You must be logged in to rate content!

5 minute(s) of a 636 minute read

10-5-2020

talked with my engine shop friday, and he said he was in the midst of working on it ?? could it be ? or was it a hoax

said he was installing pistons and such, but having an issue, said got 1 in and everything turns smooth and freely, then when he puts in the second one, it locks up ?!? i went down the question list, clearances, gaps, etc. everything in the correct direction, etc... so hopefully he will have it all together in a few weeks, i told him i want it completed by the end of October, and done right & professionally.

we will see what happens

10-10-2020

engine rebuilder called me yesterday with a few questions/concerns. thought i would post here for feedback/thoughts:

1-camshaft timing gear keyway i bought a NORS fiber one from TFS. however the keyway in it is approx 5/32 wide where as the keyway in the cam and the existing cam gear are 3/16 wide. so was wondering if we need to widen keyway in the gear or was the original one opened up to 3/16 somewhere long the line. or what are our options

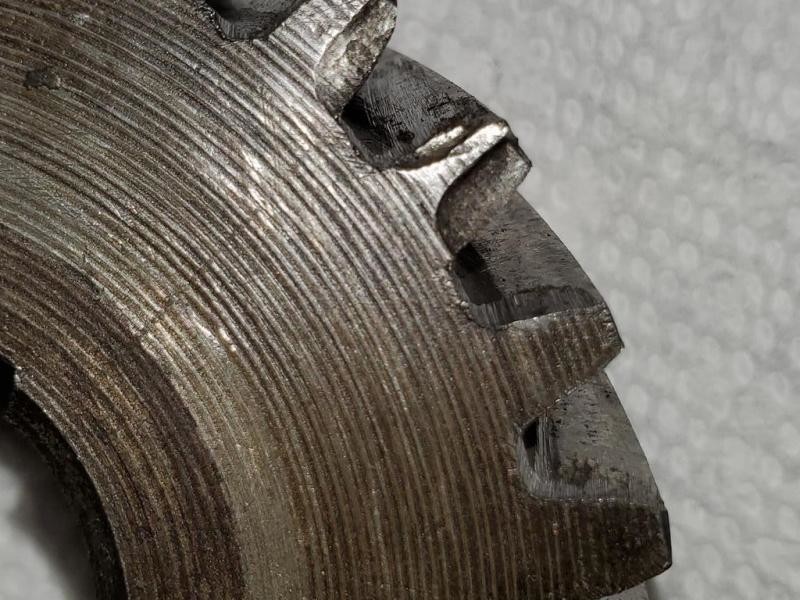

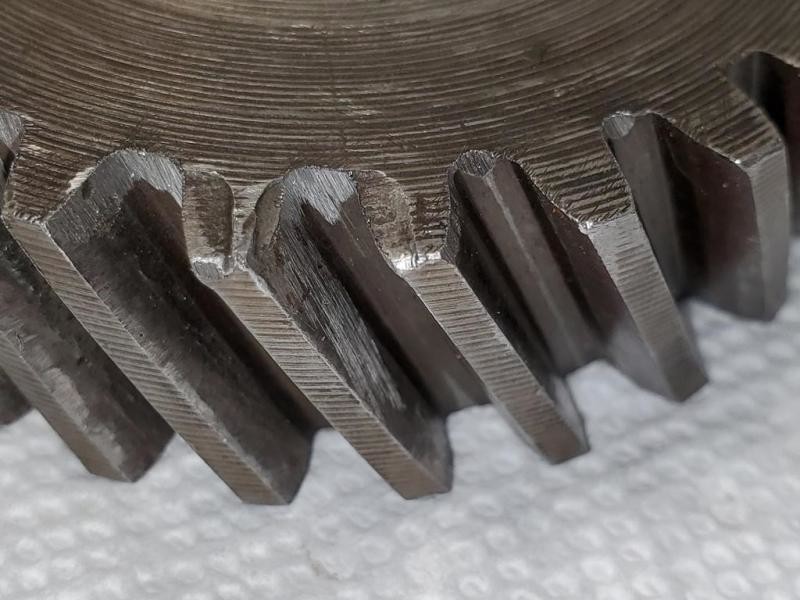

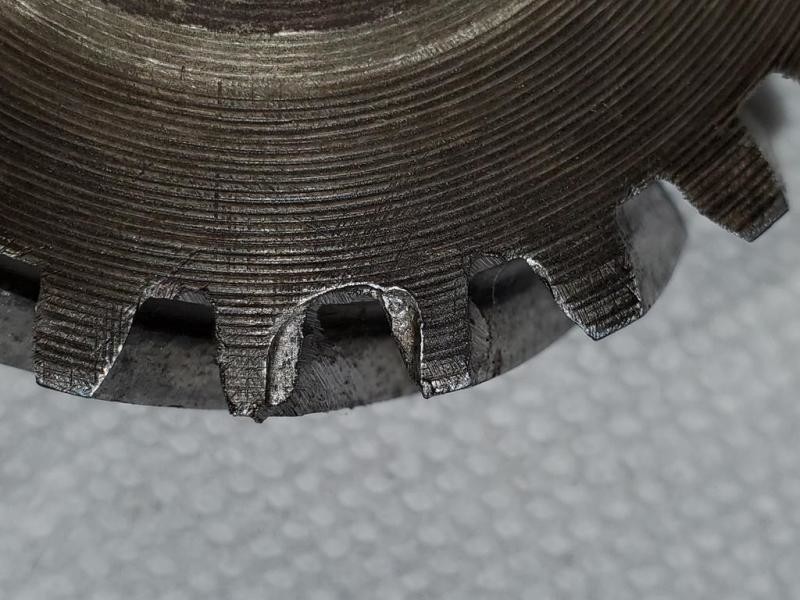

2-crank gear condition has some side wear that should be irrelevant, looks like the slinger was loose at one time and grooved the front face of the gear. The main concern is that it looks like someone used a 2 jaw puller to pull the gear off at one time. There are 2 small chips on 2 of the gear teeth. does NOT look major but he would like to put on a new NOS or NORS gear if available. if not sure we could reuse it, i can get pictures if needed.

3- crank gear spacing/gap, what is the gap / spacing on hte crank gear or should it just align with the cam gear once set ??

3-camshaft gear washer/spacing. camshaft has been reground and ready for install. On the install the cam goes in, then the new thrust plate bolts on. question was there is a .003 clearance. engine builder was asking the proper method for setting the clearance for pressing on the cam gear. he was thinking of using a washer on the shaft behind the cam gear. but was wondering how it should be done on these older 194. he has done 216 & 235s

