You must be logged in to rate content!

9 minute(s) of a 270 minute read

3-10-2010

Slowly checking off the To Do List. Trying to get this thing ready for a test drive this weekend.

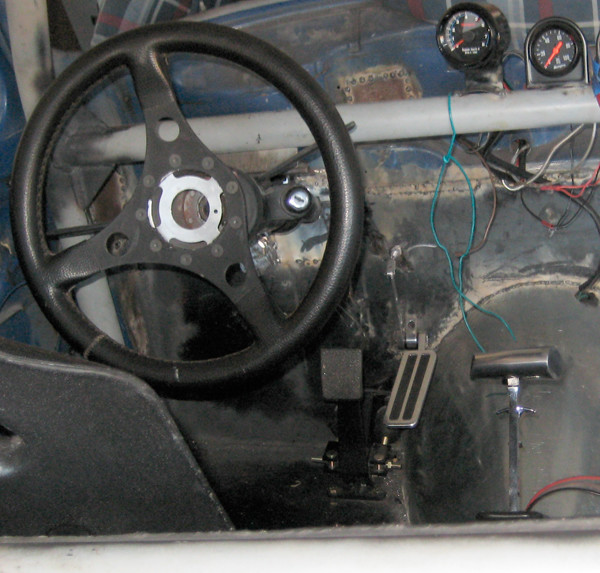

Shifter...installed.

Things left to do.

1. Relocate steering column mount to dash bar.

2. Mount trans cooler.

3. Run fuel line.

4. Make battery tray.

5. Mount seat and harness.

3-11-2010

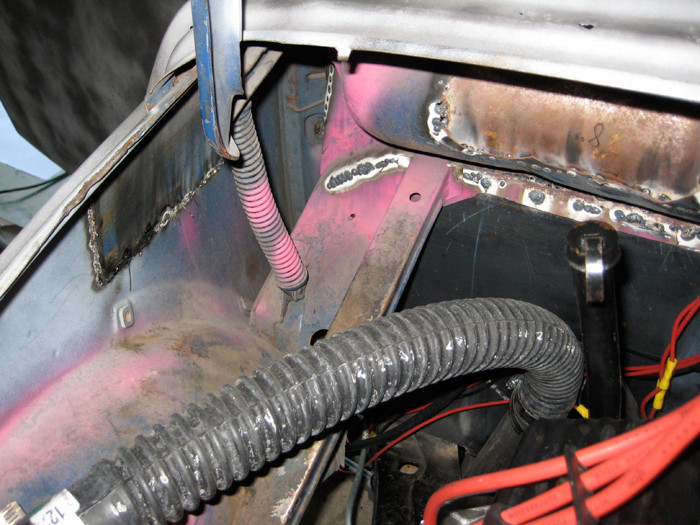

I appreciate the advice and help guys. See, I listen.  For the 10-15 minutes time it took to sleeve it I'd say it's cheap insurance.

For the 10-15 minutes time it took to sleeve it I'd say it's cheap insurance.

I ground down the existing weld, I cut out a 2" section out of some scrap steel I had laying around (the original fender support tubes that bolted to the S10 frame / fenders), slid on the sleeve and welded away at about 100 amps using flux core.

Here are the results.

Sleeved and plenty of penetration on the new sleeve. Should be VERY strong.

I also started working on mounting the column, but my grinder finally gave out after putting it to hard work for well over 2 years. Time to another.

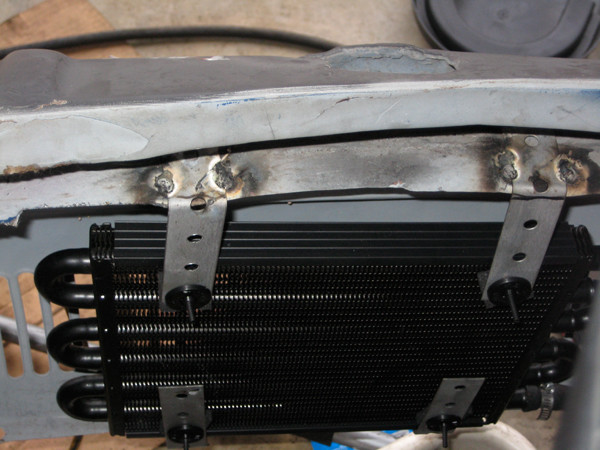

I did manage to get the trans cooler mounted. Nope, I didn't weld near the trans cooler.

