You must be logged in to rate content!

10 minute(s) of a 203 minute read

9-3-2014

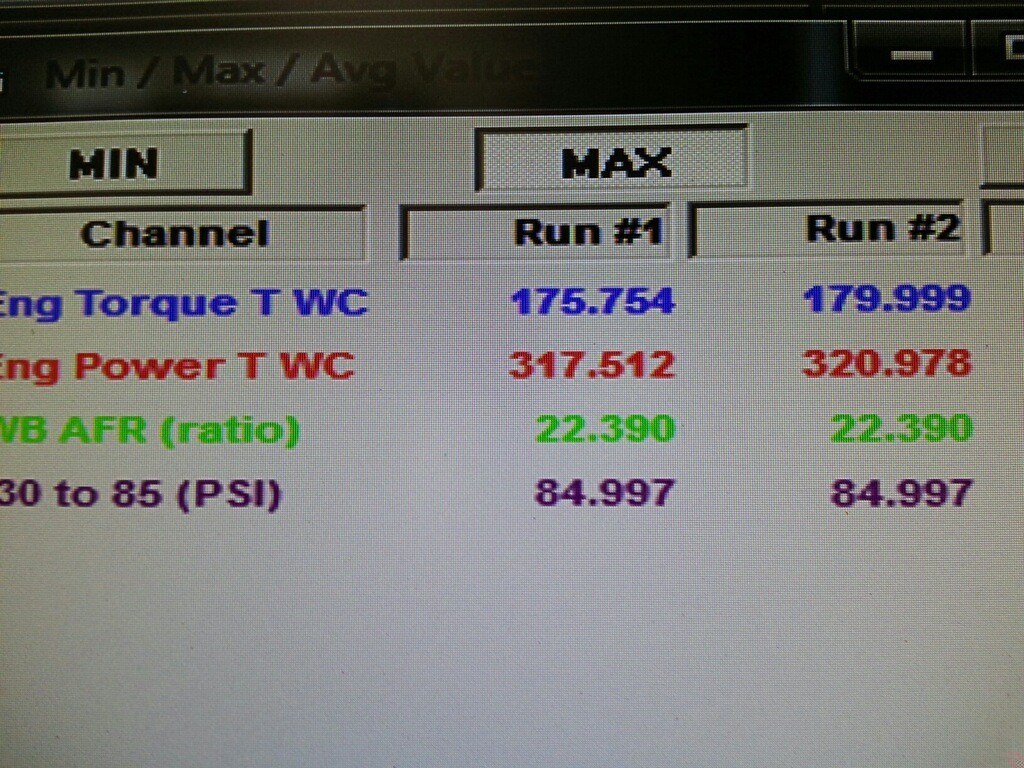

We are up to 320 hp at close to 16 psi boost. We were have a pressure leak from the rubber boots going from the plenum to the head .... time to fix that, then more boost! It is time to test that electronic shifter as well.

Well, somewhat disappointing news. The motor consumes more air than the turbo pushes. I guess we are stuck here at 16 psi until I want to buy a new turbo..... 320 hp and 180 ft. lbs. torque

9-10-2014

I heard from the tuner. He is doing some last 'tweaks' to the tune and I should have it back on Friday. I know I have been on this project for close to 4 years now, but I am actually a little anxious to get the car back and go for a proper drive. Does this seem strange?

9-16-2014

No car yet, but I have the bonnet back:

9-25-2014

Yeah!!!!!

I finally picked it up from the dyno. It made a high of 338 hp at the rear wheels in the slightly cooler weather. I did a quick drive (no pun intended ). It runs MUCH better. The throttle response is smooth. It is quite driveable!

). It runs MUCH better. The throttle response is smooth. It is quite driveable!

The tuner told me he would get the dyno videos uploaded at some point and send me a link.

I will be a while before I can drive and get some videos though.

Big thanks again to www.guruedgear.com

9-27-2014

A couple of pics for now. I may have a short video later today... I went for a short drive. I need to work on the shifter mechanism. There is too much flex in the shift rod. The car now starts easily, idles well, and has very smooth power delivery as well as on/off throttle changes.

On the dyno

Hood installed

More realistic angle...

9-28-2014

Ok, as promised, a couple of videos. I am a bit gun shy driving here. I want to get in some seat time before I really get into the power. I don't think I revved the motor past 8k rpms or so. It redlines at 11k or so. I am just concerned that I may end up doing donuts on the highway inadvertently..... When the roll cage is in, I will feel more comfortable.

9-29-2014

I really loved the sound of the blow off valve on the 2nd video at 45 seconds or so.... But, yes, I think it sounds good. I was worried that it would be obnoxiously loud. It is not, outside the vehicle. It IS obnoxious when inside and driving though.... When I get sound proofing and carpet inside, it should be much better.

This thing is a blast to drive. I am hoping to get a lot more seat time in over the next few weeks.

