You must be logged in to rate content!

10 minute(s) of a 390 minute read

5-23-2011

I've been a little concerned about using the manley pistons that I have with the oliver rods that I have. Originally I was going to custom order some low compression height Wiseco pistons, but the long block parts I got were just too good to pass up. My pistons have a standard compression height designed to be used with what has become the LSX standard 6.125" aftermarket rod. My oliver rods with the lube tubes are 6.200".

The taller rods necessitate a taller gasket. A stock LS7 gasket is 0.054" thick compressed. With the taller rods (presuming all of my measurements are exactly as advertised... unlikely) I'd need a 0.105" tall head gasket. Cometic stocks up to 0.125"! To put that into perspective for the import guys that's 3.2 mm thick!

Found this here on ls1tech about variances in LS2 deck heights by ChucksZ06 back in 2006

Piston Deck Height for stock LS2 [Archive] - LS1TECH

"My first ls2 block with 4" eagle crank and rods was .005 in the hole. I am now doing an ls2 block with a stock crank and 6.125 rods( same length as 402 build), same piston manufacturer and the pistons are .008 out. I think the stroke on the 4" crank was not quite right. So from my experience you pretty much have to mock up the parts or it is guessing. Good luck."

Keeping the top ring below deck seems like common sense. It's common for the crevice height (top of piston to top of top ring) on performance pistons to range from about 0.180 - 0.320". So presuming (what I consider) a loose quench of 0.035" and super tall 0.125" gasket you should still be safe with low crevice volume pistons all the way down to a crevice height of 0.160". Still that's a little too close if you're running a low crevice height pistons near 0.180".

9.240" stock LS1/2/3/7 Deck height

2.000" less 4" stroke/2

1.115" less my manley piston's compression height (was designed for a 6.125" rod)

6.200" less my lube-tube oliver pistons

puts me 0.075" out of the hole.

for a tight 0.030" quench I'd need a custom 0.105" thick gasket.

I also found Lingenfelters book on google. He mentions that he reccomends 0.250 crevice height for street engines, but has seen all the way down to 0.100" on all out N/A drag engines!

Good read:

John Lingenfelter on modifying small-block Chevy engines: high performance ...

By John Lingenfelter

John Lingenfelter on modifying small ... - Google Books

Stock LS3 chambers seem to very quite a bit. Stock blue print is 68.4 +/- 1cc. But in the real world they seem to very from 68.5-70.9cc.

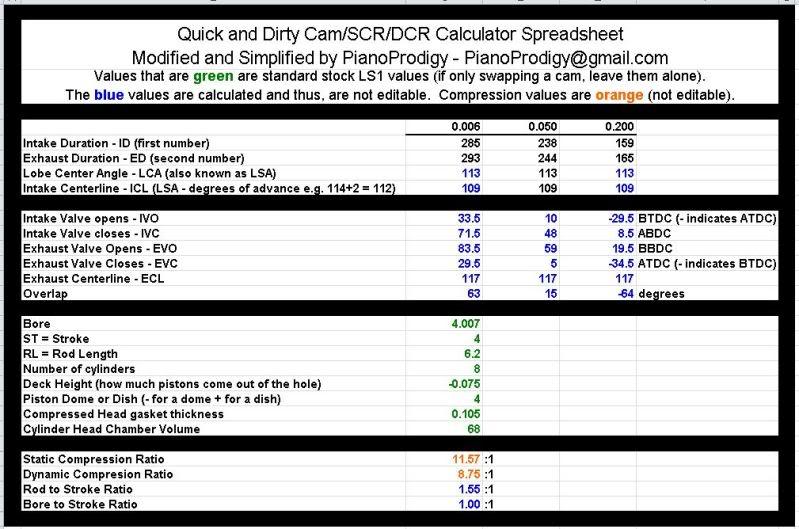

Here's a cam I'm considering having ground that would work with a stock chamber with just a .005" clean up mill to 68cc chambers. This cam has 4 degrees of advanced ground in. I'd like to run a few degrees less advance, but I like the idea of not taking the chambers too small incase I ever want to go forced induction.

5/27/11

I was pulling apart a Z32 rear subframe and noticed this reinforcement that the s14 doesnt have. Can't decide if it's worth replicating or not.

I also scanned the Ohlins instructions manual to pdf files, but they are of course in Japanese and I can't read them. If any one can help, or knows anyone that might be willing to translate them for me, please shoot me a pm and I'll email the pdf files to ya. Thanks guys!

