You must be logged in to rate content!

16 minute(s) of a 114 minute read

1-30-2009

No updates, I haven't done anything the past month due to freezing cold weather and other obligations. I'll continue in a few weeks with an average of 1 day a week working on the car. Looks like my job closes for 6 weeks in the summer, not so nice for the investors who bought the company 2 years ago but as long as I can keep my job I have no problem, should be able to finish the car then.

5-4-2009

Last update was december 2008, I took a long break but have some time now (April 2009). I did some things in the meanwhile. The rear side windows are bothering me, I think I will make plexi windows with aluframes that will be bonded in with a polymer or urethane kit, more flush with the body. The inner glass window will be left out and the window surround smoothed. Then a small door for the fuel filler cap. Another future project.

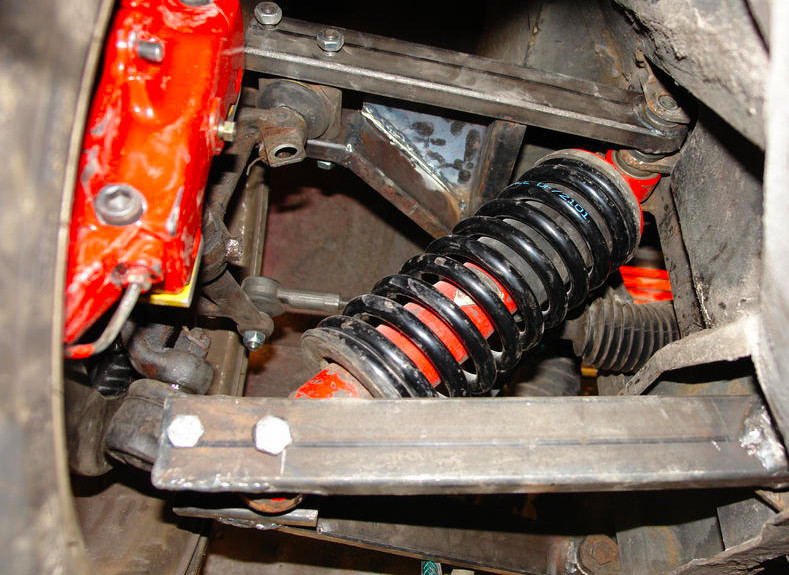

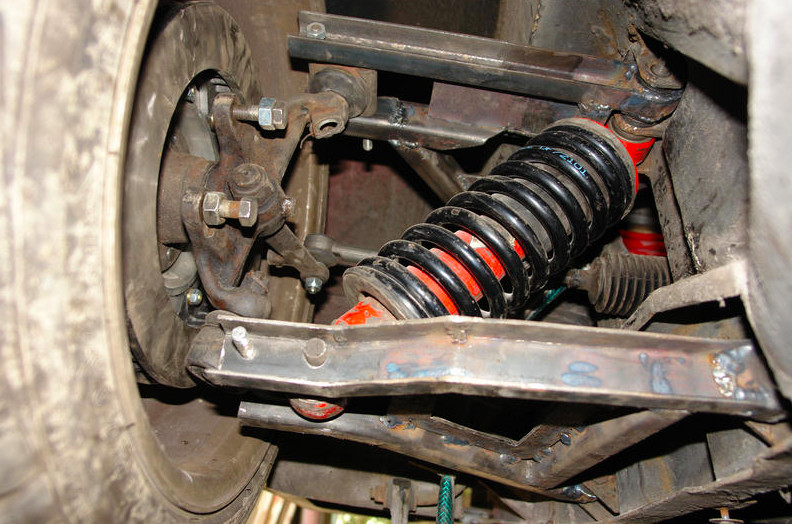

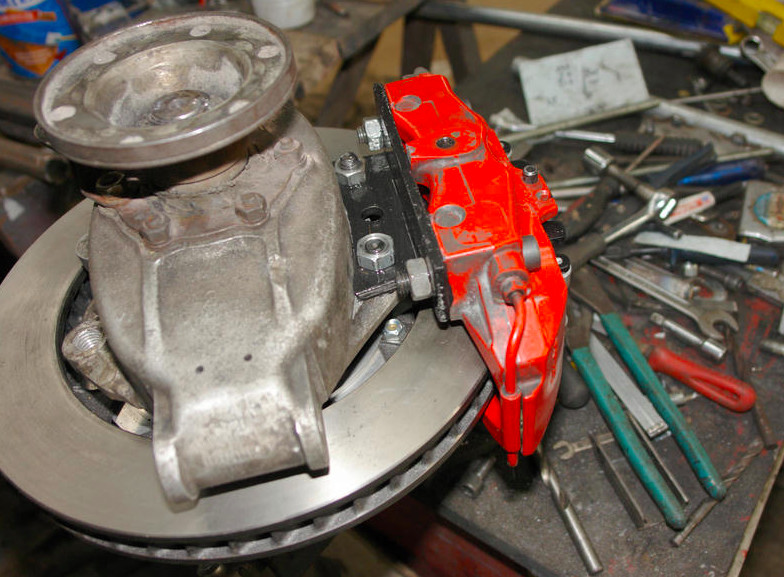

Work continued on the brakes install. Made the definitive brackets out of 6 mm thick 40x40 mm angle steel. The holes for the caliper are threaded but there will be counter nuts also. It takes extreme precision to fabricate these as I didn't want to use shimms later to properly align the caliper in the 2 dimensions.

Seen here with temporary suspension arms. The calliper sits very close to the spokes of the rim and that was what I was aiming for. I think 16 inch wheels would still fit depending on the spoke design or I could have used 330 mm discs instead of 310 mm. These discs are large enough though and already quite heavy. Also the calliper adapter is shorter and stiffer this way and it shows more brake calliper on the outside, good looks is also important! I need to get shorter bolts for the adapters.

