You must be logged in to rate content!

10 minute(s) of a 668 minute read

12-12-2014

Hi guys, yes there are a few upgrades. Not nearly as many as I'd like to have by now.

It's been frustrating, I started to tint the side windows only to find the tint roll has some small wrinkles from the manufacturer, waiting for a new roll of tint right now.

The windows fit into the metal frame by using a 1/32" thick rubber I need new rubber. The classic parts places all sell 1/16" rubber, grrrrr. I just ordered some off e-bay, I hope it's the right stuff.

I'd hate this to be a customers vehicle, way too much down time waiting for parts.

I want to use only steel braided lines from the pump to the carb, learned about 8N fittings that there are flare fittings and 8N fittings that there are o'ring fittings. Why can't the parts books be more specific.

Ok, done venting.... lets see some pics.

Finally got the hood on.

The plan was to have the firewall reflect the engine, I think the plan worked well.

I had the chrome dual feed line originally. Once I decided to use steel braided line I used it from pump to carb along with a nice filter along the way.

Like I said, slow going but I am making progress. Good thing it's winter or I'd be tempted to cut corners to get it running. Being winter time I will take whatever time I need to get this truck finished the best I can, it'll be worth it in the long run.

12-21-2014

Thank you, all I can say is patience, patience, patience. I can handle the patience of time but I have issues with patience when things don't come together right.

It gets on my nerves dealing with all the painted parts and having to be so very careful all the time. Finally this weekend I got to go back to my roots..... fabrication.

Cutting, grinding, welding, that's where I want to be more often. I went out to the storage area and grabbed a piece of black iron pipe and with the 4 1/2" cut off wheel I sliced it lengthwise.

Once I cut the pipe on one side I used the hacksaw and cut from the inside out on the opposite side. I stopped short of cutting all the way through. Then opened the pipe up.

Now you can see what I'm building here. I need a good way to support the heater hose to the inner fender. I had two choices, I build a bracket off the engine or go to the inner fender. If I stayed close to the engine they would be in the way of the view of the engine and in the way of removing the valve cover and spark plugs. To the fender they will go.

I had to deal with a top half and a bottom half. Both needing their own tabs for mounting. Here is the top coming along.

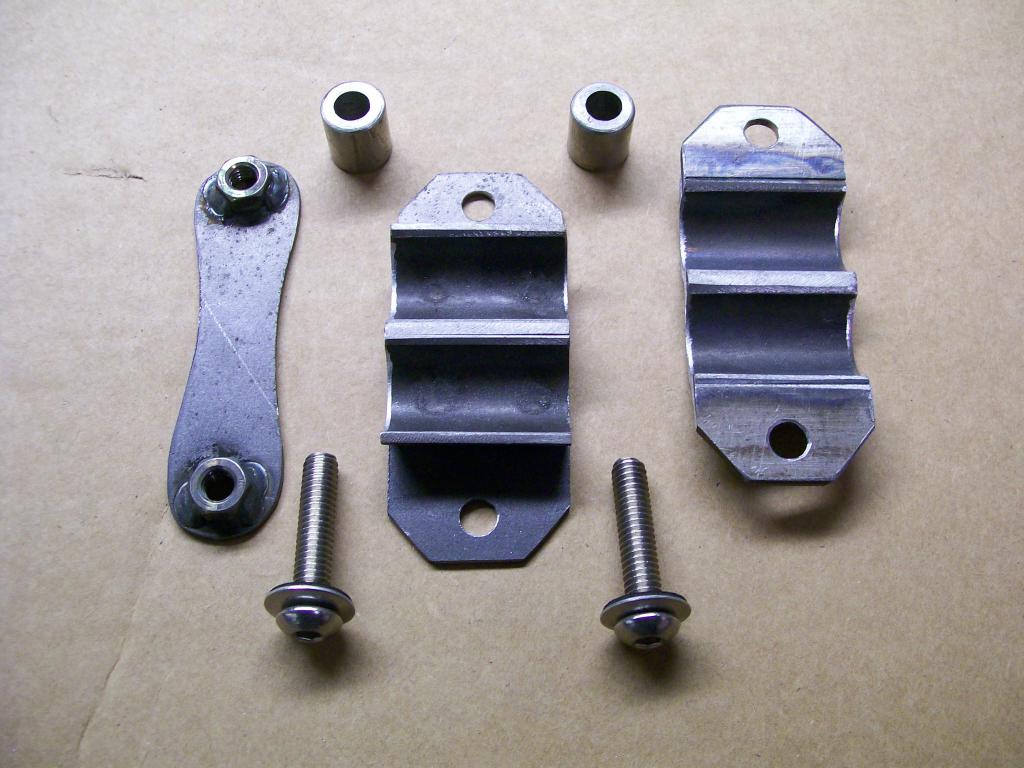

All the pieces needed to complete the holder/mount.