6/9/11

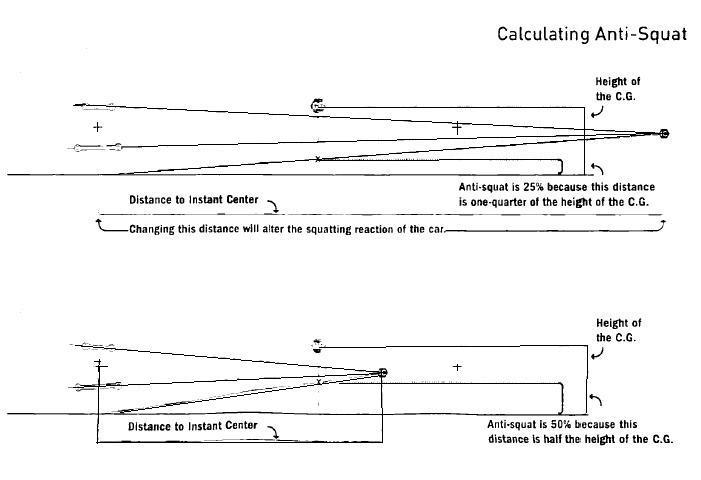

I covered anti squat and the as-engineered state of the s14. Now it's time to take a look at the other end of the car. Anti-dive is just anit-squat turned around backwards. It's calculated pretty much the same way. But for a Mac Strut car like ours with no upper control arm, the instant center is created by the intersection of the line through the lower control arm and a line perpindicular to the the top of the strut.

More caster will get you more anti dive, but very slowly. But even small changes in the FLCA mount (up), or the tension rod (down), will quickly get you more anti squat.

A refresher on on calculating anti dive/squat

My calcs show the stock s14 with 14.8% anti-dive. My sources say that 20-25% is ideal. For the calcs I used a ground clearance of 3.2", a CG height of 10.65", with 52% front weight bias, and 7 degrees of caster.

Moving the FLCA mount up 0.665" should get you upto 25%. It's also good for the roll couple.

