You must be logged in to rate content!

10 minute(s) of a 341 minute read

9-1-2009

I got the Ground Control front drop-in camber plates. These things are very nice; incredible design, the build quality is great, the materials and components chosen... Very great product overall They're pricey at $350+ per pair, but well worth it. I will probably end up upgrading my rears to GC down the road sometime.

I fabbed up all the strut mounting tabs, the bottom of the strut housings (round discs), the brake line mounting clips, and some mounts for the anti-rotation pins for the hydraulic pistons.

September 3, 2009

I fabbed up all the lower halves of the strut housings, did a bunch of test-fits to make sure everything sat where I wanted, and took measurements for the ride-height limiter spacers. These had to be custom machined and matched to each corner to account for length differences in the strut bodies (from Koni) and the strut housings (I made them).

I made all these strut housing lowers. 4 corners, 1 front spare, 1 rear spare = 6 total.

Here's one of the assemblies, before everything got plated.

Test fit everything in the car to check for brake line, axle, hydraulic fitting clearance.

What's up.

September 6, 2009

I got some mk2 tie rods because the track was too wide in the rear with the mk3 arms. The mk2 arms are 1" shorter per side, the mk2 tie rods are also 1" shorter per side.

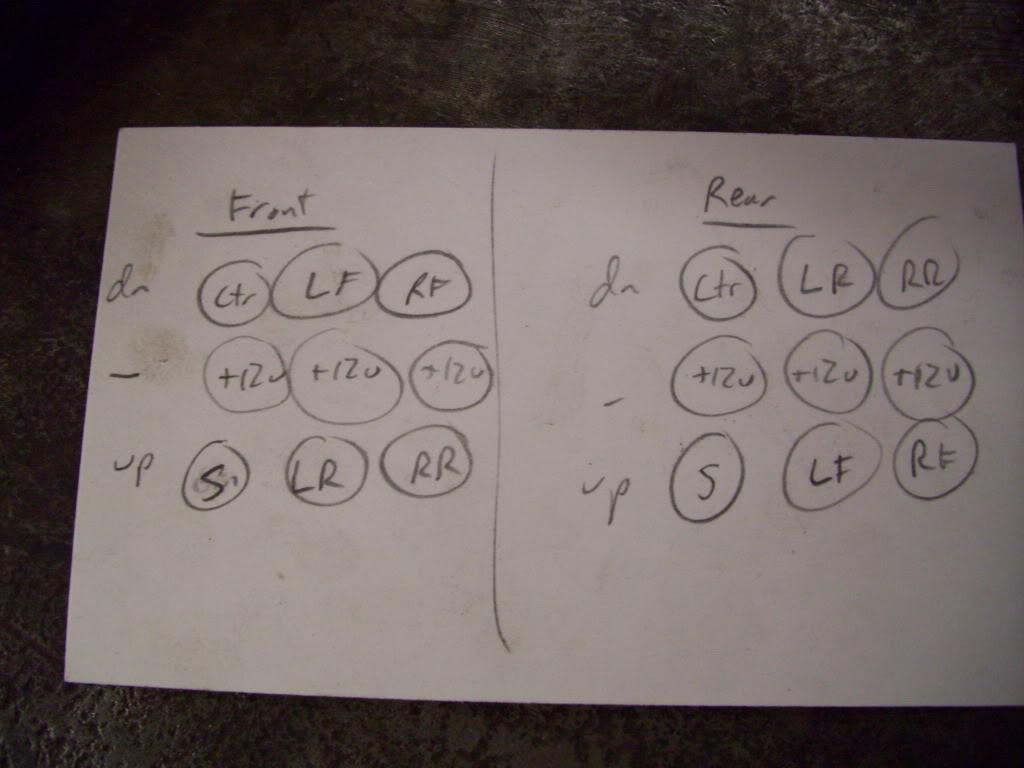

More detailed drawings and schematics. These were made in AutoCAD.

