You must be logged in to rate content!

8 minute(s) of a 636 minute read

6-26-2021

Well it has been awhile... a few random phone calls back and forth with engine shop what was needed, what was being done, etc...

Last week he called me on Wednesday and said he had my pulley back and all he had to do was install it and then machine my manifold faces. so i was excited, however Friday came and went and nothing.

then this past Friday, he called and asked if i would be around on Saturday, and i said yes, no plans. he said great, he was finishing up the machining in the morning and i could come pick it up !!

Saturday afternoon around 2pm he called and said he had it ready to go !! so away i went to the engine shop, with my punch list in hand.

Got to the shop , they were closed, but he was working. we went down the list and over the parts, and what was done along with the bill. they did a great job from what i can see, other than the timeline. he said they were swamped and actually were turning business away as they can NOT catch up. one out 3 or more in. so they are pushing back till they get caught up and projects out the door.

Wrapped up the block, as it was raining that morning, and showers in the forecast anytime.

He helped me load it up, and then we BS'd for a bit about old cars, engines, and whatever...

yes that is a 194 inline 6 Cylinder in that heavy duty black plastic ![]() or so i hope

or so i hope

the flywheel was machined and ground, however they said they did not have a way to do the pressure plate, so will be making a few calls this week to see what i can find out.

manifolds were machined, had them machine the mating surfaces, any surface that was being gasketed and bolted up

then the main attraction, looks really good inside, will need to clean up the outside and then prime and paint it up.

crank was magnafluxed, turned and ground, same for the camshaft, they had to build up the fuel pump lobe. block was decked and then bored & honed .030" over, installed set of NORS Pistons, pins onto my rebabbitted connecting rods. mains were also rebabbitted and then align bored.

