You must be logged in to rate content!

12 minute(s) of a 286 minute read

10-30-2012

Thank You

I had put off fixing the flex plate due to a bolt on the transfer case skid not cooperating. But today I bought a transmission jack to be able to lower it and had enough with this bolt.

So I started hacking up the TC drop spacer bar to gain access to the bolt. Which reminds me I ordered a SYE that will be here Thursday. So anyway I was now looking at this.

Then decided to grab this.

and make short work of disconnecting this F'ing bolt head from my frame.

I know I know I made more of mess than I started with, but damn it felt good to cut that sum ***** in half. I'll deal with the rest of it in a few days when I have the trans out.

I'll deal with the rest of it in a few days when I have the trans out.

11-9-2012

I will be pushing to get the Jeep all done this weekend so I can then install the axles in the green Jeep and bring it home to start on next week. Wish me luck, I have a lot to do but time to do it so we'll see how it goes.

Valve cover gasket

Paint and install exhaust manifold

Clean and install intake manifold

Drop transfer case and transmission

Install SYE and speed healer gear in transfer case

Replace flex plate and reinstall transfer case and transmission

Remove rear axle and put cleaned up axle in with 4:88's

Should make for a good post in the what did you do to your TJ today thread

11-17-2012

So I did mange to get a good bit done the other day but was having problems with my photobucket account so didn't have pictures, until now.

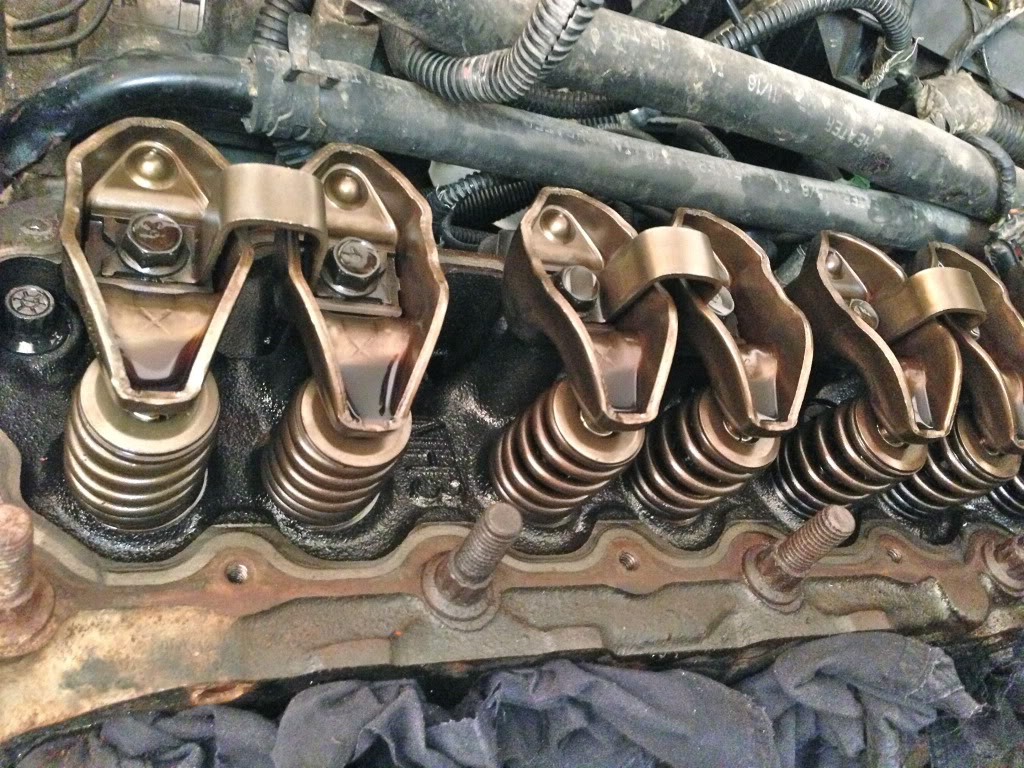

To start I went ahead and removed the valve cover to clean and install new Fel-Pro blue rubber gasket. It was an absolutely mess and ended up cleaning it on the outside with of all things hand cleaner and a tooth brush.

now that's better

Was very pleased with what I saw under the valve cover as well. Considering how neglected and left for dead this Jeep was when I bought it.