4-crank pulley fitment. assume that the crank gear pulley is a press fit, however mine is barely a slip fit. what tis the proper id of the pulley and od of the shaft ? thought was to find another pulley if the shaft is ok, or sleeving the pulley to press fit on the exiting shaft. but assume it would have to be a split sleeve for the keyway.

5-crankgear flinger does it sit loose on the shaft or ?? i know that the open end of the flinger, since it is a cup shape goes up against the ring on the timing cover since it spins freely. should the back of the flinger sit flush against the crank gear. the key on the crankshaft spins the flinger.

10-12-2020

1929 Crankshaft Gear - Condition

working with the engine rebuilder and he is asking if the crankcase gear should be replaced, or could i just reuse it ? it looks pretty good, however somewhere in its life someone pulled it off with a 2 jaw puller and made a few indentions in the end of the teeth and sheared a little material off one of them, and a chip on another. i was able to take a few pictures of the gear.

also on the front face, there are some wear marks from the oil thrower, as it must have been loose in the cover and been spinning around and wearing on itself and the gear.

1929 Crankshaft Oil Thrower

got a few shots of the oil thrower that gets sandwiched between the crankshaft gear and the crankshaft pulley.

you can see the matching wear on the one face that was against the gear. it was not held in place, as the pulley was loose on the shaft and was allowed to walk.

does this looks like it can be cleaned up ?

flatten the inside lip, so that it sits flat & flush in between the gear & pulley.

then ensure that when it is in the cover that the outer edge (large OD) does NOT rub on the inside face of the timing cover. i know there it a free spinning ring in there. should or does this thrower rest on or ride on that free spinning ring ??

Great car !

Posted by Diggymart on 9/7/19 @ 3:48:57 PM