Thanks again for the suggestions guys!

3-15-2010

2 steps forward, one step back. Got some progress made this weekend. Not as much as I wanted to get accomplished due to a last minute gig that came up Friday, but progress nonetheless.

Got the steering hooked up. It turns with ease. Drill and tapped a 3x5x.1875 piece of steel to mount the column on. I had to make a bigger hole in the firewall for the rag joint to slide through. Now I need to make a cover that will bolt on so I can easily take it off when I need to remove the column.

I also ran the fuel line. I was ready for my first test drive, engine warmed up and ready to go. Car was running great and everything. Then I went to put it into gear and the car died. Fired it back up, put it into gear, died again. I upped the idle a little (1,000 rpm), put it into gear and it really bogged down. Turns out I was having carb problems. The carb was overflowing with fuel and fuel was just pouring into the carb. See video link.

http://www.youtube.com/user/cmattdab.../0/vKclUKm4MCU

I'm not sure what went on? Maybe the floats need adjusting. I'm going to call Summit today and see what they say. It was running fine and then this just all of sudden happened.

3-18-2010

Took the bug for it's first spin tonight! There are four very short videos my friend took on his camera phone which cam out decent. Got some bugs worked out of the carb and all the leaks taken care of.

http://www.youtube.com/user/cmattdab.../0/i4Ct4LndyBk

http://www.youtube.com/user/cmattdab.../1/QKK5sYU2pHg

http://www.youtube.com/user/cmattdab.../2/ho0XJjECUns

http://www.youtube.com/user/cmattdab.../3/wKUldF9XIyk

3-29-2010

Got a few more things done off the list.

Made and tacked in some plates to cover the hole where the driveshaft runs through the firewall. I had to do it this way cause the driveshaft and column are all one welded up piece. A little seam sealer and paint and it should look decent. You can also see I filled in the holes where the gas pedal was. I'm moving it over away from the brake pedal to give me more room. It'll be closer to the trans hump, but at least it wont be an inch away from the brake pedal.

Finished off the flooring on the passenger side. This is where the trans hump comes up into the floor giving the exhaust room to tuck within the chassis.

All's left to do is make the back floor that goes above the tank, weld in some front clip supports out of some metal rod, trim some more out of the engine bay to clean the look up, and make a battery box. Then it'll be ready for the body work stages.

High five!

4-8-2010

A few things I've managed to get done.

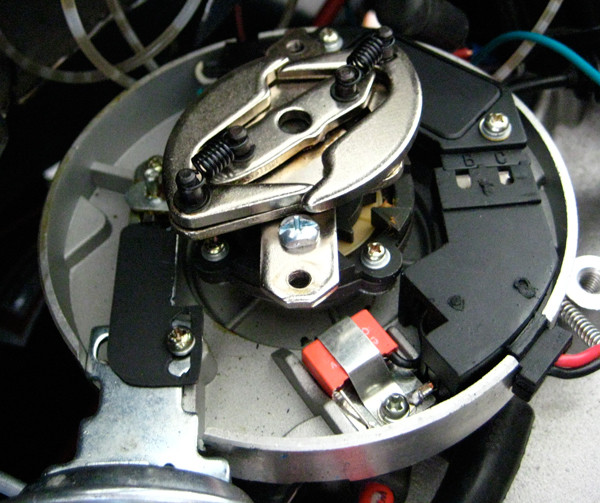

Here's how the distributor mod looks.

You can see the mechanical advance limiting screw with the side ground for "fine" tuning and the vacuum limiter which is made out of just a piece of 22 gauge steel I had laying around. Next to free modifying this thing.

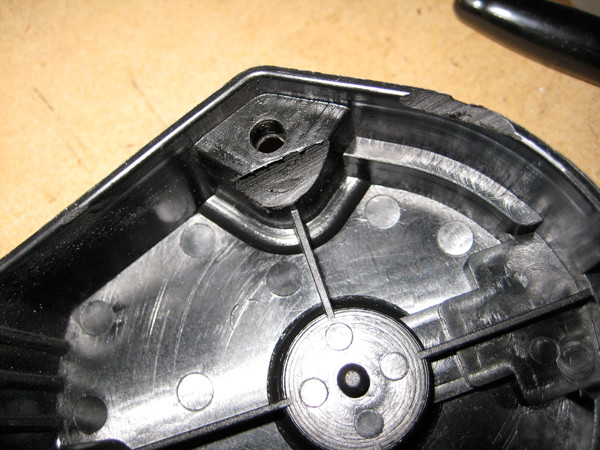

Had to clearance the rotor cap a little.