Reinstalled and looking much better.

Next I painted my new exhaust manifold to try and keep it from rusting to fast. Hi-temp silver

Also cleaned up the intake manifold then put it all back together. I'll be detailing the engine once I get it running again.

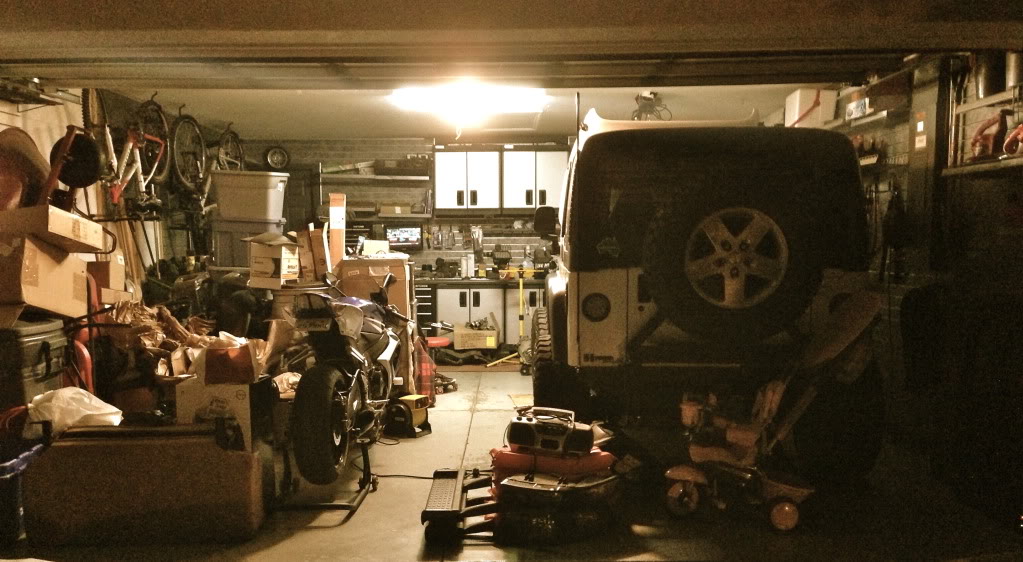

I need a bigger garage or less crap in this one.

Then on to the transmission/flex plate issue. I want to get this taken care of so I can install the new exhaust and actually hear it.

So started removing bolts drained the transmission and TC then dropped the skid.

The bolt that I had cut with the grinder was now fully exposed and with the vice grip firmly attached it spun out threads intact. Was very happy to not have to deal with this any more and will have no problem when putting things back together.

Of course I will have to clean up and paint the skid before putting it back on the Jeep. The TC drop brackets went into the trash.

I got to looking at the linkage and everything works but I know on my 97 TJ there is a bracket that mounts to the 4 holes on the side of the tunnel near where your right ankle would be when in the drivers seat. But nothing is there on this Jeep????

Not sure if you can really see anything in that crap picture, I plan on doing the Novak cable and not sure how it bolts up so I guess I will find out if I need that piece or not.

