You must be logged in to rate content!

16 minute(s) of a 50 minute read

2-16-2022

My DIY twin turbo build Gen 1 Viper

Compliments of AndyMac @ www.viperalley.com

The victim: 1995 RT/10. (yellow is the fastest color right?)

Tuning - Roe Racing VEC 3. My VEC install thread

Fuel injectors - Re-sized side feed injectors. My side feed injector thread

Fuel system - Plan on dual in-tank walbro high pressure 255lph pumps.

Turbos - A couple of internally gated T3/T4 hybrids. .82 hot side/.70 compressor. Good for about 900hp in twin configuration and should be very responsive on the street.

Intercooler and piping - Ebay specials.

Motor mounts - I built solid mounts, but there are some issues and I may revise these or go with polyurethane. Solid mount thread

So far I have the passenger side turbo hung with the exhaust piping. This is the harder of the two sides as the HVAC box/fan is above the turbo location and will require some creative pipe routing.

This setup retains the stock exhaust manifolds.

I'm not looking to break any records, and I realize that the turbo's aren't optimal, but I had most of these parts laying around the garage and decided to give them a try. My goal with this build is about 700rwhp.

So why not a Roe or a Paxton? This turbo setup will cost me less than 2k out of pocket due to the parts I already have and I wanted to quiet the car down after removing the cats and stock mufflers. Also, anyone can buy a paxton/roe and throw it on. It takes a lot of time and skill to design and build your own turbo kit, which I find rewarding.

Oh yea, and lets face it, twin turbos are way cooler than superchargers..

2/10/2010

This is what I was trying to avoid. I don't drive the car in the rain by choice, but sometimes it just happens. Our roads tend to have pools of water everywhere. 1 small puddle could sink the yellow submarine..

It also looks like the turbo hangs below the frame rails. It's all good if your roads don't get annihilated by the cold in the winter, but for us, it's like a slalom for the first half of the summer..

My third point is, I may have mounted the turbo high enough to avoid a scavenge pump for the oil drain. I intended to use a return pump anyhow, but it looks like it may be about right for a gravity drain.

I've seen this picture before, and it looks like you may have revised your filter placement? (assuming it is the same build)

Oh, and I'm not willing to loose the HVAC or A/C. (A/C is nice in traffic even with the top off)

2/23/2010

After spending a week in the Dominican, I got a chance to work on the car a bit more. Snaked the air inlet for the turbo up around the HVAC stuff so I wouldn't have to mount the air filter under the car.

Also have the charge pipe routed up into the engine bay as well.

Currently working on hanging the drivers side turbo so I can figure out where to merge the two charge pipes into one 3" and out into the intercooler.

2/27/2010

Got the drivers side turbo mounted..

EGT and AFR gauges

EGT probe and AFR sensor bungs welded in. (that is an old A/F sensor for fitment purposes)

Going to try and mount the FMIC tomorrow.

3/7/2010

One step closer.

Intercooler mounted. Had to move the oil cooler back a bit so the intercooler would clear the bumper.

Discharge side.

Charge pipe to the motor. Cheap couplers until I can find suitable 3 ply yellow units.

Here is my DIY bead roller for cheap ass ebay intercooler pipe. Not my design/idea, and took 30 seconds to make.

24 days till she's legal for the road again!

7/19/2010

Well, good news for once. I spent about 30 hours in the garage in the last week and got my TT setup back on the car. (a lot of late nights) I had removed the system in the spring when I couldn't get my oil return setup to function as I wanted it to, and I just wanted to drive the car.

So, for my oiling system, I took the sending unit out of the block and ran steel line under the car beside my oil pan where I then mounted the sending unit and check valved oil feed lines to the turbos. I used 1/4 line, and .63 restrictors at the turbo inlets. (I tapped the bottom of the fittings that screw into the turbos to accept carb jets to make changing restrictor sizes easy.)

For the return, I used 1/2" steel line to come down a few inches and then into 3/8 line to each return pump mounted on the frame. (lower than the turbos) I added a second pump as 1 pump will not handle both.. (at least not in my case) Out of the pump it goes right into a big check valve, and then into a 1/4" hydraulic line to each valve cover. I was a little concerned that the 1/4" line would not be sufficient, but under pressure, it seems to be enough so that it doesn't smoke.

The only thing left now is to get my injectors put in. They will require some modifications, but nothing too serious. I will post my results. I have been driving the car a bit, the stock injectors will handle a couple pounds of boost at 1/4 throttle, so I just need to not hammer down.

A few pics..

All cleaned for the car show

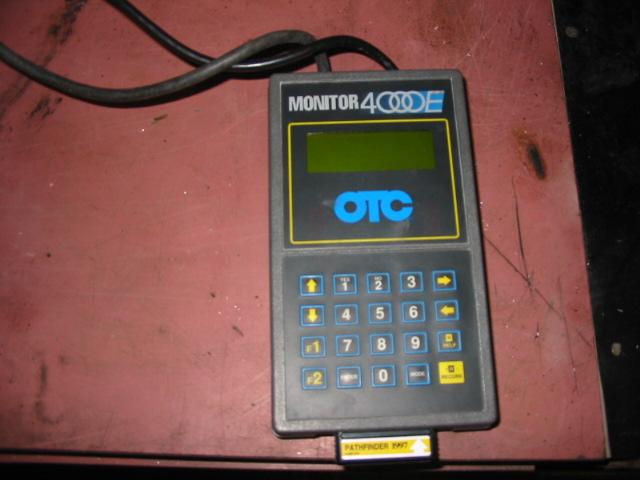

AFR and EGT gauges along with my boost controller (which also doubles as my boost gauge ATM)

Intercooler shot

7/19/2010

So, this afternoon I finished modifying my Nissan Maxima injectors and got them installed.