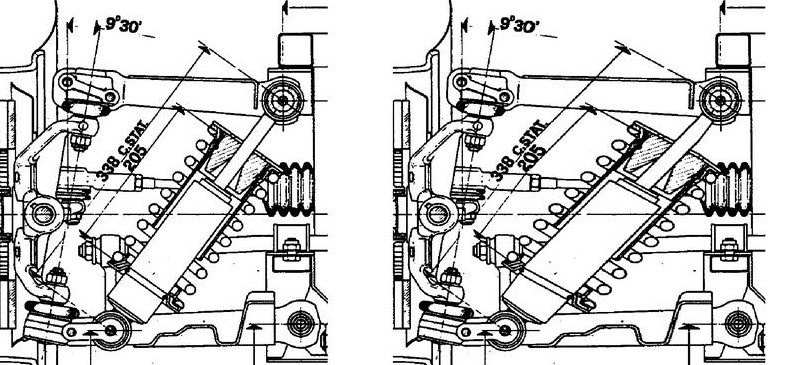

I was thinking alot about what to do with the front suspension. I wanted to get rid of spacers and not use extreme wide wheels. I thought about making subframes that bolt to the existing suspension pick up points where then the original suspension A-arms could be bolted to but rejected that as a poor looking solution and it also would introduce bumpsteer. I decided on longer A-arms but then the leverage of the spring/damper would be longer resulting in softer suspension and a too low front. I made an extender for the upper shock mount that bolts to the original mount and moves out the shock 60 mm. It fitted but looked awful.

I rejected the previous solution and started thinking about buying longer aftermarket adjustable shocks with adjustable spring seats, the QA-1 from the USA seems to be very popular among 308 owners though there are many more to choose from. But I already have new original shocks and the uprated springs from Superformance. I started doing calculations and found then that an increase in A-arm length of 55 mm only had a 6% negative effect on leverage or springrate. That is OK as my new Superformance springs are supposed to be 25% stiffer than standard. I only had to find out if the shock was long enough and that too was OK, wheel can move out 50 mm from my desired ride height before the shock is fully extended.