Here you can see it was a great concern to me whether or not I could even remove the distributor cap. Thank god it would come off. I still had to rotate the crank to get to the rotor screws.

I moved the gas pedal away from the brake pedal some more. This is as far over as I can get it.

And, last but not least, last night I made templates (night before), cut them out and welded the rear wheel wells in.

Having a couple gallons (everything is sealed...but) of gas in the tank and the fact the paint kept catching fire on the bug body when I was welding the wheel well pieces up kept me from wanting to fully weld these things up. Some MasterSeries and sealer will finish the job here.

Next thing I'm going to tackle is the "engine bay". I want to trim out all the excess sheet and reinforce the front clip with some 7/16" rod. What do you guys think? Will I have problems with the whole front end shaking or will it be strong enough with some reinforcement and the fenders bolted up?

Here you can see a guideline I drew where I want to cut it.

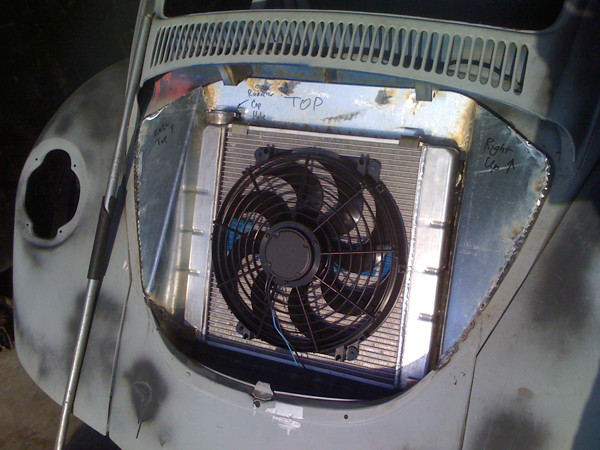

I'm trying to make the engine bay as simple as possible. No wheel wells and the wiper compartment will go so I'll have easier access to the dizzy. Also, it'll allow me to use the cowl vent to allow how air to escape. I just plan to make a mount for the wiper motor.

Things to do before body work / paint stages.

1. Rear, above gas tank, sheet metal.

2. Finish engine bay.

3. Finish filler neck sheet metal.

4. Seam sealer.

Getting there.

4-12-2010

Got some work done.

I decided to just clean up the engine compartment by adding panels to hide the strut tower mounts and gas tank rail. It didn't quite turn out how I wanted, but I'm pleased with the results.

I was aiming for a look like this.

I made patterns, again, cut out the sheet metal and went to install them. Oh, I also made a wiper compartment cover.

Everything fit well, but I could not for the life of me get the 18 gauge steel I had to bend smoothly. So I just boxed the top off instead. I think it came out pretty decent. The pics aren't great, but I think it'll look decent once It's got some hugger orange or black down.

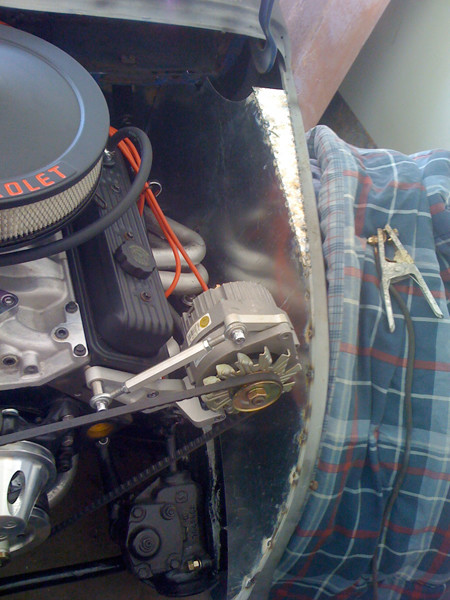

I've also been taking care of buttoning up little things like bolting in the gas tank and hooking up the kickdown cable.

I bought a kickdown cable months ago and it didn't line up with the vortec intake bolt pattern (has 8 instead of 12). So I had to cut and bend this one to make it work right. Works like a champ now.

I also think I have my alternator situation figured out. I'm going to have to make an insert in the sheetmetal panel I just made, but I think it'll work. I'm basically just going to turn it upside down on the alternator mount I have now.

More soon.

Impressive!

Posted by Diggymart on 4/27/20 @ 2:40:48 PM