You must be logged in to rate content!

4 minute(s) of a 643 minute read

11-23-2012

I wanted to follow up on this. For reference I keep track of my MBC setting by counting the number of 1/3 turns (it is 1/3 of a rotation each time the GrimmSpeed logo goes past).

Before I did this, I had the MBC in the engine bay, next to the OEM EBCS location. This uses about a foot of vacuum line to and from the MBC. Turning the MBC all the way out would get me as low as about 20psi (close to spring pressure). It took 10-12 "1/3" turns to get up to 27psi.

When I moved the MBC into the cabin I probably added close to 10 feet in total vacuum lines as well as two inline connection fittings. Then I could only get as low as about 23psi and it only needed 6-8 "1/3" turns to get to 27psi.

So I needed a lower spring pressure in the MBC in order to reach the same boost pressure. This tells me that either; the added volume of lines were taking more air to pressurise them, I had a leak, or I had a partial blockage. Something was making it harder for the pressure signal to make it to the wastegate.

I wasn't too worried because spool seemed the same and it was controlling boost fine but eventually I got curious so I did some logs and then switched back and did some more logs so I could get a back to back comparison. I found the spool was identical.

This was a while ago and I never got a chance to switch back until last night. Once I had it back in the cabin I found that the lowest boost I could hit was 25psi and it only took 3 "1/3" turns to reach 27psi. Something was not right. I. Tried redoing the zip ties on the connections but there was no change.

So I ended up moving the MBC back into the engine bay. Spring pressure is back to 20psi and it takes 10 "1/3" turns to hit 27psi. Just like it was before.

My conclusion is that the in cabin MBC works but it really must be done eight to be without problems I think that if you use continuous lengths of tubing (to minimize leaks), keep the hoses as short as possible, and make sure there are no kinks, then you will be fine. But in practice it is a bit tricky to get it working as well as if you locate it close by the turbo in the engine bay.

11-24-2012

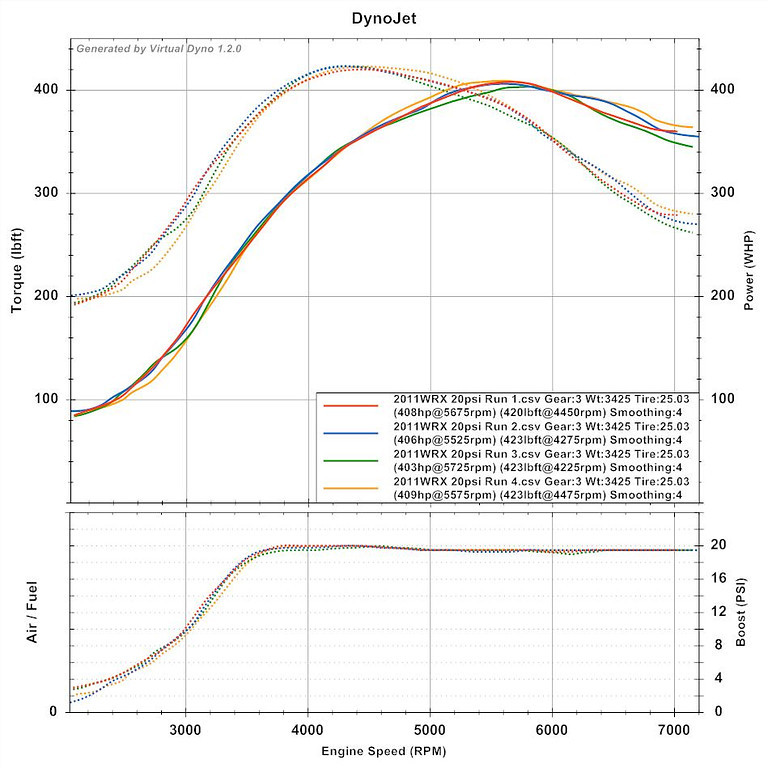

I decided to do some boost vs. power comparisons tonight (just for fun). First I started with a few logs with the MBC backed out all the way. The car was hitting about 20psi and was basically flat to redline. Pulling them up in Virtual Dyno showed nice consistent results!

Because that looked good, I decided to turn the MBC up halfway to where it normally is at. I did a couple logs and it peaked close to 24psi, with a little taper down to around 22psi. Then to finish it off I turned the MBC up to my normal spot and it was just barely touching 27psi and then tapering down close to 24-25psi.