This means I can use the original Koni dampers and the uprated Superformance springs. However, I did swap the front and rear springs. The springs are similar front and rear but the rears have 1 extra wind making them a bit softer. The rear of the car was too high with the new rear springs but perfect with the shorter front springs so I fitted the front springs in the rear. Because of the longer lower front A-arms I needed a longer spring, perfect, the longer rear springs fitted though I needed to make extra 10 mm spacers for under the springs to get the proper ride height. The front is now softer sprung compared to the rear but this is good. Because I now have a longer wheelbase there is more weight transferred to the front and softer springs prevent extra understeer. Only when all is ready and driving the car I can tell if all is well and when the budget permits I might buy aftermarket shocks and springs after all.

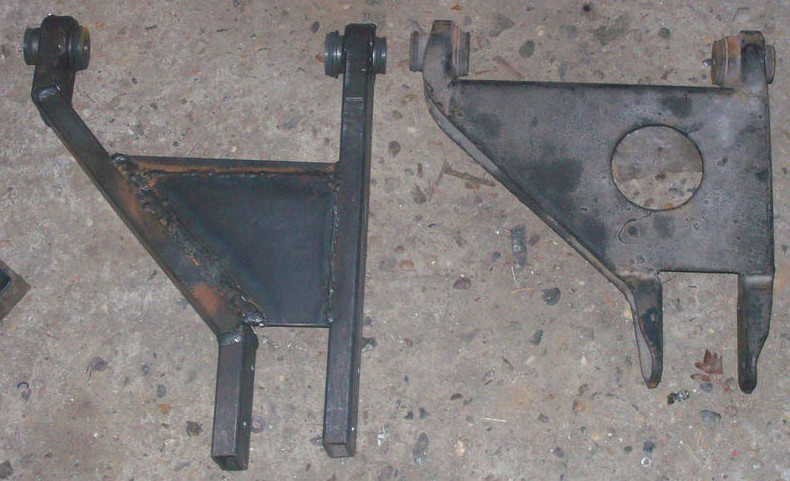

I had started building new A-arms but these were intended to be used with the upper shock mount extender that I later rejected. Also I didn't like the welded angles in the upper A-arm, the welds might break after a while of alternating loads (metal fatigue) so I didn't use these, only for measuring puposes.

Checking spring rate. Not very accurate, spring is 3 kg, 5 mm travel for 22.6 kg weight is 45 kg/cm or 250 lb/inch. Original front spring is about 180 lb/inch, good.

Building the final A-arms, more similar to the original design made with U shaped steel. I still want to strengten the bends for safety, the bending and welding has weakened the material.

It took me 6 hours for every A-arm I build it is all about measuring and measuring again. I wanted the sidewall of the tires to stick out 5 mm from the fender for the best look (the thread pattern is then well within the fender), and also give the wheels negative camber that they originally don't have without using a lot of shims that means the lower arms are lenghtened more than the upper. The camber is perfect now (2 degrees negative) with the shims that were there originally, without the ones I added over 10 years ago 1 week after buying the car. Only need to check castor angle, the same shimms should go back in the same spot but so much has happened it could need flipping shims. It should be so much in spec though that moving 1 upper and/or 1 lower from front to back should do it.

Build rear brake adapter brackets. The rear hubs are the same aluminium casting left and right and they have mounting ears for brake calipers in front and in rear of the wheel but only the rears are machined flat and provided with fine thread M12 helicoils. I checked the front side of the hubs for flatness with a flat file and it was flat after a few strokes. I don't have the stuff to install helicoils, so to make strong mounts I drilled and tapped M12 coarse thread and put in high grade allen bolts with locktite and that makes them studs for the caliper brackets. I got a question about the strength of the angle steel brackets. They are very strong because they are not flat steel that is bend or welded, they are extruded this way and very stiff. Welding in triangles would make them even stiffer but I don't think it is needed.

Red calipers on a red car is like to much lipstick ...