I cut two short sections of heater hose to get a view of how it will hold the hoses. I didn't want to be overly tight on them and the stainless spacers determine how tight they will be.

Thinking ahead I knew trying to hold nuts and washers on the backside of the inner fender when the fender in place was gonna suck so I made a bracket to hold both nuts in place.

It still needs cleaning and painting but it's one more item I can check off the list and I got to get the ole' welder back out for a bit.

12-29-2014

Going back a few years (I can't believe it's been that long) I put the radical cam in the engine. I know now the engine will not create enough vacuum to satisfy the needs of the brake booster. My best option is to use an electric vacuum pump, anytime the vacuum drops below a preset level the pump will turn on and provide the vacuum needed to satisfy the needs of the booster.

The only downfall of the electric booster is it works similar to a fuel pump, if you ever pushed the arm of a new fuel pump down before you installed it there is a strong suction sound as the air passes by the check valves inside. This electric pump has similar to the same sound so I want to build a cover to help quite the sound and since I am mounting it under the cab I want to keep road crud away from the pump.

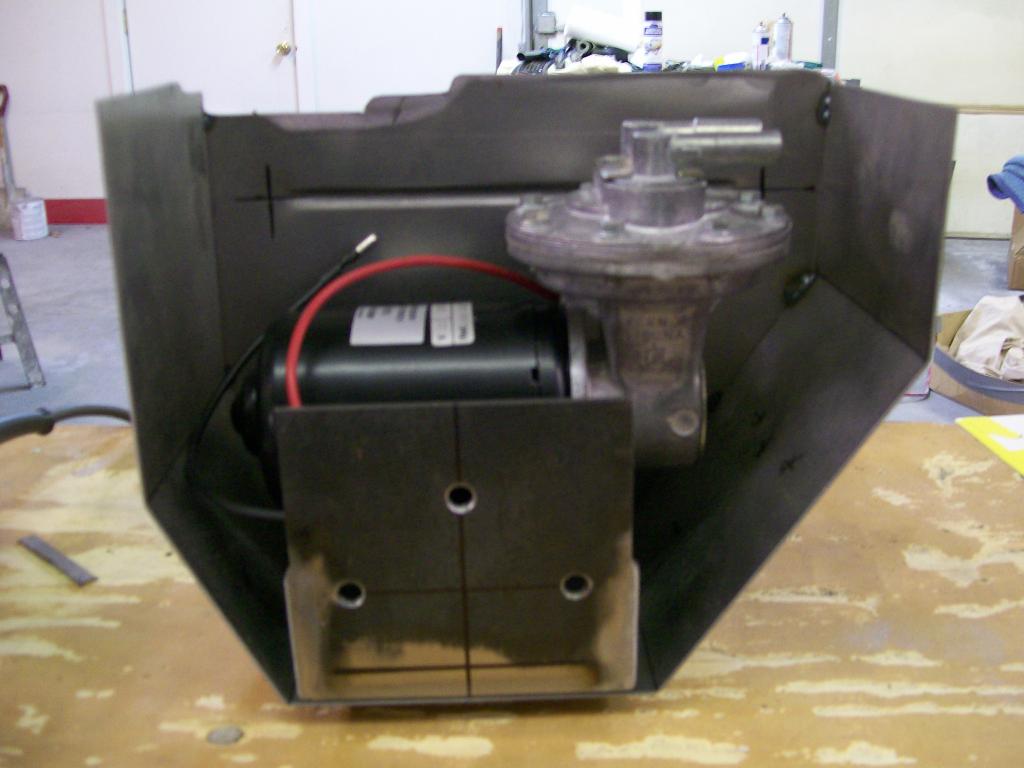

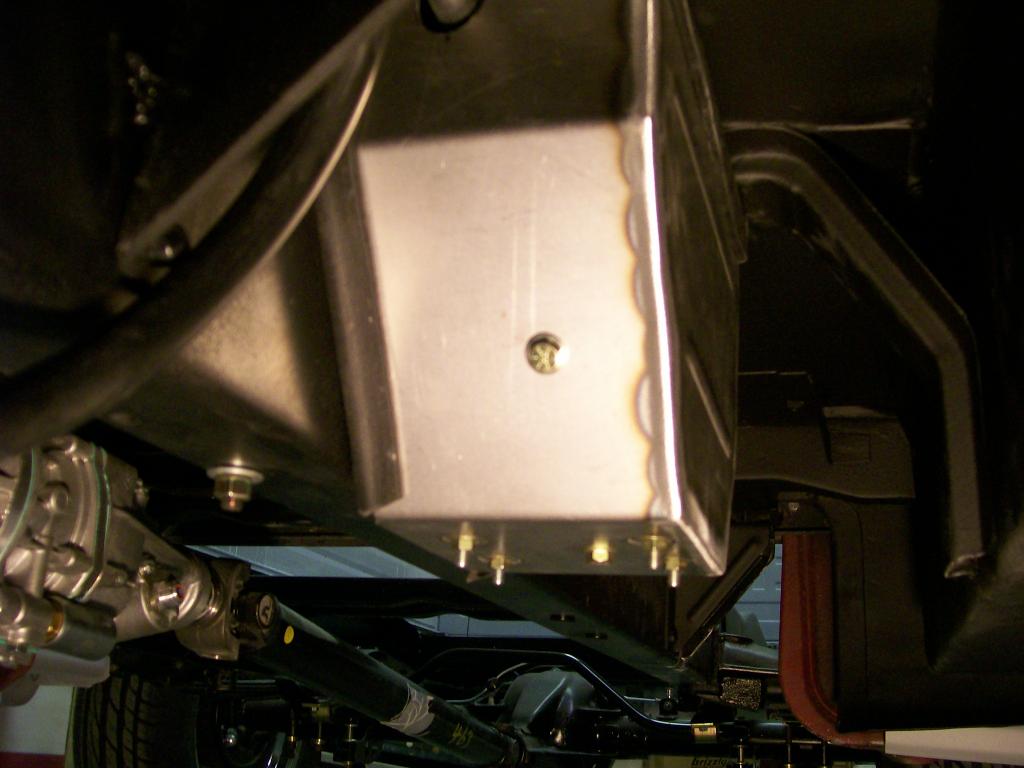

Here it is on the frame with a bracket I made.

Here is the pump, the bracket and the cover.

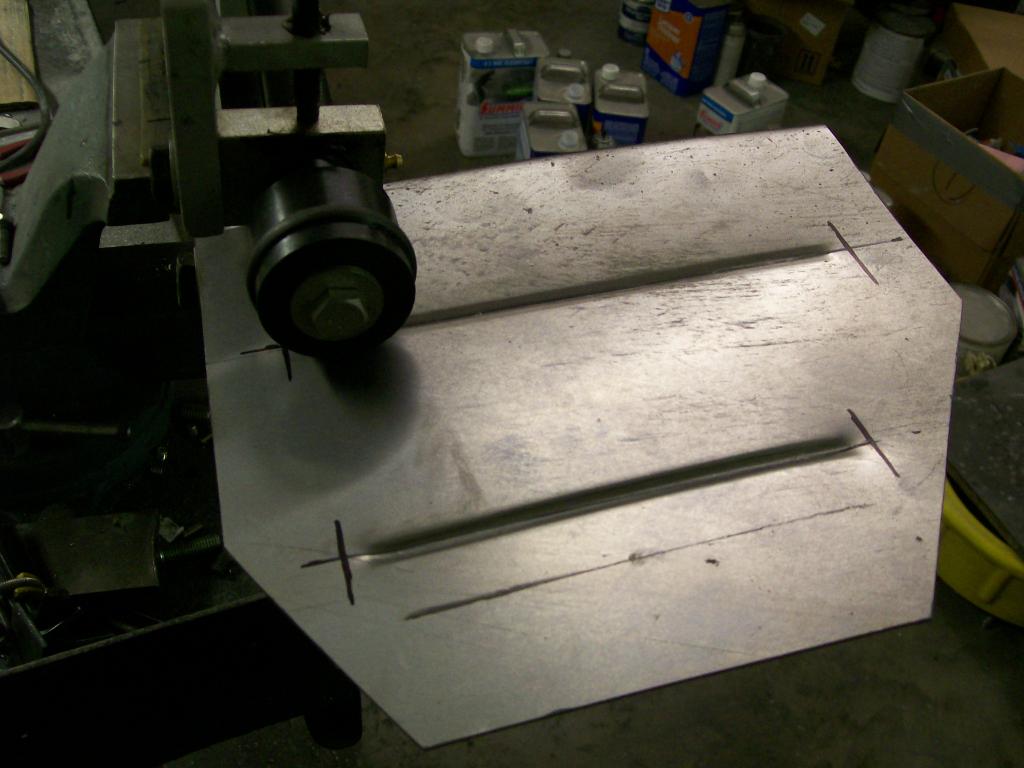

The beginning of the cover build starts with a construction paper mock-up.