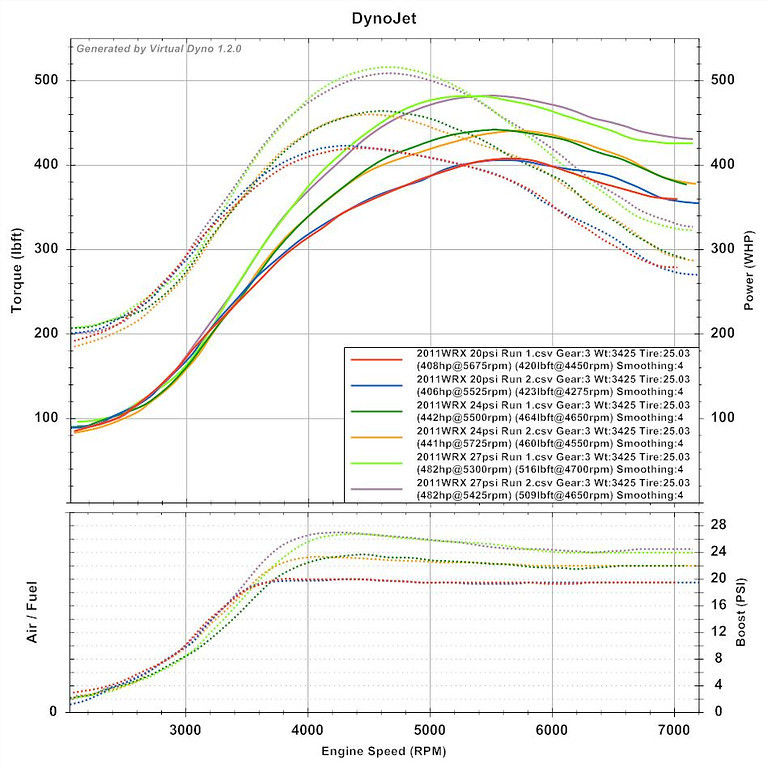

Looking at the boost and torque (for the 24psi and 27psi graphs especially) you can see that I probably did have a slight uphill for run 1 and slight downhill for run 2 of each set. This slightly affected spool and peak torque. But overall the results are very consistent.

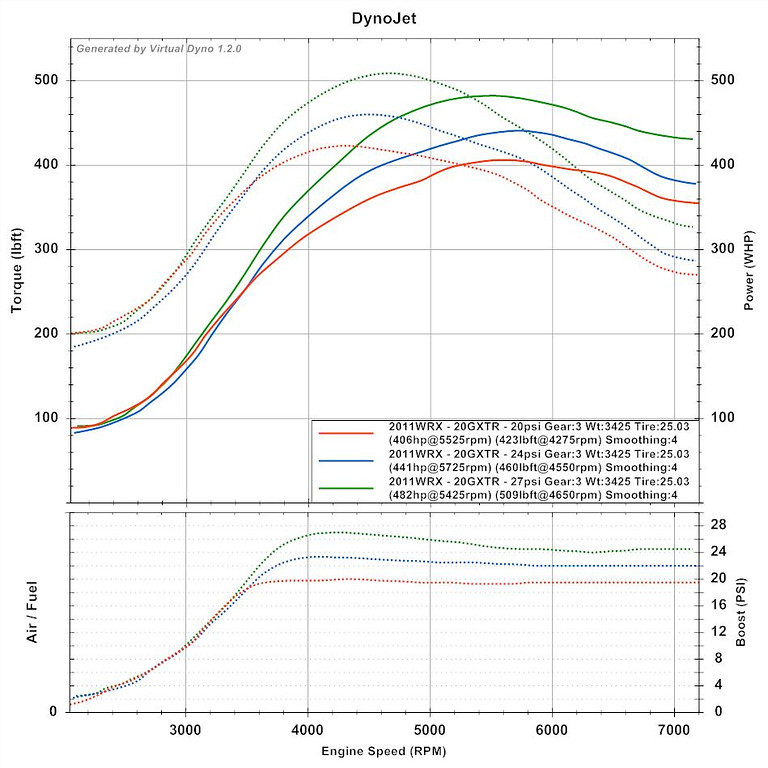

And here is the plot with just one run from each boost setting. Solid, incremental gains with each change in boost. This is a nice, easy way to see how increasing the boost can really bump up the power (assuming the turbo is still able to flow enough air). It also shows why people running this turbo (or similar ones) at lower boost will definitely see lower power.