You must be logged in to rate content!

5 minute(s) of a 668 minute read

3-5-2012

Yes, there is a direct connection. When you pump the pedal a couple times you are using the accelerator pump to put a solid stream of gas into the intake with every pump of the pedal. When starting a cold engine with a caruretor, there is usually a choke, this choke is exactly what the name applies.

The choke, or choke plate of which you do not see on the high performance carb pictures does not have a choke, so don't be fooled. On most every other engine there is a choke plate that automatically, and sometimes by a cable, that nearly shuts off all the air going through the carb. By shutting off the air supply there is a strong draw interanally that pulls the fuel from the carb to the intake manifold. This extremely rich mixture is necessary to start a cold engine.

When you tap or pump the gas pedal, you trip a mechanism that closes the choke plate, at the same time, you pump fuel into the intake with the accelerator pump. When you pump the gas pedal the first time, you set the choke and a shot of gas, when you pump more times after that, you are simply pumping more gas into the intake manifold.

I believe the older the engine, the less efficient the compression is, with a more tired engine, it sometimes takes a couple extra pumps to get it going when cold.

Once the engine warms up the choke plate automatically opens so the air can enter the engine as it should.

Good question, I never applied the cold start benefit of the acceleratorpump in my write up, glad you asked.

Holley has had a carb on many OEM stuff over the years. These 4 barrel carbs were on GM muscle cars back in the 60's.

They had a lot of 2 barrel carbs on alot of heavy duty trucks and buses too.

They've covered alot of territory over the years.

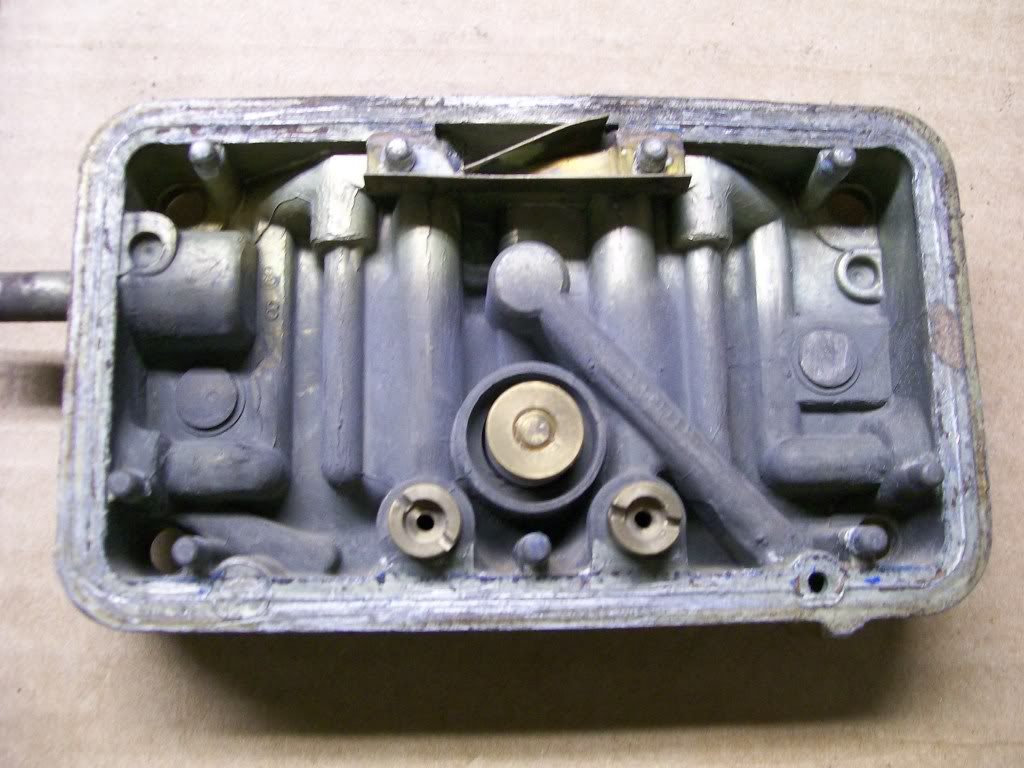

Time to break down another circuit of the carburetor. I'm posting a picture of the metering block on the primary side. I define the side I'm posting because in some carbs there are metering blocks in the secondaries also, we'll get to those a little later.

In the picture above you can see the two jets, lower and center with the slots in them for a blade screwdriver to fit them.

Just above and between the jets is the power valve. Hmmm. that's quite a name, power valve.

The jets are rather simple so I'll start with these first. Personally, I think the name is missleading, jets, sounds high tech to me, ha.

Let's see, flow restrictor, orfice, ahhhhh, ok, jets will work.

Basically anytime over the rpm of idle, the jets play a part. When Scooter402 and I mentioned the ideal air to fuel ratio being 14 to 1, the jets are where we go to obtain this ratio.

I've used 3 jets for the benefit of see all angles of them. Look closely to the center one. The jets will have a number stamped on them, in this case I believe it has "74" stamped on it. This is were we start when tuning a carb to match the needs of the engine.

Going to a higher number will richen the mixture, and a lower number leans out the mixture. Tuning the engine for most of us is a matter of installing a different set, then going by the seat of our pants feel. Then we also drive at highway speeds and pull some plugs. We're going for the tanned look on the porcelin in the spark plug.

There is a huge range of jets available, just have to know what size you need.

Now a picture of the power valve.

Once again, three of them to see all sides. These also have a number stamped on them, but, you really have to look. On the right one you see black dots. These show where the numbers are. In this case the power valve is a 6.5. The numbers are not together, the 6 is by the top dot, and the 5 is by the bottom dot.

The power valve is operated by manifold vacuum. Once again, this is the vacuum in the intake manifold, below the throttle plates.

I have to download some pics, so tomorrow we'll get deeper into the power valve operation.