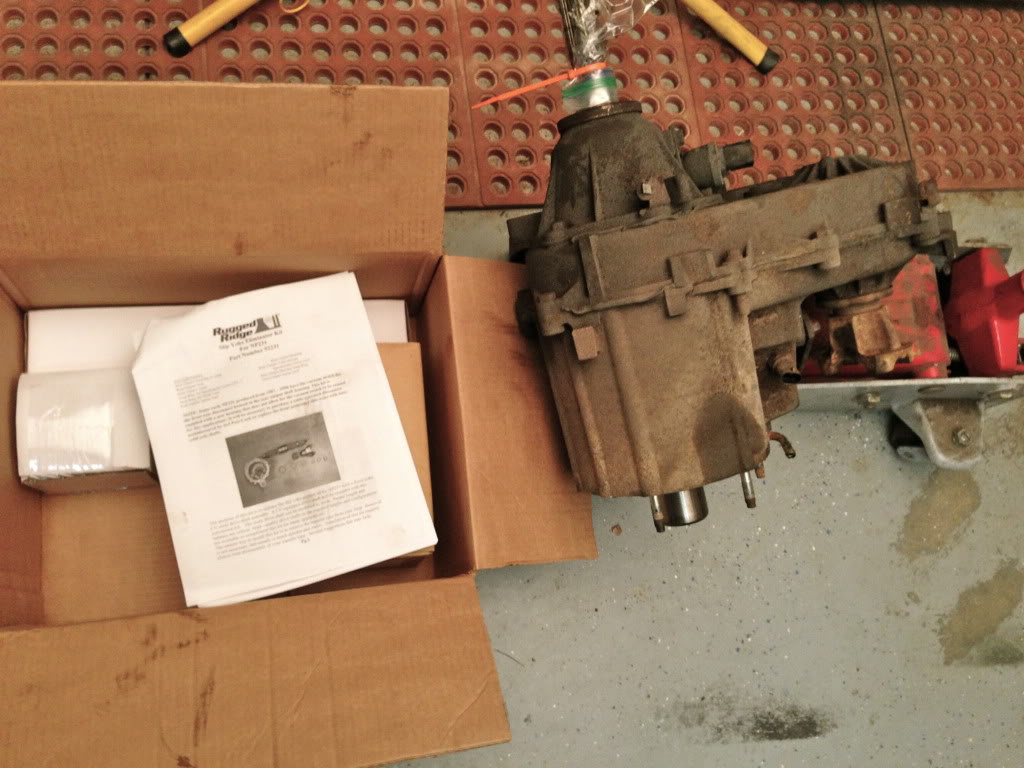

On with the dismantling. Out with the TC, needs a good cleaning, new fluid and some new parts.

The reason why the TC drop brackets went into the trash is I have the SYE ready to install. Need to order the ROKMEN adj rear upper control arms, new CV driveshaft and 35" tires (still undecided between MTZ's, KM2's and MTR's)

Also need to install this speedo gear for the 4.88's and 35's. Yes I know the revs will be high on the interstate with the 32RH 4.88 gears and 35" tires but I plan on the Jeep being pretty heavy so maybe it won't be to bad, around 3k RPM?

Was getting late and claustrophobic in the garage, I really need to sell some of this crap. Will be putting a rear seat from 98 Jeep Sahara at the curb tomorrow after posting it for free pickup on craigslist, pictured in bottom left corner. I want it gone just because I'm tired of moving it.

