You must be logged in to rate content!

4 minute(s) of a 114 minute read

9-24-2008

The stronger valve springs were just delivered. A perfect fit, but...the windings are the other way round, that's not good is it? I suppose the inner and outer spring should have a different wind orientation to eliminate a rotating force on the retainers?

New spring on the left:

9-27-2008

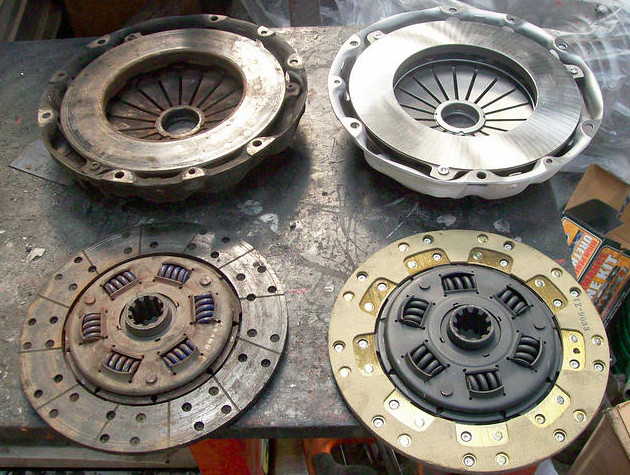

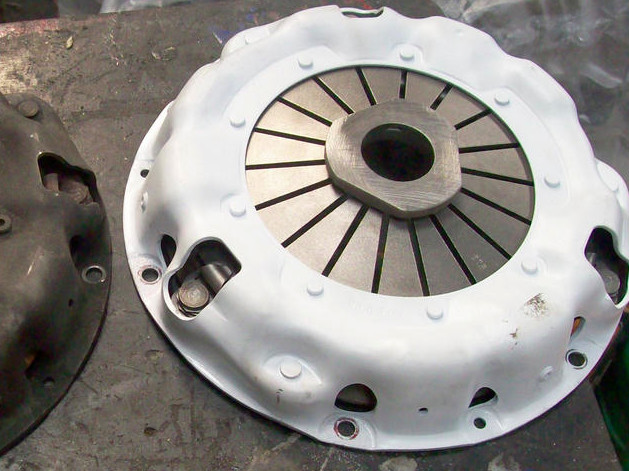

The JE pistons, total seal piston rings and kevlar lined clutch from Norwood arrived, so all the major parts are here. Good thing because I'm out of cash, this box was $3600 including shipping and dutch VAT and customs. The part do look nice, I will take the pistons and liners to the engine shop next week.

10-14-2008

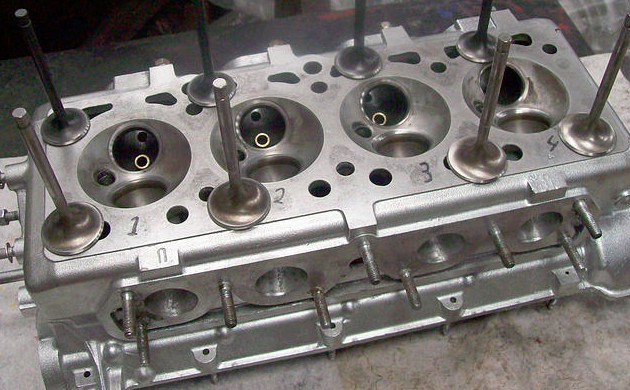

I got my heads back past week, I was a bit too worried about everything but they just grinded all the seats and most of the used inlet valves (not the new outlet valves) and there wasn't any problem, even not with the seat from the bent inlet valve. The guy said all valves seal now, I asked should I lightly lap them with fine grind paste and he said that would even be better so I did. I started installing the valves, happily installed the valve stem seals in the first head then I noticed you have to put in the bottom spring retainers first, oh well, order 8 new seals...(and a replacement for the one bent inlet valve, already received it from superformance). I wanted to use the new stronger valve springs I bought for the inlet valves, but they have a kind of press fit on the bottom retainer that is easily done by hand, in my hands, but not while the bottom retainers are in the head and trying to push the spring on, I didn't bother to experiment any further and just shimmed the bottom retainers of the inlet valves for some extra seat pressure. The grinding of the valves and seats had reduced the cam to bucket clearance (before adjusting) to zero (0.20 mm less) so also the installed spring length is 0.20 mm longer and I felt comfortable using 0.015"+0.030" shims. The outlet valve clearance was enlarged to about 1 mm before adjustment, but it turned out the new outlet valves from superformance are shorter above the retainers, that explained it, need shims up to 4.80 mm now, the maximum size available.

Yesterday I also got my liners back, bored and honed for the new pistons, and the small ends in the rods enlarged for the oversize pins that came with the JE pistons. Also the rear brake disc adapters needed to be turned down 5mm on the inside face, had them do that as the guy from my job who did enlarge the center holes said the runout on his lathe was not good enough for that, don't want wobbling wheels. So now I have everything complete to build up the engine and brakes in the next weeks or months, should be fun to assemble all new nice parts together. I asked the guy from the engine overhaul shop if I should assemble with engine oil or something dedicated, as the motor will be sitting for probably 6+ months after assembling before attempting to run it and he said, just lots of oil and after assembling turn it by hand once in a while. I'm also thinking what to do, the safest place to store the engine will be in the car but it will get dirty from doing bodywork (sanding dust) and I don't think I can wrap it up in plastic good enough, I'll see about that later.