You must be logged in to rate content!

5 minute(s) of a 377 minute read

4-28-2009

I know it will be, thats what keep driving me forwards.

Not much to report, in the middle of making plugs for inner arch moulds. Due to the size of the arches they are proving somewhat challenging. Hope to have photos by the end of next weekend.

On the advice of a friend I made a list of all the jobs that need doing, crikey there is a shed load of stuff left to do and I now find myself waiting on two plates to hold the scoops in before I can move forward with the sealing of the rear bulkhead. Which is holding up putting the engine back. The one bonus is that because there is sooooo much still to do I dont find myself sitting idle.

4-29-2009

I am starting from nothing with the inner arches. Because the outer arches are sooooo massive they require a slightly different approach. And I think that the inner arches that Z’s supply would have been too small. From what I can see the outer arches are mostly stuck to the body rather than bolted, but I still have a good 30mm of flange to work with inside the arch.

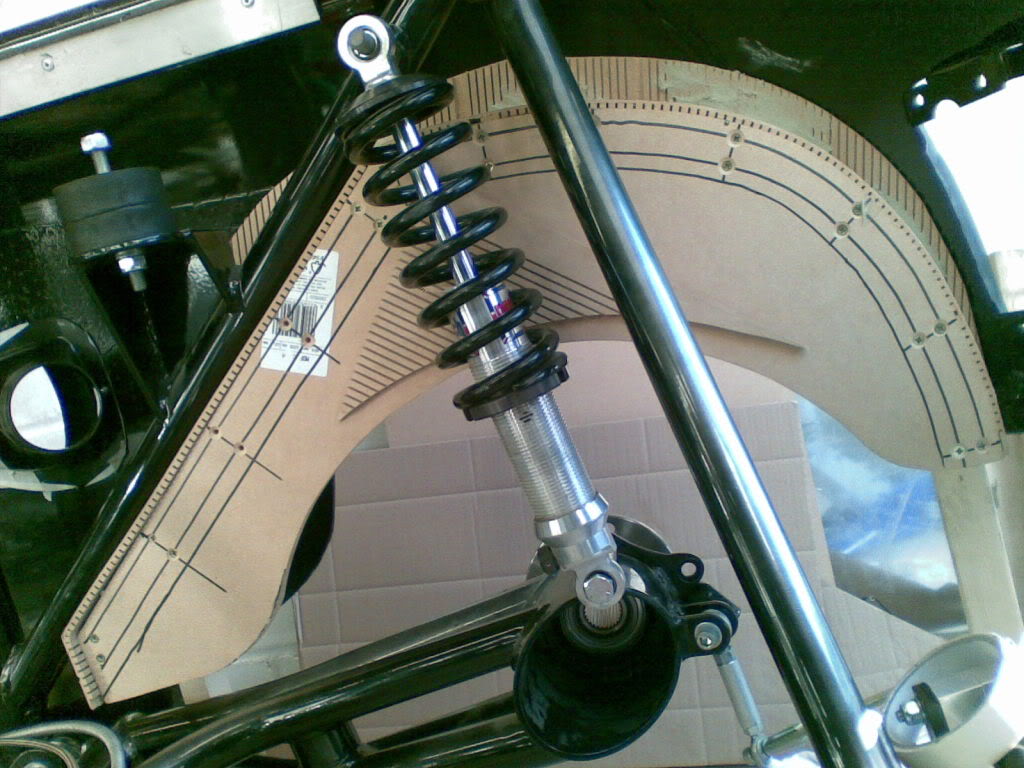

I have started making a plug that utilises the angled part of the frame that goes from the top of the suspension unit to the front of the rear suspension arm. The arch follows this angle to the top then follows the radius of the outer arch down to the rear of the car. Once I have made the plugs I will take a photo and post it on here, then all will make perfect sense – honest.

I wont have to cut mine as I will be putting them in place before the engine goes back in or if engine is in I will remove the suspension arms to get them in – that’s the plan, but as we all know the best laid plans often go to sh!t.

So I spent some time on the inner arches this evening and have got the O/S to the gluing the flange to the main body of the plug (woop woop for Gripfill).

I would like to say that whoever thought up bendy MDF needs a medal it is just whats needed when you have the curves of the body to contend with when try to make a flange for the arch.

Maybe now you can see what I was ranting on about in the post before this.

