just a simple rebuild.The long answer is...I just got off the phone with Tony Martin at Ohlins. Turns out my front struts are in pretty bad shape, but still rebuildable. So they are probably going to sell me a new set for the front at a good discount (I think this may be because they didn't bother to fully disassemble them before ordering the parts 3 to 4 mo ago, and they don,t want to ask me to wait another 3 mo). The rears required less work and the rebuild for them both should come in around $75 per corner (that includes new seals and adj. knob repair). I shipped them off to NC on Nov 10th. They didn't get the parts they needed till the end of January. Shouldn't be much longer now. There are two guys that I know of who work on these there, and they are quite often traveling, doing trackside support. Hopefully in the future that will make the waitng worth it.

4/23/08

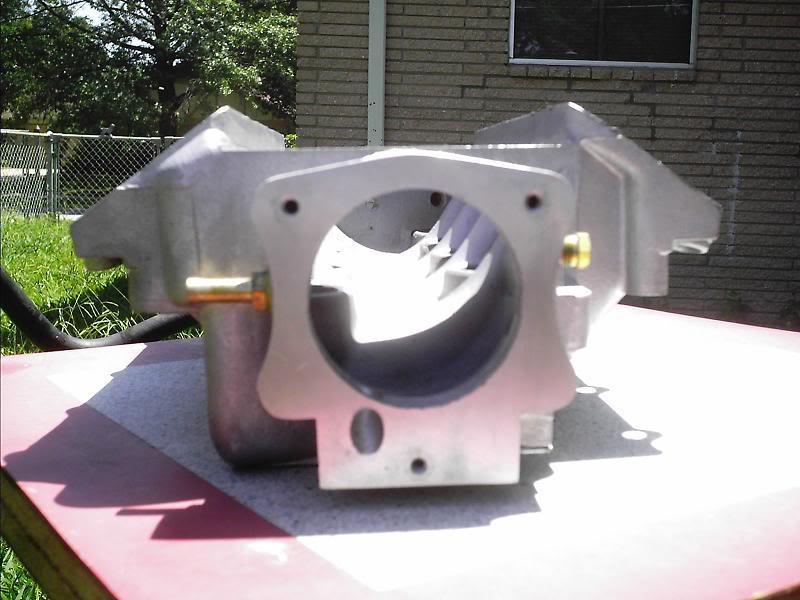

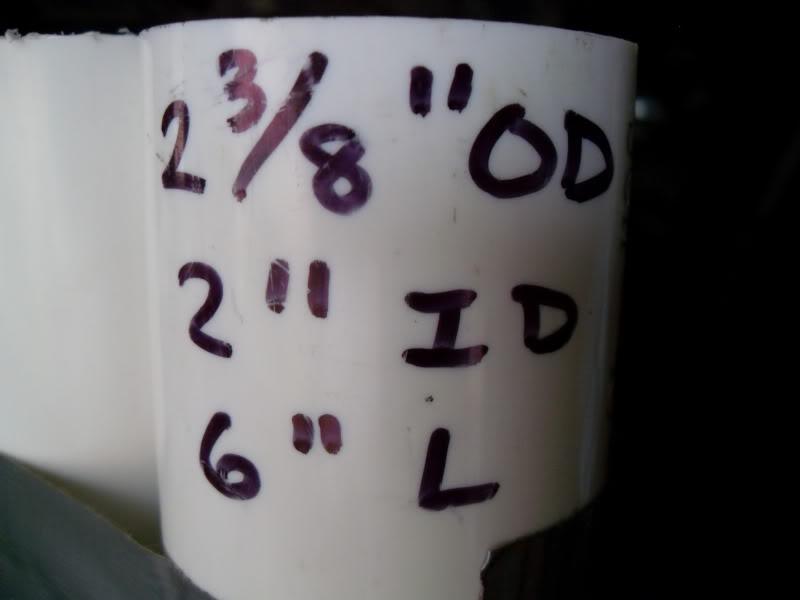

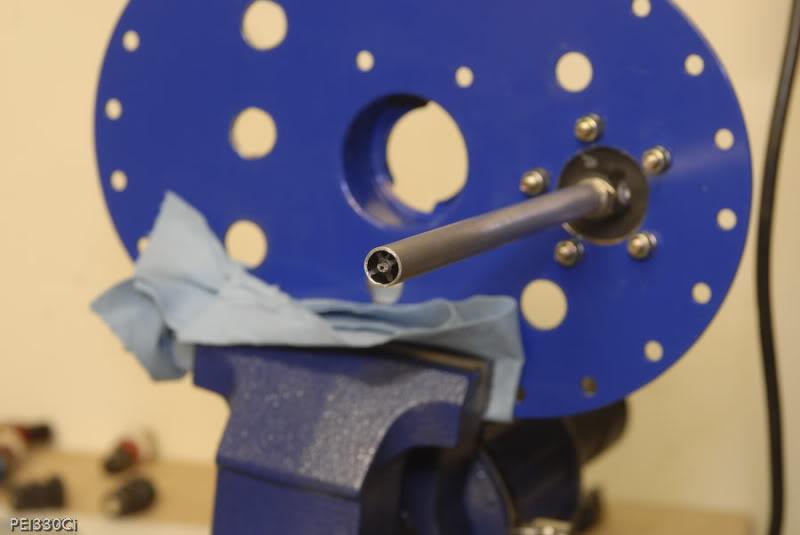

So I finally scored one of these on ebay the other week.

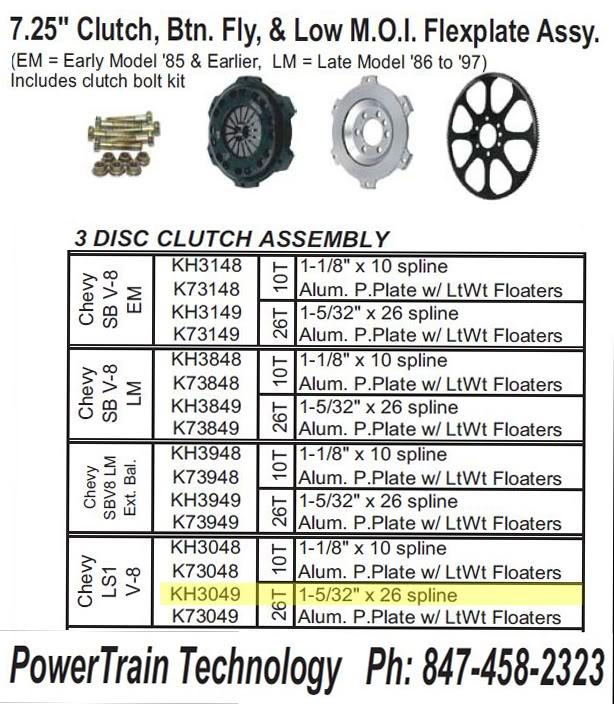

They were originally spec'd out by lingenfelter when they built the spec LS1 motors for the ASA race series.

I think that it's the third one that I've bid on over the last three years. But this one I won! It is a single stage scavenge only pump that was built by razor. Razor is a little unique because their pumps internal gears have fewer teath and therefore (supposedly) flow more oil for a given section length. But another neat feature is that they make crazy deep section lengths. This single stage is a whopping 1.825". Trust me that's big in the world of dry sump pumps. I wrote to razor about a rebuild on the pump and about the possiblilty of adding a few stages to it to increase the crankcase vacuum.

This was their reply:

Dru,

The price to convert your single stage pump to a two stage scavenge pump is $350. The price for a three stage is $479.

This is figuring new shafts, studs, fittings, pumps bodies, and gears for the new sections.

Razor

At first I thought that I would just go nuts and add two more monster 1.825" scavenge stages. At that point I would probably be pulling close to a full 15 psi of vacuum. With that much sucking going on bad things can start to happen to wrist pins (because there isn't any oil suspended in the crankcase air), so then you have to add piston oil squirters. It just kind of snow balls. Luckily I don't have to worry about engine mounts being in the way. But I do have to worry about the lines hitting the starter If I add too many stages.

I'm going to convert my gto oil pan to be more shallow and add a pick up or two or three. Then I'm probably going to mount a big fat oil tank in the trunk. So the beautiful, all steel, moroso LS1 dry sump pan that came with my kit is for sale here on ebay. If you're going to modify an LS1 oil pan, this is the one to have. Trust me, you don't want to be welding on cast Aluminum!

http://cm.ebay.com/cm/ck/1065-29

296-2357-0?uid=85924721&site=0&ver=LCA080805&item=130217297 961&lk=URL

In other news I'm getting ready to move for the 4th time in 3 months come June, and I've been futzing with installing such mundane things as working locks and windows, just in case the car has to sit in storage for any length of time this summer.

That's all...

Peace and Tire Smoke.