6/10/11

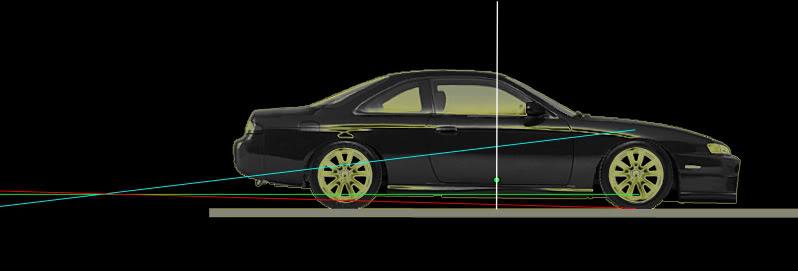

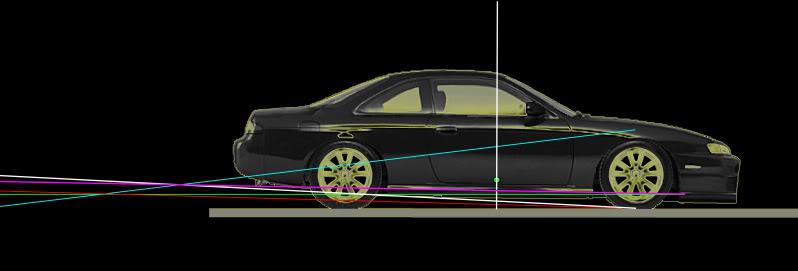

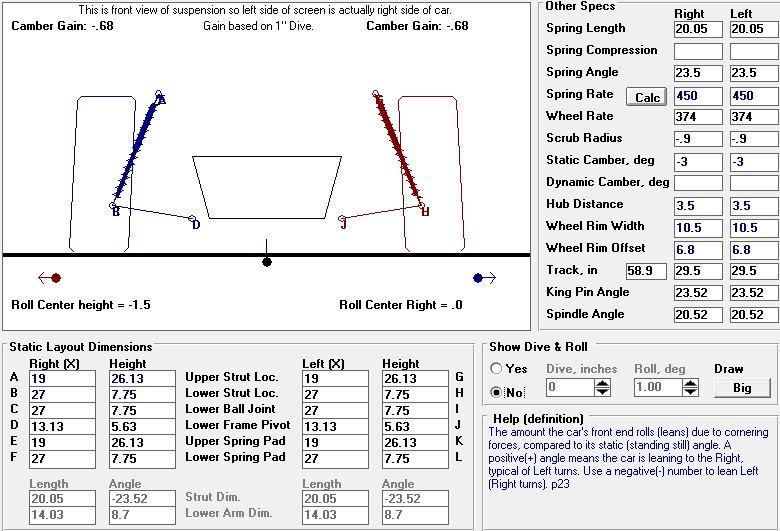

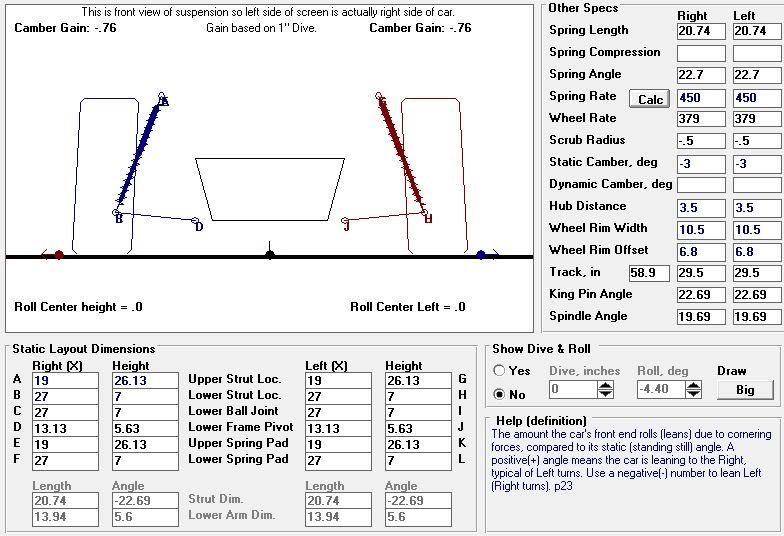

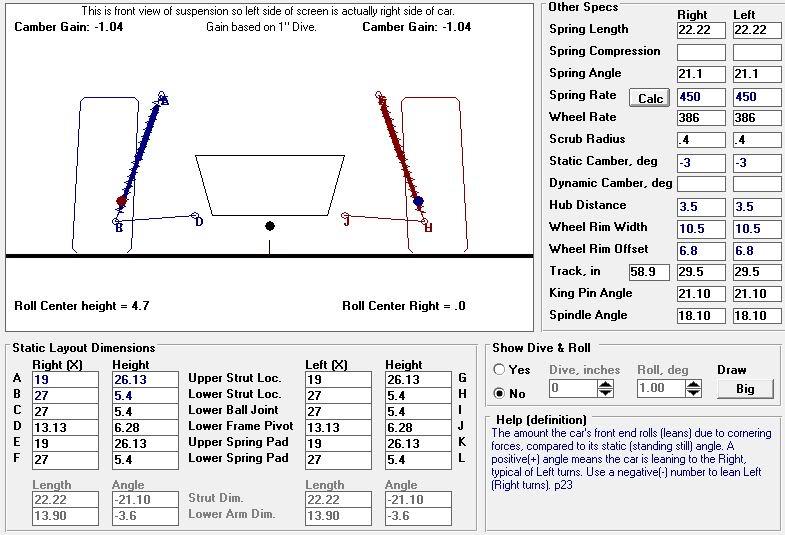

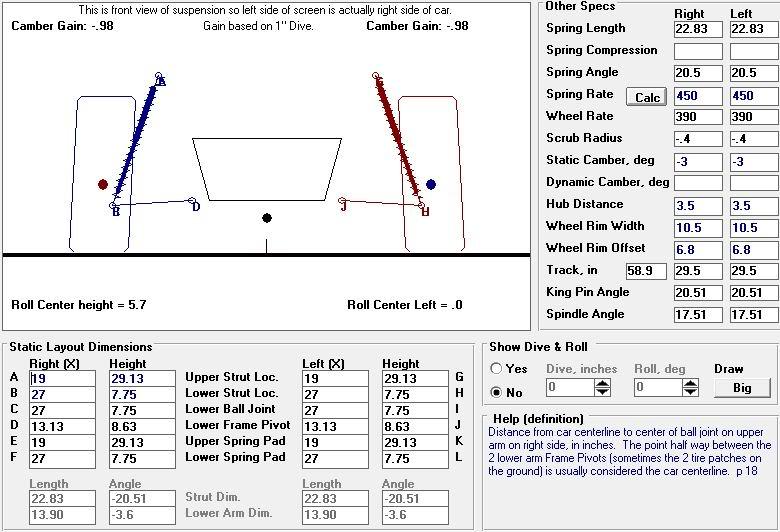

I finally got a chance to play with some suspension software! It's performance trends roll center program. All the measurements came off my s14. I used a ride height of 3.125" from the ground to the bottom of the crossmember. And my LSx crank centerline as the CG height came out to 10.625" above ground. All measuremens also presume 3 degrees of static camber.