Metallic charcoal grey ("Volvo 214") base paint + clear, then the Brembo decals, then another coat of clear. Looks great, understated and not too obvious but because they sit almost against the wheel spokes they do get noticed. Stupid me put the brakelines on the wrong side of the front calipers. I didn't want to use the painted over original lines so I made new ones and they got a layer of clearcoat.

Question: How can the car be so low without engine?

I jacked up the rear left to check front wheel clearance, the tire tucks in nicely inside the fender without rubbing. (pics not in chronological order obviously)

The steering rack track rods need to be longer with the new suspension. With the quick steering rack from Superformance I received new track rod ends and I sawed off the threaded part from the old ones. The thread is not metric and I had to source suitable threaded rods that are made of tough steel, I found bolts on USA ebay forgot what they are for but they are long enough and made from strong steel, 9 dollars per bolt and shipping, almost 40 dollars for the 2 bolts, at least I have what I need without travelling every store in my country. Also ordered fine thread nuts. The pictures tell how I made the track rods longer. The threaded part from the bolt and the track rod are both screwed halfway in the sawed of portion of the track rod end and secured by the counter nuts. I found a site were some kit car builder lengthened track rods by cutting and welding, my instinct for survival let me to the solution I choose and the guy who does the yearly government safety checks for my cars said it was OK and there is no rule against what I did.

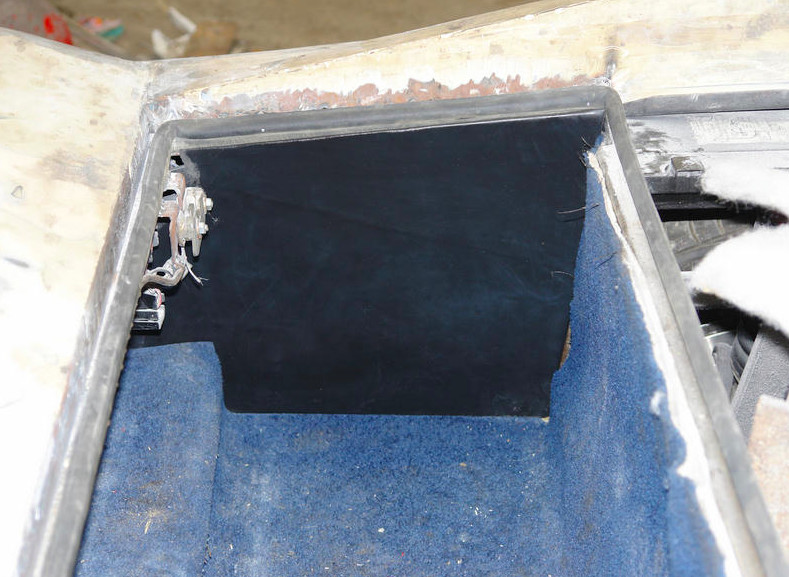

Made side panels for the trunk from 2 mm alu, they will be covered properly with black vinyl with foam underneath. The left one will get a pocket for the megasquirt. These panels go in between the tail lights, the outer trunk parts are wet sections, the wheels are shielded more or less but there will be the side vents and bottom vents that are open to the elements. So the covers need to be able to be removed regularly for cleaning and checks for rust.