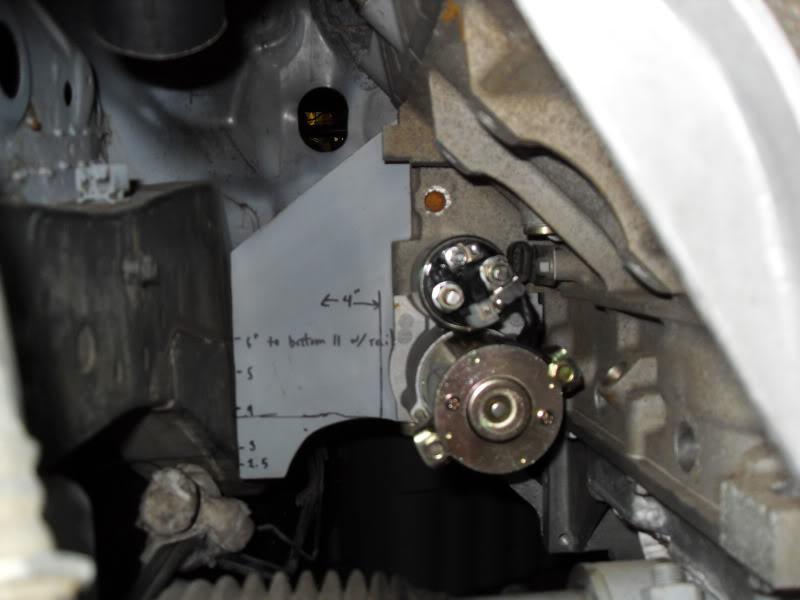

So I got the Razor pump mounted, just so I could check the clearance that I'd be left with if I converted it to a 3 stage. I'll clean up the motor plate/mount later on a mill. There should be zero issue with the starter clearance as I mistakenly feared before.

you can see the passenger side mid-plate (sandwiched between the block and bellhousing) pretty well in these next two:

I finally got around to trying to space out the 05 GTO driver side ex manifold to see if it would clear the steering knuckle/universal joint. Almost... There is a lot of grinding that could be done on the inside of the manifold though, so it still may be possible for anyone looking for a stock alternative. The passenger side will not work from the GTO because it sticks out too far laterally and hits the "frame".

Just for fun before I give them back to TTP (thanx for the loan)!

Twin Turbo anyone?

9/2/08

I found these pics comparing the stock KA 5-speed to the t56 6-speed that's bolted up to the LS1 over on nico forum, as posted by "574-240sx"

You can also see from the pics why you end up having to bash the hell out of your trans tunnel to slide the t56 back up in there.

The stock one is LONGER!!! I never thought it about, but this is why the Hinson kit comes with a steeda long reach shifter, because with their kit the shifter ends up sitting FORWARD of the stock position.

Not to toot my own horn, but now I feel even more special

7/15/08

I've moved to Long Island. My little apt doesn't have real garages available... so I rented one in Queens! Here's the beast getting dropped off. You'll notice the rear sitting low because the F'n Ohlins still aren't here (sent out 11/07)! After ordering just basic rebuild parts from Japan without without actually looking at my shocks (wait a few months), then actually ordering specific parts I needed (wait a few months), and now realizing that those specific parts that showed up are different then what I need I'm presuming that I'm going to be waiting a few months.

8/27/08

Called ohlins again today, the cat that used to "take care of" their parts ordering from Japan, no longer works there...

Talked to a nice guy named Christer who has taken his place. They said that they need to order entirely new shock bodies for the rear. I asked them to look into ordering them with the 300zx spindel mounts instead of the 240sx mounts for me. Maybe there will be a silver lining in all of this frustration. (the 300zx spindles are made of Aluminum instead of iron like the 240sx and save you 3.5 (7?) lbs per rear corner) Christer wasn't sure and said he'd get back to me. I'll keep my fingers crossed.

8/29/08

I already rolled the rear fenders. May be even a touch too much as I think I might need a 10mm spacer in back now for the wheel to look completely flush.

I should have stopped here...

But I pulled it just a tad more. Even though the above looks evil the notion of a rub at 100+ miles per hour didn't sit well with me.

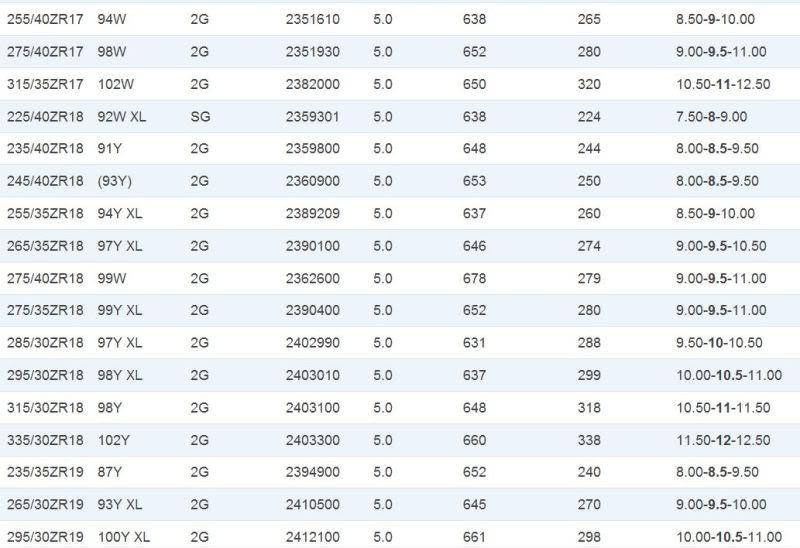

And this just for kicks. AceInHole is running 285s on all four corners! The fronts specifically are 285/30/R18 on 18x10 +20 motegi wheels. I seriously thought that I was pushing the boundries of stock rolled and pulled front steel fenders when I ordered my 17x9 wheels for 255 tires for the front of my car almost two years ago. When I can afford serious brakes that require 18" wheels I will be upgrading to this size tire at some distant point in the future.

I still think that greater than 285 is possible with stock roll/pulled fenders in the rear though. Once the ohlins are in I'll measure the inside clearance to the coilover and let you all know exactly how much clearance is left.

9/13/08

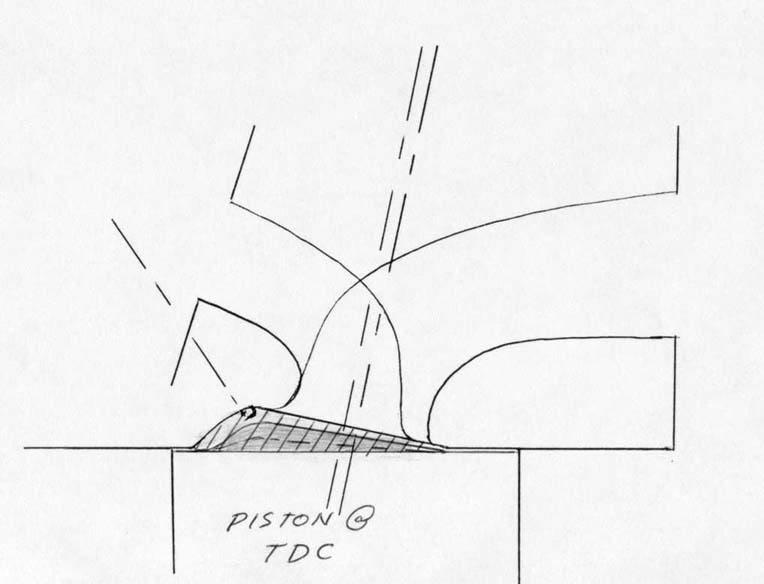

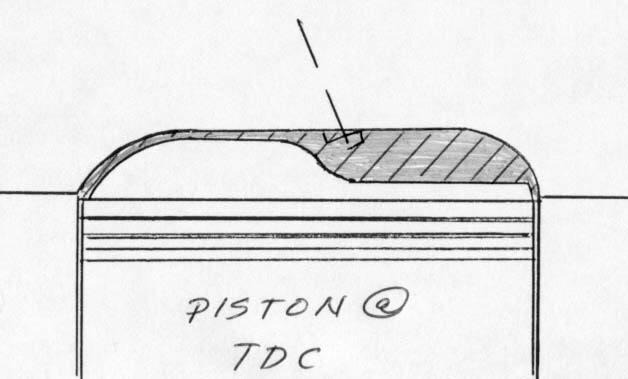

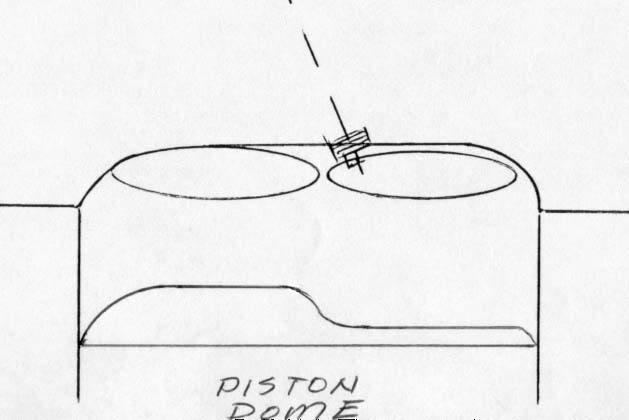

I've been reading up on piston design. I've read a few debates on reverse dome vs. traditional circumferential dish. I was leaning towards a reverse dome when I cam across some writings by Larry Widmer of Endyn.

He has some interesting theories about basically building a reverse dome on the exhaust side of the piston with a regular dome on the intake side of the piston in order to mechanically induce swirl and a better/faster/more localized burn. Even more interesting than his theories are his results! His personal street car is running 13.4:1 compression on 92 octane with VERY little ignition advance (down to 10 degrees), and 300 hp out of 2L with incredibly low BSFC. He originally developed his ideas in the 70s while working on 2 valve nascar heads, though Endyn now seems to specialize parts for N/A hondas.

I've really enjoyed his articles:

The Old One - Energy Dynamics

and here are some pics of his ideas on piston design I pilfered from his web site (I hope he doesn't mind)

I have a set of stock CNC LS7 heads that have been milled to a 63cc cumbustion chamber

What's up with the funny button of material in the chamber just above the spark plug between the intake and exhaust halves of the chamber? I hope some of the head porters stop by.

With the cam that I am considering now with a IVC of 43.5/68.5 @ .050"/.006" lift I am going to need a dish of about 16cc to keep my DCR below 9. I think that might be a difficult piston to design. Especially for these LS7 heads which seem to have the majority of their chamber volume below the intake (which Mr. Widmer suggests I eliminate with a partial traditional dome; even at the expense of intake valve lift!).

Has anyone tried "soft head" style design on an LS or any other engine?

9/18/08

Thanks for the props guys!

I've been having a lot of fun getting into the nitty gritty of suspension design and engine building with this project.

As much as finishing the project is a major goal, so is learing as much as I can. Someday I'd like to take what I've learned hear and build a one-off, half ton, single seat commuter car. One thing at a time.