Far right is one of my stock gen 1 injectors, middle is a Maxima injector with the connector shaved so that the factory Viper injector clips will fit on. Far left is a stock Maxima injector. For anyone who hasn't seen my injector thread, I filed the end caps off the Maxima injectors to increase the flow from 240cc to 550cc. (600cc in a Viper system)

I had to modify the tops of the injectors a touch and spread the injector hold down tabs to make it work. I used the stock Maxima upper injector O-rings and the Viper bottom O-rings.

Then I scaled the injectors in my VEC to get it to start and run. It was pretty close, but I used this to fine tune the short term fuel trims.

Took it out with a rough tune and it held 11:1 AFR and a rock solid 6.5 psi. I was a little concerned that the internal waste gates might not be adequate, but no problem.

The car feels good. I have a feeling the EBC is going to be a bad thing.

Fuel injectors are usually rated at a specific fuel pressure. Different systems have different fuel pressures, and I think that most injectors are rated commercially at 43.5 psi of fuel pressure. (obviously fuel pressure has a direct effect on how much an injector can inject) Viper fuel systems run at a constant 55psi, so an injector that was rated at 550cc at 43.5 psi will actually flow 618cc at 55psi.

9/28/2010

Not too much new and exciting. Been pushing the limits a bit with 10lbs of boost. Maxxing out my fuel system as AFR's are leaning out at higher RPM and Duty cycles are going to 100%. Mid range torque is pretty awesome, and third gear feels pretty sketchy all the way through.

I haven't made a trip to the dyno, or logged the back pressure before the turbos yet either. I'd like to do both before I store it for the winter. It feels strong, but butt dynos are notorious for false results.

Started designing my Water/Meth system and am going to work on a fuel system this winter. Probably should change the paper head gaskets out too as I'd hate to have down time in the summer months.

Who has the stock paper head gasket high score anyhow?

10/5/2010

So I put a fitting in the exhaust pre-turbo so I could measure back pressure today. I found that the back pressure to boost ratio is right around 2:1, even at 5500rpm. I did several pulls around 5-6psi and then a couple at 10 to 14psi. You typically want the ratio as low as possible, why still spooling the turbo in a timely fashion. 2:1 is acceptable, but getting to the upper limit.

Not saying these turbos are optimal, but they aren't as restrictive as some people have eluded to. I do think the power curve will peak early, but I do need to get to a dyno to check it out. I've tried using the HP calculator in the VEC logging software, but don't think the results are accurate.

10/30/2010

Few vids of the car

Right click, save as..

Shot inside the car turning onto the highway, 6-8lbs boost.

http://www.myturboprojects.com/viper...ost_run_01.wmv

Shot of the tach.

http://www.myturboprojects.com/viper...ost_run_02.wmv

Later,

1/22/2011

Been working on the car here and there the last few months. Built some manifolds to fit some GT45's and 60mm gates on the car.

Here's the start of the 4" exhaust off the turbo.

Gates are vented to atmosphere.

7/24/2012

Wow, guess it has been a while since I've updated... Lets add a few more pics, I'll see if I can do it in chronological order...

So, I got rid of the T3/T4's and went with two 70mm turbos.

Here is a pic with a "mock up" turbo, old turbo, and 60mm gate.

My 4" "muffler" lol, if you wanna call it that.

Pulled my heads to get rid of the paper gaskets. (They were still fine, but better get the MLS ones in there anyway.

Stock heat shield back on and pipes wrapped. You can see I had to move my filters to under the car now.

Monster exhaust wheel. (I like to think of it as traction control, or "boost by gear" lol)

Exhaust done

Tapped the block under the intake for a knock sensor. (for MSD Knock Alert)

That about wraps up the winter of 2010/2011... More to come

So, last summer I spent fighting some issues where the car wouldn't pull past 4800 rpm. I blamed it on my smaller turbos, but it still exists with the larger units and massive wastegates. I hit the dyno late last fall anyway just to see, and only managed 700whp by 4800rpm where it would start going way lean no matter how much fuel I put to it. (still stock motor, stock valvetrain, etc)

So, I finally figured out it was weak valve springs causing my valves to float under high load and lots-o-boost. Valve float sends raw gas and lots of air into the exhaust which shows lean on my WB and why I couldn't richen it up any. (Tip - o2 and WB sensors only read air content, not fuel, so if there is unburnt fuel in the exhaust, it doesn't see it)

Anyway, so Valvetrain time.. Roes dual valve springs and locks.

My home made valve spring compressor. To do this, you need to pressurize the cylinder so the valves don't fall down. You can see the line from my compression tester hooked to my compressor to keep the cylinder full of air.

New Harland Sharp rockers and hardened pushrods.

Also painted my intake and valve covers to something more appropriate.

Added fittings to my intake and redesigned my fuel system slightly.

Added a BAP

New Acer tablet running win7 to tune with

So that about wraps it up for winter 2011/2012.....

7/24/2010

The car runs strong now, strong enough to shred gears doing a 3rd gear pull on the highway even though AFR's were 10:1 at the time...

That is about it I guess, going to hit the dyno before fall to see what kind of power I can extract from the new setup. 800whp should be a joke on 91 with 800cc's of water/meth. I kind of want to push my luck for 1k whp, but I don't want to trailer the car home from the dyno..

And here is a little media for this thread. Kinda goofin around on my first run at the AutoX..