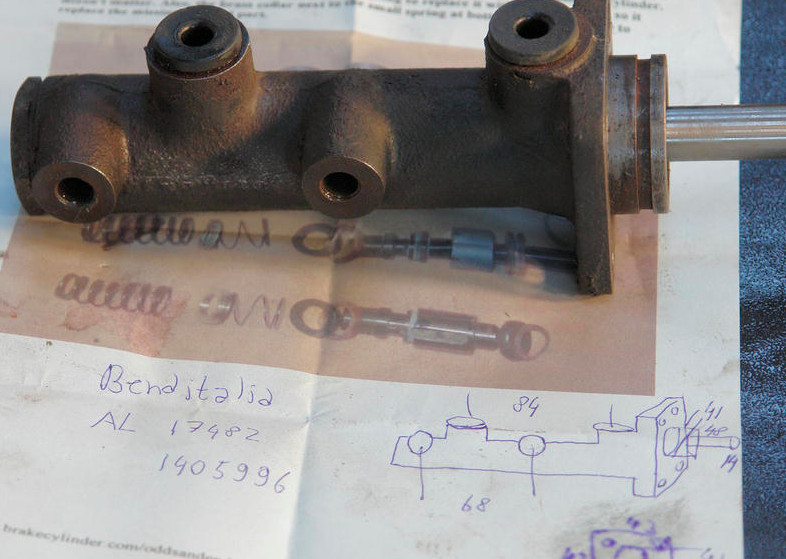

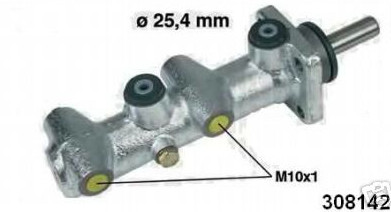

The new Brembo brake calipers have a total piston area that is 31% bigger than standard. This would mean a longer pedal travel when using the original master cylinder. I found on the web that the Ferrari 308 master brake cylinder (mbc) has 22 mm pistons and that there are versions that have 23 and 25.4 mm pistons.

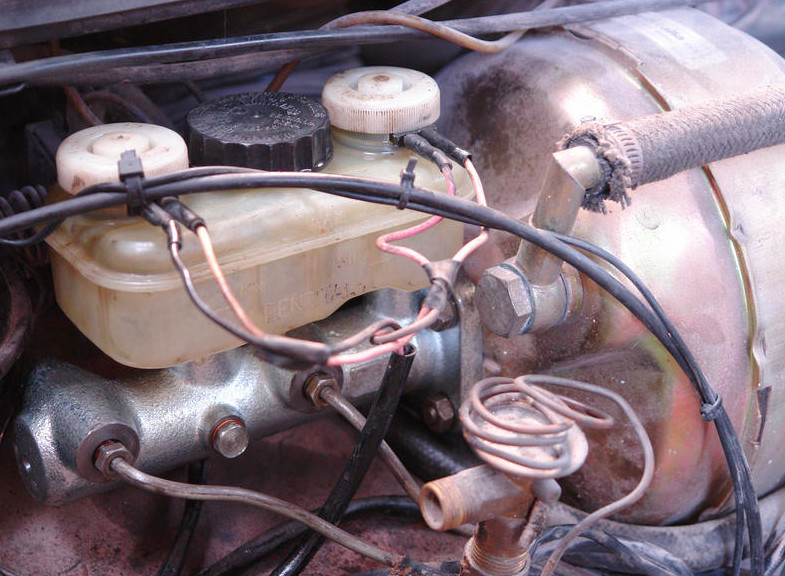

I did a long search before I finally found a suitable mbc, most Bendix compatible mbc have a 2 hole flange, not the rare 4 hole. However I found a suitable replacement mbc from a Fiat Ducato / Iveco Daily (large van or small delivery truck) and I ordered one for only 50 euro.

It is slightly longer and has an extra hole that is plugged but it is a perfect fit, the fluid reservoir fits and the seal to the vacuum booster is also the same. It bolted right in. I haven't connected the braking system yet so I can't tell if it actually works but I see no reason why it shouldn't so far. After that I dismantled my original mbc and found that it was 23 mm not 22 and in perfect order after 29 years. The new mbc 25.4 mm has 22% more piston area and that should do the job.

