You must be logged in to rate content!

7 minute(s) of a 140 minute read

4-25-2014

My original thought was to machine a plug to close the hole in the upright which would incorporate the 3 bolt flange that would bolt in place. Then bore a hole in the center of it which I could press the pin into, and tig it in place on both sides. The problem is the pin is just too huge, with too much offset, throwing the scrub radius all crazy. I may get an Impala pin and see how bad it is. If its not going to be an improvement over what's currently available, there is no use in doing it.

4-26-2014

Got the fenders finish welded and ground, will start smearing mud tomorrow.

On the spindle, I started really thinking outside the box. Stopped at a buddy of mine's 4 wheel drive shop, dug through and found a 4x4 front spindle that looked like it would fit. My buddy Brian turned down the locating index to the Vette upright I.D. Stupid big, but if I made a hub to fit this, with the unibearing standoff, I think it would work.

4-27-2014

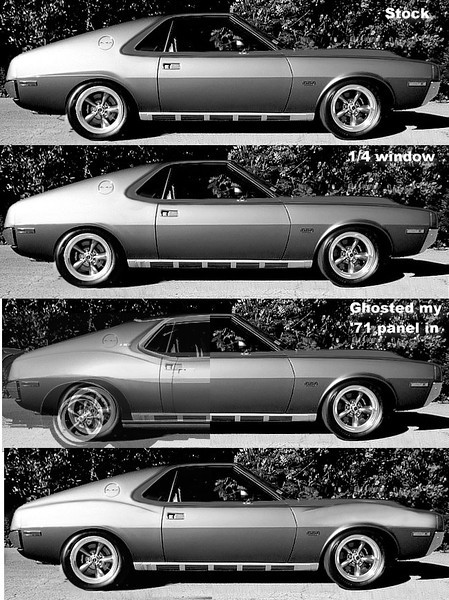

Torquedork, and I have been collaborating on what to do with my quarter panels, this what we have come up with. Reshape the rear window opening a bit, and install an eyebrow over the wheel opening. Love the way he was able to C14 wheels in gold on the thing, the dude is a real artist with a computer. What do you think?

Yeah Dan, you know I have brain damage.

Andrew, I'm just playing, trying to keep my self sane while doing body work. In the end I'll probably run the ZR1 stuff. Have talked to several engineers about this, its very deceiving how this stuff is made. If you think about a unibearing, all the bearing load is on one side of the wheel mount surface, and the bearings are only about 1/4" apart. With the old school bearing arrangement the bearings are spread several inches apart, one on each side of the wheel mount surface. It doesn't take an engineer to see that is a much stronger arrangement. It would put increased load on the aluminum upright though.

On a side note, I got the one side portion of the fender roughed in.

4-28-2014

The driving force on the front was the 335's. It was either Mustang flares which I've already done, or something a little different. I've tried to keep the AMX flavor, and still meet the wheelbase/width requirements of the car. I purposely didn't go with a modern front bumper, but did attach the bumper to the fender which is kind of modern. Like everything I do you'll like it, or really, really HATE it. LOL

5-2-2014

ONE DOWN, ONE TO GO!!

5-4-2014

When you're doing something as miserable as smearing mud and sanding, its hard to stay on task. You'll take your motivation where you can get it. Funny how big tars, especially on the front keep me trudging through.

5-7-2014

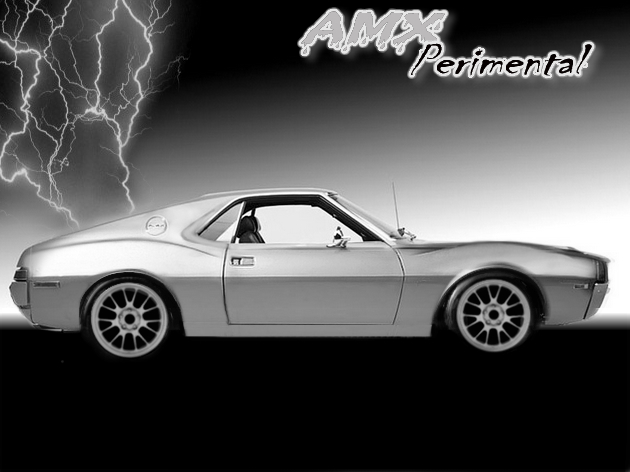

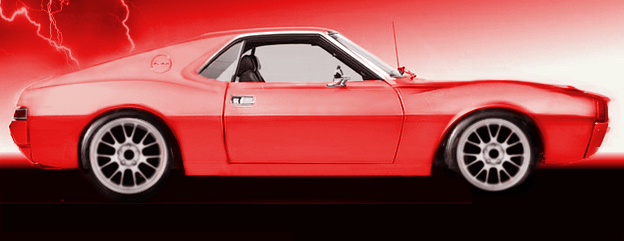

Torquedork was at it again, from stock to C14's on an Xperimental. I'm hoping I can do his photoshop justice.

Coolest one yet.

5-8-2014

The rendering that Torque is playing with is awesome in my opinion. Unfortunately he can only do so much with the computer, the actual car will lay out slightly different. The lines your talking about Norm will have to be parallel to look right.

There is a lot that goes into body mods that are this severe. To produce that eyebrow from scratch would take a long time. I'd have to english wheel curve in the panel, machine a set of dies for my bead roller to have the correct profile, roll the brow, shrink all that material along that edge. English wheel the other half of the panel, tig the two together. Although doable, I would have months on each quarter. It was easier to find a donor, and cut them off. There will still be plenty of english wheel thumb smashing, and plenty of welding, but I figure a week of nights and weekends, for the first, a couple of days on the second.

Its been cool watching Torque play with the lines on this car, but in the end it comes down what can be done with the metal. While I'm typing this I'm looking out the window at the car pushed out in my driveway. Funny how different the car is then the rendering that is here. Wheelwells are way higher to clear the 335's at full lock, I raked the nose down about 1.5" to try and correct the way the cars always look like they are driving up hill. The way I look at it AMC did the hard work, all I'm doing is a little plastic surgery. A nose job, some lipo, and some double D's. LOL Its all an Xperiment, we'll see.

5-15-2014

Everything is kind of roughed in, and I do mean roughed in. Now I need to fit it to the car, and clean up the edges. The nose still looks kind of long to me, even after cutting 3" off of it. Front end definitely shows off the need for the quarter panel mods. Man I hate body work!!!

It will be an eyebrow like the newer Javelins, with a bulbous flare like the front has.

Very cool!

Posted by bl_steel on 1/26/21 @ 1:24:52 PM