You must be logged in to rate content!

5 minute(s) of a 891 minute read

7-5-2018

Thanks! My TIG is about the best tool I've purchased for myself since I started doing major fabrication on the car... ironically about a year after I got mine, I started just using the one at work for most of the stuff I've made. Takes lots of patience, but the results should [hopefully] just keep getting better and better!

I was just about to check in on this thread to see if there were any replies I missed. I've been away for 3 very sunny, very long weekends to use up vacation time.. and I'm itching to get working back on the car this weekend. Tonight I'm going to tack weld radiator shroud mounts on the the rad, and finished hacking up the bumper brackets.. by the end of this weekend I really want to have bracketry tacked onto the rad support and have the radiator+intercooler+bumper+grill all held in place under their own weight.

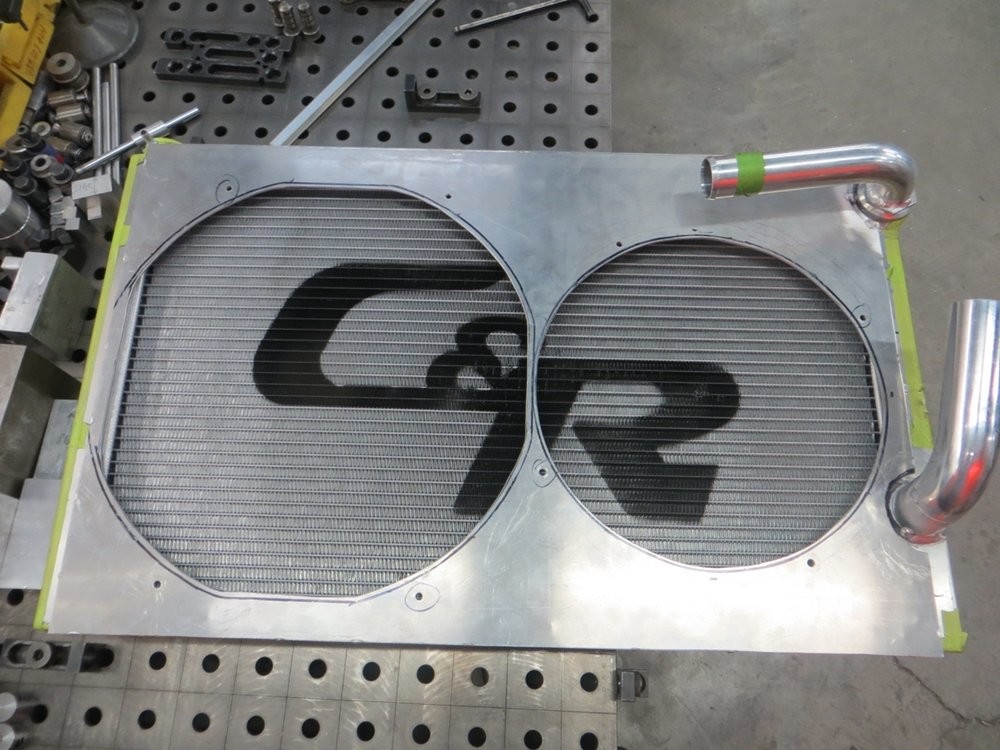

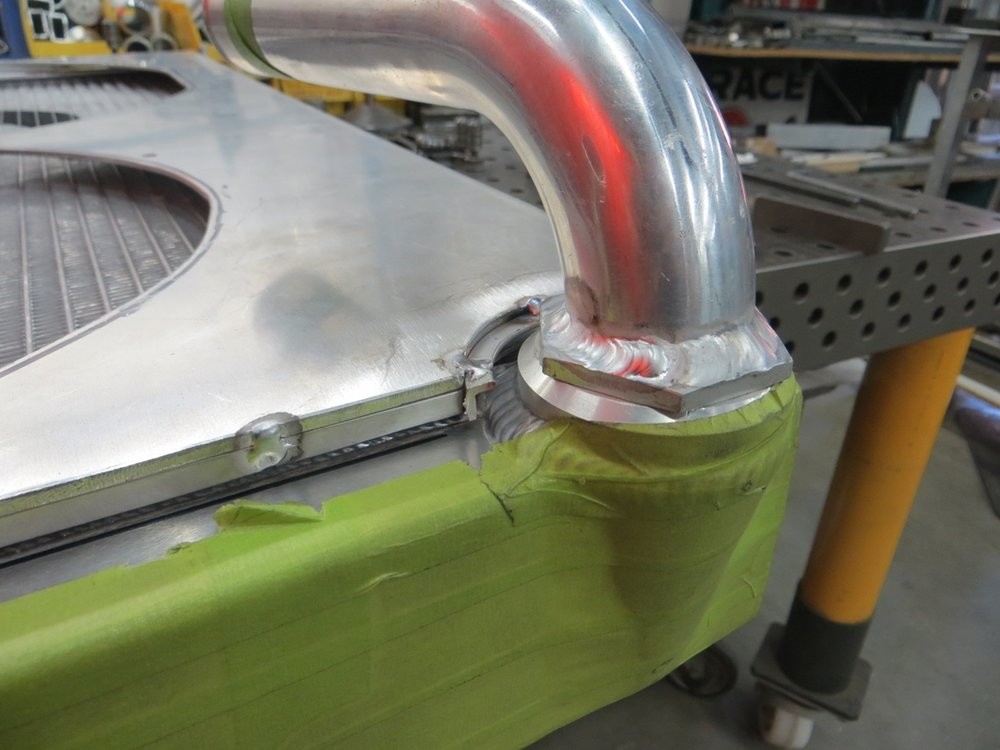

These past couple weeks, every so often I'd chip away at the radiator stack after work for an hour or two, and have made a bit of progress. I started with tack welding a mockup rough routing of how I wanted the lower outlet (or inlet? I can never remember) to be positioned, to clear the smaller fan but also to clear the subframe...

Next up was how to try and seal the shroud around the necessary clearance notches for the inlet/outlet. I figured I'd try and cut a section of the C channel into L channel, then piecut it and have it be a matching-curve base to glue foam seal to...

The curvature was good, but when I went to strike a weld arc to just smooth over all the cuts, the piece started immediately spitting and popping, even after grinding the tungsten clean twice. I figure there was some oil from the bandsaw that contaminated all the cuts, so simply fusion welding it to make it look smooth was out of the question.

Then it occurred to me that maaaybe I'm over-thinking this. what if I just tried to bend the L channel. Well after a bit of hammer-flattening to get out some of the twists from bending an L channel such a tight radius without a mandrel, it turned out pretty okay...

This shows the L channel that I'll glue the seal to, to try and seal the shroud in both directions (horizontally to the outlet, and vertically to the rad end tank....

This shows the orientation of the smaller 12" Derale fan. This fan was listed as a pusher/puller on the website, but unconventionally it had the mounting tabs drastically stood off of the mounting surface... weird.

For the 16" fan, I made stepped spacers so that they're located in the mounting tabs, and reduce from the 5/16" or 8mm tab ID to a 6mm ID for the M6 screws I'm using...

No such room on the ID of the tabs on the 12" fan, so I just made simple standoff spacers. I then turned and tack welded threaded M6 slugs onto the backside of the shroud, so that all hardware is single-tool to make it a bit easier if I need to change out a fan(s) with the rad/shroud left in the car (if room permits that)....

Wow thanks for sharing!

Posted by Diggymart on 3/3/19 @ 12:40:25 AM