You must be logged in to rate content!

5 minute(s) of a 136 minute read

11-29-2011

11-29-2011

This will be a long update, but here goes

So to continue up on............

Part 4!!

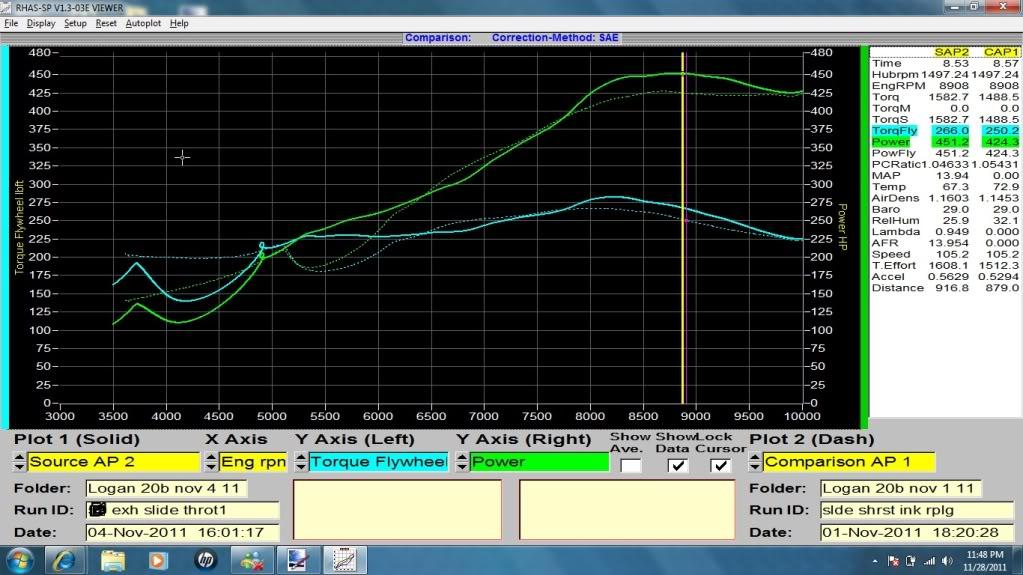

All the revisions made for a nice improvement. I shortened the intake a bit more to shift the torque higher, and the experimental exhaust changes boosted torque VERY well.

Two downsides to this dyno session-

First- I only had a couple days to make changes and get back to the facility. (hard to get dyno time). So I installed three 1600cc injectors in the secondaries, since that what was laying around. Needless to say 1600cc injectors are not atomize friendly AT ALL!

Secondly- The 1600's didnt mount correctly into the fuel rail, so some band aids were made on the dyno (like a awesome zip tie) to make it work. This took up extra time, and I rushed the tune. Afr's at peak torque were 13.4 and going to 14.0 in the 9-10k range. 8+ more ft-lbs were on the table!! Which could have hit 465 or so.

So here is the chart-

So there it is, 282 rwtq and 452rwhp ![]() The torque gain was awesome. I felt some higher numbers could be within reach without too much trouble.

The torque gain was awesome. I felt some higher numbers could be within reach without too much trouble.

