You must be logged in to rate content!

10 minute(s) of a 266 minute read

1-7-2013

yeah when im doing my mini there seems to be 100 things to do before i see any difference most of this work goes unseen but yeah the big gas botlle was a major improvement my latest welds look great they will be shown in my picture update in a minute once i have downloaded the pictures onto photobucket cant wait till bingley hall im buying so many parts there

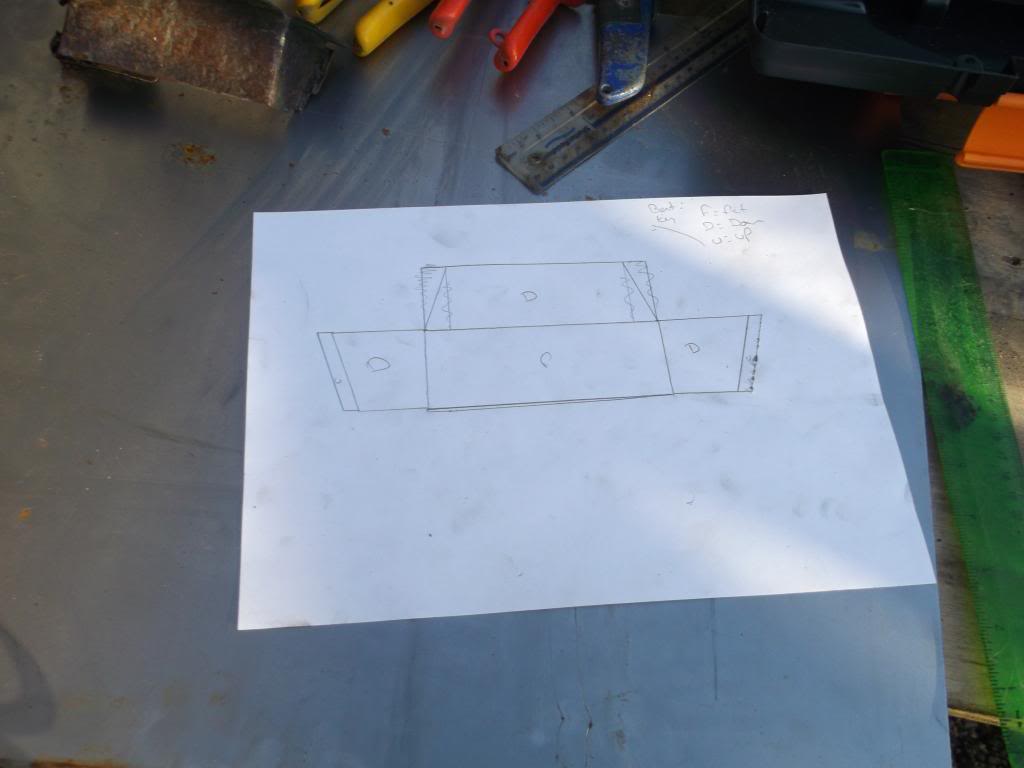

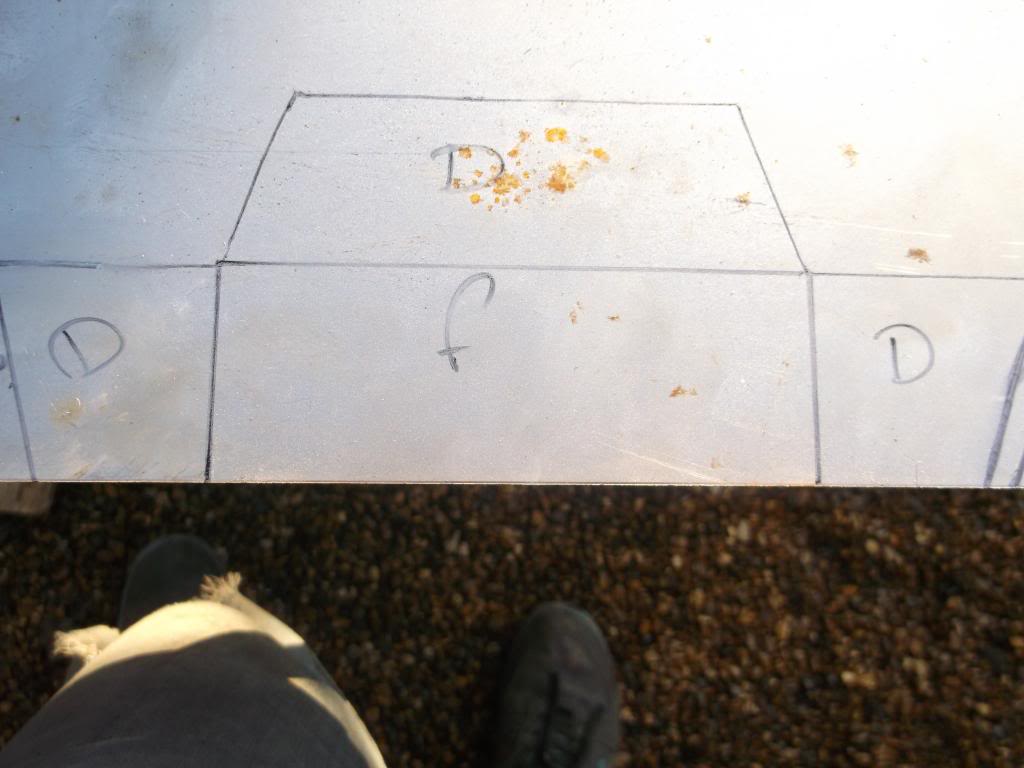

f for flat

d for bend down

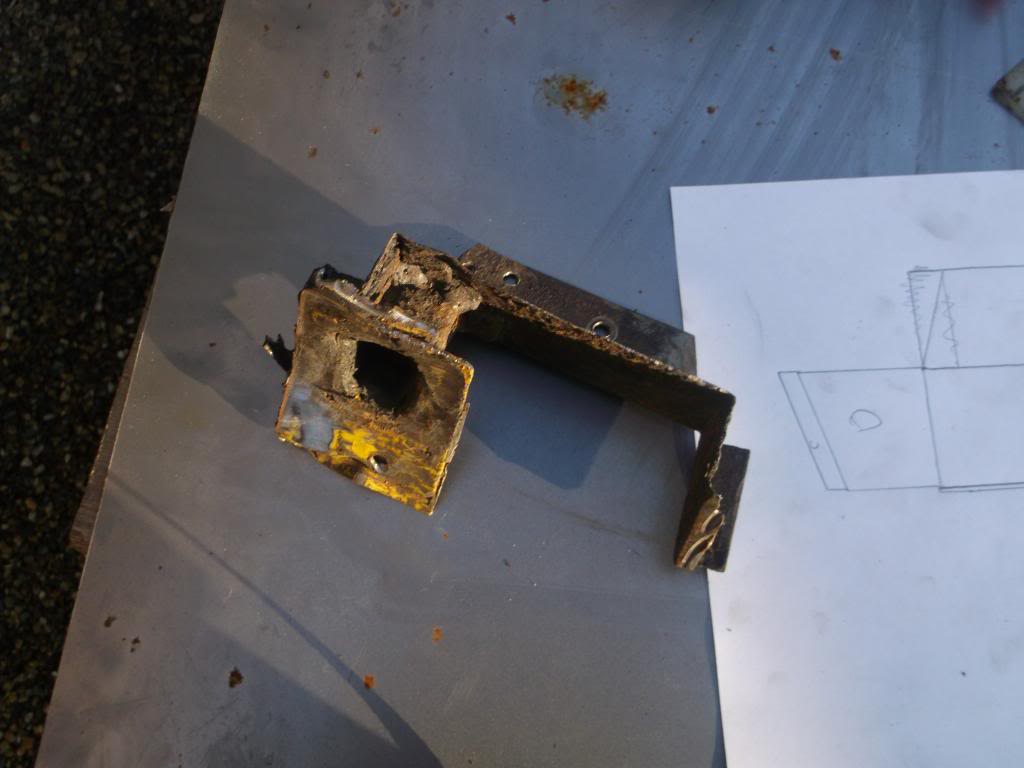

fabricating the strengthening/jacking point but making it without the jacking point

next making a plate to cover the door catch as i wont be needing this on my mk1 door conversion so time to cover those ugly holes

made a repair for my dads car

some more blanking off and grinding because of my door conversion

door conversion pictures

ground down the mk1 latch so that it wold fit in the door frame but had trouble where i fully pressed down the handle the latch would stay inside the casing so i tapped an edge of the casing down and that solved the problem

putting the a pannel on i made sure the gap was equal taked it on at the bottom and welded up the top

made a door latch

the door line up is very good mk1 conversion successfully works need to put the hinges on and reskin the door

a pannel lip bending guide

tools:

mole grips/ welding clamp

hardwood block

welding glove

steps

1. cover the hardwood block in a welding rag

2. place the rag and block on the outside of the a panel

3. set the clamp so it only bends the lip a little

4. clamp the wood and panel on the edge

5. go gradually down the panel until the lip is bent a small amount but evenly

6. increase the clamp so it bends the lip almost all the way and consistently clamp all the way down the panel

