You must be logged in to rate content!

5 minute(s) of a 891 minute read

6-6-2018

Got the passenger side downpipe welded up the other night, including an O2 bung as well as a secondary 1/8" NPT bung in case I want to measure exhaust backpressure in the future...

Got started experimenting with rubber exhaust hangers. Because my design intent was to isolate the majority of vibration/flex between the firewall and the turbo's, I wanted to mostly-rigidly mount the rest of the exhaust pipes to the floorplan. I didn't want solid mounts, but wanted to have minimal flex that still allows for heat expansion, movement if the exhaust bottoms out on the ground.. general wiggle room.

My design thinking is that the tailpipes are going to be in a very specific location side-to-side (frenched into the rear bumper), however the system can expand/move front-to-back if needed. So I decided to try rubber strap that's about 3/8" thick, oriented side-to-side so that it allows minimal movement side-to-side when there are two mounting bolts on one end (vs one hole on either end allowing the strap to freely pivot side-to-side easily.

I ordered a couple examples, but the below Walker 35261 was the right stiffness.. other similar looking or thicker "heavy duty" rubber straps could elongate and stretch surprisingly easy just by hand.

One hanger strap produced two hangers..

I didn't like the idea of a bolt compressing the rubber and the rubber being the "soft stop" for the bolt's tightness, so I wanted to make some steel sleeves that the bolt will tighten to, preloading the rubber a bit to keep it tight, but also allowing a "hard stop" for the bolt tightening. I used some 3/8" coated steel tube from old S10 tranny cooler lines. Cut a small chunk of the tubing off to turn into a punch, to make clean holes...

Used a countersinking/deburring tool to sharpen the edge of the tube, for punching...

Punch it!

So punched..

This is the core that was punched out, can see the composite layer of rubber and some other fibers to give it stiffness. Not sure what materials it was, but doesn't really matter since it just seems to be the right feel...

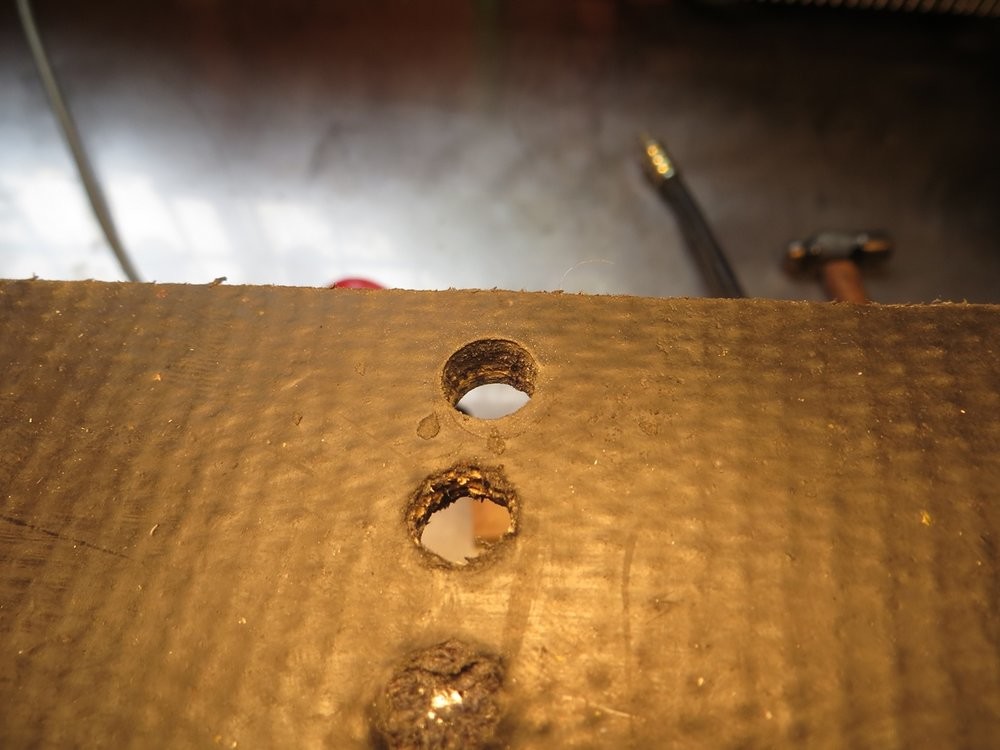

The far hole is the punch hole, as clean of a hole as it really needs to be. The nearest hole was a test-drilled hole, was super unclean...

Hole location for the hanger on my fabricated driveshaft loop crossmember...

Hanger mockup.. I'll weld a mounting bracket to the exhaust that will be flush or above the bottom of the exhaust...

Similar setup in the rear, I'll use two mounting points on the top and bottom of the strap just to keep movement to a minimum the further rearward we go on the exhaust...

Here are the straps all punched with trimmed sleeves installed...

Front hanger with top bolt installed. More to follow as I make the exhaust-side brackets later this week and weld them onto the exhaust this weekend....

Wow thanks for sharing!

Posted by Diggymart on 3/3/19 @ 12:40:25 AM