You must be logged in to rate content!

7 minute(s) of a 390 minute read

3-19-2010

I guess there's no reason I couldn't use the ladder bar adjusters, or even a turnbuckle/female rod-end combo.

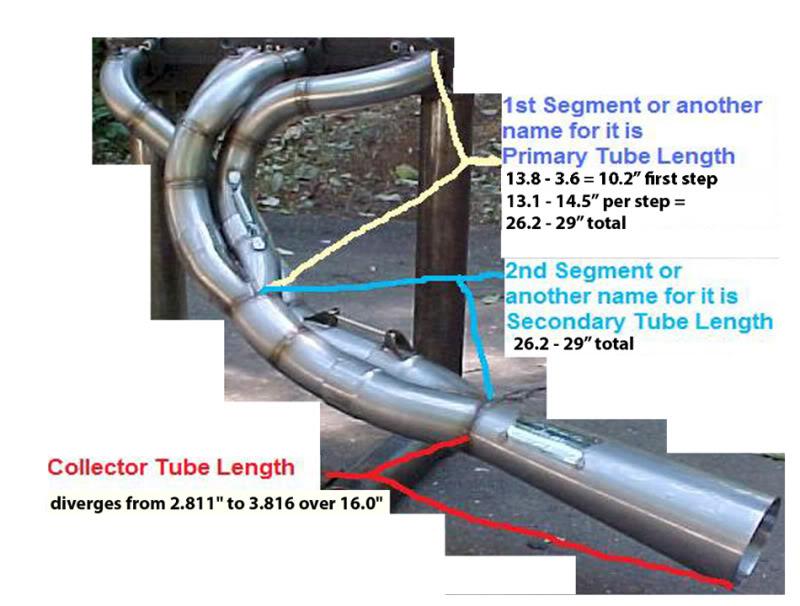

Here's the latest pic I made as a build guide for myself. I printed it out and hung it in the garage for reference. I doubt you're going to find 49"-55" headers (not including the collectors) over on LS1tech.com! Then again we are talking about the latest version of the SBC. It's hard to be the first to do anything on a small block. That try-y I posted a pic of above was built for an LS7 and dyno tuned at Katech. Supposedly it made the most average power from a header they had ever seen there. Coming from Katech who developed the C6R program... that's saying something.

There will be a seal going from the bottom of the radiator towards the motor plates on the bottom, and a hood vent directly above/behind the radiator. There is also at least 9 inches from the back of the radiator to the motor plate. Given the space, crazy 3000+ CFM fans, and vent location I don't think there will be any cooling problems. It's true that not as much air will circulate around the engine, but with a flat bottom that was never going to happen anyway.

This is the first time I got to use both a rivet gun, and my polishing wheel. Good fun. These flaps were a semi-original idea of mine. I used a small piece of angle aluminum to sandwich flaps that I cut out of rubber that was originally meant for plumbers to make custom gaskets. The angle aluminum stiffens up the whole shroud, while the rubber acts as a slight vibration damper.

6/18/10

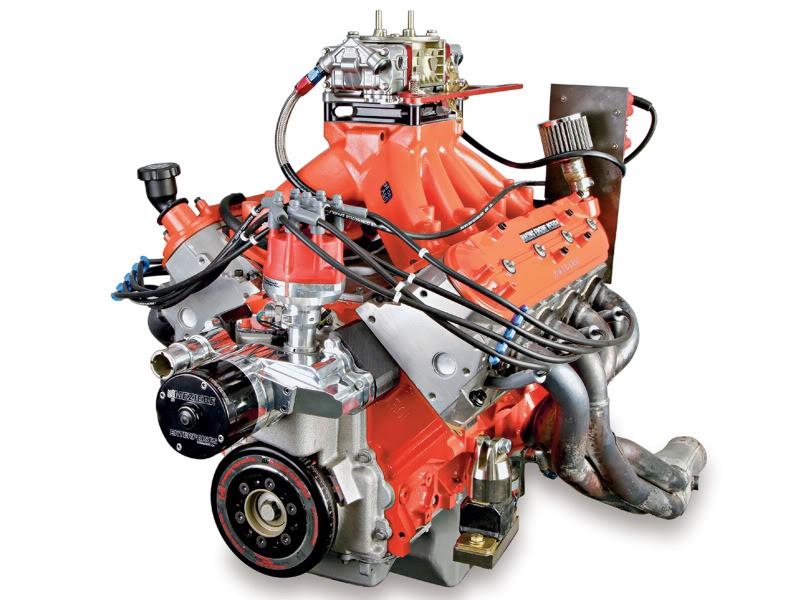

A recent Engine Masters Challenge redefined what blocks you could use the LS7 heads on. Just like the guys at RED I scored a bare set of LS7 heads for a screamin deal. But now don't want to pony up the cash for the big bore block that they really require. Before this article came out the smallest bore I've heard an LS7 head being on was a .035" over LS3 block at 4.100".

