You must be logged in to rate content!

6 minute(s) of a 390 minute read

2-21-2010

I updated the pic in the last post. Should make it a little easier to understand where you'd have to put SPL's spacers to get the effect you want.

I could never understand why the corvette had the alternator placed so high. I weighed my GTO alternator today, and it was 14 lbs!!! I have an F-body alternator bracket that will not fit a GTO alternator which has wider mounting boses. I plan on using only the botom mounting holes of the F-body bracket and lowering the alternator to almost the level of the bottom of the crossmember with heim joints and rod.

Red line will be the heim and hex

The corvette's alternator is actually above the head. That must be almost 2 feet higher, and 14 lbs!

stock vette alt location

The old subframe bushings finally came in handy. I removed the metal cylinder from the center of the bushings and cut one in half so I could push the steel alternator bracket liner (marked with pencil) flush with the inside, so that the F-body bracket will be wide enough for the GTO alternator.

2/24/10

I called wegner motorsports about a 1/2" water pump spacer. They had two sets of 0.520" in stock at only $14 each!

[Recall I'm running a .25" motorplate and a corvette waterpump that is made to sit 0.75" behind the the camaro acc. offset I'm using. = 0.50" to make up @ the WP.]

I may have to knock them down a bit on the mill though. They told me that each WP gasket is about 0.060" thick. A normal application uses one, I'd have to use 3! Wegner suggested that I might be able to get away with just silicone and no gaskets. What do you guys think? It's all flat aluminum on aluminum. If I want to use all of the gaskets a perfect offset for the spacers ould be 4.880".

I've also started to label my wiring harness. It's a used harness I got off ebay a while back from a 2006 GTO. It was missing the interior harness and throttle pedal so I had speartech make me the extension harness for the GTO gas pedal I have. I'm struggling figuring out a few of the connectors. Does anyone know where I can get a wiring diagram with the wire colors for free?

I've figured most of it out just by looking at the connectors here:

EFI Connection

Thanx for the Christmas label maker Mom!

3/2/10

I purchased pipemax last year and have been very pleased with it. But I am having some trouble figuring out what lengths to use initially on a hybrid tri-y design.

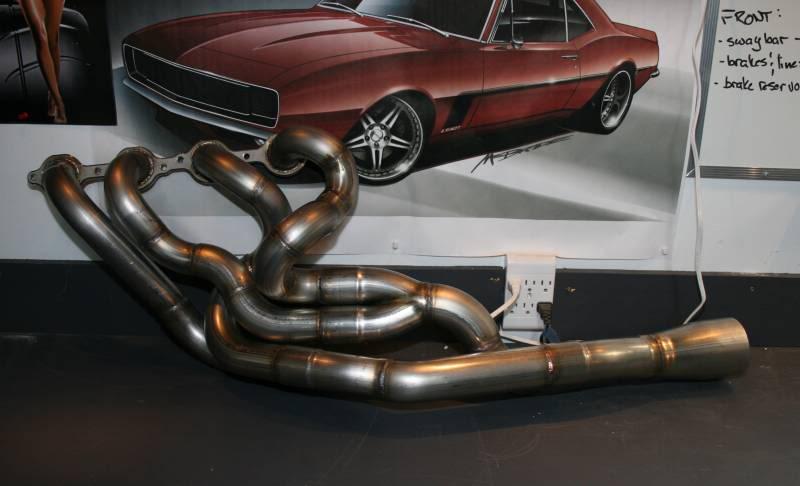

Normally a try-y header is tuned to have the first collector at the very short 3rd reflected value usually about 15" from the ex. valve. It would be very tough to get the collectors that close and I'd rather use the further 2nd reflected value about 29" from the ex valve, this set up is sometimes called a hybrid try-y because the try-y collectors start where a traditional 4-1 would. Except for the LS7 header with the pic of the 67 camaro in the background the other pics are of honda headers cuz they are easier to see, and also one of the only communities where hybrid tri-ys are common.

traditional tri-y

hybrid tri-y

same collector location as a traditional 4 into 1

The following is a letter I sent to Larry Meaux, the creator of the program pipeMax: I have been considering using a pair of used nascar tri-Y collectors in place of a traditional 4-1 collector on my LS7 427 V8. Problem is I don't have room to use RV3 (14")as is traditionally done as the location of the first 2-1 near the heads. I wanted to place the first set of collectors at RV2 (28"). My question is, "can I use the 4-1 (3.5") header collector LENGTH quote from pipeMax for the pair of collectors (2.5" each) from the first tri-y step to the second, or does the difference in diameter change the length required too much? Suggested collector lengths are 16" 26" or 64", would I be better off using one of these lengths or RV3 (14") length for a third time. And what about the final collector length?

Just cuz I dig pictures: LS1 on L, LS7 on R

I was re-double checking that the LS7 and LS1 had the same location for the header bolts. They do.

I also got the a response from Larry Meaux, the creator of the PipeMax program. That was really cool of him, he didn't owe me nutt'n but sent me this great response.

"One thing-> when you switch over to TRI-Y design,the Primary 1st and 2nd Segment Lengths are very important

they must be within an inch or two from PipeMaxbut you can also "double" their lengths if necessaryto fit Headers inside bays or for a little more Torque.

TRI-Y example->suppose PipeMax predicts the total length of the 1st & 2nd Segments = 25 inchesthen you could use 50 inches if you needed to , but nothing in between

but if it was a 4-1 Header,then you could have very different Primary Pipe lengths (Unequal length Headers ),and not really see too much Loss if the Collector dia + its length were perfect to what PipeMax predicted

so in other words,

TRI-Y = Primary Lengths are almost as important as Collector Lengths 4-1 System= Primary Lengths are not that important, but Collector Lengths are critical !"

Good Nissan read!

Posted by Diggymart on 11/1/21 @ 12:53:02 PM