I've been following dent sport's build for a long time. I'd like to do a lot of the same type of events as he's doing. Like time attacks and hill climbs. I've printed out red lines rules regarding cage design and other things, as well as nasa's, and while I was at it the NHRAs (all though it seems they will allow most things if they were built to the rules of another sanctioning body).

Check out dent sport's build here

DSG 240RS Updates...still a ways to go

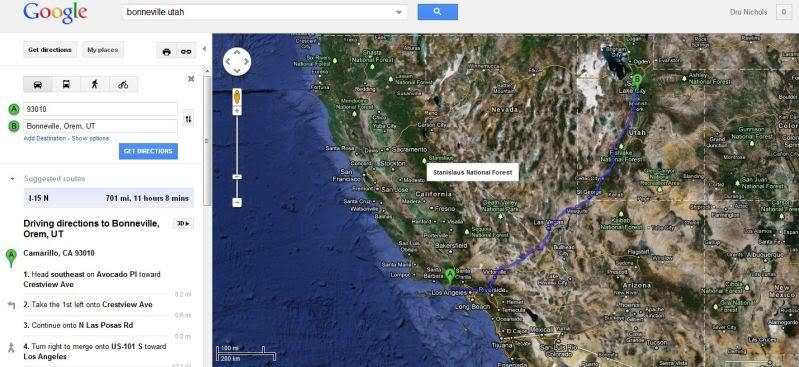

And something else that I would love to do is buy a rally computer and go do a targa with my pops. Oh and Bonneville has always been a dream, maybe the silverstate classic, or maxton here on the east coast. My grandfather used to race a model A at the dry lakes is CA when he was younger than I am, I'd love to do that too. I just want to go have fun and have the fastest car I can build. I've got a lot of dreams!

check out targa Newfoundland here:

Targa Newfoundland - It's About the Drive

-=Peace and Tire Smoke=-

9/19/08

David Vizard had a hand at MTI in the development of their LS7 head porting program. He wrote a short article about it here:

7 Liter Corvette Heads - can they be improved upon? - GoFastNews.com - All Racing News All the Time!

They obviously removed the little pad above the spark plug! If it works for David Vizard...

Also, after not calling me back I called Ohlins again the other day. They don't think that they are going to be able to hook me up with a 300zx style rear-bottom mount even though I need entirely new shock bodies back there! I'm about to change my avatar.

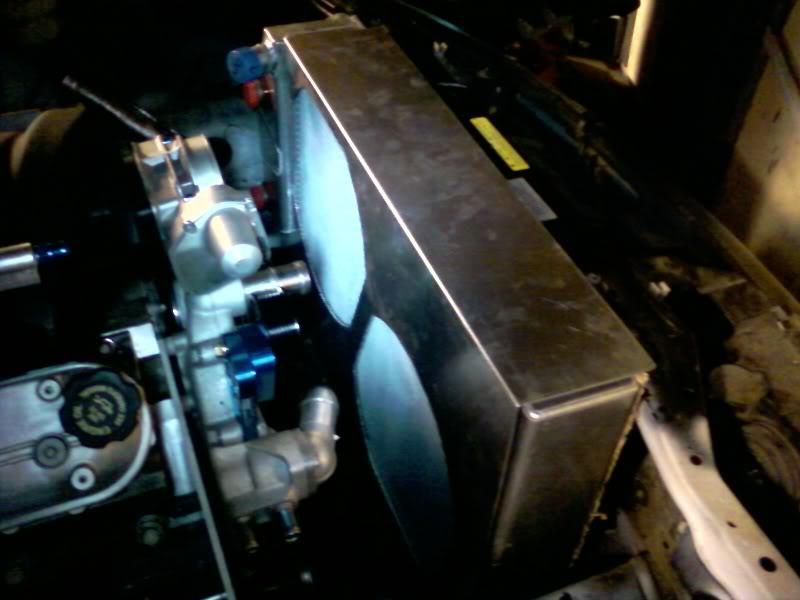

I found my radiator on ebay, although monster motorsports is a good source also. Mine was custom built for Hendricks motorsports for a nascar qualifying car, but never used. Scored it for $260 (they are about $1300 custom/new)... twice because the first one I found UPS threw over my fence and destroyed it. There's only 26-27" between the frame rail which is much more narrow than 90% of the nascar radiators. But we have more room verticly. Also beware of the built in oil to water oil coolers because they will prevent you from putting any angle/v-mount because of frame rail clearance issues. The welds on the C&R are amazing. But beware of superspeedway radiators with >15 fins/sq.in. they may be a little too dense for street use. Mine is 15. Also don't go too thick if you don't need it. 5" thick radiators get pretty heavy once they are full of water.

9/20/08

My garage isn't at my house so it might be a while. But there's a reason for all of the kits sitting so hi. The GTO pan forces the block up, and the tunnel forces the engine/bellhousing forward. Banging is a severe understatement regarding what I did to the trans tunnel to get the engine back, and then I strapped my GTO oil pan down to the mill and took a lot of material out.

it's also subtle to see, but I cut out the ENTIRE center section of the crossmember and reinforced it underneath the steering rack.

The only kit out there that I see right now addressing the oil pan problem is Sikky.

For those interested in N/A power, I asked Brian Nutter of Wiseco Pistons to check out my thread on my latest piston dome idea and here's his response from over on LS1tech.

The soft head concept is valid, but there are some things you need to consider. Larry Widmer is a good friend of mine and a good customer. We do the pistons for his 420+ crank horsepower naturally aspirated Honda 4 cylinders. At the same time, you've got to look at Cup and Pro stock engines today for the most advanced 2v technology. These are the people who know the most, but they aren't going to talk about it on a forum. I've seen the CFD combustion analysis they do and it's incredible. Efficiencies well beyond F1 due to them developing against a standard that remains in place for longer than a couple years. Larry certainly stands as a person that got many of these people to start Studying and Thinking about the art.

Most of the present high end N/A engines do not enhance swirl in the intake port. In general, we don't want swirl at the expense of flow and tumble designs are better. To this end, Larry has some interesting features in the Venturi area that act as a vortex generator and induces the air to stick around the short turn of the intake runner.

Where swirl can be accomplished without hurting flow is in the combustion chamber. A Pro Stock engine COULD use a smaller chamber and get a flat top to net the needed compression, but they don't. What does that tell you about mixture motion? We build up dome around the intake side without shrouding the valve (made easier by the cant of the intake valve used on those heads, and the exhaust side of the dome is smaller-but still above the deck a fair amount. I'd say this area is "funnel like" in the chamber and the dome that matches it.

For guys that are truly gluttons for punishment, we've built pistons that had a dome on the intake side and a Reverse dome on the exhaust. It was a nightmare to engineer, machine, and I hope the customer had an easier time of getting it into the engine than we did building them. The pistons were VERY heavy because of the Mass could not be removed underneath the intake side, yet the crown had to be thick enough under the reverse dome side. All in all, it's an excellent exercise, but the heads and pistons almost need to be designed around each other from the start to not shrowd the valves.

So what's a guy to do?: You'll find the easiest way to get good results is to mill the heads enough that a small reverse dome is necessary. Be careful because you CAN hurt flow and that almost always hurts more than the enhanced combustion helps. Speak to your cylinder head manufacturer as the best have flowed the heads at different chamber volumes. Back to the reverse dome- The wall created with this reverse image actually reflects the combustion back to the center of the cylinder for a split second longer resulting in a more complete burn. I have seen this in CFD and in burn patterns on pistons. As always, there are other things that can offset the gains...deep valve pockets may require lowering the top ring and creating more crevice area. Where does it stop! It doesn't!

Our three part numbers k462,k463, and k464 use something we call the Wiseco flow dome. When we went to a multifit pocket to accomodate different heads, it made it hard to hit the negative -3cc volume necessary for many applications. We designed a nifty little dome that mirrored the face of the valves on the intake and exhaust...this left a natural flame slot around the plug area. In theory, it may promote flow around the valves when the piston is around tdc. Because the intake dome is larger than the exhaust, it could promote movement toward the exhaust side, but the PERFECT combination would require a cylinderhead and dome be built in conjuction....literally minimal piston to valve clearance and the chamber sized to net the compression ratio in conjuction with the dome. We have some visuals of this if you want to email me at [email protected] . Larry and I have spoken about him doing flow testing with the piston under the cylinder head in the bore fixture and the valves opened up as they would be around tdc with typical camshafts. For now though, it's unproven to help or hurt. Some day I'll retire and mess with this stuff every day. Until then, take anything I say with a grain of salt.

The SBC has a lower deck height than an LS1. The LS1 also has much deeper skirt. And I built my pan with enough clearance for a 4.125" stroke. Most SBCs are only running a 3.5" stroke I believe. So of course they can have the bottom of the pan sitting that much closer to the block, thus allowing the entire engine to sit that much lower.

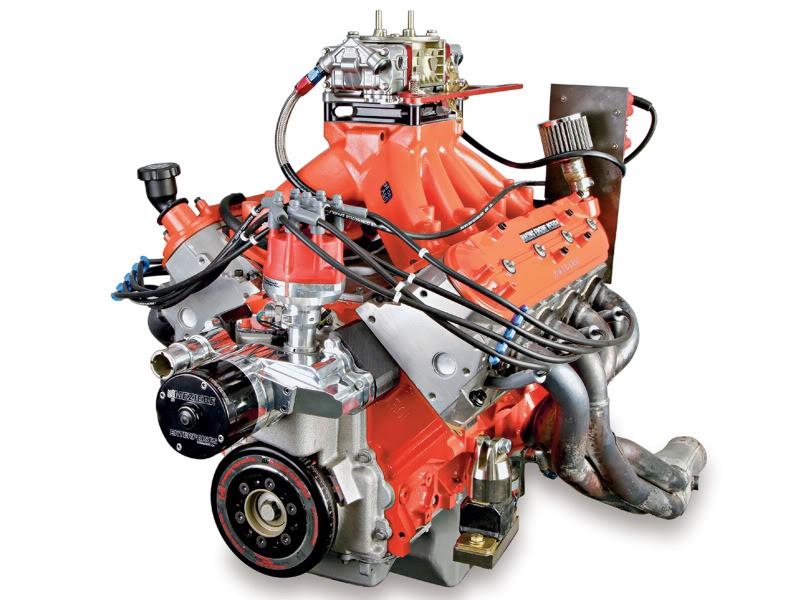

Even with this relatively tall single plane on an LS1 (I'd bet you're intake isn't this tall) you'll notice that the carb base is not taller than the fuel rails.

