You must be logged in to rate content!

10 minute(s) of a 758 minute read

11-10-2012

I lowered the car down on the 215/35/18 front tire, and this represents the ballpark ride height, and it appears the air dam might not be that far off.. I might end up going with a slightly larger tire, maybe a 225/35, but I wont know until the wheels get here.. I dont have any wheels that will fit over the 14in brakes at this time, so the suspension is obviously not loaded, but here are a few pictures of the Air Dam at the approximate ride height.

There is a 4.5in ground clearance with the center of the air dam at this ride height, and I think that is a great start for being a rough and adjustable first mounting, so it could work out just fine. That is if the look is worth the effort of course.. It hasnt quite grown on me, but I think I am getting there, it all the cut outs and hardware works out fine.

I am waiting for a few more of the exhaust pieces to make it in, but here is the X-pipe and flexible joint setup I am planning on running.. As I have said earlier, I will be solid mounting the mufflers and tail pipes to eliminate any chance of body rattle, due to the tight tolerances I have set up with the exhuast tips.

I plan running an electric dump setup for an open exhaust option, but I am going to run the dumped exhaust through the same tips, rather than just exit on the ground underneath the car. I think I have the room, and can do it, by adding a custom Y-pipe just before the mufflers, so the unrestricted exhaust can go through the rocker tips, while bypassing the mufflers..

At this time, it appears that this is going to be the bulkiest part of the exhaust, when it comes to running it back, so things should work great with a ground clearance.. This narrow exhaust setup will fit up in the center floor board relief, and shouldnt be more than a half inch below the pinch weld on the rockers, which is the lowest part of the exhaust.

I was messing with air dam mock up a bit, and I think this will look much better.. I have extened the splitter out about 1.5in further than the bumper, and it appears to give it a bit more dimension, rather than just have the appearance of the splitter just beind cut off at the edge of the body. I have also cut out the brake cutouts, and mocked them up on the opposite side.. Once I feel comfortable all this will work, I will add the steel reinforcement to the air dam for its mounting and splitter mounting, along with make it fit the fenders better.. I will not blend/bond this unit into the body, because I want to be able to remove it and service it at anytime.. I also dont want any ground clearance accidents affecting the body of the car, so it will definitly have to be a seperated piece.

11/12/2012

The wheels are getting closer to being completed, so I can finally set this car back on the ground. I dont have any wheels that will fit over the 14in/13in front and rear brakes, so I cant wait to get them in.. You can see the custom logo'ing that is being done, and along with that, the center caps will have the Swedish Ops (Special Builds Division) logo.

After all that is done, they will then be done in a Brushed Aluminum finish and clear coated, for that Unfinished Machine look the rest of the body is going for..

All the cool stuff should start coming in shorlty, so I will have some great update really soon..

