You must be logged in to rate content!

4 minute(s) of a 206 minute read

8-10-2008

I started the day today by taking the motor mounts off of the frame. It was one of those things that was bugging me. I cleaned them up the best I could, but I figured since I had taken the suspension down this far, I may as well, take them completely off and clean underneath. Plus, I could put the bolts back in upside down, so it will be easier in the future to remove if need be.

Then I cleaned up the mounts themselves, and painted them flat black.

Then painted the frame, and put it all back together.

After that, I moved on to the upper control arms. Since my replacement bolts are here, I can install them finally. Unfortunately, I had to grind down some off the weld on this one. There was no way the ball joint would sit flush against the control arm.

Its the weld on the left hand side.

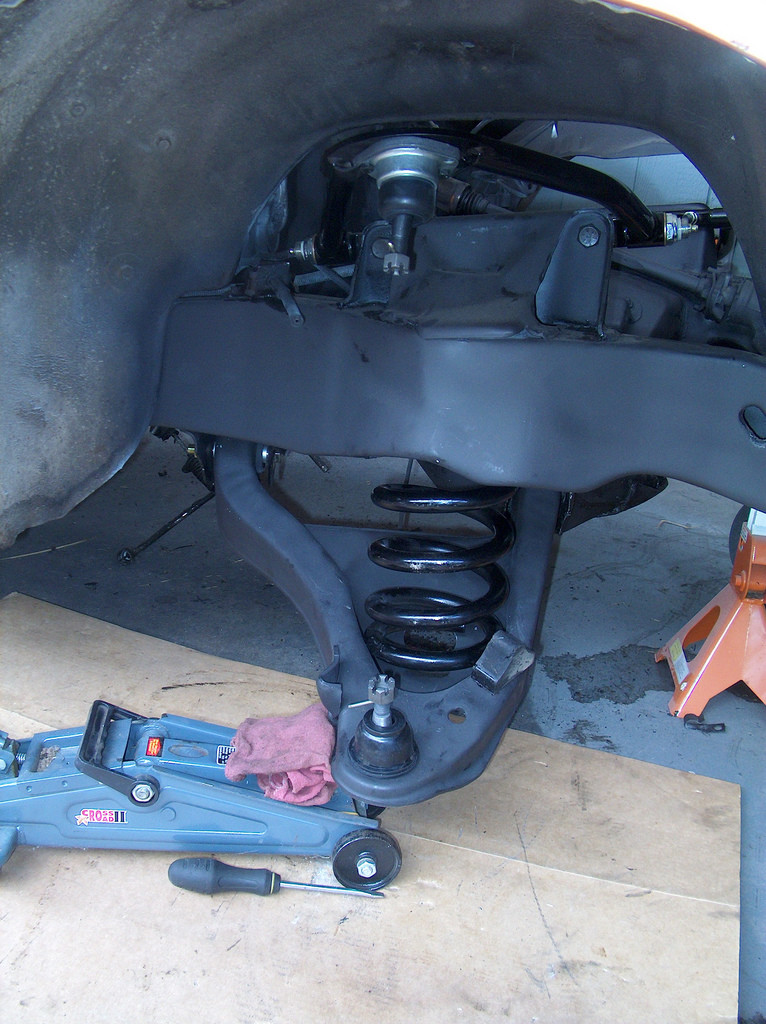

After that, I greased the ball joints, and installed them. Then I took the lower control arms and installed them with replacement bolts. I took the lowering springs and made sure they were seated properly in the frame, while taking notice to make sure that they were aligned with the lower control arm.

I used the small jack to apply pressure between the lower control arm and the frame. Then I gave the spring a tap with a big hammer, and the spring seated properly.

After that, I applied even more pressure with the jack, and sat the spindle in place. Then, I attached the upper and lower control arms to the spindle.