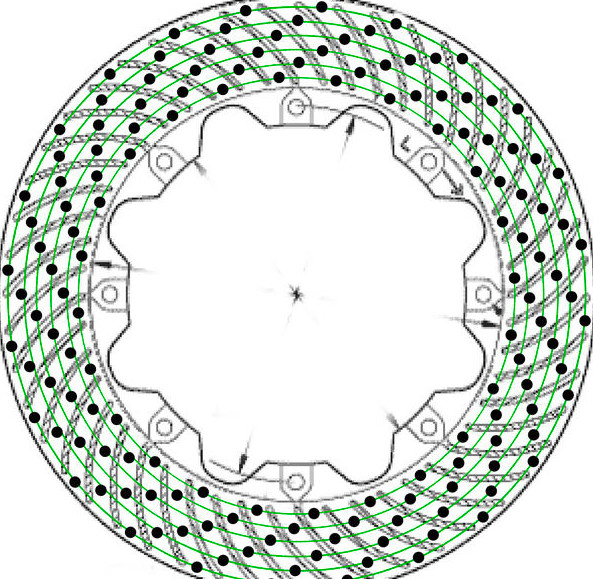

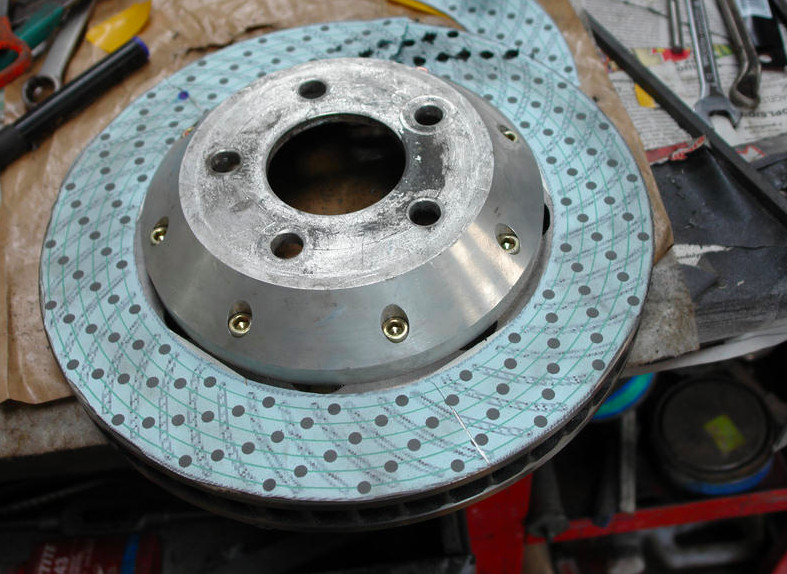

I found the brake discs to be very heavy, and decided to drill them. Drilling is not advised for track cars or heavily used brakes because there can form stress cracks around the holes, but I thought the brakes for my car and use are a bit overkill so I could make them lighter (and cooler looking) by drilling. Made patterns on my computer and choose this one.

Maybe I should have chosen a pattern with fewer holes... The discs are about 700 grams lighter now, substantial. Don't get fooled by the pattern, the inner vanes are in the other direction as the hole pattern suggests, so the disc is still strong, I hope.

