You must be logged in to rate content!

7 minute(s) of a 390 minute read

7-10-2011

Got my hands on Engine Analyzer Pro software. Seriously cool program. I have a top of the line i7 processor and 6 gigs of ram, and the computations can still take upto a minute every time I try and get it to run a combo! Crazy. I've been playing with options on my 404 with LS3 heads. Originally, after a lot of research I settled on a 238/244 cam. After playing wiht the new software that may change a bit. Here's some interesting things I learned while playing with the software:

1) don't need more than .604 exhaust lift

2) I'm not willing to loose >60 ft lbs of torque below 4000 rpm with a tunnel ram intake even if it gains me 50 hp up top.

3) decreasing intake duration from 238->232 lowers avg hp 1

4) increasing intake duration from 238->244 lowers avg trq 2

5) the only change w a big 90mmX1" spacer is a loss of 1 hp!

One thing that I was really interested in was exhaust valve duration. The LS3 heads are very unique in the world of modern performance heads in that the exhaust only flow 66.5% of what the intakes flow. This is considered pretty low. Unless you're talking about a modern Winston cup car. All of Comp cams off-the-shelf LS3 cams try to "overcome" the relatively poor exhaust flow by running a huge 15 degrees more duration on the exhuast lobe than the intake lobes. Normally this would be considered excessive on onything short of a full blown nitrous motor. And really didn't make sense to me.

My intake duration 238 + 15 = 253

I did multiple tests on the simulator. I would always add the extra duration to the exhaust opening in my tests, so not to change the overlap. And with comps 15 degree split I would loose between 5 and 15 ft lbs below 5000 rpm. In one simulation I lost 50 ft lbs at 3500 rpm with the greater exhaust duration! And I usually only gained 5-7 hp over 6000 rpm.

Then I thought maybe even my split was too much. My proposed 238-244= 6 degrees of split. Dropping down to only 3 degrees of split with a 241 exhaust duration picked up a huge 13 ft lbs at 3500 rpm and only gave up 1-2 hp above 5500 rpm.

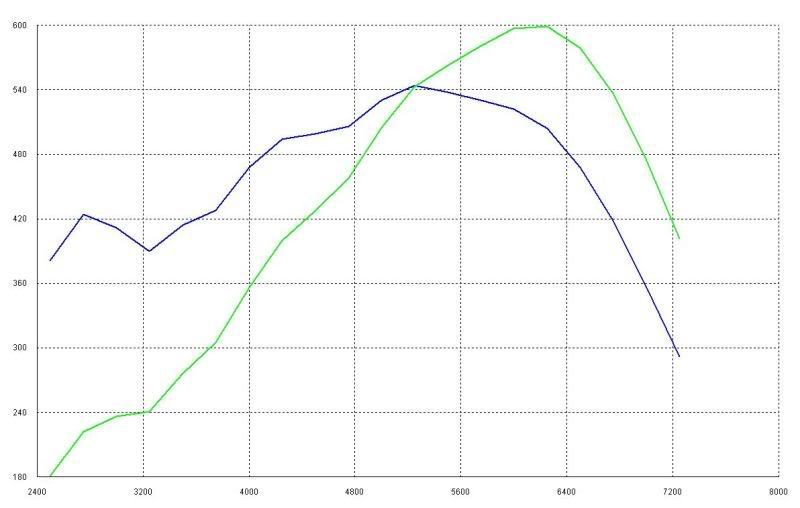

Here's the Winner cam as of right now.

238/240 112 +1 .612 lift in and ex

max trq 570 @5000, 479 avg 2500-7000 rpm

max hp 600 @6000, 436 avg 2500-7000 rpm

Every one warned me not to get my hopes up over 6300 rpm with the stock intake. And boy the Engine Analyzer doesn't disagree! This thing just falls on its FACE over 6500 rpm. But with an AVERAGE of 480 ft-lbs!!! everywhere, my heart's not exactly broken up about it.

Here's an example dyno plot produced by the program. These would be engine dyno numbers with a 300 rpm/sec accel rate, and with all accessories and a flywheel. Here the cam is retarded to -1 (+4 has almost become the standard in the LS world)! It trades 4 ft lbs down low for 5 hp up top compared to my +1 cam (that is 2 degrees more advanced).

My only complaint about the Performance Trends Engine Anaylyzer software would be it's exhaust system inputs. There's no way to compare try-y to 4-1 headers, which work on completely contradictory reflective wave ideas. The software will only let you input just primary diameter and primary length. I combined my primary and secondary lengths (tri-y) to get a primary diameter for performance trends. Fortunately I also have Larry Meraux's "Pipe Max" software, which goes into minute detail on the entire exhaust system.

8/27/11

Got a little work done on the rear subframe yesterday. I noticed that even without an upper bushing in the front frame attachment points, that the subframe was contacting the car frame on the lip around the tube/cup that used to house the stock bushings (where everyone puts the collars). I still want to raise the rear roll center a bit, so raising the front of the subframe with no upper bushing makes sense. But raising the whole subframe up for a little free roll center correction is a massive bonus. The cup lip sits about 6mm higher than the rest of the subframe. The stock subframe bushings sit about 10mm higher than the cups in the rear and about 15mm higher in front. I've reduced that to about 2 mm in the rear and -6 in the front now for a total roll center correction of ~15mm (-8mmR and -21mmF)!. That's like installing drop knuckles! Even if it is less than an inch. Drop knuckles...$1100 Dead Grinding wheel... $3

Stock S13 bushing

My front S14 subframe less stock bushing but pre hackery. Notice the ~6mm step to the top of the cup even without a bushing.

Post Grinding. I'll probably throw a bead in there to make up for what I took off.

11/13/12

I'm living in NYC now and to get to my garage in Long Island (only 17 miles away) takes walking a total of 3 miles, 18 stops on the F train, and 45 minutes on a bus. 2:15 each way...

Made the trek yesterday and got a little bit of ugly welding done on my subframe. It penetrated and will hold. That's all that matters right?

11/22/11

I bought a custom kit on NRR to make my own toe and traction rods. The kit only requires you to come up with threaded rod and heim joints. Here's one of the kits assembled, traction rods with steel hex.

I was going to go with threaded 7/8" aluminum hex (like the original battle versions), but then the other day I noticed that coleman racing has a new part:

Trailing Arm, Ez-Just - Racing Parts and Products

I like that you get an extra 1/2" of thread engagement per side (even if the tube is split) because you're not using jam nuts.

I was a little confused because the thread sizes are not listed at Coleman. FYI: The trailing arms are 3/4" L&R thread, the tie rod arms are 5/8" thread. At ~$20 ea they are almost twice the price of hex rod, but still not a bad deal. I asked for QA1 rod ends for Christmas, so I might have this rear subframe all together in a few months.

11/30/11

Is it just me or do these MAX tension rods have a striking similarity to the coleman pieces?

Now that I look at it the threads on the max part look like at least 0.75", and the clamp looks more beefy too. BTW, mad props to MAX for the most elegantly/functional/lightweight modified stock knuckles I've ever seen! I love it!

12/2/11

I've had a lot of trouble getting center of gravity heights. It seems that no one in the nissan world has ever gone through the bother of measuring. But I just heard the quoted CG height of the newish toyobaru GT86 wich has a "low center of gravity of 475mm".

FYI for those messing with their roll-couple calculations. But I think I can do better. We'll see.

That's 18.7"

Good Nissan read!

Posted by Diggymart on 11/1/21 @ 12:53:02 PM