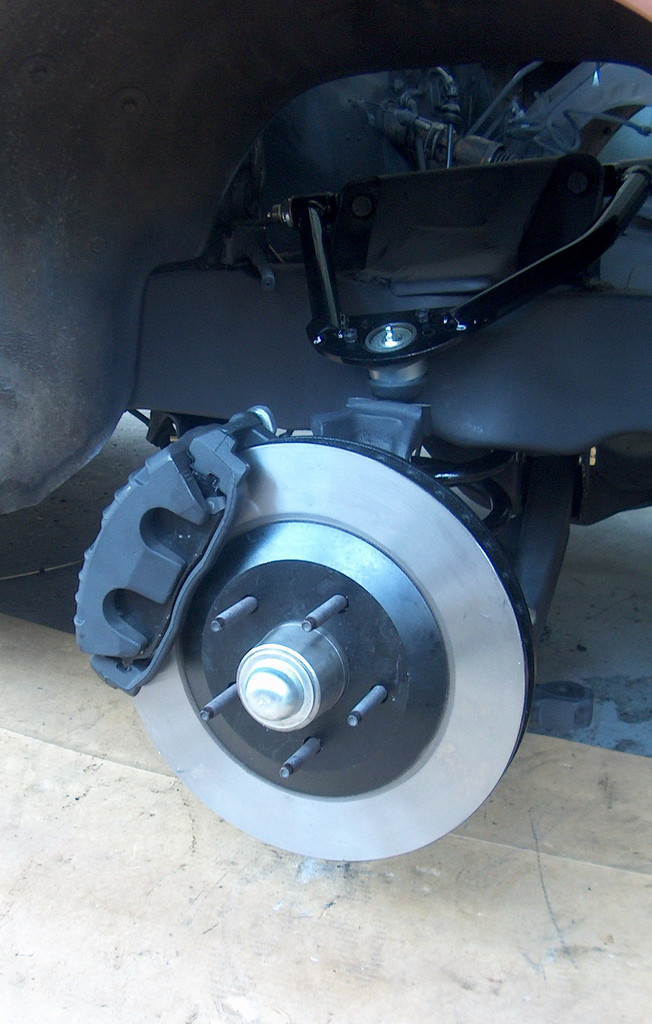

Next, I attached the adapter to allow the C5 calipers. I also used RED locktite, but blue would have been fine. Torque to 75fltbs.

Then I installed the races into the modified 3rd gen hub.

Then I used high temp bearing grease, and greased up the bearings, and installed them into the hub.

Then I installed the hub onto the spindle. Don't forget to seat the hub bearings to avoid premature wear. Do this by torquing down to 12ftlbs, while rotating the rotor. Back off the castle nut, hand tighten, and install cotter key.

I put the C5 rotor and caliper on. Normally you would now add some locktite, and torque down to 120ftlbs, but I can't since I need to modify the spindles a little bit more.

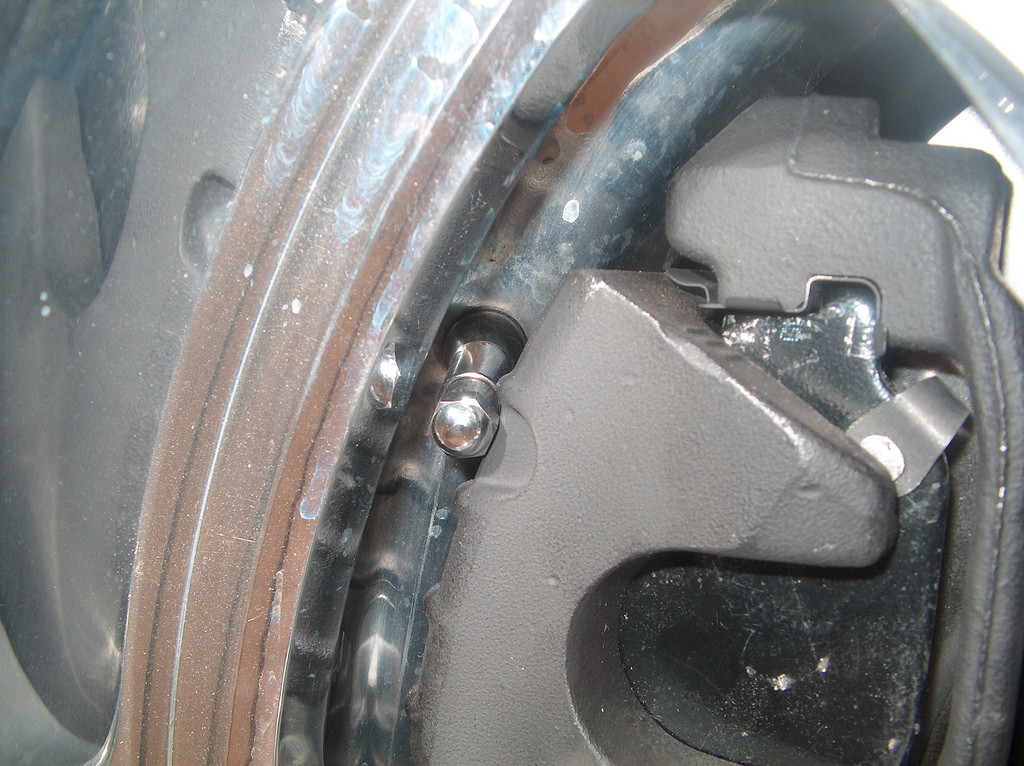

This is where some of my problems began. I made enough clearance for the bolts to go into the bracket and attach the calipers, but didn't make quite enough clearance to be able to get a socket on the bolt! LOL So I am going to have to do a bit more grinding on the spindles.

Here is another one of my problems. The valve stem hits the caliper. I am going to search around and see if they offer a style of valve stem that sits flush with the wheels.

Here is Cindy back on all three. LOL

Since then, I have done the same thing for the other side, so she is actually sitting on all fours again. Another problem that I have is the wheel studs are too long. I can't tighten the lug nuts down all the way. Is it okay to cut them down?

Love the old camaros

Posted by Diggymart on 4/27/20 @ 2:39:52 PM