We were working on the electric shift and the speedometer pickup today, creature comforts.

Ther is an autocross here where I live in 2 weeks. I think I will try to make that for some fun!

I still need to make it to a 'closed course' environment so I can get into the throttle at high RPMs and feel the real power.

In the first video, you can hear the boost coming on for a split second when I shift to second gear ... I am still being a wuss. I still had 4k rpms to go in 1st gear

9-30-2014

Ok, a little more progress, but no pics, sorry ...

We are struggling with getting the speedo to work.

The electric shifter is full operational.

The headlights are in.

Roll cage is next.

Videos of driving and the electric shifter are forthcoming.

10-3-2014

Been busy at work, but a little progress.

Headlights are installed and hooked up

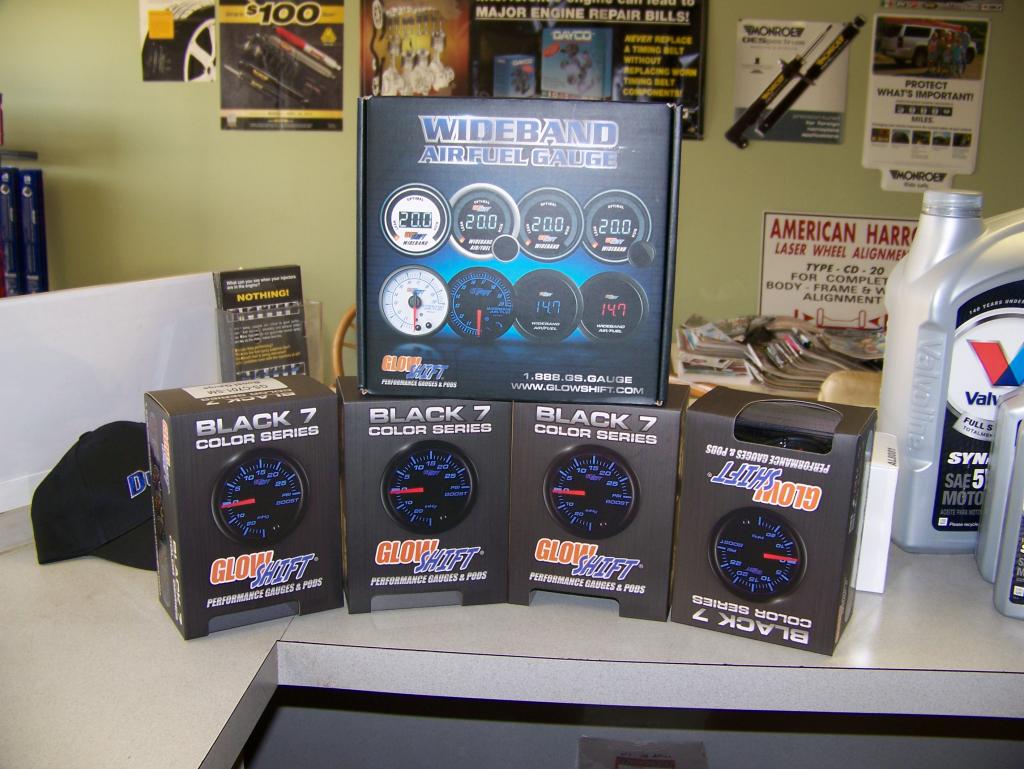

I got my new gauges in. Wideband air fuel meter, oil pressure, volt meter, boost/vac gauge, fuel pressure (already had), and clock. I got the clock to make 6 gauges for symmetry on the dash. I replaced a couple of gauges I had so they all match.

10-6-2014

Thanks Jimmy ... yes, intercooler, not radiator.

I have the 6 pack of gauges in, but neglected to snap a pic.

I Signed up for an autocross this weekend, but apparently have problems. They are being ball busters. Instead of running novice, they want the car in modified. Modified requires a full roll bar, several point harnesses, and all sorts of other crap. I am pissed. I searched diligently on the website ahead of time. I tried to figure out all of the info. I could find no phone number to call and ask questions, so I signed up in good faith. Now, I am signed up, they likely won't let me run, and they don't do refunds :rolleyes:

At any rate, pics of the gauges tomorrow.... and maybe some pre fab on the rollbar.

10-7-2014

I will be working on the roll bar soon. I researched how to cut/ notch the tubing to fit it at angles. Outside of a nice $10,000 tool, it appears that a paper pattern and cutting torch is the way to go. I found a program online to print the paper patterns for a given tubing size, wall thickness, and angle of intersection.

http://www.ozhpv.org.au/resources/shed/tubemiter.html

Here is the pic of the new gauges, installation is still in progress.