Ideal camber curves have about 1 degree of camber gain per degree of roll. The senarios I plotted varied from 0.45 - 0.63 degrees of camber gain. Such is the strut...

Just from visualizing the geometry in my head I expected the set ups with roll center correction to have better and better camber gain as the FLCA angle further down towards the ball joint. This isn't the case! Improving the roll center, hurts camber gain, but not much. Who new?

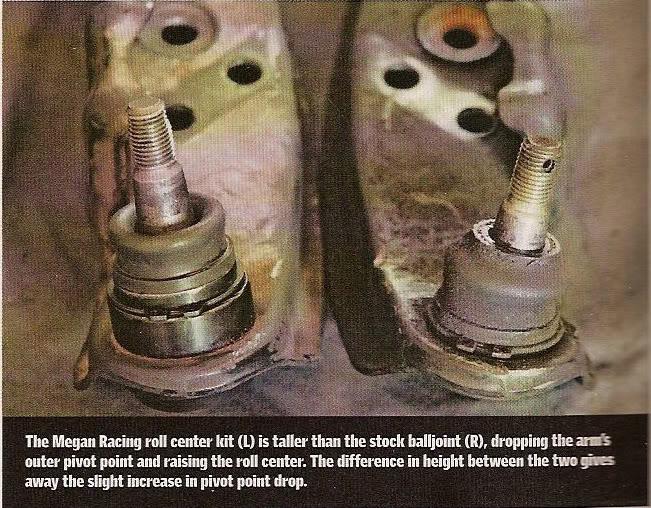

Before we can get to the nitty gritty of roll couple we need to talk about ball joints. I found this totally sweet pic in the roll center thread. From the pic I extrapolated that the stock ball joint is about 1.5". The whiteline and moonface pieces go for around $270, while the stockers (only 0.69" shorter) go for only $27!

And here's an example of goin all hardcore with the ball joints. But notice that even after all this there's no more correction than the moonface offers. Looks a bit over two inches of from the ball joint articulation to mount. Of course with this kind of set up you can go bigger. But would you want to? Those bolts in single shear start to look real scary real fast.

So here's what it looks like without any correction: OPTION 1

roll center 1.5" below ground

With a ball joint that is >2" long: OPTION 2

you reduce the roll couple by 1.5" (or 14%), and at least the roll center is level with the ground

Now if you cut off the bottom of the spindle, and weld in a big block of steel (2.35" tall) above the ball joint spindle taper/mount,

you'll get a lot more correction than the 0.69" that expensive ball joints buys you. A 275/40/17 tire has a 4" all side wall, in the below calc this 2.35" "inner-spindle spacer" puts the articulation at only 5.4" above the ground. This will be damn close to scraping the bottom of your inner wheel!

This Driftworks Geomaster front spindle only has 1.97" or roll center adjustment built in and already looks damy close to these wheels!

Surprisingly raising the chassis mounting point for the FLCA doesn't do much. But in the following calc it's raised 0.66" just for Anti-Dive.

With these two mods here's what you'll get: OPTION 3

A roll center height of 4.7" above the ground! Thats a roll couple that's been decreased from 12.125 to 5.925, for a roll couple that's only 48% of OPTION 1.

With this final set up: 3.6 degrees of chassis roll only moves the roll center down one inch. Dynamically the only way to get a negative roll couple is to have the front of the car come up >2.7" from static ride height like a wheelie. Honestly I wouldn't mind decreasing the roll couple even more, but I just don't think it's feasable without messing with the Kingpin angle, and that would take so much work that you're better off picking a different chassis or going double a-arm.

And just for shits and giggles. OPTION 4. If you really want the highest roll center, don't change anything! It looks like a stock 240sx with a (STOCK???) ride height of 6" ground clearance has the roll center 5.7" above ground. But of course it also has a center of gravity 3" higher, and a roll couple (what this is really all about) 2" worse than OPTION 3.

Knoop,

2700 with cage and our stock depleted uranium hood!? That's awesome to hear. And your new paint looks epic, I have to be honest, I never expected the fenders to turn out that bitchin. Cutting the inner rear fender-well in back, and trailer fenders in front was brilliant!

How much weight did you save with your custom front bumper? I was checking out the stock front bumper, and was wondering how much wieght could really be saved?

Re. the ball joints. I think that the moonface articulation point is is almost a full inch higher compared your custom/adjustable ball joints in relation to the top of the FLCA. Which probably robs some

Megan on left LOL. Stock on right, with articulation point above FLCA.

Knoops sweet custom set-up, with articulation point level with FLCA top.

Good Nissan read!

Posted by Diggymart on 11/1/21 @ 12:53:02 PM