You must be logged in to rate content!

3 minute(s) of a 114 minute read

7-9-2009

I first brought out the window even more and was trying an aluminium surround 20 mm wide 2 mm thick, but that didn't look right, 2 mm is too thin. I will leave out the rubber mount and make a 10 mm thick surround (black of course) and louvres over the fuel filler like a GTB. The GTO vent is too complicated to make with difficult cutting and welding in a rust prone area and I don't want to move the fuel filler because of all the extra work. It will look ok eventually.

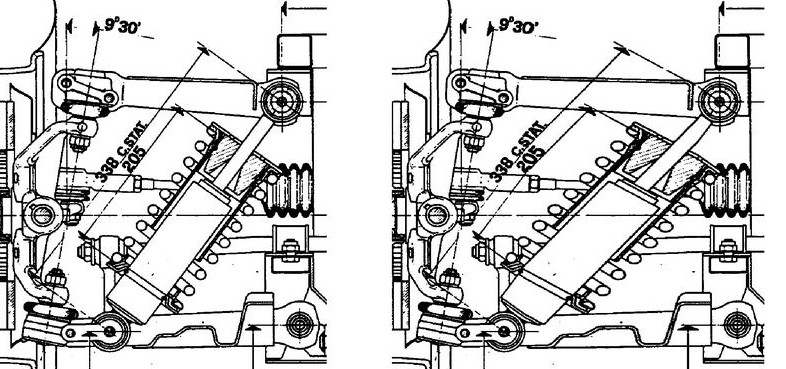

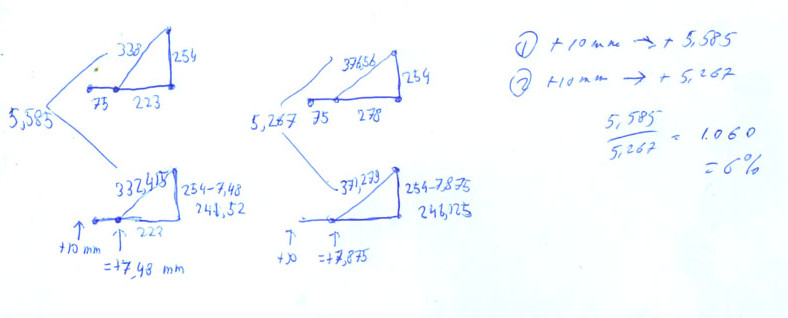

I had the same doubts before I started and wanted to bring out the upper shock mount but then did the calculations and the difference is only 6%, originally 10 mm wheel movement is 5.6 mm shock movement, with the longer arms it is 5.3 mm. And I have a 300 rated spring now, original was about 200. The shock I have adjusted stiffer almost to the max and dampens the spring perfectly. There is no extra load or wear on the shock as the force on the shock is only a straigt line from upper to lower mount, it is not a McPherson strut were there is side load on the shock.

8-5-2009

Thanks!

Yes, I installed all the new steel brakelines and then filled and bled the brake system. At first that didn't go to well, the front were done in 20 seconds with the easy bleeder but no fluid went to the rears until I totally turned anti-clockwise the knob on the brake bias valve, that is releasing the spring that is inside. Only then fluid went to the rear and I could totally blead the system. But if I turn the knob on the bias valve all the way clockwise, that should give maximum rear bias, it barely brakes. I spin a rear wheel (jacked up) and have to put large pressure on the pedal and then it barely slows down. With the knob released there is more pressure to the rear, that is not the way it should be. I did connect the bias valve the proper way. Will see about that later when testdriving when the booster works.

I started to make the indents for the shilelds in the front fenders and the rear vents behind the rear wheels. Where metal working skills end filler does the rest . I'm thinking of putting the airfilters behind those vents and use the side air scoops only for the intercoolers. I realise the vents are facing the wrong way for that but air can also be drawn in through the vents in the bottom and the vents below the rear bumper.

. I'm thinking of putting the airfilters behind those vents and use the side air scoops only for the intercoolers. I realise the vents are facing the wrong way for that but air can also be drawn in through the vents in the bottom and the vents below the rear bumper.

Coming weeks I'll be doing further smoothing the body but it is hard to show progress in pictures.