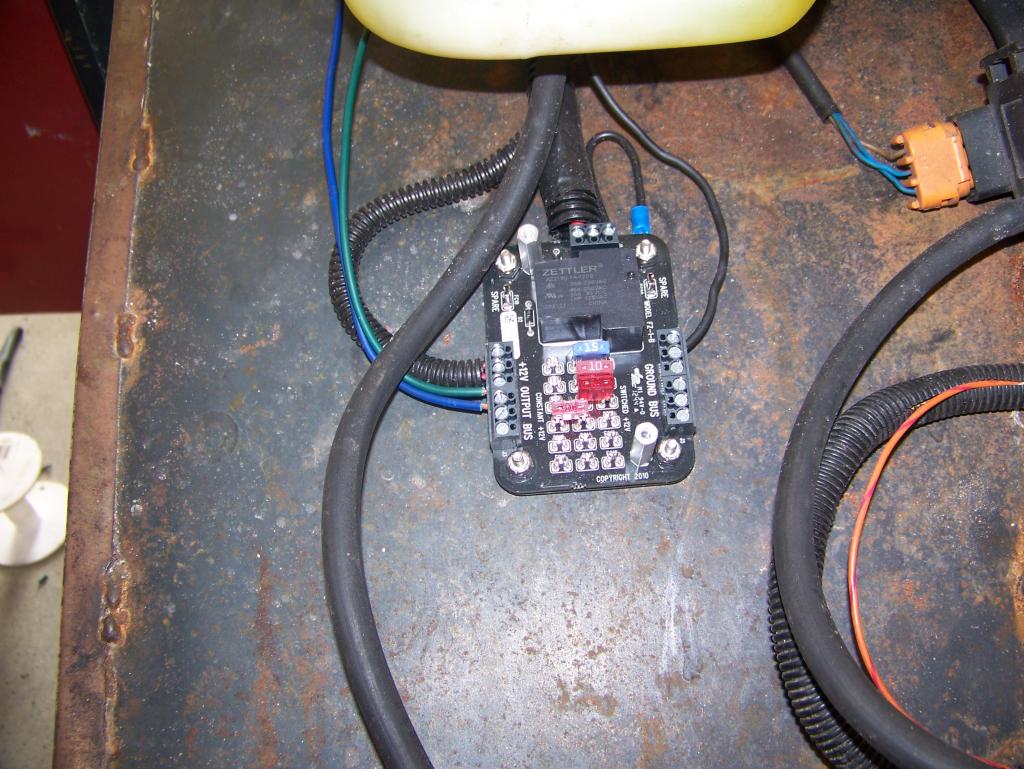

Also, here is a nice fuse block. It includes a row for constant power as well as a row for keyed power. All one needs to do to switch between the 2 is move the fuse over.

10-8-2014

A little progress today. A battery tie down

Sheet metal over the diff. The only stuff the metal shop had that was thin enough was galvanized. I will make some boots to encase the coil overs. I will likely separate the passenger compartment from the boot at some point as well.

Here are the gauges. The video is not in focus, but all the gauges are working properly. I hooked up a horn too. I still think I want the old time Aoooga horn though.

10-13-2014

Made the cover for the pedal box

Still have this piece of firewall to fill in

I was getting too much flex in the all thread I used for a shift rod, so changed it out for this. It was a 3/8" drive extension in a previous life

10-15-2014

The last piece of the firewall is in place

And the air box is almost done. It will be fitted to the bonnet with some foam weather strip to seal it off from the hot air coming from the intercooler, radiator, oil cooler, and motor. I suppose it will work as a ram air as well provided that the hood scoop isn't in a low pressure area of the bonnet. We will never know though, as it will likely never make it to a wind tunnel.

10-22-2014

I am over most sort of competition at this point in life. I am more into enjoying everything I can. I can also say with relative certainty that I wouldn't have anything to 'compare' my ride to because it is so different.

As far as the autocross, SCCA wanted to classify me in some purpose built racing class and make me conform to their safety standards. There are current production cars with better performance that aren't required to meet the same standards. I don't need the hassle. I will seek my entertainment elsewhere. As for the autocross: I can set up my own orange cones in a parking lot and not have to deal with a bunch of pretentious assholes

On a side note, I worked on the roll bar today and will likely have some pics before the weekend.

10-23-2014

Ok, back to the build. I wanted to be able to remove the rollbar, so I plated and bolted it. There are plates on the backsides as well for strength.

I did one large overhead bar

A diagonal brace on either side

And another cross bar for the 4 point harness mounts

Now, time to remove it, finish the welding, and perhaps paint it.

Comments

This thread was donated to our website to be preserved. If you want to message the author, please click the source link to contact.

Posted by diyauto on 8/25/21 @ 1:32:42 PM

This is a great build with so much time and effort put into recording in words and pictures. Can you help me with this question please, Is the top arm inner pivot point is in the same place as the original pivot point? Regards Davy

Posted by DavyF on 4/16/20 @ 6:44:51 PM