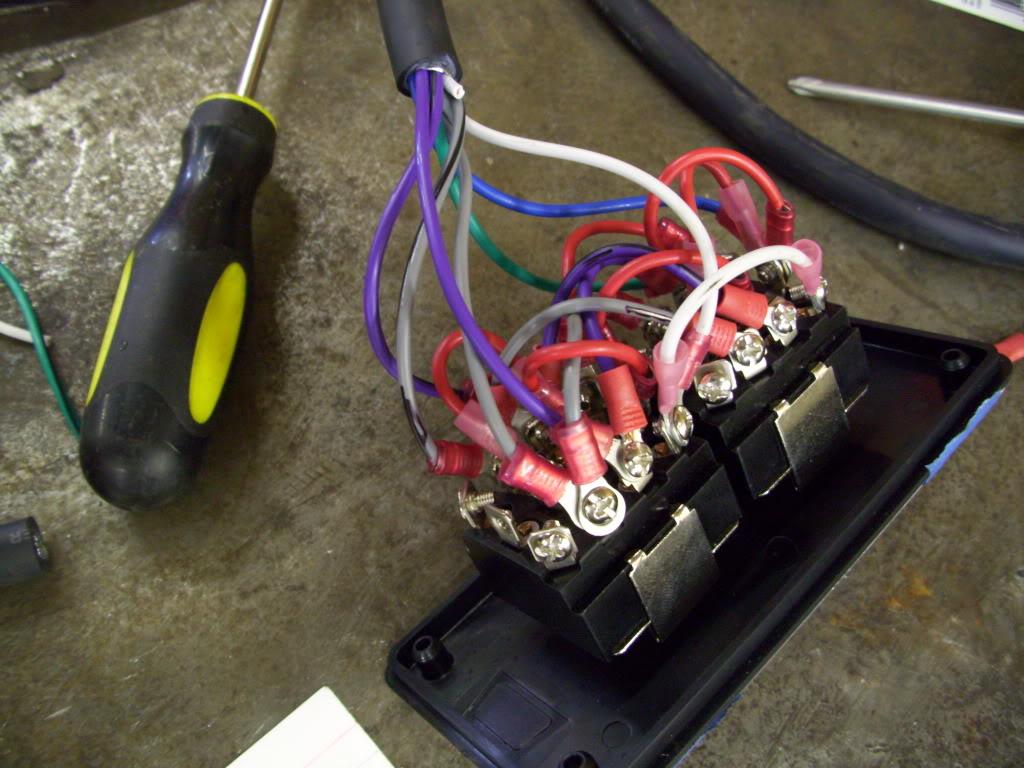

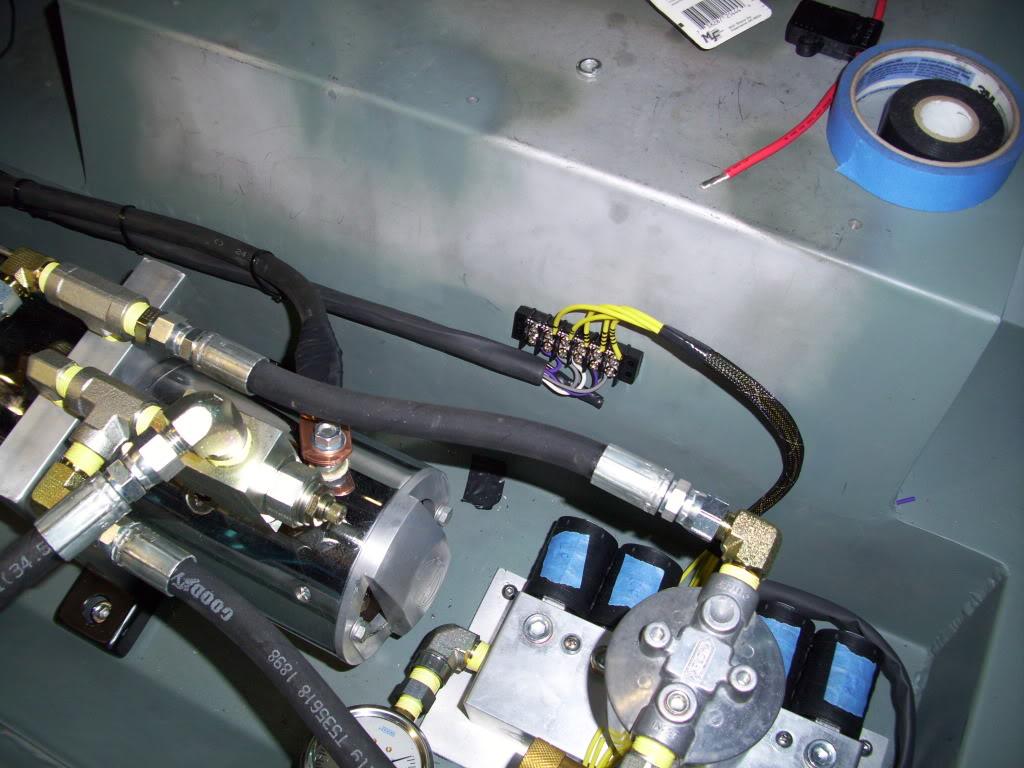

Did some wiring for the switchbox and valves

I decided to just leave the switchbox on the end of a cord and hanging on the floor. I want to mount them in the dash, but couldn't decide where to put them. I don't want to cut into my early dash until I'm 100% sure they're staying there, so I left them in the box until I make the final decision.

September 7, 2009

Papa Fazz, wiring professional, comes out to the garage to inspect my work. He approves He has tought me a lot about wiring, he really knows his shiz.

200 Amp fuse for the hydraulic pumps, 2/0 power cable. Yeah.

I had 2 more parts to machine, and the drive belt exploded on my lathe. Luckily I was able to use a friend's lathe.

September 8, 2009

I wired in this quick-disconnect fitting for the power wire in case things go wrong. This is just a welding connector, commonly available.