7. set the clamp so it bends the lip flat to the hinge panel and do this all the way down the panel

8. continue until the bend is smooth and flush

panel lip bent

in the pictures i did not use the glove so you could see what i was doing

just a fun picture

fitting the wing

cheers appreciate the comments just got the drivers side to do and some other jobs before he gets sent of for his custom designed roll cage i am 15 now so only have another two years to complete him saying that i hardly did anything in the first year i got him

my improved welding

my christmas presents a bench metal folder and a clrke welding trolly also loads more tools of my parents

also prepped the sill to be welded on i welded up all the holes and the jacing mount so it is nice and smooth

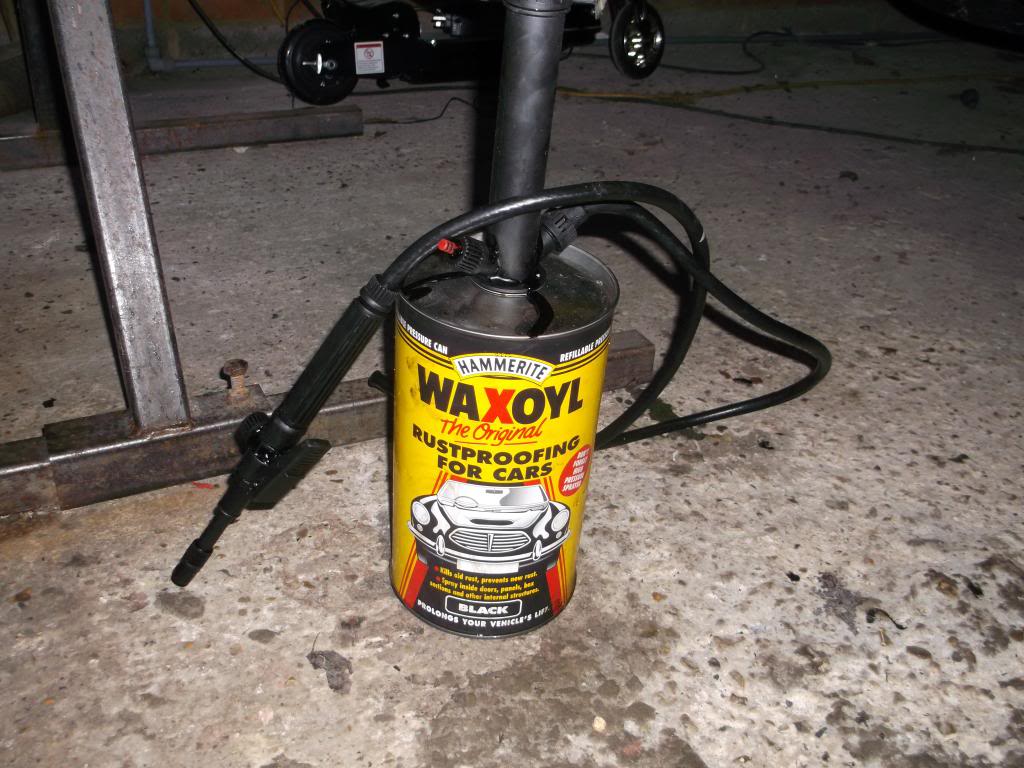

brought some black waxoyl to pump into every hole crease and cavity also welded the sill on where i cut the front so it sits smooth with the inner wing

this is how he looks now finally got my topic up to date

ive switched to 0.8 wire now and i am having no trouble with blowing through i have turned the wire speed down and although it takes me longer to weld they look no different and the wire is alot cheaper as i get the 5kg spool instead of the little rolls

managed to do some work on my door today i filled in the holes in the bottom of my pocket so that the pocket looks smooth and finished still need to finish sanding and filling but im back to school tomorrow so there probably wont be any updates on progress until the weekend