You must be logged in to rate content!

5 minute(s) of a 636 minute read

7-6-2021

7-11-2021

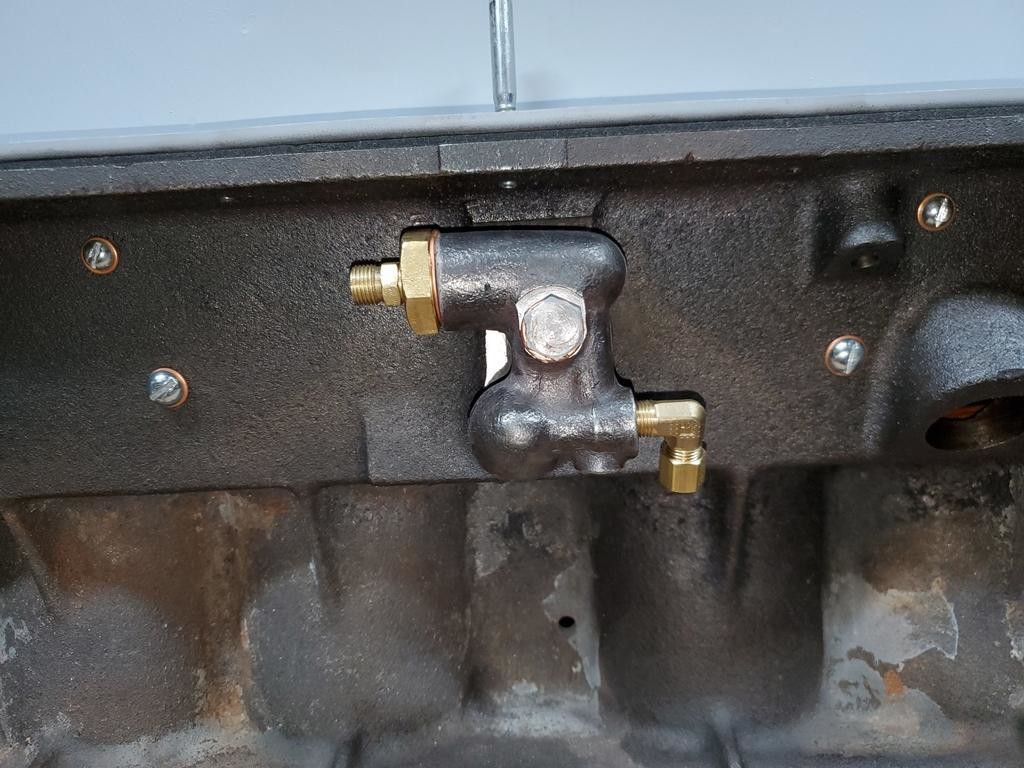

finally got in my 2 copper crush washers i have been waiting for. these are for the 2 screws that hold in the dipper distribution blocks/tubes.

installed them and now the bottom end oil feed is complete, only oil feed left is the line that runs from the oil distributor valve to the rocker arms. i will install that once i flip it over and get the head set & installed.

7-19-2021

now that the bottom end is done, oil feed lines and Oil Distribution valve & Oil Pump in place, oil pan gasket installed and seated. Time to flip it over and start on the top half. When Flipping it over I used both my Engine Stand & Engine Lift. Wanted to ensure that if it slipped in the stand the Engine Lift would have it ![]() Slow and steady wins the race.

Slow and steady wins the race.

i placed it on my Wooden stand i made years ago.

prepping for the head install, i bought 4x .500-13 UNC bolts 6.00" long and cut off the heads and the cut in a slot for guide pins, per the manual this makes installing the gasket and head a lot easier and prevents sliding of the gasket. I did a test and the gasket can only go on in one direction, so can not put it on backwards or upside down. I went with 6.00" long bolts as i knew that they had to be longer than the head is deep or i would not be able to get them back out ![]()

Was wondering should i spray/coat the head gasket with Copper Gasket spray for extra security ? i know this is a common practice, but is it worth it ??

note pins were randomly installed just for test purposes, they have been relocated and set per the Repair Manual guidelines.

Got the Guide Pins in the designated holes per the Repair Manual.

cleaned up the block deck and head surface. then cleaned up the copper gasket and put a coat of copper gasket spray on it and let it dry. then dropped the gasket on the block, then placed the head on the gasket, and put in the NEW head bolts. tightened them in stages per Manual in proper order ![]()

Head is on and secured in place...

you can see that the 6.00" long guide pins were perfect for this application, pretty tall head on this 194 !!

top down of block cleaned up and guide pins set

top down with head in place

side view head in place, can see the guide pins

head installed and torqued in place

thought i took a shot of the copper gasket installed, before the head ? not going back now ![]()

Great car !

Posted by Diggymart on 9/7/19 @ 3:48:57 PM