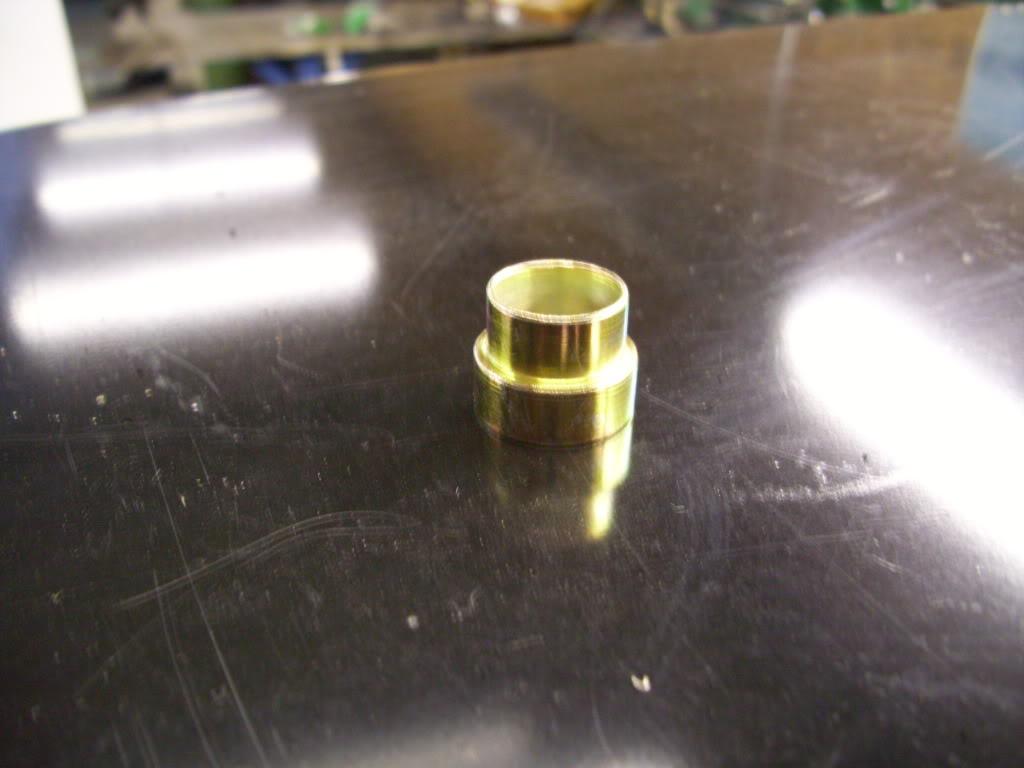

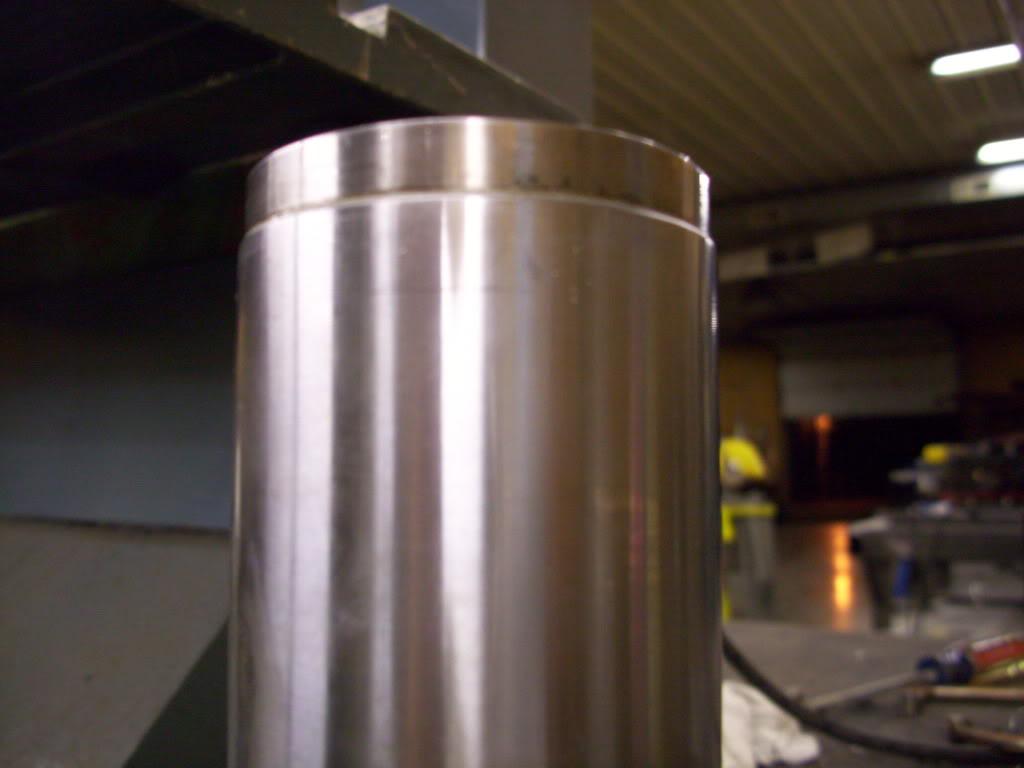

I machined these travel limiters for the suspension. These go on top of the strut housings which limit me to exactly 2.1" of strut stroke per corner. I intentionally made this a separate piece so I could make them different to accomodate for length differences in the housings, which weren't super precise.

Each one was marked for which corner it went into.

September 09, 2009

I had to bore out the upper springs seats I found from the ebay coilover kit to fit over the Koni strut shafts.

I got two sets of Eibach springs. 6" long 450lb/in for the front; 7" long 300lb/in for the rear. These are only 12% stiffer than the springs in my H&R coilovers, so the ride quality should be pretty good. I did some calculations based on the corner measurements I took a few weeks prior, and the numbers looked good.