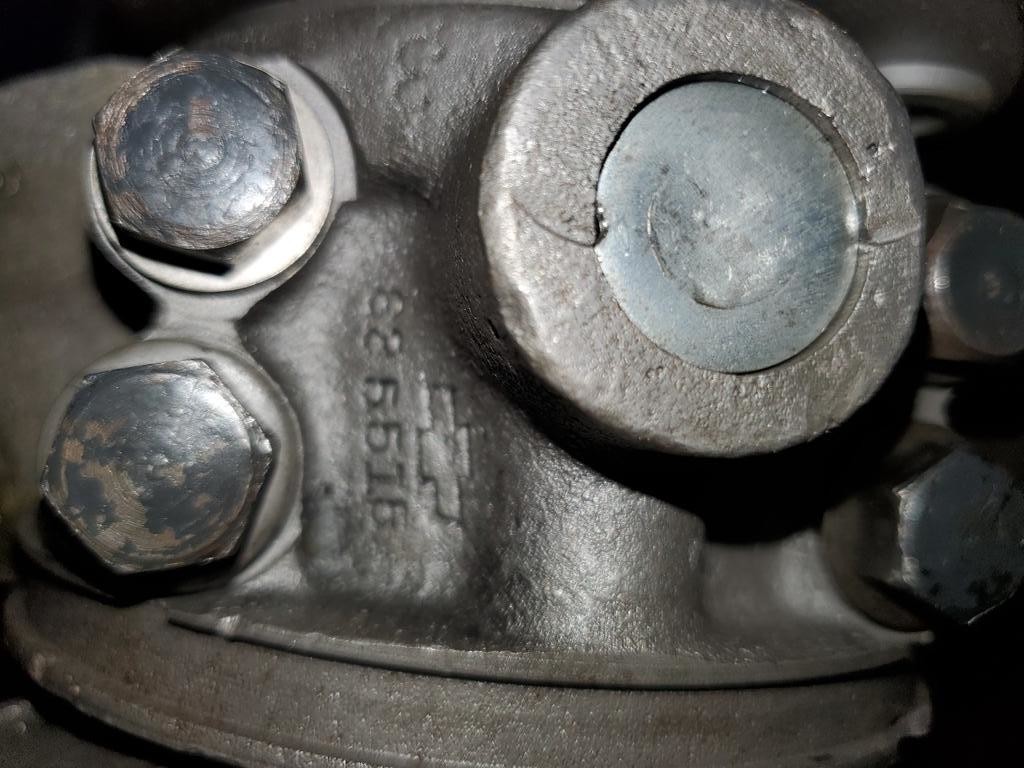

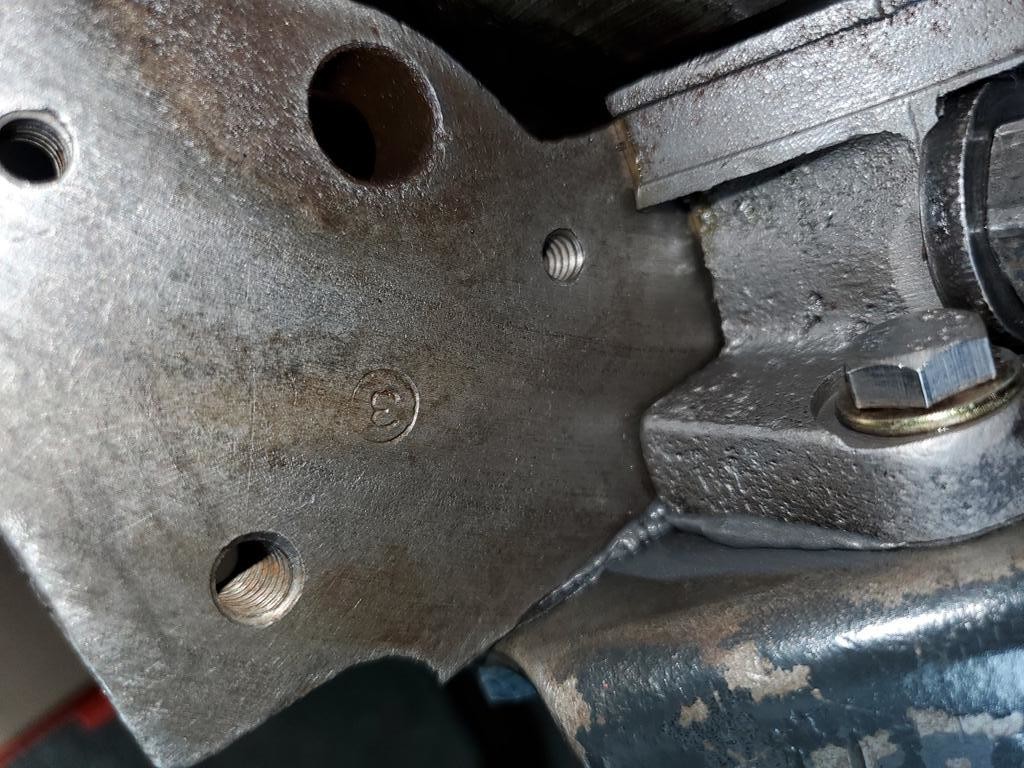

few closeup of the crankshaft and mains. cleaned up and can see the casting numbers and markings !!

few random markings on the bottom flange of the engine where the oil pan gasket seats.

ready to start putting the engine back together and then back in the car. i know this will require a lot of questions, and assistance/guidance from all of you. I took a ton of photos and notes on disassembly but want to make certain that I putting it ack together correctly. I figured once my storage shelf and bench are empty of parts, the car is complete, once again. if there is a part on the shelf then i forgot something ![]() and you know what that means.

and you know what that means.

First step i figured would be to get in the lube lines, this includes the oil distribution block, oil pump, and feed lines, lower & upper.

numbered in the order of operation/assembly, let me know if i should flip or flop any of them

1-how do you set the oil pump to the correct depth/setting for the distributor and all ?

...my thought was to install and set the distributor, then install the oil pump up to it and secure it in place. i assume there is some spacing between the two or do they fit up against each other.

then main feed line from discharge of oil pump connects to the block port to feed the oil distribution block

2- installing the feed lines

...i know that the center distribution on the side feed lines connects to the inside of the block, there the copper tubing is set. see attached photos. then the 2 trough feed blocks that fee the troughs connect to the end of the short tubes, and screws into the block from the inside, there are also 2 places that tube clamps screw to the inside of the block to hold the lines in place.

...is there a washer or anything that goes in between the copper tube in the block and the center distribution block that connects to it ??

...how does it stay in place other then press on fit and the clamps that hold the tubing to the block ?

the two main tubes feed the oil reservoirs at each end of the block for the front main and the rear main

the two short tubes feed the trough feed blocks that feed the troughs, so tubes will be adjusted to direct oil to the dipper troughs in the pan

Great car !

Posted by Diggymart on 9/7/19 @ 3:48:57 PM