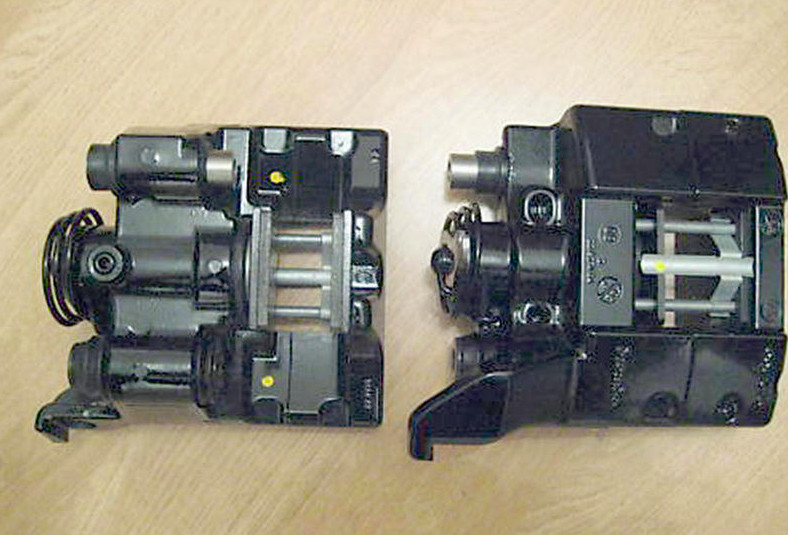

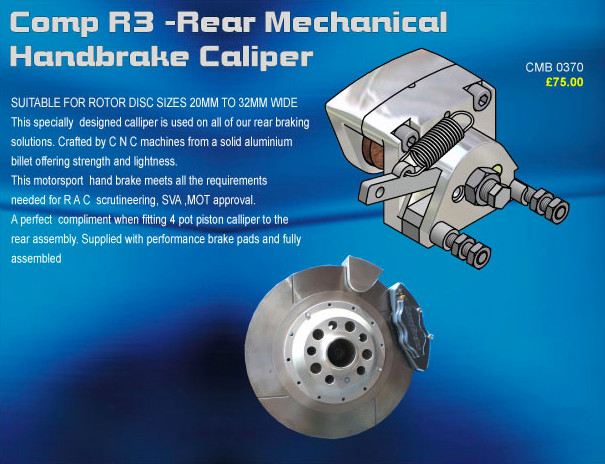

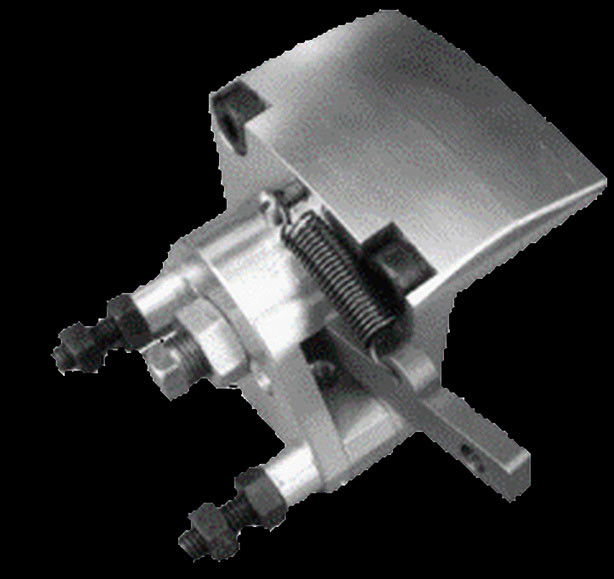

Still need a handbrake. I considered many options, like building one myself from a regular caliper that I would strip and lighten. I tried that but that led to nowhere, ugly, heavy and not dependable. I considered the Brembo handbrake calipers that the Ferrari 360 uses (among others) they are >1000 Euro from Ferrari but can be found cheaper for 300 from independ Brembo distributers and some kit car builders. Here is how they look, and fitted to a 308 rear hub like a fellow enthusiast did.

These are substantial calipers, as big as the main calipers from many "ordinary" cars, floating, selfadjusting and probably maintanance free. However they seem quite big and heavy and I couldn't easily find a pair for a good price. Then I found these and I ordered a pair, haven't received them yet. They seem light and easy to mount and low profile. They are not floating so the mounting adapter should be a little flexible to allow the outer brake pad to get to the disc without dragging when the handbrake is not engaged. Handbrake pads shouldn't wear but if they do the inner screw is for adjustment I think. Also need something to guide the action of the handbrake cables in the proper direction.

Finsishing the build of the body. Rear under vents, I was planning to make them like a GTO with 6 large openings from 2 mm alu sheet but it was no succes, the alu warped and I stupidly misdrilled a hole. So I opted for a simple solution, the original 308 vents are to big now because I have a shorter rear overhang but the home improvement store had a suitable thing. Everything will be black and only visible when laying on the floor so it doesn't matter much. The screws will be sunken in and the alu trimmed to be 3 mm within the body.

Not my favourate part, working in the wheels wells. Some Honda or whatever forum found my site and critisized my welding, they are absolutely right.

Need to get new rubber seals for around all the alu coverplates, probably will rob some trunk seals from the local wrecking yard.