11/13/2012

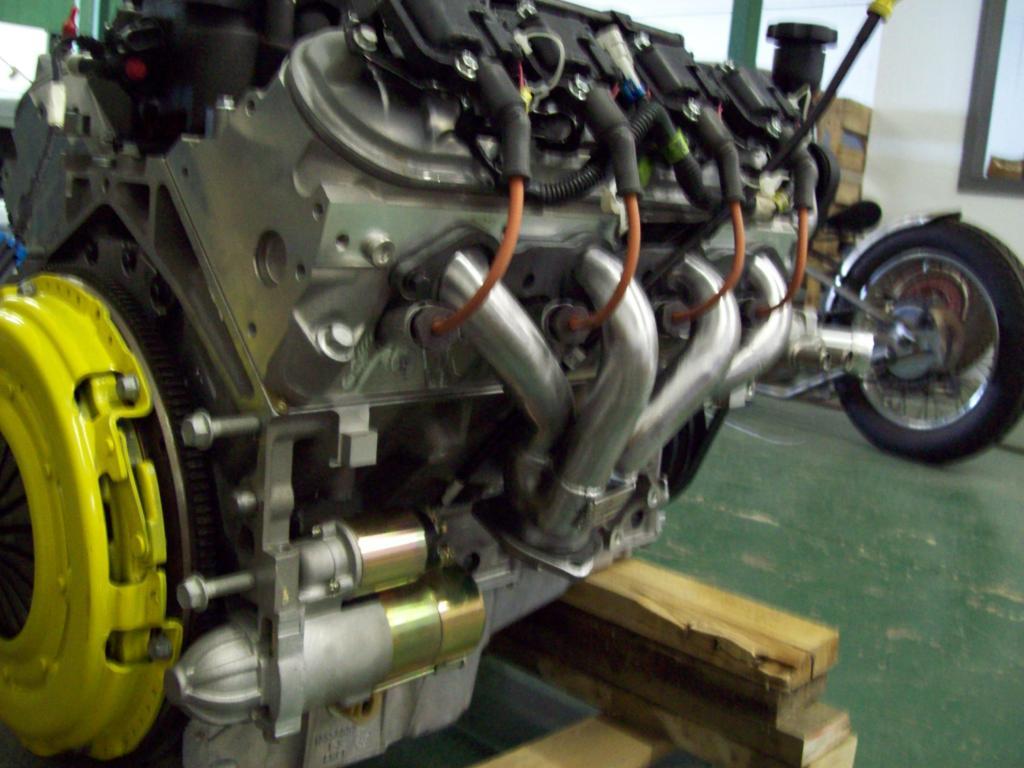

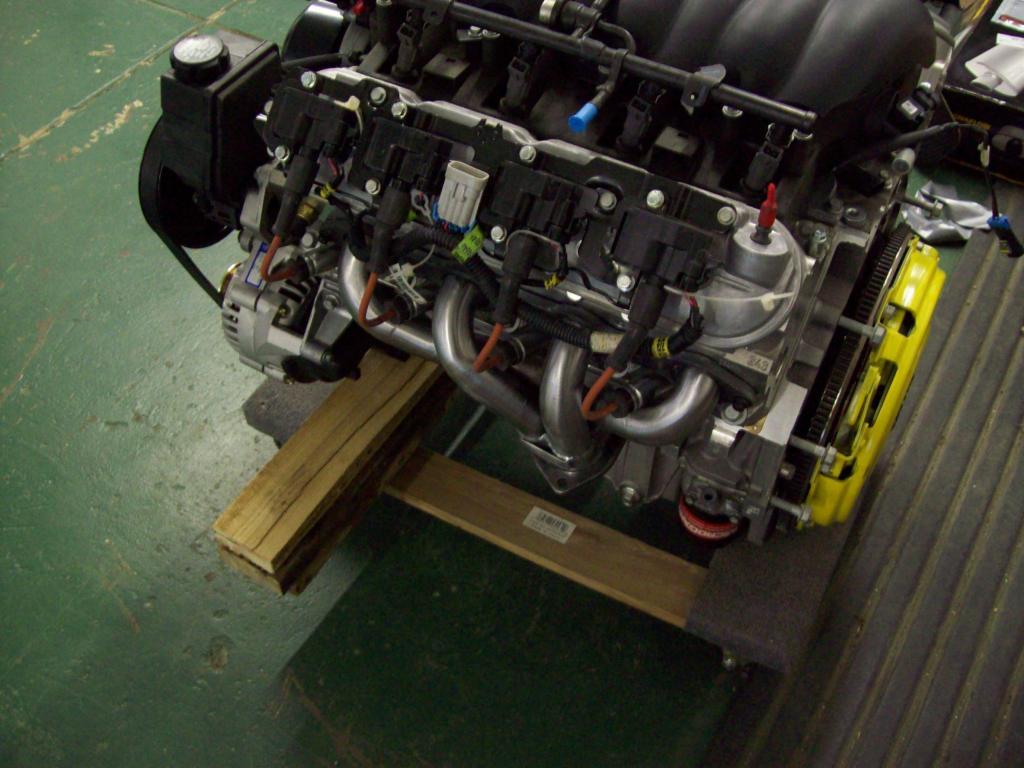

Got a delivery today.. It came fully accessorized and run/PCM tuned, so it is basically turn key at 538 horsepower LS6, so look out.. LOL The standard Swedish Ops (Special Builds Division) car will be a 375 horse LS1, which is more than adequate for the job.

11/16/2012

Got a couple of items in today... I recieved the uncoated version of the Swedish Ops/Sanderson LS Conversion Headers, and they came out pretty nice.. They will not be offered in stainless, but will come with a coated option. As you can see, the spark plugs have great access, so maintenance and tune up will be very easy.

Here you will see the final production Swedish Ops/Speedway Engineering Mod-Light 9in rear end assembly. I have the 13 Wilwood brake kit attached to it, and it is complete with an emergency brake set up.

11/17/2012

I tried the production rear end assembly today, and it all looks great. I didnt button everything up tight, because it will have to be removed for powder coating, right after I get all the rest of the car buttoned up.

I have the offset of the wheel about dialed in, and I think the flares are going to work out better than I had hoped.. I havent finished them out yet, because I wanted to make sure they wouldnt need any tweeking for the final production rear end assemblies. These pictures are at a slightly loaded ride height position, sort of like you would have someone sitting in the back seat, or a load in the trunk

The final header tweek looks like they will work out perfectly, so we will begin final production on these also, and they will be alot cleaner looking bare metal or coated header, than what is pictured here. Keep in mind, these headers drop in from the top, after the motor is already installed, so there isnt alot of the typical header installation issues.

Now that these items are dialed in, I can start the firewall kit install and do all the finish welding to the rest of the car, so it should be full steam ahead now.. I cant wait to get the new motor set in, with all the engine bay welded, cleaned, and prepped, because it will finally feel like progress is happening.. There are so many behind the scenes things going on, and now that they are almost at the end, production on all the cars should be a breeze in the future.

Nice details!

Posted by Diggymart on 7/15/19 @ 1:21:16 PM