You must be logged in to rate content!

5 minute(s) of a 668 minute read

9-13-2012

Inspiration, I love that word.

Looking back through the posted pictures I see we got slightly off track. I want to get back to building the filler panel.

It is different than welding and fabricating 1/8" or thicker metal. Heat is not our friend when working with sheet metal.

If I had this panel made specifically for this situation I would have the size be slightly different. I have what I have and I will make it work.

Getting back to the welding and grinding, I had to do short welds to keep the warpage down.

Yup, back to the 4 1/2" flap disc.

9-17-2012

Wooooohhhh, somebody want to tell me what's going on here. I'm seeing some 80 people viewing this thread at one time.

Just to catch up on what's happening in the shop, and to correct any missinformation for any new viewers.

Back about 1 year and 3 months ago my Willy's truck was in desperate need of frame repair. Wondering the internet I found this site and the build thread forums. I found the builds interesting, but I wanted to see more than just the finished poject, I wanted to see how and what process was taken to get to the finished product.

So I decided to start this build thread. It created alot of enthusiasm as I was doing metal fabrication and welding. I showed every step with pictures.

Then the Dana 60 had issues, so it got rebuilt. Then suspension, then brakes, and on and on. We did a huge session on Holley carbs also.

I got the Willys back in running condition back in early spring, I was done on the Willys for the time being.

I announced that my next project was a memorial build of a 1957 Chevy truck, although this doesn't fit the Jeep catagory, it was decided that I will continue to post since the vehicle itself wasn't the most important part, it is the learning and teaching along the way that has been inspirational for those who have continued to follow this thread.

I wanted to give this update since 70 pages are alot to go through to catch up on what is going on here.

With that said.... MajorDuc. Thanks for checking in. Memories, that is so much what our vehicles are over the years. I know at my age, alittle over 50, I have two things that spark my memory and give me time references of my past. One, music, songs that remind me of stuff I was doing when the song was on the radio. Two, vehicles, so much of history over the last 30 years has a refernce to what I was building or driving. I hate the thought when I hear the government trying to take away our ability to be car enthusiasts or to restrict our ability to fabricate and modify. Thank you for making me relflect.

MajorDuc. Thanks for checking in. Memories, that is so much what our vehicles are over the years. I know at my age, alittle over 50, I have two things that spark my memory and give me time references of my past. One, music, songs that remind me of stuff I was doing when the song was on the radio. Two, vehicles, so much of history over the last 30 years has a refernce to what I was building or driving. I hate the thought when I hear the government trying to take away our ability to be car enthusiasts or to restrict our ability to fabricate and modify. Thank you for making me relflect.

Yes LA-Sahara, let's get the updates caught back up.

Finally I'm finished modifying the back of this old Chevy. I have fulfilled all that my dad wanted and more. The chains on the tailgate, gone. The taillights are not hanging by the original bracketry. I like the fact that I was able to use original parts.

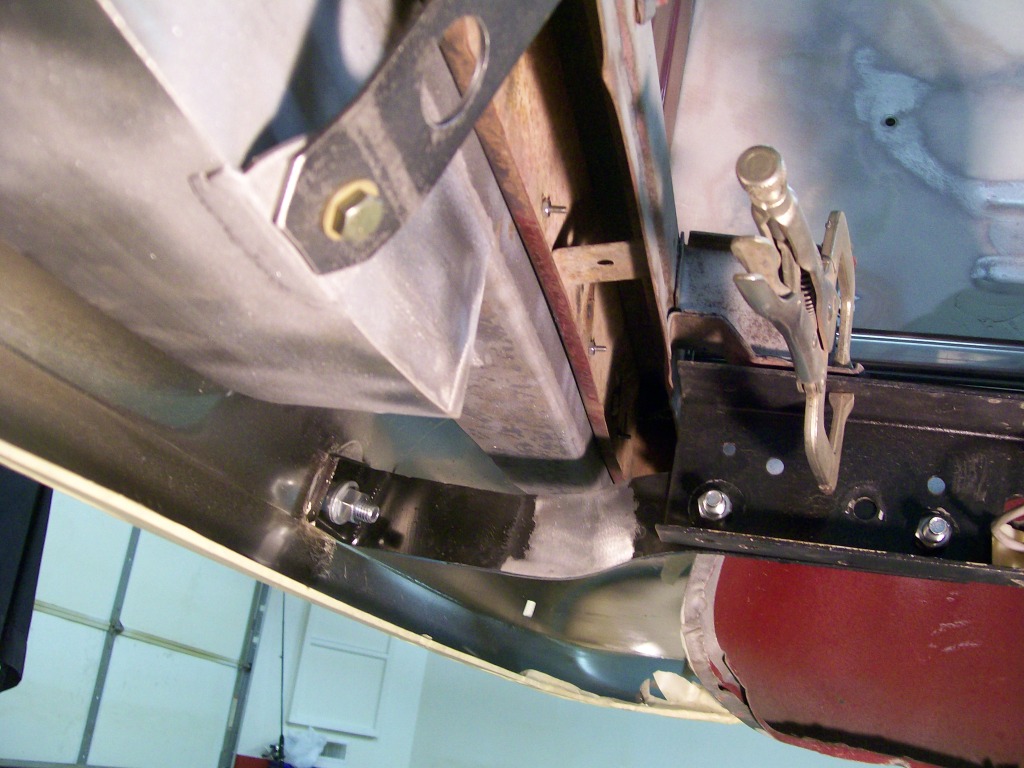

On those "spears", I never had a picture of the underside of them to give a visual of how they attach. One major mechanical benefit of using these spears vs individual screws or bolts is... if I used individual screws or bolts I would have indintations or divits where the screws or bolts are tightened down. With the spears, the clamping force is spread out across a much larger area.

Two benefits, one, good clamping force, two, adds a new dimention to the build.

One more picture, this from the underside. With just the spears holding the panel in place there was movement at the bottom of the panel. One thing I've learned over the years is when there is vibration, there will be fatigue, where there is fatigue, there will be cracks in welds later.

I made a bottom support bracket and looking beyond that you can see where the threads of the spears come through to hold the panel to the bed.