Also the LSx style plenum under runner intakes aren't as low as you might think. Here's the Al BBK intake for the LS1

These 4 things together, incrementally, make the LS1 look quite a bit taller than a SBC.

And regarding the fire wall. I really did want to cut it, but that would relegate me to a different class in nasa time trials among others. I believe it also forces you to have a heavier cage in other sanctioning bodies.

11/7/08

I couldn't take driving just the explorer anymore and just bought a '95 miata. Don't worry, though, the LS7 nissan is still the priority. I've been going back and forth with both Katech and Oliver Rods, trying to decide between lube tubes or piston squirters. I got worried about small end lubrication with my dry sump cranking at 15" of vacuum. I'll let you all know which way I go.

I take my last exam for a while next week, and started organizing my new garage yesterday so that I can actually move through it without killing myself. I also couldn't take driving just the explorer anymore and bought a '95 miata. It's equipped with pretty much the entire flyin' miata catalog including the Corky Bell designed whipple "Ubercharger U3". It's currently at 9 lbs and is a lot of fun. I called BEGi last week to ask about upping the boost and how to calculate a projected boost level based upon pulley drive ratio. I ended up speaking to Corky directly for about an hour! It was a real treat. I've read his book "Maximum Boost: Designing, Testing, and Installing Turbocharger Systems" cover-to-cover more than once. He was extremely helpful. He walked me through what turned out to be pretty simple math, and we talked about screw supercharges, and improvements he's thinking about/working on for my kit. It turns out that for a relatively narrow range (that I happen to be operating in), the pressure ratio (aka boost) = the pulley ratio. Flyin' miata reccomends not going over 12 psi on a stock 95 1.8L motor, but Corky said 14-15 is in the range of doable with 93 octane and an excellent tune. To that end Flyin' Miata sold me a very small supercharger pulley (67mm) that they had left over (the stoped selling the kit) at an excellent price because the didn't sell many because they don't recommend them. I also installed an LC1 wide band from innovative motorsports. I plan on polishing up the tune before I swap pulleys. The LC1 and new Link Ecu have not been fun to learn. But I shall overcome, and study, and practice until I am of EFI guru status! Once the street tune is done I'll head over to my old shop in New Jersey, TTP for some dyno sessions and precision alignment. They just moved into a bigger/nicer facility in Little Falls and are having a grand opening BBQ tomarrow, if I can pry myself away from this computer, deny the urge to go play with the link ecu, and get enough studying done tonight I might stop by.

Basically Oliver only makes thick I-beam billet rods. The thickness allows them to use some fancy laser to bore two holes inside the rod lengthwise. The holes supply the small end with oil from the mains. Just like with piston squirters, more oil pressure/volume is probably a good thing.

When running a high vacuum sump pump there is no oil being splashed around lubricating the small end of the rod, and failures sometimes occur.

http://www.flatlanderracing.com/olivertubes.html

12/10/08

The lube tube rods showed up from oliver the other day!

And some news from Ohlins... but first I thought that I'd introduce my lastest distraction

A whipple charged and intercooled 95 miata with 220whp! It's a lot of fun. The second pic is not from mine, just what the kit looks like on a pre '94 with out an intercooler.

Ohlins informed me that they have lost my front shocks, including the tein camber plates, and tender springs. And the custom wooden crate that I spent an entire day making and requested be reused.

Feeling trapped and without a lot of options I asked what they planned to do about it and was informed that they would ship me a new set for $1500 which is supposedly below their cost. I asked if they had the newer DFV valving available and was informed... no. Also something that I have mixed feelings on is that they are steel, not Aluminum. I realize that the retail on these things is $3200, but honestly I don't exactly feel taken care of (at $1500) after a year of being dicked around, and not even getting my parts back.

Am I being unreasonable?

What would you guys do?

1/11/09

Ohlins & Cam Update:

There's a new guy at the North Carolina shop Joey, that's actually been calling me back when he says he will. He told me that he recently found my front shocks, but that the tenders, springs and camber plates weren't there (in a storage closet). He called to tell me that my new set is in from Japan finally and he'll try and find the rest of the parts. I told him I want everything back, so he's going to do his best. He's holding firm on the $1500 ($3200 is retail) stating that is below their cost. I have trouble believing that, but I'm not going to call him a liar.

So every thing should be back in my hands by February!

And I'll be putting my original Ohlins up for sale with full disclosure to what ever brave soul wants 'em for $500, when I get 'em.

I've been farting around looking at the most popular LS7 cams and comparing them to what I've been spec'n. Here's what I've gathered about the QM600 & Katech's Torquer:

QM600

Specs:113+X 23X/25X 6XX/6XX (14-24.5 overlap @ .050â€Â)

Carlos from Vette-Air, “QM600 cam have made everyone pretty happy. With bolt-ons and tuning you are looking at 545 to 565 and with ported heads 575to 600 on pump gas!!!â€Â

Peaks at 6500 with very little taper

600.3 RWHP / 534.2 Torque (RPM ported heads)

598 HP / 529 TQ (WCCH ported heads and bolt ons)

564RWHP / 501RWTQ bolt ons

Stock Dyno: 432 rwhp /419 rwtq

Bolt Ons & Tune: 490 / 462

QM600: 555.6 / 485.5

542rwhp and 485 ft-lbs (with only 24 peak timing)

542RWHP 482RWTQ w bolt ons 91 oct (baseline stock was 448 hp though)

Katech Torquer LS7 cam

Specs: 220/244 .615.648 110lsa (usually +4)

(12 overlap @ .050â€Â) From 0 to 4 degrees advance: It increases torque about 6 lb-ft and sacrifices about 4hp

very drivable at 1500rpm in 6th peaks at 6500 rpm. Katech considers it a trade-off for drivability for a loss of power above 6000 rpm. Peaks at ~6400

06 Z06 makes about 500rwhp on a Mustang.

Depending on whose chassis dyno, we have seen 508-557rwhp

And exactly 600hp / 570 lb-ft of torque on an engine dyno.

In judging the aggressiveness of a cam I often look at the overlap first, and the qm600 definitely carries more overlap than the Torquer, despite the wider LSA. It's surprising to me that the qm600 doesn't seem to produce much more upstairs if any!? With both of these cams, it appears no one's made >565 whp without porting the heads on a 427cc LS7.

The cam I'm spec'n right now changes weekly, but for comparisons sake here's what I like today: 236/244 110 +4

If you use David Vizard's chart to determine LSA based on a ratio of discplacement to intake valve area, he states that the ideal LSA of an LS7 would be 108. I think that the LS7 can probably get away with a little bit wider of an LSA due to it's exceptional flow qualities, especially compared to the SBC heads that I believe David's chart was intended for.

Let's compare LSAs:

Vizard's Chart: 108

Mine:110

Katech:110

qm600:113

stock LS7: 120.5

Also from Vizard's Article:

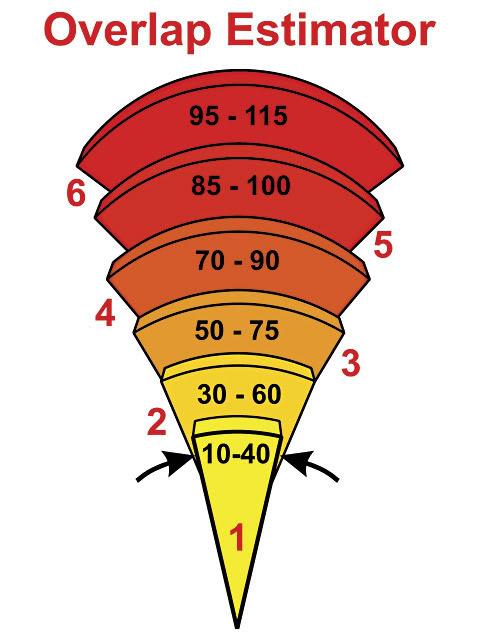

Level 4 is considered the "street/strip" range of overlap given in "advertised" duration (~0.006" of lift). But once again, I think that for the LS7, these values need to be shifted a little more conservatively.

Let's compare the overlaps @ .050" lift

mine: 20 (69 @ 0.006)

qm600: 14-24.5

torquer: 12

stock LS7: -20

Per Vizard's chart (via overlap alone) my cam is so mild that it doesn't even qualify as a street strip cam! And the Torquer (and probably the qm600) is/are even more mild still. Katech has some videos on you tube of a c6 lugging along on the freeway at 52 mph in 6th gear @ ~1500 rpm. This mild overlap is probably part of the reason these cams are touted as being so "driveable".

Let's compare IVC ABDC @ .050" lift

mine:44 (68.5 @ 0.006)

qm600: ~44- ~52.5

torquer: 36-40

stock LS7: 42 (~66.5 @ 0.006)

I'm used to looking at LS1/LS2 cam numbers, and when I first sat down to spec out my own cam I thought that I had an extremely late IVC. For reference: Patrick G once said IVC no later than 46 (maybe 48?) on a 346 w/ 241 heads. I also presumed that the stock LS7 cam would never have a late IVC with its smallish 211 intake duration. But, interestingly, it's massive LSA of 120.5 pushes the IVC within 2 degrees of my cam! Even more interesting, you'll notice that Katech's cam has an IVC even earlier than the stock LS7 cam! So that's why they call it the TORQUER! Installing that cam, has the same effect upon your dynamic compression ratio, as milling the heads!

