You must be logged in to rate content!

6 minute(s) of a 341 minute read

5-31-2009

I did some work on the custom filler neck and mounts

I removed the stock filler neck mounting bracket

June 4, 2009

More fillerneck work!

Gaskets, weld-in plugs, weld nuts

This process was a bit awkward because I can't TIG weld Aluminum. I had to have my buddy tack it one piece at a time, or use tape and mark everything and just hope it all lined up! Unlike steel, where I could tack and move on, so the process was a bit slower

So I cut up the u-bends and made it fit around the tire... barely!

Vent hose ports come off the top of the fillerneck

All taped up and ready for welding!

May 7, 2009

More tank mods! I had to enlarge the hole in the tank for the fuel pump to fit through

Stock fuel pump:

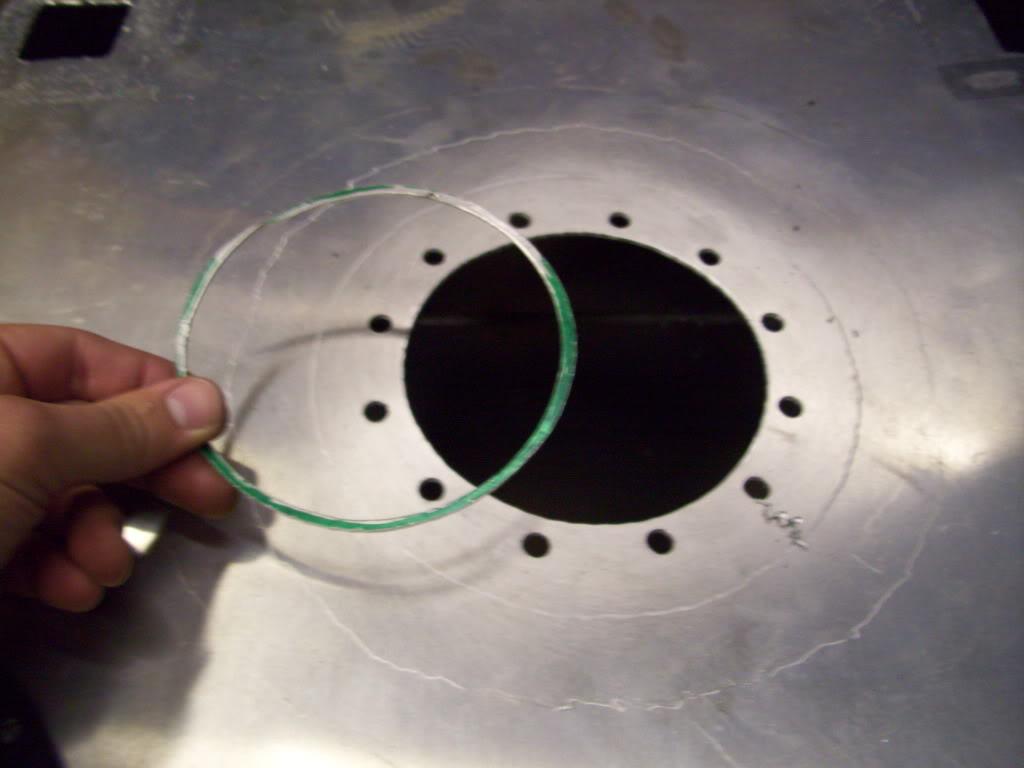

This ring is bonded to the bottom of a stock tank, so I cut it out:

And this ring is bolted to the bottom of the stock fuel pump, so I unscrewed it

They lock together like this.

June 11, 2009

I cut some more patch panels for the fuel cell. I had to fill the gap at the bottom where I deleted the factory supply ports, and I also decided to plug the factory drain and return line. The tank was designed to be mounted in a trunk, and gravity feed down to an inline fuel pump (carb motors), then the return line and vent out the top. Since I'm mounting it below the trunk, with a remote vent, and an in-tank pump, all that crap needs to move. I should have just built my own damn tank

My friend welded up the aluminum fillerneck for me, and it turned out great! He's a pretty good TIG welder. This is one of the very few parts I didn't make myself

I welded this little bracket on the inner fender to support the center of the fillerneck. There is a little tab off the tube that screws into this boss.

Now I needed to figure out the brakes. I could run a front caliper and delete the ebrake, which as far as I know is how this has been done every time in the past. A lot of the mid-engine or rallye or race guys doing independent rears using VW fronts just use the hydraulic caliper with either a hydraulic or no ebrake. I wanted a mechanical parking brake, so I needed to use a rear caliper with the integral parking brake. This isn't a VW-specific type setup, so I looked into some other cars. I had a Nissan S14 rear caliper available, some Accord rear rotor parts, some Nissan S13 parts... All sorts of stuff that ended up not really working out. I would like to keep it in the VAG parts bin if possible, so I did a bit more research.

I initially wanted to run a 9-9-1/2" solid rotor, 10mm or 12mm thick, but couldnt find the right combo of parts I needed. Here I was comparing a mk3 stock front caliper (2.0, 10.1") to a stock mk3 rear caliper, and just trying to come up with some ideas.

Stock front:

Comparison, stock front on left, stock rear on right:

Here's a rear caliper on a front spindle, front carriers, front pads, front rotor.

Maybe that will work? But the reach of the caliper isn't wide enough to use new pads with the 20mm thick vented front rotor.

I gave up for the evening, armed with these pics and some ideas, and hit the books researching all sorts of rear brake options. Everything from A8's to coupe quattros to .:R32s and TTs.

Nice build! Great photos and detail ????

Posted by Diggymart on 4/23/19 @ 12:52:48 PM