Here's the article in question,

Racing Engine Design 370 Gen III Chevrolet LS Engine - LS1 Performance - Popular Hot Rodding Magazine

Per the article RED made no changes to the combustion chamber. But did swap out the stock 1.61" exhaust valves for smaller 1.54" exhaust valves. This would free up 0.035" on the exhaust side and possibly allow for a 4.065" bore, but the RED 370 supposedly was on a 30 over LQ9 block at 4.030".

Where did they come up with that other 0.035" of clearance? Moving the valves with a fancy valve job, offset block to head dowels? Or maybe it just works!

RED 370 EMC

MY STOCK LS7 CHAMBERS

It doesn't look they moved the valve at all. And you can pick up an LQ9 block for $250.

10/14/10

Powers back on in the garage! I wanted to get the pedals all mounted up. The bolt-on throttle pedal mount I made was sturdy as all hell, but the stock pedestal was flexing so I made some reinforcements.

b4

after

So it's still a bit flexy... But it's the firewall that's flexing now, not the mount! I'm sure that my access holes aren't helping. I plan on replacing my hacked access holes with neat, clean, strong tubes with caps. That's still not going to stop the firewall from flexing though.

I've long wanted to make my own strut tower bar. And I got really inspired when I went to the (NAHBS) National Hand Built Bike Show in Virginia last winter.

North American Handmade Bicycle Show | NAHBS

A whole bunch of down to earth, talented, cool people. It was great. I would probably just buy something if I could find what I was looking for. Most 240sx strut bars are bent to clear the tall KA, and also never triangulate the firewall. Both glaring design flaws imop.

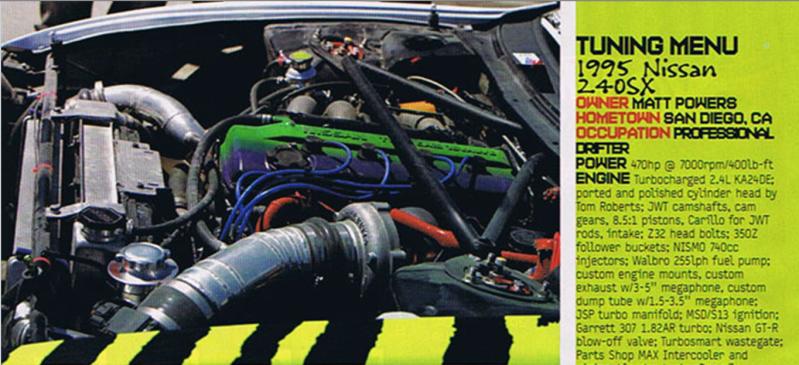

I love the bar that Matt Powers is rocking on his s14, but I suspect it was custom made. If anybody knows otherwise, or has better pics of his please let me know.

MP

MP

At the NAHBS I met a few guys that cast their own lugs (the part that connects the tubes of brazed (not welded) bikes. The custom artistry that many people carve into these is amazing. And as cast they are only $20 a piece.

I also spied the S&S stainless coupler for the first time. A lot of high end tandem bikes are starting to incorporate these to increase portability.

Features of bikes with S and S Couplers:

Strong: Couplings are stronger than the actual frame tube! No added flex!

Lightweight: Adds only 8 oz. (226g) to a road bicycle. (1"x1 1/8" tube size)

Durable: Rider reports 25,000 + miles with absolutely no detectable wear.

S & S Couplers

So if I can't find more info on Matt's strut tower bar, I might make my own using lugged chromoly tubing.

10/18/10

I started a thread on subframe reinforcement.

S14 Subframe Reinforcement

I've also been thinking about a Q45 diff swap (but keeping the 4.083 ring and pinion) just to get the supposedly beefier axles and VLSD until I can sace up enough for the OSgiken. I've heard that the Q45 has 30 spline axles, compared to the 29 spline s14 axles. Does anybody know how much thicker they are? I measured my s14 axles at 28mm.

Good Nissan read!

Posted by Diggymart on 11/1/21 @ 12:53:02 PM