Re: future changes?

Before this is over, I may add a touch more exhaust duration, and reduce the advance. I don't know, we'll see!

One more thing I just noticed:

Katech's torquer cam raised the LS7s DCR from 8.5 to 9.1!

And this is still on pump gas! Wow. That goes a long way towards illustrating how good the quench and heat dissapating properties of the LS7 are engineered. A lot of the engine masters challenge engines seem to run with a DCR of right about 8.5. Very few people claim to run around on pump gas on the street with a DCR >9.0:1.

1/14/09

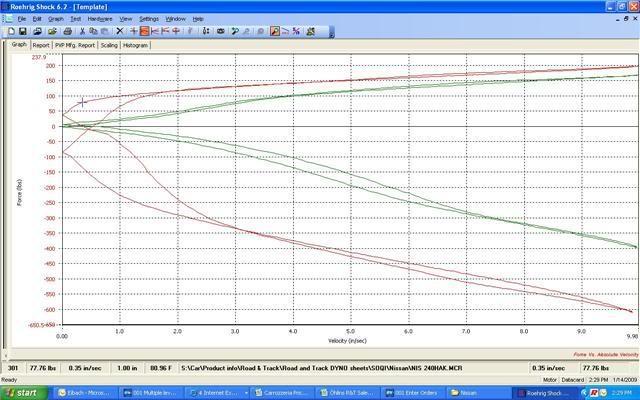

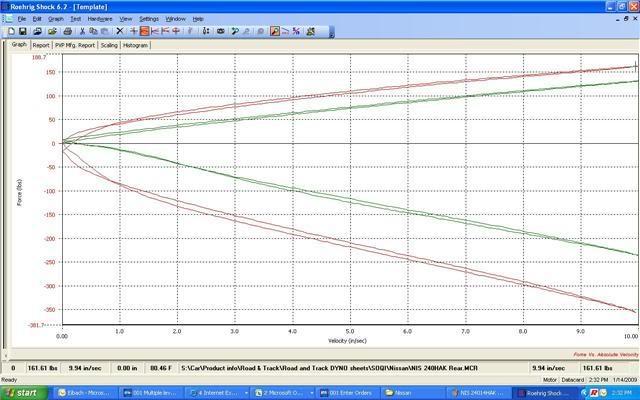

I spoke to Joey at Ohlins USA again today. Here are the Shock dynos from my new coil overs. He told me that they put 'em up on the dyno when they first go in because they had never seen these before in person, and were wondering what they would do.

There are runs for both rebound and compression at full soft and full hard (thus the 4 lines per graph). I'm hoping to get a dyno graph at each seperate setting for each corner later, mostly to just match the dampers left to right. Ohlins assures me that they will be the same L2R, but I'll believe it when I'm holding the graphs in my own hands. I'll shoot some PMs to those that know more about reading these than me and we'll all see what we can learn.

Fronts:

Rears:

1/15/09

Tim,

What exactly are CVP files? Will I need a special program to read them? If you click on the pictures above they get a little bigger, at least enough to read the velocity and force axis numbers. Lemme know I can call Ohlins later today.

David,

I was half joking when I made that post, and I've always loved the lay out of the s2000 no doubt. Matter of fact the s2000 is set up a lot like an old 240z. But if you want to get technical, it's safe to say that my engine's cg is behind where a front axle would be, so... It's all semantics, regardless, these things rotate great when all is said and done. And even with my monster radiator I'm hoping to have <53% of the weight on the front when complete. We'll see!

That post was actually a copy of a post I made for MMDB's LS1tech thread about his LS1/240sx build

My 240sx / S14 LS1 Swap - Progress *56k beware* - LS1TECH

MMDB post 264: "Update: It's been bout a year since I've completed this swap. The swap has proven to be very rewarding reason being I haven't had the engine fail on me and I've been able to have fun with the car almost every day going to and from work (30 miles each way) and more. What I want to bring up now is handling. GIGPUNK's post (261) illustrates the position of the motor within the chassis, which leads to a few things. First off, the t-56 being heavier allows the 240 to rotate much more. This could be good, and this could be bad.

In my case I was running 11kg / 9kg spring rates front and back respectively, which proved to be TOO stiff! This was bad. The car found itself difficult to plant the rear tires under acceleration. During corner exit as well, the car wanted to slide out.

What is good is that the car WANTS to rotate. But with such high spring rates it's difficult to put down the power and the car just wanted to slide whenever applied.

To counteract the negative affects of oversteer and prevent it I dropped the rear spring rates from 9kg to 6kg, and dropped the front from 11kg to 9kg. I also lessened the rebound dampening (my shocks do both rebound and compression) which allowed for smoother weight transfer during mid-corner to corner-exit transition. Removing the sway bar in the rear helped a lot as well (basically a sway bar increases spring rates during lateral weight transfer).

I thought this post might help whom ever is battling this issue and wants more grip. Of course there's many other ways to tune the suspension such as running a bigger sway bar up front, but for my purposes changing spring rates was more convenient for me. "

You'll also notice that Wikipedia lists my car as being FMR

Mid-engine design - Wikipedia, the free encyclopedia

Oh I bust me up.

1/20/09

Backspace & frontspace!!!

This is a repost from one I made for the max rubber thread:

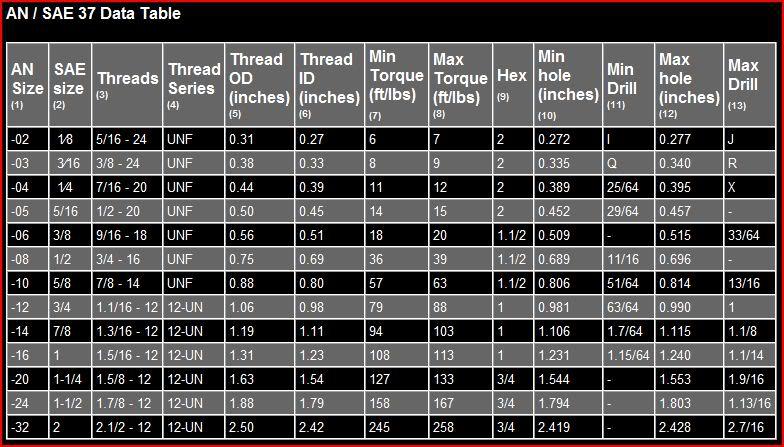

I think the reason that this topic seems so hard to nail down is that there are really two dimensions to a wheel that you need to know on a 240sx, one objective, one subjective.

The objective measurement is the distance from the hub face till you hit something on the inside (like a control arm or the strut). This is also referred to as BACKSPACE. This distance really doesn't change much, even between s13 and s14. Sure an 18" wheel may have a bit more clearance than a 16" wheel to the control arm, and 5* camber may get you in more trouble with your strut before 1.5* will. But for the most part, this number doesn't change, and is what we should be comparing!

The subjective measurement is the distance from the hub to the outside of the wheel. I've never seen this distance labeled on a wheel diagram, so I'm going to call it FRONTSPACE. This is the only thing that should be changing depending on overfenders, stretch, monster rubber/buldge, S13 vs. S14, roll, pull, etc. I find FRONTSPACE to be a matter of taste, as such it should be calculated from proper measurements and good wheel/tire size with accompaning pictures as have been provided in this thread already. Bust out the calculator people!

Once you know what the max backspace IS, and what frontspace you WANT: bust out the calculator again, and you've got your max wheel.

Almost all of these pictures and descriptions were pilfered from this thread. I'll break em up by front and back, because I'm trying to define max backspace per end with this post.

FRONT

backspace 153mm

I think that this first picture is the most helpful. Yes the wheel is hitting the strut at exactly 153mm, but it wouldn't be with shorter springs/taller ride height/small spacer.

backspace 157mm

backspace 149mm

backspace 157

backspace 159

REAR:

backspace 172mm

yall may not be impressed by this cat's "flushness", but the sucker goes deep!& those are 275s (on 17x9.5 +39), look how much room there is on the frontface still, and those fenders don't even look rolled! This echoes my earlier post that there is no excuse for an s14 to be rolling around on anything <275s in the rear.

backspace 173mm

Again one of the most helpful pictures that our fellow zilvians have bestowed upon us! Basically this tells you that unless you're running skinny ass stock type dampers, or relocate your rear damper, that you will NEVER get much deeper than a 178mm backspace!

proving my backspace is universal idea here's a couple s13 pushing the limits:

backspace 173mm

backspace 174mm

Putting this together took a bit of work, but we now have half the equation.

MAX backspace Front~ 150-159mm

MAX backspace Rear~ 172-179mm

Calculate the backspace, of a zero offset wheel by multiplying your rim width in inches by 12.7mm/in

9in x 12.7 = 114.3mm

Add that number to your current offset to get your wheel's actual backspace.

114.3 + 22 = 136.3 mm

subtract your back space from the theoretical max posted above to see how much clearance you currently have on the inside. or just get under your car and measure it with a ruler/caliper. I predict you'd find these clearances if you did so. Let me know if you find different.

rear 172-136.3= 35.7mm

front 150-136.3= 13.7mm

1/23/09

I went crazy and figured out the max wheel/tire that could be put under a 240sx. There have been a million posts asking, "will this wheel/tire fit?" Now you know.

