You must be logged in to rate content!

7 minute(s) of a 99 minute read

6-8-2014

Another change in direction!

http://www.pirate4x4.com/forum/engin...l#post26142545

6-29-2014

Ok so to catch up a little on where my thoughts are headed. Right now I'm at 6 up/10 down in the front with 2" bumps and 8 up/ 8 down in the rear with 4" bumps. I was planning on 8/8 in the rear for two reasons. 1. It seems silly to me to run a 4" bump stop with only 6" of travel, what is the point of running dual rates if you've only got 2" of travel before hitting the bump stop, basically negating most of the softer dual rate. Leaving a very short transition between either running a really short rate stop or compressing the bumps. 2. With the 231/300 and motor pushed back my rear DS is less than 30" and JB is back ordered on their 32 spline upgrade making 1410 yokes hard to come by and I don't think I can get enough travel to run 1350 and don't want to be constantly breaking 1310s.

Soooo, that led me to selling the doubler set up and buying a buddies brand new atlas 4.3. Between the atlas and switching to the newly acquired ax15 I'll be losing over 10" of drivetrain length, making both shafts almost equal length. And that led me to wanting more down travel in the rear. So thinking about running triangulated lowers and straight trailing arm uppers. I'll be possibly sacrificing some stability but I think between the rear anti rock and how wide the chassis is I think I can move my uppers out far enough to make up for it. So I'm shooting for 20" of total wheel travel in the rear, which given this rig is primarily just a trail rig I'd like to some day build an ultra 4 buggy and so I'd like to experiment with some go fast tuning. I've decided this rig is basically just one big experiment for me to test my skills and push myself into territory I've never been. No one in our group has really built anything like this before so I've been kinda of shooting in the dark as to what's going to work based on all I've gathered from this board. This thread has been mostly pictures and I'd like to get some tech in here so if anyone has any feed back, advice I'd love to hear it.

Summary of the rig:

4.0/ax15/atlas 4.3

115" wb

39.5s

20" belly

16" FOAs

6/10 in front

8/12 rear with the trailing arms

Anti rock rear

Pics of some progress

Welded up the pass motor mount

Went wheelin with tribe 4x4 to break in the new ultra 4 buggy and test out my cousins CJ5

Got home and my seats had been delivered. Decided it was worth it to spend the money and get new corbeau baja ultras. I've decided in my older age that something's are worth just buying new. And these def were!

Driver motor mount is done

Built a stand for the vice

Threw a piece of tube in that I'm calling the driver heel support, when I cut off the frame I lowered the chassis and raised the belly, so under the cowl is a little tight, but my size 13 feet have just enough room.

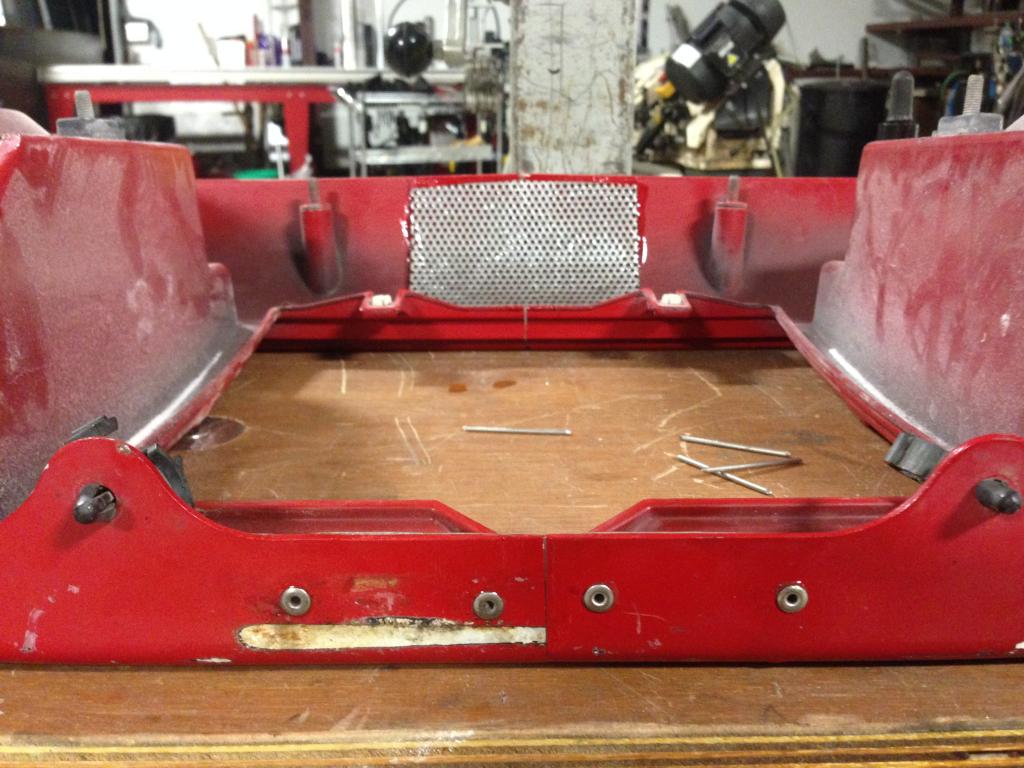

I've been stuck for a while on what to do next on the rig, lots of things need to be done in order to do the next thing but that thing needs to be done to figure our another thing that the first thing depends on. It's a vicious circle. Talked to nick for a while about it and we came up with a way based on where my lower coil over mounts will be to approximate how much the tire will move in at full flex full lock, after lots of triangles I came up with a max grill width of 39", with 3 slots the grill would be 39-3/8, 2 slots is 34-3/8. Decided to go with two, prob could've cleared 3 since the inside of the tire won't fully stuff that high buuuuut decided it would be safer to leave room for future jump in tire size. So first I picked the two best grill slots and cut them out and used blue tape to get a cut line.

Once cut I used a piece of 1x12 ga stanless and riveted and epoxyed the bottom section together.

Took a piece of 14 ga stainless perforated and rolled it to fit the inside of the header panel. Epoxyed that on and let everything cure.

While that was cureing I sectioned the header support bracket.

And used a soldering iron to fuse the two grill pieces back together.

Over all I couldn't be happier with how this turned out, a little sanding and some paint and you won't be able to tell where it was sectioned. Took about 4 hours but the extra time spent getting everything ground straight really helped it come together clean in the end.

Time to finish out the front tube work!

Great journey! Looks like fun getaway. Nice build.

Posted by Diggymart on 1/28/19 @ 1:42:50 PM