You must be logged in to rate content!

4 minute(s) of a 891 minute read

9-8-2018

So I made a major change.. I decided to ditch the front mount oi cooler, for several reasons:

1) I would have had to move the grill forward at least 1/2"-3/4" to fit the oil cooler behind it

2) Even with moving the grill forward, I would've had to lean the radiator back ~3/4" at the top in order to have oil cooler clearance, which would cramp access to the accessory belt around the waterpump area

3) There was a lot of complication and number of fittings on the -10AN cooler lines as routed next to the block and beside the driver side downpipe.. if a fitting needed tightening it would've been a nightmare to access

4) The bulk of the 2 x -10AN hoses along with heatshield sleeve around them pushed them away from the block and closer to the driver side downpipe than I liked

5) Most importantly, my very smart friend Marktainium reminded me of a point that I previously considered but kind of just brushed aside.. there's going to be a lot of heatsoak of the intercooler sandwiched between two hot exchangers.. this is a street car first and foremost which means it needs to make detonation-free power on 94 octane at the best, 91-92 octane worst case.. and I spent all this time making a nice expensive high quality Garrett-core'd intercooler... would be a shame to just heatsoak it at idle. I have a couple of ideas for remote oil cooler options with fans and ducting from high-pressure areas of the car... so the car will be oil-cooler-less for now while I sort out the car/engine setup, then maybe in the winter or next spring I'll add a cooler if/as necessary.

To replace the Holley oil cooler adapter on the pan above the oil filter, I got an Improved Racing multi-port junction block to get my two turbo feed lines as well as a 3rd port for the oil temp sensor..

These analog fluid temp senders have quite the long body length, which makes them impossible to mount on any inline hose fitting since they poke down into the flow path, so it was nice to "have" to use an adapter to go from the -10AN straight thread in the junction block to 1/8" NPT female to accept the sender.. this kept the tip of the sender well out of the oil flow path...

In order to keep thing simple, I redid the turbo supply lines so they single (per side) continuous Earl's braided lines from the oil junction block all the way to the turbo's...

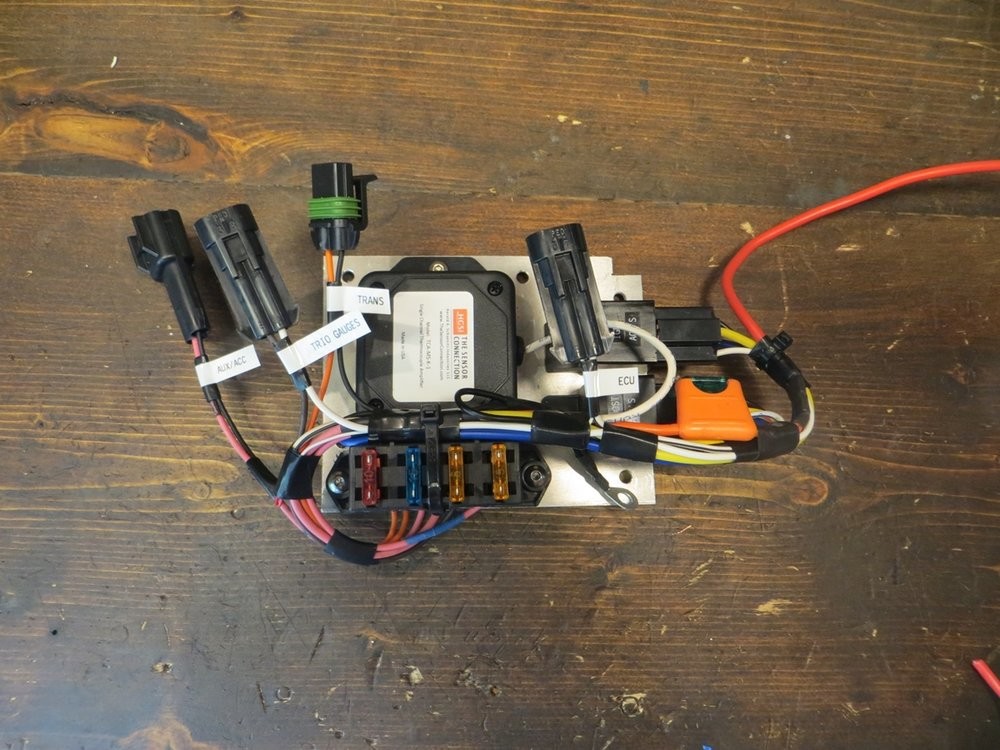

Next up was a mini electrical panel under the glovebox for several accessories. I needed switched 12V power for the EGT signal converter box, as well as a 5A fused feed for my wideband gauge, and an extra relay for the transmission pump, so I made a little setup...

Mounted to the backside of the heater-box-delete filler plate...

And ran my 12V power to the bulkhead fitting I previously mounted in the passenger side kick panel area..

And finished all of the engine bay wiring! Need a little more loom-laying work, but overall it's pretty clean and should be hard to tell any difference from a box-stock Holley wiring harness...

Wow thanks for sharing!

Posted by Diggymart on 3/3/19 @ 12:40:25 AM