MAX backspace (Same for s13 and s14)

Front~ 150-159mm

Rear~ 172-179mm

MAX Frontspace [backspace + frontspace = wheel width in mm]

S13 Front 95-105 (looks great at 99)

S13 Rear 80-95

S14 Front 109-116

S14 Rear 97-117 (110 really is perfect with a good r+p)

I also downloaded the Roehrig shock/spring dyno software and thought the displacement graphs might be helpful to some in addition to the above (post 155) velocity graphs.

front

rear

I think it's interesting (and probably most usefull) that the adjusters only significantly affect the low speed damping. The small change they make in high speed is one of the few faults I can see in the ohlins; at high speed the adjusters actually do the opposite of what they are supposed to, but to such a small degree (percentage) that I don't think it is significant. Anyone disagree?

1/28/09

I'd like to share with all of you a quote from my chief of surgery, "Are you functionally retarded?"

That's all I have to say about that...

In other news, here's some new pics:

The Oliver rods came back. Oliver is a class act! Every rod came back cleaned, oiled, and with each rod individually sealed in a heavy duty clear bag. Here's a pic of the recently added lube tubes.

To the front face of the block was 14.125" behind the core support. I think that distance would be a little bit more in an s13. Also notice how rust/battery box free my engine bay is! Drilling that tray out was not fun!

I was asked to quantify my blocks placement so here ya go. Looks like a little less than 7" from the top of the block to the seam. With a 2" cowl I'd have a whole foot of clearance!

At the front/top edge of the block I currently have 8" to the bottom of the hood. This high mount alt actually fits! But my GTO alternator is too big for the f-body alt bracket, so custom mount to the lower, driver side motor plate is coming up. Anyone need a billet, passenger side alternator hi mount for (I was told) a vette offset?

Hey guys I'm trying to figure out the length of the spacers that I need to mount the alternator to the motorplates. I measured the above alternator mount that I randomly got on ebay and will not be using. It puts the inside of the belt exactly 4" from the front of the block. Anyone know if that is F-body or Y-body offset?

I finally paid for the ohlins today, it looks like they really did loose my rsr springs, tender springs, tein camber plates, and custom heavy duty crate. They are going to give me some new tender springs as I was planning on using them on the miata, and they knocked another $100 off the price. That won't exactly cover another set of camber plates and springs, but it's time to cut and run.

And this is bitchin: Active aerodynamics for your track day car!

http://aeromotions.com/gallery/

I also have gotten tired of running to home depot to not find the bolts that I need and am thinking of getting a monster/complete set of nuts and bolts from Fastenal

3850 Pieces Asst. Bolts Nuts and Washers M4 to M12 | Fastenal

I've also been sourcing endlinks and threaded hex rod so stay tuned for some custom sway bar endlinks and home made adjustable suspension arms; part numbers to be included!

3/5/09

Ohlins showed up today. Here's some pics of the parts and part numbers.

Looks pretty fancy http://www.carrozzeriajapan.co.jp/ohlins/4w/pcv.html

I can't make sense of these Germen sourced Eibach/Federn spring codes that came with the camber plates and helper springs.

I'm pretty sure the rears are 2.5"/65mm ID x 10" tall 6kg, and the fronts are 60mm ID x 8" tall 8kg.

And just when I thought my ohlins were expensive:

http://performanceshock.com/index.ph...roducts_id=807

and

http://performanceshock.com/index.ph...roducts_id=561

no more complainig.

3/6/09

The same thing happened when I priced out aurora bearings for my sway bar end links. Not even using the high-mis-alignment stuff the price came to about $37 per corner.

AW6 3/8_24 female steel rod end $15 x2

Steel jack screw at midwest control products $1.62

Aluminum spacers and grade 8 bolts $5

It turns out mazdaspeed sell the same thing for $39.

I ended up just ordering the mazdaspeed ones from goodwin racing to save myself the time of sourcing the spacers, nuts and bolts. I also ordered some extra boot protectors from seals-it that I'm going to fill with some synthetic brake caliper grease just for corrosion protection.

Seals-It

Even though the US economy has seen better days, it seams that most the rest of the world is doing a little bit worse. We are doing pretty damn well against both the yen and pound, which makes these a pretty damn good deal:

Driftworks Lower Arm Front And Rear S13 S14 S15 R32 R33 R34

With current exchange rates these come out to about $615 before shipping for all four corners! I'm pretty sure these are what Bill from DSG is running in the front, and these guys have an excellent reputation in Europe. Plus, then you don't have to actually do any work, or make any delrin bearings.

3/11/09

I got the mazdaspeed ball-end, sway-bar, endlinks and am a little dissapointed. Originally I priced out low offset aurora ptfe lined female ball ends with male jackscrews that came out to about $35 bucks. But I didn't want to bother figuring out what size spacers I would need, and tracking down the hardware. I've never read a bad review of the mazdaspeed miata endlinks and at $39/corner thought they were a good deal.

These are some cheap ass endlinks

Both the front and rear parts use the same spacers, ball-ends, jam nuts, and bolts. But the rears use a slightly shorter steel turnbuckle vs the fronts loosely threaded aluminum hexlink. Both for the fit and finish and for the couple extra mm shorter adjustment range I'd order 4 rears and use them on the front too.

The ball-ends are really loose, unlike quality ptfe lined ball-ends, and there is probably a thousandsth or so of play in them.

I used Seal-it rubber boots to protect them and filled 'em with a little synthetic brake grease. The Seal-it boots are a quality product. But seem a bit pricey at $5 apiece. It's a bit of a puzzle to get them on the first time, but the rubber is super tuff stuff. Just grab some plyers and go to work. I'm just going to keep my fingers crossed, and hope that they last a while. Hopefully the boots will buy me some time.

3/14/09

from post 170

MAX backspace Front~ 150-159mm

MAX backspace Rear~ 172-179mm

When I made these determinations

I was taking advertized wheel widths, deviding by 2, and adding the advertized offset to calculate backspace. As cnichols recently pointed out to me, that only gets you the backspace to the inside of the inner lip! True backspace is to the outside of the wheel, not the inside of the lip that holds the tire.

This picture should help explain:

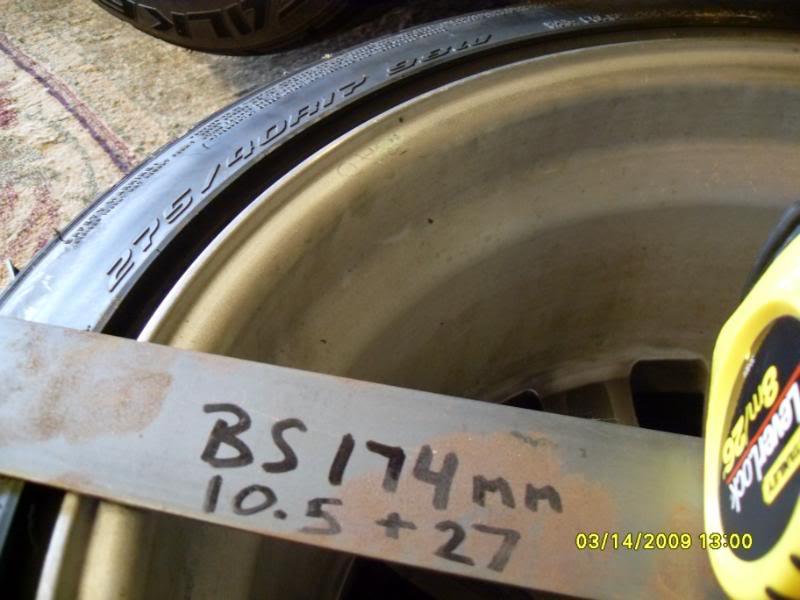

This is a pic of my rear wheels 17x10.5 +27.

Using my previous calculations would yield a back space of

(10.5x25.4)/2 + 27 = 160.35 mm

which is 13.65mm off from the actual measured backspace of 174mm

So how well does a 174mm backspace 17" wheel fit the rear of an s14?

My new Ohlins shock body is 49.7mm in diameter and sits exactly 13mm from the above wheel.

And 22.8mm from the front edge of the lower control arm

and no clearance issues to the rear

With the coilovers up high no problem

With them low... uh...

sill clears, but...

So if you're about to order a new set of custom CCW wheels what backspace to you ask for? Less than 174+13= 187 (7.362")

Max Frontspace with stock fenders: (calculated using my old method)

S13 Front 95-105 (thatguy looks great at 99)

S13 Rear 80-95

S14 Front 109-116

S14 Rear 97-117 (107 really is perfect with a good r+p)

So far I've only done the roll and pull on my drivers side rear fender.

I took this measurement directly below the back edge of the rear window.

Looks like my R+P gave me an extra 38mm over stock. Presuming both sides have the same depth of well. And It damn near looks stock too!

Stock Passenger Side

My current front space, from hub face to outer tire edge is

(25.4x10.5)/2 - 27 = 106.35mm

I probably could use a 10mm spacer and still be fine with my fender clearance, but I doubt that I could pull the fender much more without it looking weird.

So lets call it a max frontspace of 115mm and a max backspace (only to the outertire edge) of 170mm would yield a wheel 285mm (11.22"). If you go any bigger you're going to have to do something drastic to your fenders. Also, to pull this off, your coils will probably have to sit higher than the tire.

I would really like to own the redline time-attack street class some day. The current rules only allow tires upto 285s, and forbid inboard/cantilevered dampers. I think that a 11.22" wheel would be perfect for 285/30/18 tires. Personally I'd order up four of them all with the same <7.362" backspace and just use whatever spacer and fenders are necessary in the front.

I've also been hunting for an inexpensive cast wheel that that would come as close as possible to this. I was looking at the rpf1, but it only comes in +15 (wasting a lot of space). The knock off ford wheels come in 18x10 +27 but I've heard that they weigh 31lbs! The closest thing that I've found so far are the 18x10.5 +30 Enkei nto3+m; they weigh less than 22lbs and cost around $350 a piece.