I would like to point out it is a work in progress and there is still alot to do before it is ready to make a mould. Plus I still have to do the N/S.......

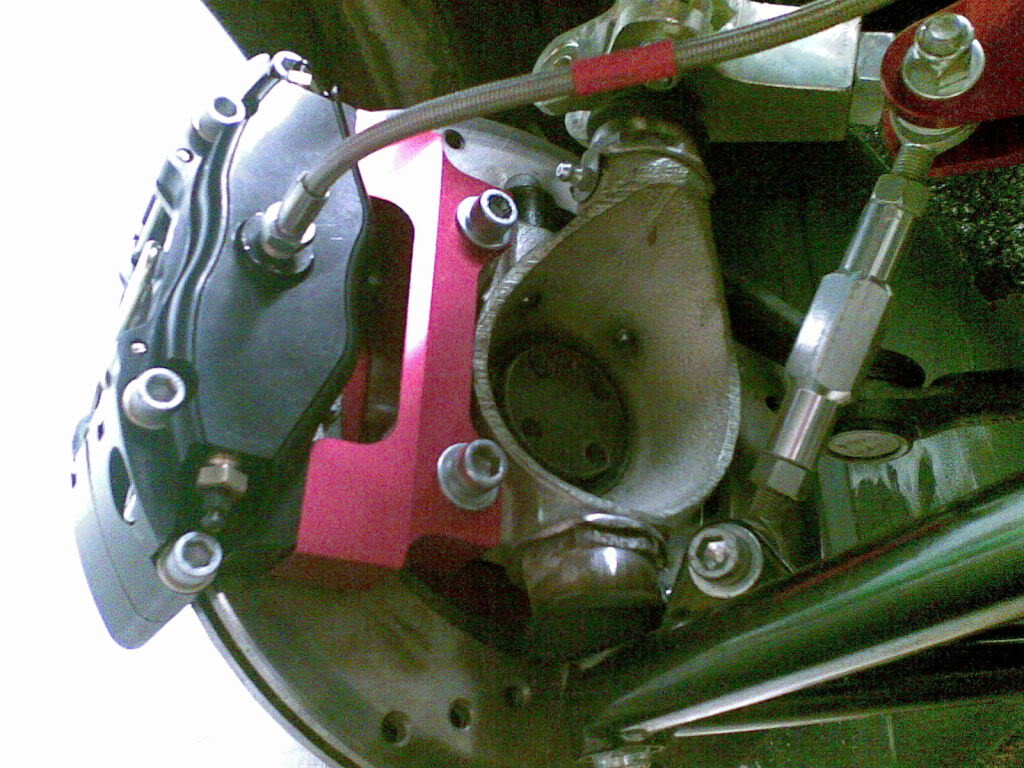

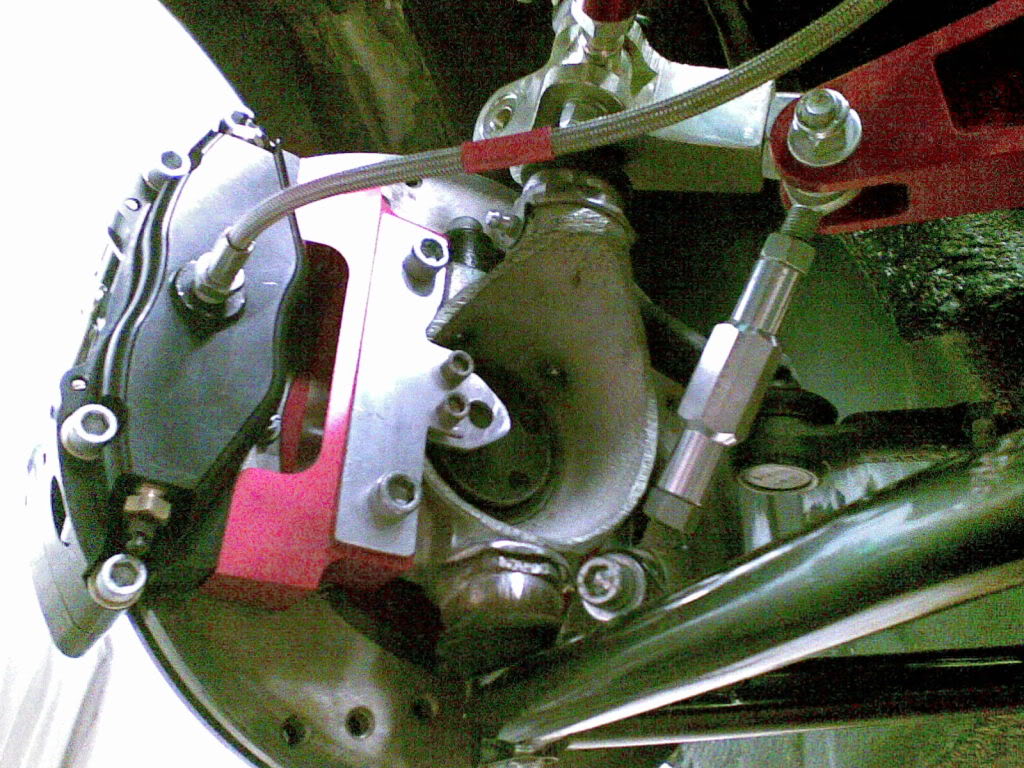

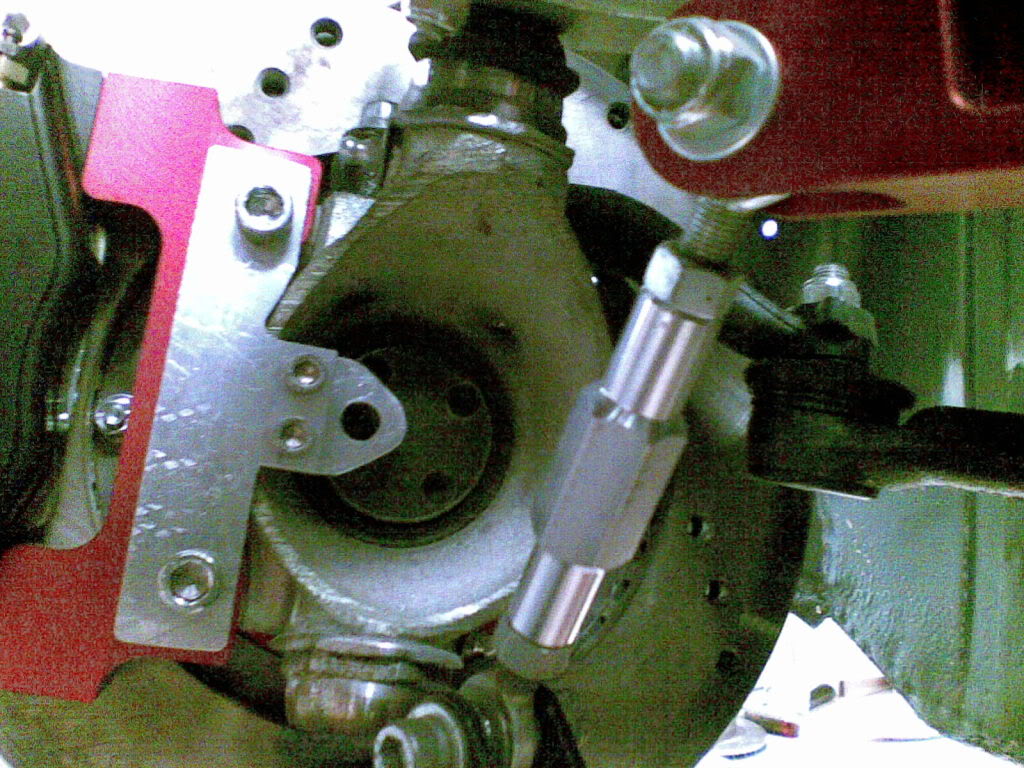

Once I had thoroughly covered my finger in gripfill making the inner arches I set about making the speed sensor mount, please excuse the photos, out of focus and grainy comes to midn but you get the idea:

We start with a picture of where it is going and then onto the mount with sensor in and then the mount in place (minus the sensor as I think I need to buy some longer bolts for the caliper so no point mounting fully at this point), I also need to stick the magnet to the shaft.

I also got around to taking a couple of snaps of the throttle pedal with the spring and adjustable return stop now attached:

Wow this is amazing build!

Posted by Diggymart on 2/3/20 @ 4:10:14 AM