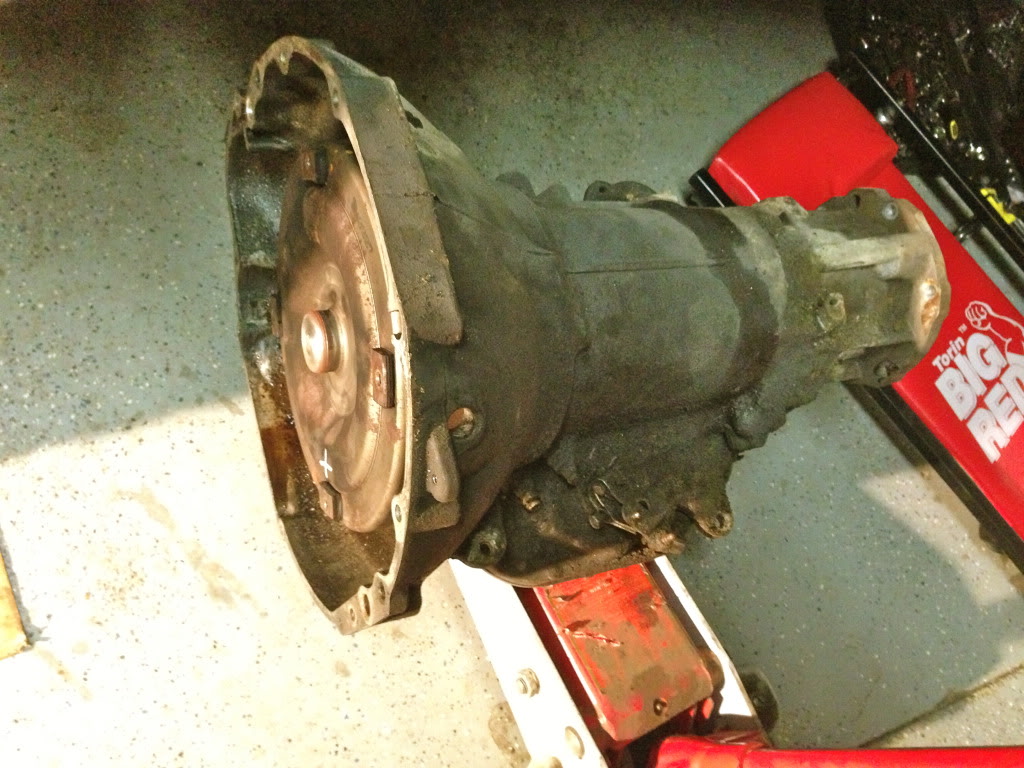

Pushed on with the removal of parts and wrestled out the transmission. It is filthy, never left any fluid on the ground while it was in the Jeep but seems to have or had a small leak because it is covered in grim.

Then I started to scratch my head, The flex plate doesn't look to have any issue. I will be removing it to really inspect but my first thought is it isn't my problem. The bell housing of the transmission has alot of little metal shavings I imagine from the bolt heads that where rubbing the dust shield.

Then I remove the torque converter and get looking at the input shaft coming from the trans that the torque convert attaches to and it seems to have been rubbing. Not sure what a normal shaft looks like but this one is sort of milled away at the back of the splines and past then lips back up to what looks like the normal level. Also pretty dirty in the bell housing I'm chalking this up to a leaking rear main seal which will be replaced while the transmission is out of course.

Not being a transmission mechanic I don't know what to look for in order to determine if this is a major problem. The fluid doesn't smell burnt and the fluid in the torque converter is still reddish. Then while sort of inspecting things I noticed the inner shaft moves up and down (see video) and in and out. Should it have all this play in it??????

CLICK VIDEO PICTURE BELOW

After this I was feeling tired and called it a day. Plus wanted to look up some info on the transmission like rebuilding, replace, swap. As well as how to determine the tolerance of the torque converter which didn't seem loose or wobble when on the shaft. still hopeful that I see what I expected when I remove the flex plate.

My daughter received a book about cars from her grandmother (my mom) today and it pretty much sums it up.

11-23-2012

So as is typical in the work I do on the Jeeps it has been slow and steady. I just can't put a dirty part back on so I end up spending a lot of time cleaning things up. This transmission/TC deal is no different.

Here is the belly of the Transfer case skid when I dropped it. I think all the trans fluid that was mixed with the dirty helped keep the rust to a minimum.

After a good scrapping to get the heavy stuff out.

Then worked on buffing the rust spots clean.

Finally all painted up and ready to be reinstalled.