4/18/09

Builds been on a slight hold while I'm preparing for a liscensing exam. But yesterday I went with my girl to this really nice seafood restaurant here in Long Island. It's finally crested 69 degrees here in the NE, and we took the miata with it's supercharger and Link fuel management computer. The valets were standing there but I just parked my self anyway. And as we were walking into the restaurant they were kinda pushy about getting my keys. So I finally just handed the Dick my keys not wanting to make a scene, for my girls sake. The aftermarket ECU surges a bit, doesn't like light throttle, and requires ~30 seconds of waiting in the accesory position to turn on, prime the fuel pump, and sync the cam and crank angle sensors, before it will let you ignite the engine.

We had a great dinner and when we came out instead of getting bent out of shape, I just handed the Dick my valet stub, then whispered to my girl, "Watch this, this is going to be funny." Of course the Dick couldn't get it started, my little miata is parked between some $100k Mercedes and Jaguar turning over and over. We both laughed as the Dick came back with his head held low and handed me back my keys without looking me in the eyes. Then we hopped in the car, and because I waited the requisit time before turning it over, it started instantly. All the valets were watching as it started right up, and with a little creative clutching pulled out as though it was dead stock. As I drove past the Dick I said, "There was a reason I didn't want to give you my keys." My girl thought that was a good show.

4/24/09

Well I'm mad cash strapped until I get a job after I graduate in June, so I put some parts up for sale on e bay. The Ohlins are up for sale if you think you're crafty and can get them back together with a reserve of $100. I'm probably also going to list my black billet hi mount alternator bracket, and c5 throttle peddle with TAC.

eBay Motors: Ohlins Nissan 240sx coilovers S14 JDM silvia springs (item 130302376520 end time May-01-09 13:54:26 PDT)

I also rolled out to the weekly car gathering in the parking lot of Best Buy in Woodbury last night. I couldn't believe how many guys rolled out there. Good time, smelled like gas and burn outs.

5/19/09

So I'm starting at the back.

So I left my stock s14 fuel tank back in CA when I moved to the East Coast. It's actually a pretty good design and if it was still here I'd probably use it. Most of the stock tanks volume sits above the diff between the rear shock towers, then has two legs that go forward and below the rear seats on either side of the drive shaft.

My idea is to try and get the weight of the tank a bit lower and further back. I also want to build my own rear diffuser. So originally I was thinking of cutting out the bottom of the trunk, and making a custom aluminum tank whose bottom doubled as the majority of the diffuser.

My dad was pointing out that aluminum tanks should probably be rubber mounted to reduce the likelyhood of fatigue cracks which Aluminum is susceptible to. Anyone have any experience with aluminum gas tanks?

So what does a fuel tank have to do with the exhaust? Well with the sides of the drive shaft space open there is extra room for my expansion chamber and cats.

From Random Technologies Website: "...a 3" diameter 7000 series SuperStainless catalytic converter flows 617 cfm. Most 3" diameter high performance mufflers flow less than 475 cfm at the same test pressure."

I also found these test results where 2.5" aftermarket cats were tested and compared to stock LS1 f-body cats.

Table 1

CFM @ 20.4â€Â H2O

CFM @ 28â€Â H2O

Passenger Side Catalytic Converter

299.5

350.9

Driver's Side Catalytic Converter

268.3

314.4

TTS Bullet Catalytic Converter

277.1

324.6

Carsound Catalytic Converter

372.7

436.7

FLP Catalytic Converter

376.0

440.5

First a word on CFM flow rates. Heads are usually flowed at 28â€Â H2O, while carburetors are usually rated at 20.4â€Â H2O, and my hero David Vizard rates exhaust flow CFM at 20.4â€Â H2O. By the looks of things Random Technologies rates their cats at 28â€Â H2O.

But why care about cats on a 700hp v8? Redline time attack street class rules, that's why. Oh and they are way more restrictive than you might think.

David Vizard’s research shows that 2.2 cfm of flow at 20.4â€Â of H2O will support 1 horsepower. 2.2 cfm is the optimum flow through the exhaust keeps horsepower losses under one percent.1 Removing the stock catalytic converters on the LS1 usually results in a gain of 8 rear wheel horsepower.

FLP or Carsound = 373cfm

373/2.2= 170 hp per cat (w/ 2.5â€Â i/o)

Random Technology 3" diameter 7000 = 617 cfm (probably 524 cfm @ 20.5" H20)

524/2.2= 238 hp per cat

Now it should be a little more clear.

If you're rolling a single cat, you have a restriction if you're making over 170-240hp, regardless of which fancy pants stainless "race" cat you're running! Bogus!

This also means that if I'm running FLP aftermarket race cats that I would need 4 (3 if I ran the randoms) of them in parallel to build a truely free flowing exhaust! I've never seen anyone run cats in parallel. The reason for this is either cost, space, or you can't get enough heat into them. I dunno.

To make sure that street class participants aren't running gutted cats, redline states that they will use infraread thermometers to make sure that your cats are lighting off.

more from random technologies web site: "...Under normal operating conditions, the catalytic process doesn’t begin until temperatures inside a converter reach 500 to 600 degrees (F). If air/fuel ratio is on target, and the exhaust is free of contaminants, internal converter temperature stays at about 1200 degrees. But when unburned fuel enters the picture, temperatures can reach 2200 degrees and either burn the precious metals out of the washcoat, or literally cause a melt down of the bricks."

So now the real question is: will three or four parallel cats get up to temperature if they are sitting five feet from the heads with an expansion chamber between them? By definition anything richer than 14.7 will have "unburned fuel". And considering my car will be running richer than 13:1 most of the time, maybe the extra exhaust temps will actually be useful? Redline doesn't say when them test your cats temps. I'm pretty sure I'd be ok after a hot run.

This is getting too long, but here are some pics of preliminary measurements for the rear diffuser/new fuel tank area, and I'll talk about expansion chamber design another day.

This is a pic of a one inch piece of steel stuck to the bottom of the subframe. The piece of steel creates two rectangular spaces about 3"x5" on either side of the diff. Should be enough for four 2.5" exhaust pipes.

would four 2.5" exhaust pipes flow enough for 700hp?

Check this out:

A section of straight pipe the length of a typical muffler, rated at the same test pressure as a carb (1.5â€Â of mercury= 20.4â€Â H2O), flows about 115 cfm per square inch.

open horsepower

pipe supported w/

size single pipe

2.0â€Â D = 3.1 A X 155/2.2 = 218 HP (x4=872 HP, probably a better idea)

2.5â€Â D = 4.9 A X 155/2.2 = 345 HP (x4=1380 HP, yeah should be ok)

3.0â€Â D = 7.1 A X 155/2.2 = 500 HP

3.5â€Â D = 9.6 A X 155/2.2 = 676 HP

4.0â€Â D = 12.6 A X 155/2.2 = 887 HP

Proof Hondas with 4" mufflers are built by assholes.

It seems that diffusers can sit anywhere from 4-14 degrees. Less than 7 degrees to prevent flow seperation/drag unless of course you have a massive wing within a verticle foot for interaction like F1.

So I just took a look at the revised 2009 Redline time attack rule book and it looks like full undertrays are now allowed in street class. The wording on the fuel cell rules is a little strange:

"1.6.4 Fuel Cells permitted (modification of factory floor pan is allowed for installation of

Fuel Cell)

1.6.4.1 Good quality fuel cells contain a bladder constructed of Nylon or Dacron

woven fabric impregnated and coated with a fuel resistant elastomer and

are FIA FT-3 (or higher) rated.

1.6.4.2 The cell should be in a container made of at least 0.036-inch steel, 0.059-inch

aluminum, or 0.125-inch Marlex, fully surrounding the bladder.

1.6.4.3 Foam internal baffling is required, as per FIA FT3-1999 (or higher)."

So it says that fuel cells are permitted, then it goes on to define a good one as one with a bladder. It doesn't seem to expressly require a bladder within the cell though. The rules also seem to say that there "should" be a container for the bladder. Does should = required? Or am I just seeing what I want?

Bladders are around a $1000. I was hoping to get the car on the road without one, with just a custom aluminum fuel tank, then add a custom bladder to it way down the line.

How do you guys interpret the above?

7/9/09

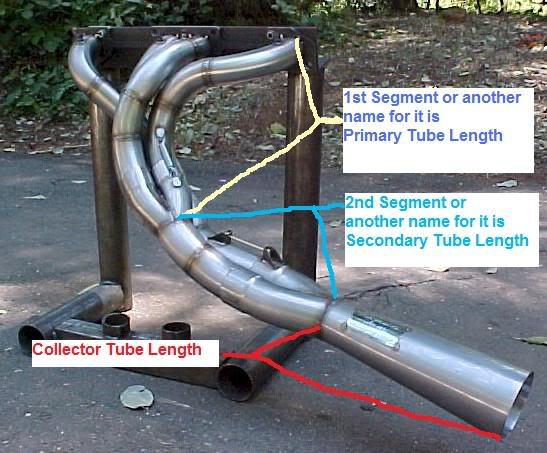

Headers:

I'm going back and fourth between three options:

1. I found these guys Custom Headers Built To Your Specifications

they have a neat idea, they send you mock up kit, you position all the tubes where you want them and mail it back. All said and done in stainless for $1300+s&h with merge collectors. Plus the fact that they purge weld the headers is pretty bad ass.

2. But then I also have an old set of plain steel headers that some guy had for an OLD gm F or B body LS1 swap. They do not fit at all, but I scored them for $100 and figured they'd make a good starting point with the flanges at least. Plain steel headers always seemed like a waste of money to me. I don't care what you coat/paint/wrap them in they will be rusty within a year. Rust isn't the end of the world, but in a car that gets used rain or shine I don't think steel headers last much more than 6-7 years. It would take probably another couple hundred in j bends and collectors to make them.

3. My third option is to just drop the car off at Kooks or American Racing Headers here in Long Island. MINIMUM of $1500, and I'd have the least control over where the collectors end up.

Also, does anybody have any software to help determine tri-y vs 4 into 1, and primary and collector lengths?

