You must be logged in to rate content!

4 minute(s) of a 377 minute read

5-1-2009

I see it like this with these projects; everyone wants to do it differently and some may have no idea where to start, if I show the things that I have done people can choose to copy (which I dont mind as long as they dont end up with an identical car) or it can spark an idea for a different way of doing things. I also hasten to say that alot of what I am building I haven't tested in earnest so be aware, if copying, that it may not work.

All said I just love making things, there's few better feelings than coming up with an idea, drawing it out and then making it with your own two hands (plus sometimes the hands of others when you need a bit of machining or ali welding doing).

It's a man thing.........

5-2-2009

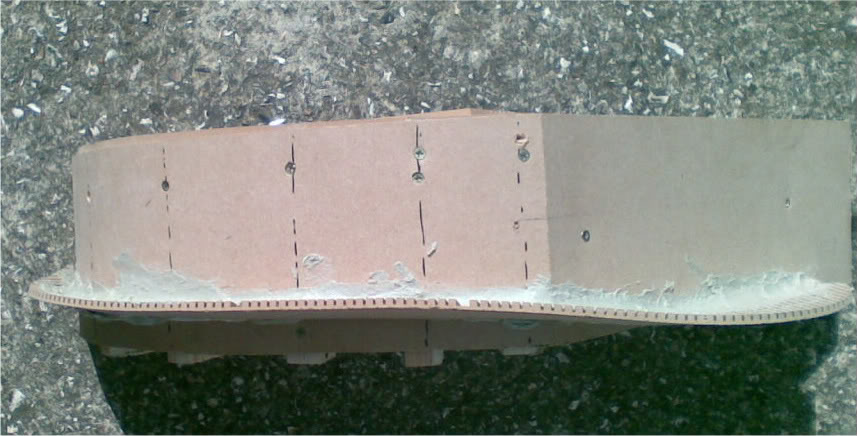

Update on inner arches:

O/S pulled out, thought I would show the photos so you can see why you have to use bendy mdf when trying attch the flange to the arch, serious curves:

More to come as the N/S is made and then onto filling, smoothing, priming and then hand over to my mate Stuart to finish off and make me some fibreglass arches.......

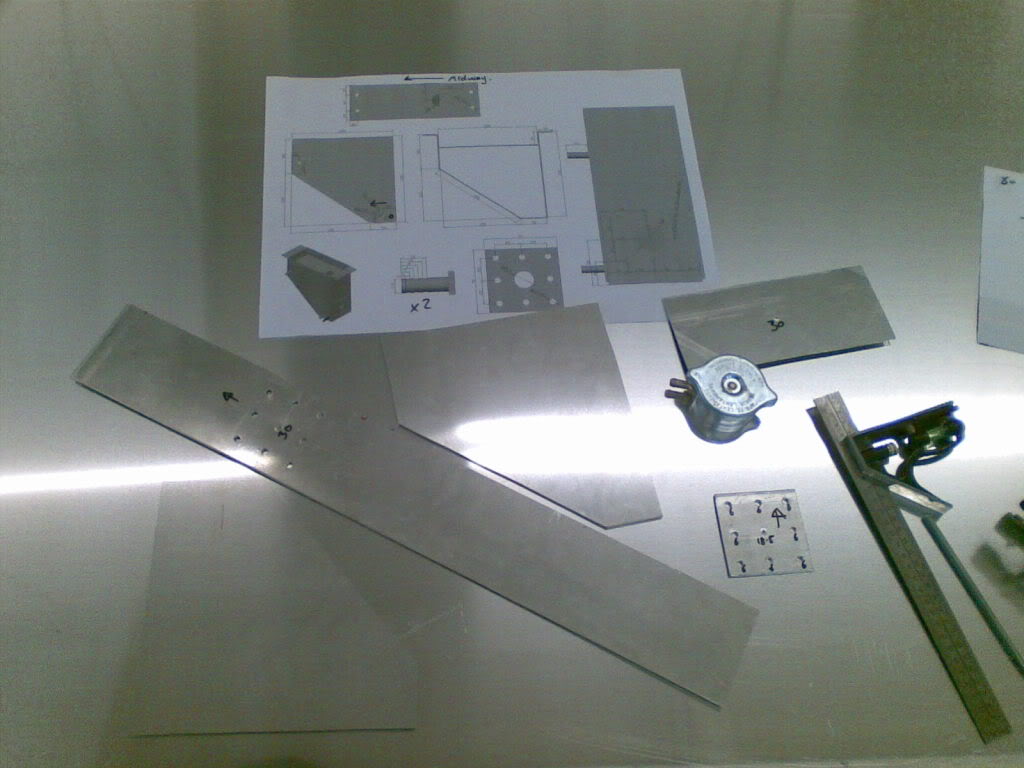

Started making my expansion tank this morning at my good friend Stevie G's place.

So as you can see in the drawing in the first photo, I had drawn up and checked the volume of a suitable exp tank approx (2.25L) I have incorporated into the design a float switch to warn against low water in the tank, incase of leaks more tha anything else. The finished article will have the usual one inlet, high up, but two outlets, one for the engine coolant system and one will initially be unusd but is intended for the intercooler water system, the benefit of which is that the I/C coolant then is also pressurised, aiding to the efficiency of the pump if the outlet is connected in the right place.

I reached the stage of it needing welding and its missing the holes for the inlets and outlets as I need to talk to the Barry the Welder about hole distances.

We start with photos of the flats parts then onto a bit of bending and how to overcome not having a bending machine available, then just some shots of the parts offered up. Hopefully it will be welded up in the week and ready for installation next weekend - woo hoo.....

Wow this is amazing build!

Posted by Diggymart on 2/3/20 @ 4:10:14 AM