Chapter 5- Refinement of a excellent system

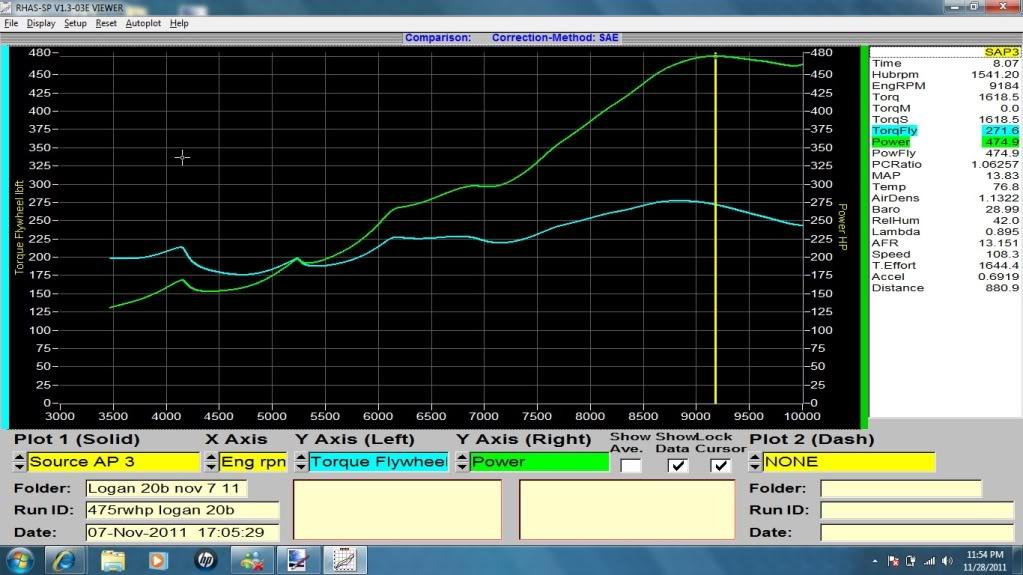

Striking a bit of luck we were able to convince slowmotion (shop with dyno) to let us on again in two days. I didnt change a whole lot, just some minor adjustments of what was working.

Result?

475rwhp ![]() Outstanding

Outstanding ![]()

But you guys can notice a torque loss. 277rwtq is still excellent, but a loss. Looks like the intake ports have finally maxed out. I never dreamed 1" p-ports could go this far, so cant complain. Basically larger p-ports or possibly just bigger sideport ITB diameter is needed. The sideports are on a 52mm throat size, because I felt 55mm was too large with semi p-port at 10k rpm. A close estimation.

So here are some raw footage from the dyno runs, before we make a nice vid. You can see the 1600cc injectors are not doing a great job. But it worked ![]()

http://s254.photobucket.com/user/fd20na/media/IMG_0336.mp4.html

http://s254.photobucket.com/user/fd20na/media/IMG_0337.mp4.html

Chapter 5- complete inspection, streamlining, and slight disaster.

So this brings us up to my most current efforts. Since I had almost three weeks of time, all the stops were pulled to try and tap on 500's front door! While the engine itself was definitely maxed on breathing capacity, I felt making EVERY part and componet perfect might net the torque in the 287 range. 12ft-lbs would allow 500 rwhp. So what did I do? I removed the entire exhaust, and intake and looked at every detail. Remeasured every pipe with the upmost care. Modifications were much more intense this time. The intake recieved some changes I've never even heard of before haha. 10 things in total were improved-

1) Ordered three ID 1000cc injectors to replace the historic 1600cc.

2) Header was made to be true equal length, instead of the unequal method used before

3) New internal intake modifications for increased torque

4) Added three o2 bungs to each header pipe to aid in exact tuning

5) Put high temp silicone on each exhaust slip fit connection, and put saftely tabs on to eliminate any pressure drop

6) Made air boxes for both side port and p-port intakes (this always gains 1-2hp)

7) Intake gasket re-checked and port matched to eliminate some areas of turbulance

8) Header length re-adjusted a final time to PERFECTLY match my intake/exhaust math ratio

9) Finally run the proper smaller diameter main pulley to prevent waterpump cavation. Which gains 1hp or so too ![]()

10) Try race gas for the first time, 100 octane

So all little things, but little things add up. I went back to the dyno with some good hopes.

Did 4 pulls, all of which were SUPER lean. Of course using the 1000cc instead of 1600cc took some time to dial in. Even with 14:1 afr torque was already at 274ft-lbs. 13.1 vs 14.1 on my engine is a difference of over 13ft-lbs, 287-289ft-lbs was a reality.

Things were looking great..... and then.............. it destroyed 3rd gear. How the hell do you break a dogbox transmission, in 3rd gear, on the dyno?? No gear changing, no clutch releasing, just smooth pulls. At 6,000 rpm it totally generated 3rd gear. 1st gear still works and was enough to put it on the trailor. So sad. 10k rpm must be really stressful on parts I guess. Good news is that is on video ![]() A employee happened to be taking a vid of it right when the gear broke. Should have that posted soon too.

A employee happened to be taking a vid of it right when the gear broke. Should have that posted soon too.

Still amazed that going from 410rwhp all the way to 475rwhp was possible strictly by tuning the exhaust length and intake design. Next step... going inside the engine finally ![]()

Almost victory........... almost.........