I also started cleaning the 8+ months of garage dust out of the rear trunk, since most of the hardcore fab work was done.

I also started cleaning up some of the wiring I had been moving around during welding. I even replaced a section I caught on fire

I melted one of the vacuum lines that goes to the rear trunk lock, so I took some measurements to order some new line.

Oops!

To be continued...

September 10, 2009

I got everything back from plating!!!

Strut lowers and anti-rotation pins are Zinc plated with yellow chromate. This is very common on everything from Grade 8 bolts to coilovers.

Strut caps are black anodized.

Here are the housings, these have been done for months and now I finally get to assemble everything!

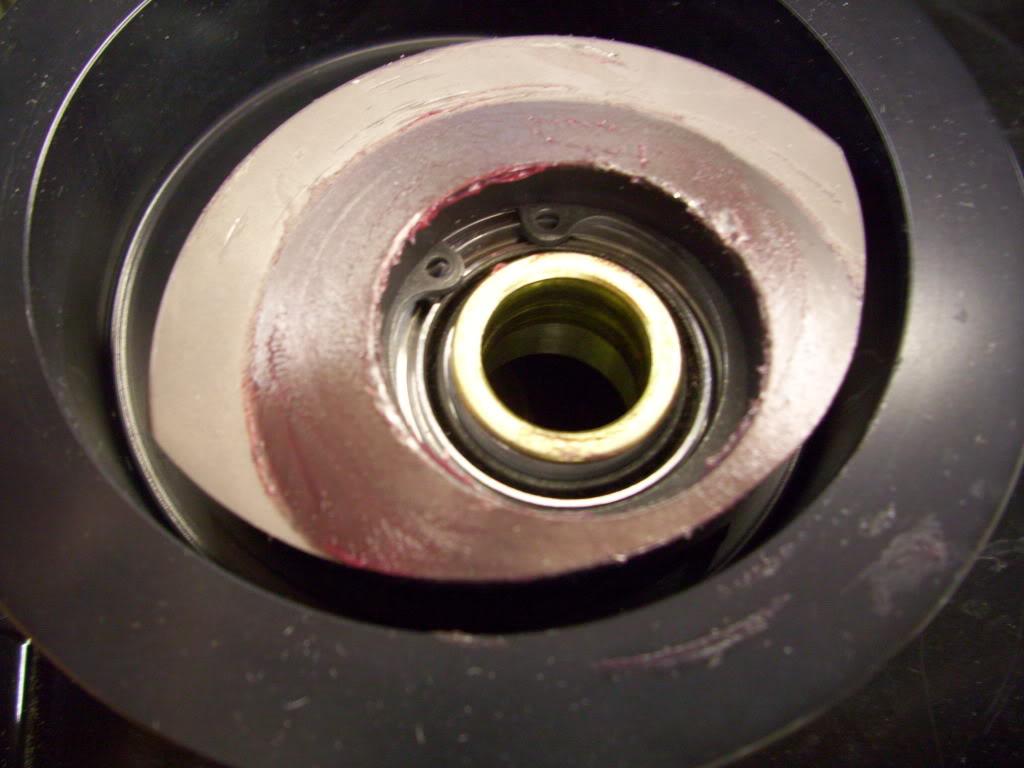

Here's where the hydraulic fitting will let fluid into the pistons

Here is one of the struts, all assembled. In this pic, it's all the way down:

In this pic, it's all the way up.

The hydraulic fluid enters the fitting and because of the stepped bore and stepped housing, what you end up with is a hollow cylinder around the outside of the strut. I've got 2.10" of stroke in each corner.

I also made the decision on which hydraulic fluid I wanted to run. This stuff has the right viscosity, price, and availability. I didn't want to run anything crazy just in case I need to get more, and this stuff is available from any auto parts store. Lots of lowrider guys run ND-30 also, but I chose AW-32 because it's real hydraulic fluid.

Nice build! Great photos and detail ????

Posted by Diggymart on 4/23/19 @ 12:52:48 PM