After using the 4 1/2" cut off wheel to cut the metal I used the simple bender to get the metal to match the shape of the face of the cover.

Just a side note, both the bender and the roller together is just a couple hundred dollars, two items that are rarely used just like the press but when it comes to getting certain projects down they are very handy to have.

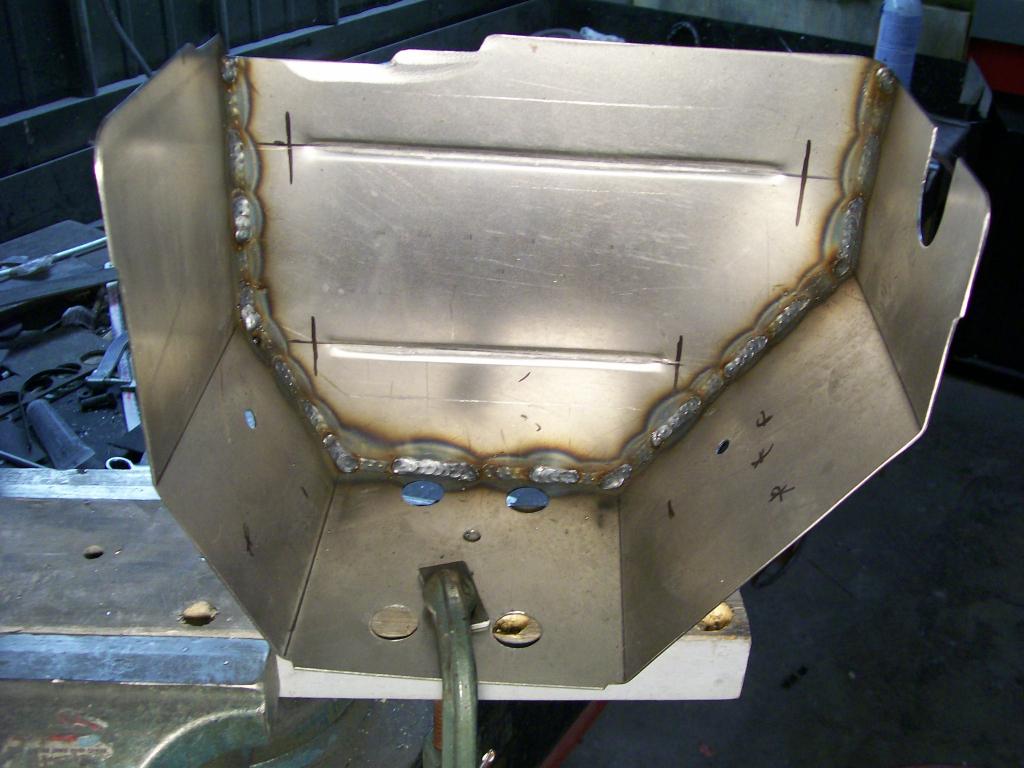

Great, I got to do some welding again..... Following the rule of welding sheet metal I weld a short weld then move to another place and repeat process also allowing the metal to cool occasionally

Following the rule of welding sheet metal I weld a short weld then move to another place and repeat process also allowing the metal to cool occasionally

The close to finished cover.

Test fit of the cover. By using a rubber seal around the edge I help keep the sound within the cover and I keep the cover from creating a metal to metal contact with the frame and the cab bottom.

Once spring time comes I'll paint it to match the frame and it should blend in well under the cab, plus keep the road crud from getting on the pump.

Thanks you 4everjeepin, the detail stuff just kills the speed of finishing the truck but the payoff is great when it is all finished.

Just to bear a little soul of my thought process.....

I'll use my daily driver, a 1980 Pontiac Grand Prix, I've had it for 15 years now. I treat it with very little respect, I check the oil, put gas in it and only do what absolutely needs to be done. Very seldom does it fail me, this continued dependability is what I hope for when I build a project.

My point is, how often do we work on something and curse at the original manufacturer, either because of a part or design. Yet we drive these vehicles well over 100000 miles and they keep on going.

It is because they foresaw either by design or past experiences how to protect and seal vital parts of the vehicle from rain, salt, snow, ect.

Things like this cover, trying to foresee the future and knowing in 5 years I probably won't do much maintenance to this truck I want to be confident I can jump in and take off on a long road trip just as I do my 35 year old Pontiac.

Keeping road grime off this pump is one thing, we also have to look at the long term problem of a wire or fuel line rubbing on the frame or going through the firewall. Fatigue is a huge problem factor they had to figure at the factory also.

Just some thoughts, thanks for checking in, Jim