You must be logged in to rate content!

4 minute(s) of a 87 minute read

2-6-2012

Timing cover/oil pump

Pretty straight forward here, with just a few wrinkles.

I used a new TA cover, and then their Scavanger plate system.

The use of this requires some modification to the new timing cover..

3 xtra holes drilled in the cover- these provide some additional oil to the inlet side of the gears, the majority of it flows in thru the cover itself, but a little extra suction side oil never hurts.

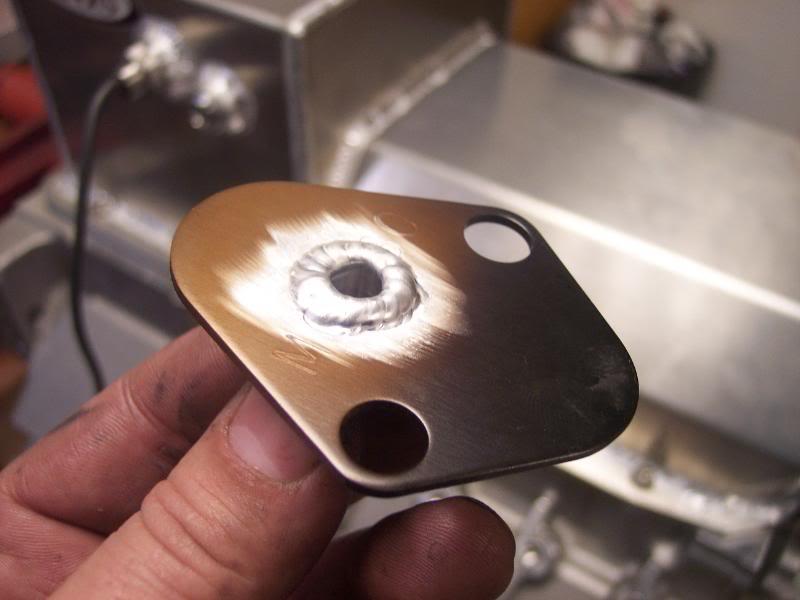

And then plug the factory inlet hole.. to insure no loss of suction. After this picture was taken, I filled the cavity with epoxy, over the plug, just to insure it was airtight. Nothing needs to be done with the factory pressure passage in the cover, the plate does not use it, and remember, there is no hole drilled in the block for it.

As installed, with standard length gears.. Note I had a custom 1/2 NPT to -16 fitting built, my experience in the past taught me that a -12 feed line to the pump can be marginal in some situtations. IN fact, the block has provisions for a 3/4 inch pickup tube, and the next motor in line here will be built with that. Simple is always better, and external lines are a pain.

The next motor is actually a supercharged/FI one, but it is going to be baseline tested with a carb, and I am going to use a stock oil pump setup in that test. If it will pump enough, it will make things a lot simpler. The biggest challenge for the customer when installing this motor, was fitting all the lines around the frame and mounting the filter ect..

It has an external by-pass, so you have to have a place to dump the oil back in the motor, so we tigged up a fitting, on an aftermarket fuel pump block off plate.

Makes for a good timing chain oiler, and since there is no fuel pump eccentric on the large journal cam cores, an electric fuel pump will always be required, at least with the current parts available.

The only picture I have of the complete system is on the dyno..

And here is a related video..

Working with a whole bunch of new stuff, I left nothing to chance.. we pre-heated the oil with the oil heater (worked slick) and then spun the pump, with the intake off, and watched it fill up the motor.. I was curious if a 70 jet in the restrictors was enough. Several builders with extensive alum block experience told me to use the 20-50 oil, and since we have pre-heat capability, room temprature viscoscity was not a concern.

I should have added in the video.. we have pressure and flow... all that oil you see in the heads, under the valve covers, was pumped their, thru the pushrods and rockers, in the time that drill ran.. the system was dry when we started, and there was no oil standing in the heads. It pre-lubed and filled the top end, almost instantly..

So we backed off on the oil restrictor hole, found a set of 25 Holley jets from a 2 barrel..

You can see the size difference.. 25 on the left, 70 on the right.

JW

Awesome build, amazing you can get so many passes at 750 horsepower. Nice job!

Posted by stevegolf on 3/13/21 @ 3:45:39 PM