You must be logged in to rate content!

5 minute(s) of a 390 minute read

9-20-2013

9-20-2013

UPDATE

Turblown received my turbo and gave me the news. Essentially, heat killed it. The turbine shield behind the turbine is deformed. The bearings are toast and the turbine was touching the housing. If the housing is okay, it looks like a new CHRA is all that's needed. Still waiting on the final word though.

As soon as he told me this, I knew what had happened. When I first got the car running I took it for a 20 minute drive around my local neighborhood to see how it would do, and I then noticed something wasn't right. I had some pretty high EGT's and idle wasn't smooth. Upon return, my DP flange was glowing from just that quick drive and the heat was radiating bigtime. After a quick ponder, I had a HUGE lightbulb go off. I realized that I never unchecked the timing lock from zeroing it... All 4 plugs locked at 0.

Of course, I let it cool, made the fix and I went about driving it. It obviously didn't show any issues immediately as it dyno'd well and drove fine all weekend. But that it seems really was the beginning of the end.

As I said before, I trusted Logan with the turbo's condition as he seemed to be a stand up businessman. After chatting at Rotorfest before my tune, I had even more reinforcement that he was a stand-up guy. This is why I don't jump to conclusions when something goes wrong. It is apparent that I alone took a perfectly good working turbo, and killed it in about 20 minutes. Live and learn...

Turblown is rebuilding it, and I will hopefully have it back soon. From there, it's getting bolted back up and away I go. Considering the turbo did well on the dyno, I don't feel a need to retune high boost. But I do plan to run some logs as I get into boost again gradually with the new turbo. Just to be sure...

I have seriously considered a billet wheel upgrade as now would be the time. But I just don't see the necessity. My achieved power is more than enough for my street car. At the cost of another trip to the dyno and retune, I may get the same power at a couple less psi. Tempting, but I am pretty happy with my results.

I also still plan to press forward with no BOV. With a fresh turbo, I plan to clock the miles and frequently check shaft play. I really feel like I need personal closure on this debate. So we will see where it goes.

10-4-2013

Carbon Panel

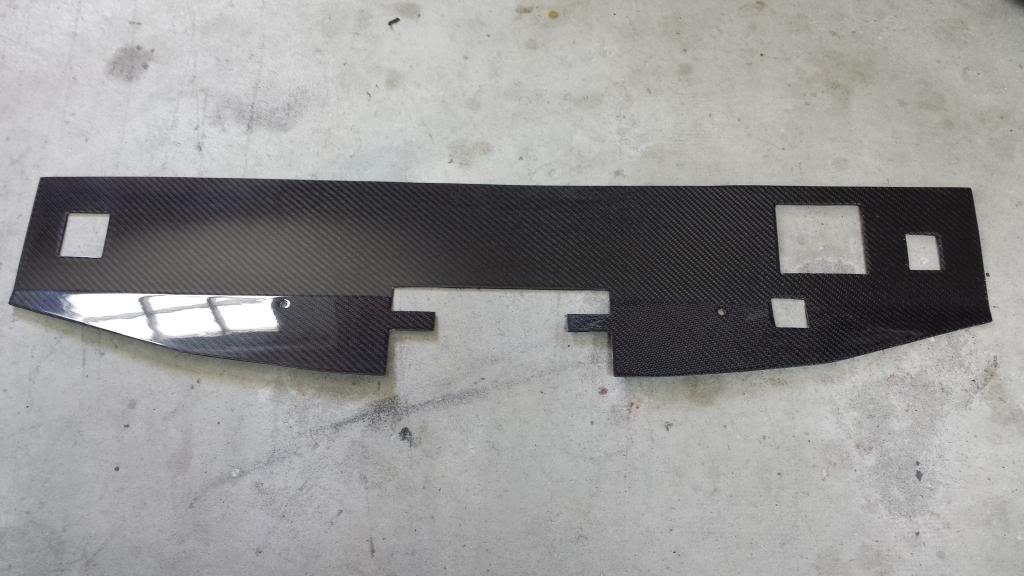

While I have had some down time, I figured I would tackle a job that I hadn't made time for, the carbon radiator panel. I ordered it in a group buy a few months ago by CarbonRXX. As it was designed to fit the factory car, I knew it would need some modification. With this, I requested he cut the large section off of the original design and make it flush across. He was happy to help and didn't charge many any extra. It was packaged nicely and came looking like this...

With some advice from FCinWV, I took some measurements and went to work with my Dremel. I used Dremel's "plastic cutoff wheel" and it worked very well. After mowing through it like butter, I went back and ran a "sanding" tip across the edge to take away any small flaring. I had to cut it a few times as I got closer to the shape I wanted.

I feel the end result turned out pretty well... I ensured the Rotary Extreme SN stamp remained visible as I like it. The panel will be painted Montego Blue, but for now it will remain bare carbon fiber as I get other things up to speed...

Turbo TIME!!

After a few weeks of waiting and discussing my options with Turblown, I finally received my FRESH turbo. It is now sporting their 35R replacement billet compressor wheel. I am ecstatic over the continued EXCELLENT customer service, and products I have received from them!

My decision to go with a billet wheel ultimately came down to a "might as well". With a total limited investment to upgrade and a nod from the wife, it was an easy decision. Looks like the little voices won, and my rational side was once again bound and gagged..... ![]() . I'm headed back to the dyno on Oct 19th, and looking to wring this sucker out! With much cooler ambient temps, billet wheel, and fresh CHRA, I am very anxious to see what it will do.

. I'm headed back to the dyno on Oct 19th, and looking to wring this sucker out! With much cooler ambient temps, billet wheel, and fresh CHRA, I am very anxious to see what it will do.

All that needs to be done is have my elbow re-welded, and bolt her on. Turblown wanted to machine my compressor housing as the billet wheel is slightly larger. With needing it to fit on the lathe, the elbow needed to be cut off. I will once again be doing some test driving before dyno day, and ensuring everything is solid.

Overall, very pleased, and excited!!