You must be logged in to rate content!

3 minute(s) of a 234 minute read

4-4-2011

I took an old v-belt crank pulley, and bolted it up to a timing belt pulley to position it on center, since bolt pattern is not equidistant. I then put the timing belt pulley (with V-belt pulley attached to it) in the lathe and turned down the V-belt pulley to the exact same diameter as the Ford trigger wheel I.D. (got a full EDIS 4 kit with trigger wheel, coil etc, on e-bay for 50$) I then had a proper pulley "core" to fit with the ford trigger wheel. Basically its just keeping the center...

With turning the pulley core, to the same diameter as the trigger wheel, you get an interference fit, thus giving you the needed concentricity of the trigger wheel mounted on the pulley core. I then positioned the trigger wheel axially on the pulley core, for proper timing belt clearance. Marked it at 90 BTDC with missing tooth with VR sensor positioning, & then preceded with TIG welding alternatively at about 9 tack points between trigger wheel, and pulley core. I just sandwiched the now "proper bolt pattern" trigger wheel between V-belt pulley & timing belt pulley.

4-4-11

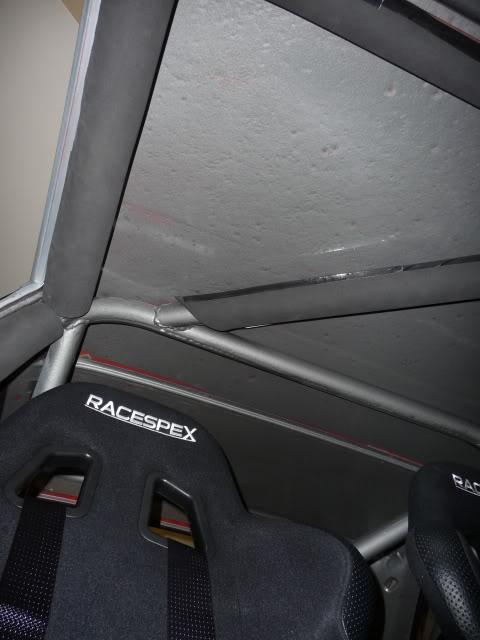

Car almost done still things to do:

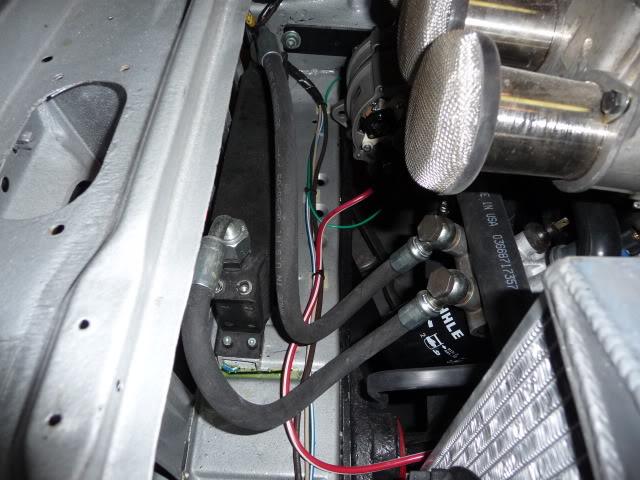

Download ignition map & test out Megajolt Jr (still running on EDIS 4 limp mode)

My Innovate LC1 came in D.O.A. , so still waiting on getting the controller back to finish up wiring

Shift linkage needs to be completely done; no linkage installed

Hood & pins need to be installed

Windshield needs to be installed

Tach needs to be wired: Some diodes coming from the coil pack, yada, yada, yada...

I have not yet completely heat cycled the engine (thermostat to open & fan to come on) because:

1- Car is inside the house

2- I need a proper ignition map, in order to run in proper temperature range

3- I need to get C12 fuel

4- Need to time the cams properly

So I need to finish off the shift linkage so I can bring it out...

Nice job!

Posted by Diggymart on 3/3/19 @ 12:38:17 AM