You must be logged in to rate content!

2 minute(s) of a 241 minute read

5-15-2016

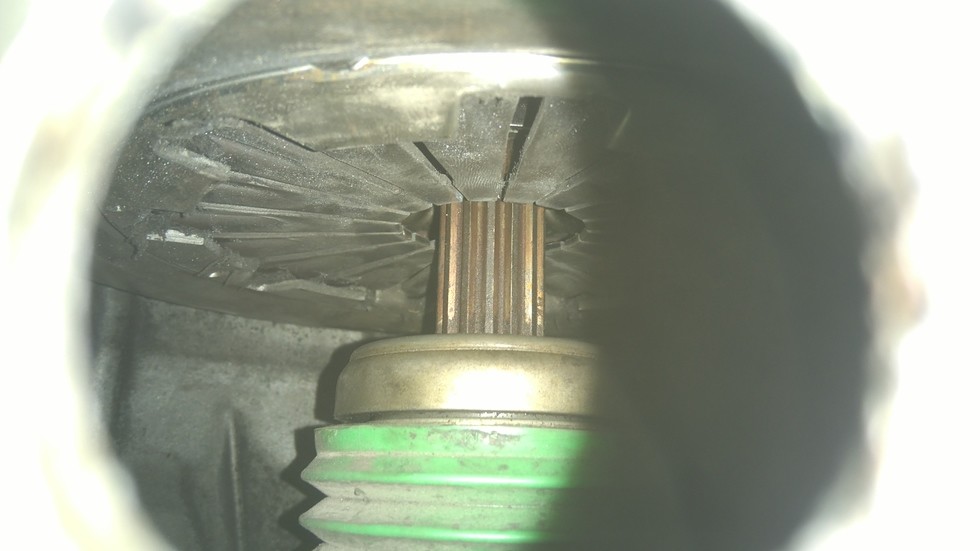

After measuring i need to enlarge the hole between the fingers on the pressure plate to 44mm from 30mm after thinking about it, i can't cut them no a lathe only way is with an abrasive stone, so i made this jig from some scrap steel and an old Stanley grinder, worked great until the stone got too hot and melted the glue that was holding it, unfortunately it was my last small stone and been sunday all stores are closed, tomorrow will buy couple more stones, i've enlarge it to 38mm now, 6mm more i'm done.

5-16-2016

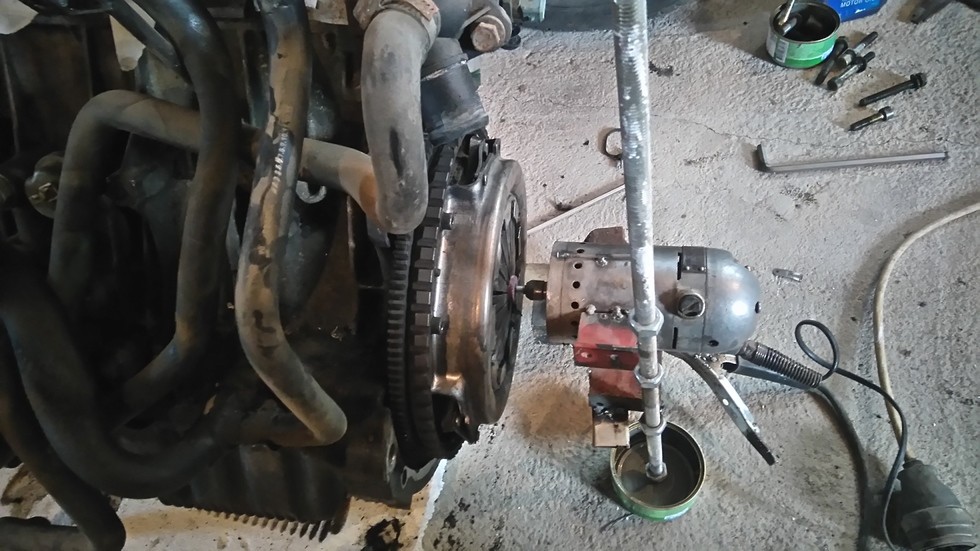

Today i went to the hardware store and bought couple more abrasive stones, and got back to work enlarging the hole between the fingers on the pressure plate , it took a lot of time and at the end the grinder burnout, but finish the job, i'm satisfied with the resultat, i will wash the pressure plate before final assembly, you can see the difference in size next to the stock one, and i need to cut back the bellhousing much more than i thought, in the picture the throwout bearing is fully extended, the engine and box are surprisingly short, so i have very little floor to cut.