7/13/09

So it looks like Kooks is way down in NC now. I called the guys at American racing headers, in nearby Amityville Long Island. They were very cool and said that I could come down and try any of their LS headers (they make like 10 different ones) to see what is closest. And if nothing quite came close enough they could do a total custom job in 5 days for around $2500. That is about the going rate these days. While it's a lot of money. Five days of a professionals time costs. This is a bit of a DIY project though and right now I'm leaning in other directions.

I'm going to do a little multi post series on header design, starting today with choice of materials:

You basically have two choices. Stainless or Plain steel. Most people think that the only advantage plain steel has over stainless is cost (almost %50), but they are wrong! Plain steel is also a bit lighter than stainless! Even given these two advantages I’ve always thought that making headers out of plain steel was a waste of time and money, mainly because plain steel headers rust like motherfuckers. Some would say, “well then just coat it.â€Â

When I was woking at TTP back in Jersey on all the hi dollar LS1 cars, I was lucky enough to become the header bitch. I swapped out a lot of headers! And I don’t care what coating was used ( I saw at least 4 different kinds), rust was visible through the coatings with in a year! Bogus.

“Ok don’t coat it then, wrap itâ€Â you say. While I have to admit that I love the old school hot rod look of fiberglass header wrap, it’s murder on steel headers. It basically acts like a big sponge soaking up whatever oil and water comes its way, and then holding it against the header. Can you say instant rust? While header wrap will reduce under-hood temperatures and improve looks, it also shortens the life of your already ‘livin on borrowed time’ plain steel headers.

Now if you’re building a circle track race car with a short expected life cycle, or you plan on a different set of headers in a couple years, save some bucks and weight and go with plain steel.

In my hopeless attempt a fiscal solvency I thought about going this route, and even picked up a set of steel headers that I thought I would use the tubes from, but obviously I’m having second thoughts. The advantages of stainless include better heat insulating properties, and corrosion resistance. Plus, they look damn nice.

More on header design to come…

7/14/09

What I don't know is: Presuming you know what rpm your top end is tuned for, what rpm do you tune the headers for? The same rpm? A little before or after? How little? Or do you just forget what you know and try to get a bump where you think you'll need it in the powerband?

I thought that it was interesting that in his book on intake manifolds David Vizard seems to pull no punches in stating that an intake is almost secondary/dependent to a good exhaust scavenge.

Here's what I've done so far.

I pulled David's "How to Build Horsepower vol 2., Carburetors and Intake Manifolds" down off the shelf and used his formulas to determine what rpm the stock intake manifold was tuned to.

Based on my measurements:

LS7 stock plastic intake runners (7 of 8, the first runner is shorter)

Outer radius 312

Inner radius 188

Average = 312 +188 = 500mm/2 = 250mm plastic intake runner length

161.5mm tract in head from intake valve to gasket

Total = 250 +162 = 412

412mm = 16.22â€Â total intake tract length

Head ports

Intake: 61x35mm= 2135mm^2 = 3.31 in^2 = same area as a 1.81" square

Then using an effective cam duratio of 260 (a comp XER 238 @ .050 lobe, is 287 advertised - 27 = effective) which is pretty close to what I plan on running I cam up with the following tuned rpms at the respective reflective values:

rpm @1 17459.85401

rpm @2 8729.927007

rpm @3 5819.951338

rpm @4 4364.963504

rpm @5 3491.970803

rpm @6 2909.975669

rpm @7 2494.264859

rpm @8 2182.481752

If I was going to try and match the headers to the intake/cam the 3rd reflected value is the only one that makes sense for me. I'm building this motor for a RWD time attack car that will be limited to street tires. So bottom end isn't too important, and I was actually planning on building the motor to drain a little power down low to pile it on later, towards a 7100 rpm redline when I have a chance of putting it to the ground.

Just a side note. The stock LS7 comes with a 211 @ .050" intake duration. If you presume an effective cam duration of 237 (211 + 51 should get you pretty close to an advertised duration, then subtract 25 to get effective cam duration, cuz intake valves don't start flowing well the very second they are off the seat) the 3rd reflected value comes out at 6110 rpm. Pretty neat since that's about where most LS7s peak even with bolt ons. I guess David's math works!

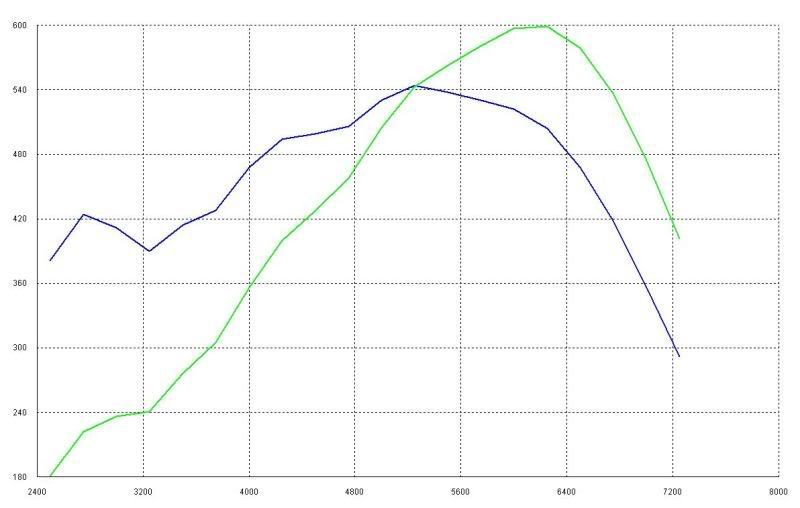

LS7 on the Dyno:

rpm----tq---hp

3000--455--260

3500--467--311

4000--504--383

4500--526--451

5000--529--503

5500--512--537

6000--480--548

6100--472--548

6200--463--547

6300--454--544

6400--445--543

Dyno results stolen from here:

Thanx for reading guys, now what rpm do I tune the headers for?!

Stan helped me a bit over at gofastnews.com

The formula I was using:

rpm * rv = [(720 - effective intake duration) * (.25v * 2)] / (L + .5* intake port D)

I did use 1300 for V. Should I be using 1141? It is a plastic intake, and I will be using a good cold air intake isolated from the engine bay's heat. Your clarification for the port diameter makes sense too. I found this speed of sound calculator

Speed of sound in air and the temperature calculator air pressure - table density of air calculation acoustic impedance air density sea level - sengpielaudio Sengpiel Berlin

115 F makes more sense to me for air deep inside a well fed plastic manifold, which comes out to 1175 f/s

Inputs:

speed of sound 1175

.050" 238

advertised in. cam dur. 287

effective in. cam dur. 260

intake length 16.22

port diameter 2.0529

Unfortunately it look even worse now. I don't need no bumb at 7800 rpm!

rpm @1 15669.89148

rpm @2 7834.945742

rpm @3 5223.297162

rpm @4 3917.472871

rpm @5 3133.978297

rpm @6 2611.648581

rpm @7 2238.555926

rpm @8 1958.736436

But the question remains. Do I tune the headers to the rpm of the intake's RV=3 rpm, or something else?

7/16/09

So I broke down and bought it.

PipeMax36xp2

I think this is the first piece of software that I've paid for in a very long time!

Interestingly enough pipe max doesn't care what your intake runner length is either. Regarding the intake it only wants flows from tb to valve, valve sizes, and cam specs. Luckily I've got that! And then it spits out the lengths where the reflective valves would be optimal, given your flows and cam.

So just like headerdesign.com the intake length is not a consideration in the calculation of the header dimensions.

With my combo it suggests that

RV2=19.5"

RV3=13.6"

Presuming I'm just going to follow pipemax's instructions blindly for the header dimensions, the problem becomes avoiding the old garbage in garbage out. Once all of my inputs were entered I adjusted the VE until the "low horsepower" matched what I expect from the dynos I've seen of similar builds. That came out to about 112% VE (618-670hp). Then I noticed the calculate ve from head flows blurb. And following those instructions was given a VE of 125.8% (735-795hp)! I know these new LS7s are impressive pieces of engineering, but seriously? Which VE do I use?

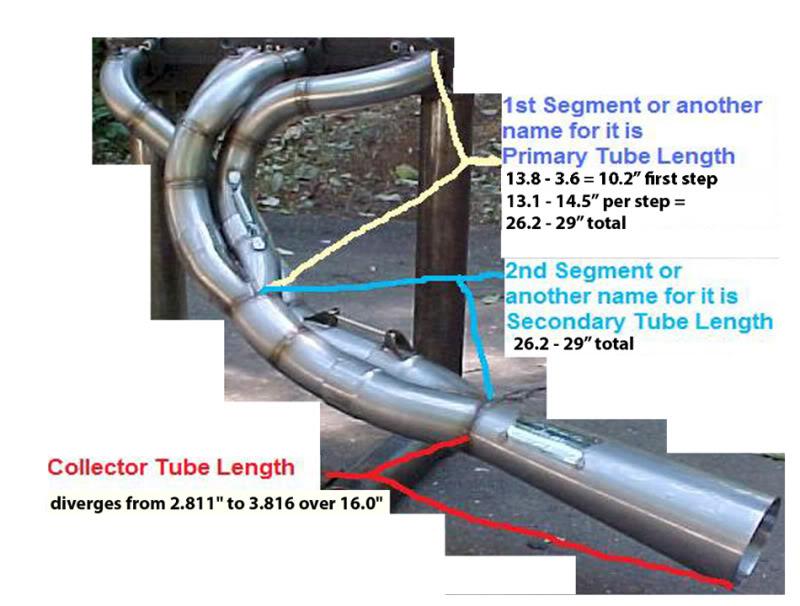

Also, at 112% VE it reccomends the primaries be 1.75" to 1.88" & 28-31" long

While at 125.8% VE it reccomends 1.69" to 1.82" & 26-29" long