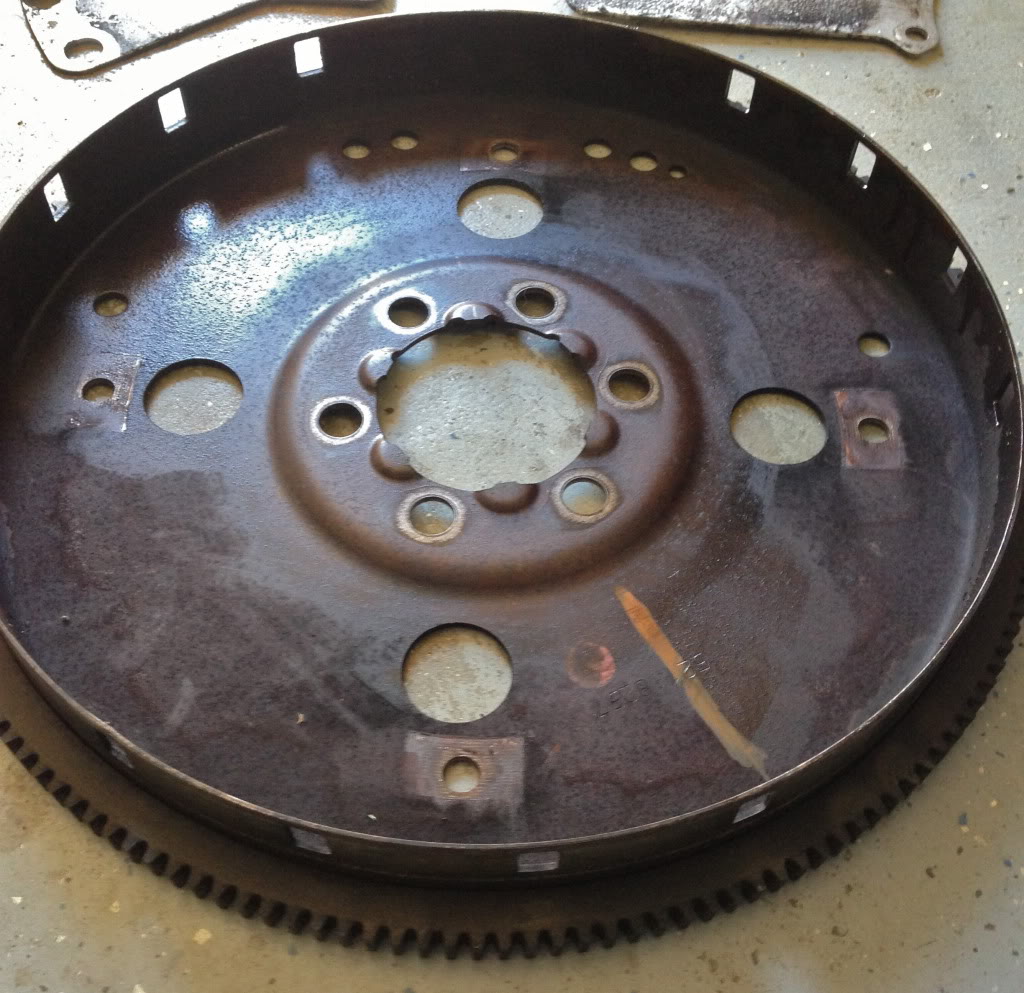

Also was able to get the flex plate removed and ...........

Absolutely nothing wrong with it, WTF. I thought for sure a cracked flex plate was my issue but no.

Instead, and I can't figure how, the large dust shield was bent and rubbing the bolt heads. Had I just let it go it would have eventually just rubbed right through and then no noise

Since I had already picked up a new flex plate and bolts (also grabbed new stock length skid plate bolts and throttle body bolts to remove the spacer) I'll just replace the old one and hold on to it for now.

Keeping with the "Black Friday" theme I ordered these bad boys from Rokmen with their 10% discount. Will come in handy as I do the SYE and will need to set the pinion angle. Everyone says they are worth the moneyand I figure at some point I'll replace the lowers and front uppers as well.